Abstract

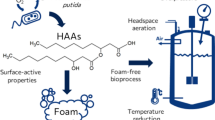

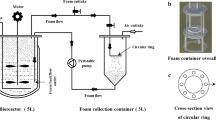

The potentialities for the intensification of the process of lipase production by the yeast Yarrowia lipolytica on a renewable hydrophobic substrate (methyl oleate) have to be investigated. The key factor governing the lipase yield is the intensification of the oxygen transfer rate, considering the fact that Y. lipolytica is a strict aerobe. However, considering the nature of the substrate and the capacity for protein excretion and biosurfactant production of Y. lipolytica, intensification of oxygen transfer rate is accompanied by an excessive formation of foam. Two different foam control strategies have thus been implemented: a classical chemical foam control strategy and a mechanical foam control (MFM) based on the Stirring As Foam Disruption principle. The second strategy allows foam control without any modifications of the physico-chemical properties of the broth. However, the MFM system design induced the formation of a persistent foam layer in the bioreactor. This phenomenon has led to the segregation of microbial cells between the foam phase and the liquid phase in the case of the bioreactors operated with MFM control, and induced a reduction at the level of the lipase yield. More interestingly, flow cytometry experiments have shown that the residence time of microbial cells in the foam phase tends to induce a dimorphic transition which could potentially explain the reduction of lipase excretion.

Similar content being viewed by others

References

Jaeger K-E, Schneidinger B, Rosenau F, Werner M, Lang D, Dijkstra BW, Schimossek K, Zonta A, Reetz MT (1997) Bacterial lipases for biotechnological applications. J Mol Catal B: Enzymatic 3(1–4):3–12

Fickers POM, Destain J, Weekers F, Thonart P (2006) Production and downstream processing of an extracellular lipase from the yeast Yarrowia lipolytica. Enzyme Microb Technol 38:756–759

Beopoulos A, Cescut J, Haddouche R, Uribelarrea JL, Molina-Jouve C, Nicaud JM (2009) Yarrowia lipolytica as a model for bio-oil production. Prog Lipid Res 48:375–387

Elibol M, Ozer D (2000) Influence of oxygen transfer on lipase production by Rhizopus arrhizus. Process Biochem 36(4):325–329

Lee SY, Rhee JS (1993) Production and partial-purification of a lipase from Pseudomonas-Putida 3sk. Enzyme Microb Technol 15(7):617–623

Chen JY, Wen CM, Chen TL (1999) Effect of oxygen transfer on lipase production by Acinetobacter radioresistens. Biotechnol Bioeng 62(3):311–316

Lopes M, Gomes N, Gonçalves C, Coelho MAZ, Mota M, Belo I (2008) Yarrowia lipolytica lipase production enhanced by increased air pressure. Lett Appl Microbiol 46:255–260

Kar T, Delvigne F, Masson M, Destain J, Thonart P (2008) Investigation of the effect of different extracellular factors on the lipase production by Yarrowia lipolityca on the basis of a scale-down approach. J Ind Microbiol Biotechnol 35:1053–1059

Kar T, Destain J, Thonart P, Delvigne F (2010) Impact of scaled-down on dissolved oxygen fluctuations at different levels of the lipase synthesis pathway of Yarrowia lipolytica. Biotechnol Agron Soc Environ 14(S2):523–529

Destain J, Fickers P, Weeckers F, Moreau B, Thonart P (2005) Utilization of methyl oelate in production of microbial lipase. Appl Biochem Biotechnol 121–124:269–278

Fickers P, Destain J, Thonart P (2005) Methyl oleate modulates LIP2 expression in the lipolytic yeast Yarrowia lipolytica. Biotechnol Lett 27:1751–1754

Ghildyal NP, Lonsane BK, Karanth NG (1988) Foam control in submerged fermentation: state of the art. Adv Appl Microbiol 33:173–222

Junker B (2007) Foam and its mitigation in fermentation systems. Biotechnol Prog 23:767–784

Delvigne F, Lecomte JP (2010) Foam formation and control in bioreactors. In: Encyclopedia on industrial biotechnology: bioprocess, bioseparation and cell technologies. Wiley, New York (in press)

Boon LA, Hoeks FWJMM, van der Lans RGJM, Bujalski W, Wolff W, Nienow AW (2002) Comparing a range of impellers for “stirring as foam disruption”. Biochemical Eng J 10:183–195

