Abstract

Cold forming of polycarbonate films results in the formation of shear bands in the necking zone. The numerical results obtained from standard viscoplastic material models exhibit mesh size dependency, requiring mathematical regularization. For this purpose, we present in this work a large deformation gradient theory for a viscoplastic isotropic material model published before. We extend our model to a micromorphic model by introducing a new micromorphic variable as an additional degree of freedom along with its first gradient. This variable represents a microequivalent plastic strain. The relation between the macroequivalent plastic strain and the micromorphic variable is accomplished by a micromorphic coupling modulus. This coupling forces proximity between the macro- and microvariables, leading to the targeted regularization effect. The micromorphic model is implemented as a three-dimensional initial boundary value problem in an in-house finite element tool. The analysis is performed for both uniaxial and biaxial specimens. The provided numerical examples show the ability of our model to regularize shear bands within the specimens and address the issue of localization.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

When glassy polymers undergo large deformation, they initially deform uniformly. However, at a certain point, strains start to increase specifically in the so-called shear band zones, while the rest of the specimen undergoes unloading. This strain localization occurs due to a discontinuous bifurcation caused by a jump in the velocity gradient on the material surface. Numerical results obtained from standard continuum elasto-plasticity theory exhibit a pathological mesh dependency, where the boundary value problem loses ellipticity. The authors in [1] propose a method for analyzing the conditions of ellipticity in finite strain theory by evaluating the second-order acoustic tensor. They conclude that the loss of ellipticity occurs when this tensor becomes singular.

One of the methods proposed in the literature to address the issue of mesh dependency is the nonlocal plasticity model proposed by [2]. This model defines a nonlocal equivalent plastic strain by spatial averaging of the equivalent plastic strain \(e_v\) as

where \(\alpha (x,y)\) is a weighting function of Gaussian type, and l is a length parameter that determines the effective size of the volume contributing to the nonlocality of \(\bar{e}_{v}\).

An alternative approach is the implicit gradient theory proposed by [3]. By expanding \(\bar{e}_{v}\) in Eq. (1) into a Taylor series and applying the Laplacian operator \(\Delta \) to it, the authors derive a Helmholtz-type partial differential equation for the equivalent plastic strain \(\bar{e}_{v}\) by neglecting fourth-order and other high-order terms, as

Equation (2.1), which involves an internal length scale l, is solved using the Neumann boundary condition in Eq. (2.2). The authors in [4] incorporate a damage model for quasi-brittle materials by utilizing the nonlocal variable \(\bar{e}_{v}\) through a damage function \(\omega (\bar{e}_{v})\). However, they derive Eq. (2) without providing a thermodynamically consistent theory. In contrast to the implicit gradient theory, the micromorphic theory proposed in [5] introduces the kinematic variable \(\bar{e}_{v}\), enabling the development of a thermodynamically consistent framework. In this theory, the micromorphic balance equation is given by Eq. (2.1).

This research aims to develop a finite deformation gradient theory for viscoplastic isotropic materials by means of a micromorphic approach. The approach involves extending the viscoplastic model for glassy polymers in [6] to a micromorphic model by introducing the micromorphic variable \(\bar{e}_{v}\) and its first gradient \(\nabla \bar{e}_{v}\). The micromorphic variable is coupled to the macroequivalent plastic strain by a coupling modulus. This coupling enters our theory as a stress-like variable and contributes to the desired regularization effect. A similar approach is used in [7] based on the multiplicative decomposition of the deformation gradient, where the authors evaluate their theory for various load cases. Furthermore, in [8], the same authors apply the micromorphic theory by coupling the micromorphic variable \(\bar{e}_{v}\) with a saturation internal variable \(\tilde{r}\) to overcome certain limitations of standard strain gradient plasticity.

We have implemented our model using an eight-noded nonlinear brick element with four degrees of freedom at each node. The numerical analysis, performed on uniaxial and biaxial specimens, shows that the model effectively solves the problem of shear band localization within the specimens.

The main aspects and the structure of this paper are summarized as follows: In Sect. 2 we introduce the thermodynamic framework for a micromorphic model, followed by a general framework for viscoplasticity with its micromorphic extension in Sect. 2. Numerical aspects are addressed in Sect. 3, where we present a numerical integration scheme, including the algorithmic tangent moduli arising from the micromorphic extension. The application of our theory is demonstrated in Sect. 4, where numerical analysis results for both uniaxial and biaxial loading scenarios are provided. Section 5 gives insightful remarks and outlines potential future works.

1.1 Notations

Square brackets \([\bullet ]\) are used throughout the paper to denote ’function of’ in order to distinguish from mathematical groupings with parenthesis \((\bullet )\).

2 A thermodynamic framework for a micromorphic model

2.1 Kinematics

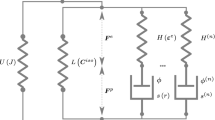

Using standard notation we let \(\mathscr {B}\subset {\mathbb {R}}^{n_{\textrm{dim}}}\) be the reference configuration of a continuous body with smooth boundary \(\partial \mathscr {B}\) and \(\textbf{X}\in \mathscr {B}\) be the position vector in the Euclidean space with spatial dimension \(n_{\textrm{dim}}\). The parts of the boundary \(\partial \mathscr {B}\) with prescribed macrodisplacements \(\bar{\textbf{u}}\) and macroboundary tractions \(\bar{\varvec{t}}\) are denoted by \(\partial \mathscr {B}_{v}\) and \(\partial \mathscr {B}_{\sigma }\), respectively. Analogously, an order parameter \({\varvec{\alpha }}\) is introduced, with prescribed values \(\bar{{\varvec{\alpha }}}\) and boundary tractions \(\bar{\varvec{T}}_{m}\) on \(\partial \mathscr {B}_{v}\) and \(\partial \mathscr {B}_{\sigma }\), respectively. The time interval of interest is defined by \(\mathcal {I}:=[t_0,T]\in {\mathbb {R}}_{+}\). We assume \(\partial \mathscr {B}_{v}\cup \partial \mathscr {B}_{\sigma }=\partial \mathscr {B}\) and \(\partial \mathscr {B}_{v}\cap \partial \mathscr {B}_{\sigma }=\varnothing \) as well as \(\partial \mathscr {B}_{{\varvec{\alpha }}}\cup \partial \mathscr {B}_{\varvec{\zeta }}=\partial \mathscr {B}\) and \(\partial \mathscr {B}_{{\varvec{\alpha }}}\cap \partial \mathscr {B}_{\varvec{\zeta }}=\varnothing \).

The fundamental mappings \(\varvec{\varphi }\) and \({\varvec{\alpha }}\) describing the current configuration of points \(\textbf{X}\in \mathscr {B}\) and the order parameter \({\varvec{\alpha }}\in {\mathbb {R}}^{n_{\textrm{ngrad}}}\) for varying time \(t\in \mathcal {I}\) are given by

Here \(\textbf{x}\in \mathscr {B}_t\) is the current position vector within the current configuration \(\mathscr {B}_t\subset {\mathbb {R}}^{n_{\textrm{dim}}}\), and \({n_{\textrm{ngrad}}}\) is the number of order parameters. The displacement field is then given by \(\textbf{u} = \varvec{\varphi }- \textbf{X}\). With the definition of gradients

we restrict ourselves to configurations \(\varvec{\varphi }\) satisfying \(J=\det [\textbf{F}] > 0\). The deformation gradient \(\textbf{F}\) in Eq. (4.1), its determinant J and its cofactor \(\text {cof}[\textbf{F}] = J \textbf{F}^{-T}\) map line segments \(\textrm{d} \textbf{X}\), area vectors \(\textrm{d} \textbf{A}\) and volume elements \(\textrm{d}V\) of the reference configuration \(\mathscr {B}\) to the corresponding quantities \(\textrm{d} \textbf{x}\), \(\textrm{d} \textbf{a}\) and \(\textrm{d}v\) of the current configuration \(\mathscr {B}_t\), and the order parameter gradient \(\varvec{H}\) in Eq. (4.2) maps line segments \(\textrm{d} \textbf{X}\) of the reference configuration \(\mathscr {B}\) to line segments \(d {\varvec{\alpha }} \in {\mathbb {R}}^{n_{\textrm{ngrad}}}\)