Hoeks F, Boon LA, Studer F, Wolff MO, van der Schot F, Vrabel P, van der Lans RGJM, Bujalski W, Manelius A, Blomsten G, Hjorth S, Prada G, Luyben KCAM, Nienow AW (2003) Scale up of stirring as foam disruption (SAFD) to industrial scale. J Ind Microbiol Biotechnol 30(2):118–128

Garcia-Ochoa F, Gomez E (2009) Bioreactor scale-up and oxygen transfer rate in microbial processes: an overview. Biotechnol Adv 27(2):153–176

Koch V, Ruffer HM, Schügerl K, Innertsberger E, Menzel H, Weis J (1995) Effect of antifoam agents on the medium and microbial cell properties and process performance in small and large reactors. Process Biochem 30(5):435–446

Amaral P, Colo M, Coelho MA, Fontes G, Nele M (2009) Characterization of a bioemulsifier produced from glycerol and glucose by Yarrowia lipolytica. New Biotechnol 25(1):138–138

Smita SZ, Aditi P (2002) Emulsifier from a tropical marine yeast, Yarrowia lipolytica NCIM 3589. J Basic Microbiol 42(1):67–73

Aldric JM, Gillet S, Delvigne F, Blecker C, Lebeau F, Manigat G, Thonart P (2009) Effect of surfactants and biomass on the gas–liquid mass transfer in an aqueous-silicone oil two-phase partitioning bioreactor using Rhodococcus erythropolis T902.1 to remove VOC from gaseous effluents. J Chem Technol Biotechnol 84:1274–1283

Parthasarathy S, Das TR, Kumar R, Gopalakrishnan KS (1988) Foam separation of microbial cells. Biotechnol Bioeng 32:174–183

Pilon L, Viskanta R (2004) Minimum superficial gas velocity for onset of foaming. Chemical Eng Process 43:149–160

Prins A, van’t Riet K (1987) Protein and surface effects in fermentation: foam, antifoam and mass transfer. Trends Biotechnol 5:296–301

Van’t Riet K, Van Sonsbeek HM (1992) Foaming, mass transfer and mixing: interrelations in large scale fermentors. In: Ladisch MR, Bose A (eds) Harnessing biotechnology for the 21st century. American Chemical Society, Washington, pp 189–192

Guerzoni ME, Lanciotti R, Vannini L, Galgano F, Favati F, Gardini F, Suzzi G (2001) Variability of the lipolytic activity in Yarrowia lipolytica and its dependence on environmental conditions. Int J Food Microbiol 69:79–89

Ruiz-Herrera J, Sentandreu R (2002) Different effectors of dimorphism in Yarrowia lipolytica. Arch Microbiol 178:477–483

Zinjarde SS, Pant A, Deshpande MV (1998) Dimorphic transition in Yarrowia lipolytica isolated from oil-polluted sea water. Mycol Res 102(5):553–558

Szabo RSV (2002) Presence of organic sources of nitrogen is critical for filament formation and pH-dependent morphogenesis in Yarrowia lipolytica. FEMS Microbiol Lett 206:45–50

Neubauer P, Junne S (2010) Scale-down simulators for metabolic analysis of large-scale bioprocesses. Curr Opin Biotechnol 21:114–121

Hewitt CJ, Nienow AW (2007) The scale-up of microbial batch and fed-batch fermentation processes. Adv Appl Microbiol 62:105–135

Enfors SO, Jahic M, Rozkov A, Xu B, Hecker M, Jürgen B, Krüger E, Schweder T, Hamer G, O’Beirne D, Noisommit-Rizzi N, Reuss M, Boone L, Hewitt C, McFarlane C, Nienow A, Kovacs T, Trägardh C, Fuchs L, Revstedt J, Friberg PC, Hjertager B, Blomsten G, Skogman H, Hjort S, Hoeks F, Lin HY, Neubauer P, van der Lans R, Luyben K, Vrabel P, Manelius A (2001) Physiological responses to mixing in large scale bioreactors. J Biotechnol 85:175–185

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kar, T., Destain, J., Thonart, P. et al. Physical and physiological impacts of different foam control strategies during a process involving hydrophobic substrate for the lipase production by Yarrowia lipolytica . Bioprocess Biosyst Eng 35, 483–492 (2012). https://doi.org/10.1007/s00449-011-0614-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-011-0614-z