A key point in constructing a framework of finite plasticity is the definition of the total Hencky strain tensor \({\textbf{E}}\) in a logarithmic form, see, e.g., [9,10,11,12]. We assume this strain measure to be a function of the right Cauchy–Green tensor \(\textbf{C}\), that is

For the subsequent analysis, two fourth-order projection tensors and a material rate of deformation tensor are introduced

where \(\textbf{1}\) and \({\mathbb {I}}\) are second- and fourth-order unit tensors, respectively, and the dot above the argument denotes the derivative with respect to the time t. As seen for example in [13,14,15,16] the fourth-order \({\mathbb {P}}\) projection tensor becomes necessary, whenever constitutive equations are formulated in terms of \({{\textbf{E}}}\), whereas the proof for thermodynamic consistency and the algorithmic implementation is based on formulations including \(\textbf{C}\). Furthermore, by use of the spectral decomposition

the following relation can be shown

For the elasto-viscoplastic modeling an additive decomposition of the Hencky-strain tensor is assumed

In addition to the current position \(\textbf{x}\) we consider its (real and virtual) variations \(\textbf{x}_{\epsilon }:= \textbf{x}+ \epsilon {\varvec{\eta }}\), \(\epsilon \in {\mathbb {R}}_+\), where \({\varvec{\eta }}\) is an admissible field, if it satisfies Dirichlet boundary conditions \( {\varvec{\eta }} \big |_{\tiny \partial _{\mathscr {B}}} = \textbf{0}\). For a function \(\textbf{G}: \textbf{x}\rightarrow \textbf{G}[\textbf{x}]\) dependent on \(\textbf{x}\) we introduce

as the Gâteaux–variation at the position \(\textbf{x}\) in the direction of \({\varvec{\eta }}\), see, e.g., [17]. In particular \(\partial _{\eta }\textbf{x}= {\varvec{\eta }}\) holds. Due to \(\textbf{v}\big |_{\partial _{\mathscr {B}}} = \textbf{0}\), the velocity \(\textbf{v}=\dot{\textbf{x}}\) is an admissible variation, such that, exemplarily, we can apply Eq. (11) to the right Cauchy–Green tensor \(\textbf{C}\) in Eq. (6.1):

which is equivalent to the definition for the material rate of deformation tensor in Eq. (7.3).

In the subsequent sections we make use of kinematic variables summarized in Table 1. These are induced by macroscopic quantities, velocity \(\textbf{v}= \partial _t \textbf{x}\), material variation \(\delta \textbf{u}\), material linearization increment \(\Delta \textbf{u}\), as well by its order parameter counterparts \(\dot{{\varvec{\alpha }}}\), \(\delta {\varvec{\alpha }}\) and \(\Delta {\varvec{\alpha }}\), see [18]. Here, the symmetric operator \({{\,\textrm{sym}\,}}[\bullet ]:= \frac{1}{2}\bigl ( (\bullet )^T + (\bullet ) \bigr )\) and the co-variant metric tensor \(\textbf{g}\) are used, see, e.g., [19].

Remark 1

Note, that all quantities in Table 1 are linear in either of the macroscopic quantities \(\textbf{v}= \partial _t \textbf{x}\), \(\delta \textbf{u}\), \(\Delta \textbf{u}\), or the order parameter like quantities \(\dot{{\varvec{\alpha }}}= \partial _t{{\varvec{\alpha }}}\), \(\delta {\varvec{\alpha }}\) and \(\Delta {\varvec{\alpha }}\), respectively.

2.2 Balance relations

Using balance relations in a material representation with respect to the reference configuration \(\mathscr {B}\) we have, see, e.g., [5, 20]

where

is the mechanical power due to macroscopic and order parameter-related stresses and forces, [5]. In accordance with and in addition to the previous notations we use: \(\rho _{0}\)—density in the reference configuration, \({\textbf{u}}\)—displacement vector, \({\textbf{D}} \)—material rate of deformation tensor of Eq. (7.3), \(\theta \)—absolute temperature, \(\textbf{S}\)—(symmetric) 2nd Piola-Kirchhoff stress tensor, \(\textbf{f}\)—mass density of external forces, e—mass density of the internal energy, \(\textbf{q}_0\)—heat-flux density vector, \(\eta \)—entropy per unit mass, \(r_{\theta }\)—mass density of heat supply, \(\varvec{\Lambda }_{}\)—rate of microstrain, \(\varvec{Z}\)—microstress, \({\hat{\varvec{m}}}\)—microforce, \({\varvec{m}}\)—microload, and the terminology “micro” is a synonym for order parameter-related quantities. We also recall that inequality (13.3) is known as the Clausius–Duhem inequality. We require that relation (13) has to be fulfilled in the space-time domain \(\mathscr {B}\times \mathcal {I}\).

2.3 Dissipation inequality

Upon using a Legendre transformation between the internal energy e and the Helmholtz energy \(\Psi \) relation \(\Psi = e - \theta \,\eta \), inequality (13.3) becomes

Here \({\mathcal {D}}^{\textrm{me}}\) and \({\mathcal {D}}^{th}\) are, respectively, mechanical and thermal dissipation terms. In the sequel, we restrict ourselves to the mechanical part subjected to isothermal conditions and require

Let us assume the functional relationship

for the Helmholtz energy, where \({\textbf{E}}^{e}\) is the elastic part of the Hencky strain tensor in Eq. (10), \(\underline{q}=(q_1,\dots ,q_{n_{q}})\) is a vector of \(n_{q}\) hardening internal variables of strain type, \(\varvec{H}\) is the microstrain tensor in Eq. (4), and \({\varvec{\alpha }}\) is the order parameter in Eq. (3).

Next, by use of kinematic decomposition Eq. (10) the time derivative of the Helmholtz energy \(\Psi \) multiplied by the (bulk) density \(\rho _{0}\) is obtained from Eq. (17) as

where \({\mathbb {P}}\) and \(\textbf{D}\) are defined in Eqs. (7.2) and (7.3), respectively, and we have defined thermodynamical forces

Consequently, dissipation inequality (16) reads as

Employing standard arguments, inequality (20) should be valid for all processes, including \(\textbf{D}= \textbf{0}\), \(\dot{\underline{q}} = {\underline{0}}\) and \(\dot{\varvec{H}} = \textbf{0}\). Therefore, as a necessary condition we conclude

and the reduced form of inequality (20) becomes

Upon defining a vector of state variables and history variables, respectively,

in a general setting it is necessary to formulate the Helmholtz energy \(\Psi \) according to relation (17) and evolution equations

which can simulate available experimental findings and which are in accordance with dissipation inequality (22), such that the model under consideration becomes thermodynamically consistent. In summary, the coupled strong form for the initial boundary value problem is given as

Here \( \textbf{P}= \textbf{F}\cdot \textbf{S}\) is the first Piola-Kirchhoff stress tensor, \({\varvec{b}}\) is vector of body force and

is the pair of primal variables. Equilibrium conditions Eq. (25.1–2) constitute a coupled problem due to the dependence on the primary fields \(\textbf{u}\) and \({\varvec{\alpha }}\). As mentioned before, we require that relation (25) has to be fulfilled in the space-time domain \(\mathscr {B}\times \ \mathcal {I}\).

2.4 Weak formulation

For construction of a weak formulation of equations Eq. (25) the spaces of macrodisplacements \(\mathscr {U}\) and order parameters \(\mathscr {V}\) are introduced as follows:

where \(\textbf{e}_{i}\), \(i=1,2,3\) are orthogonal unit basis vectors. Furthermore the space \(\bar{\mathscr {U}}\) is introduced, which in addition to \(\mathscr {U}\) considers boundary condition Eq. (25.4). Next we take the scalar product of Eq. (25.1) with a test function \(\delta \textbf{u}\) \(\in \) \(\mathscr {U}\), integrate over the volume \(\mathscr {B}\), apply the Gauss theorem and impose Neumann boundary condition (25.3). In the same way, Eq. (25.2) is reformulated with a test function \(\delta {\varvec{\alpha }}\) \(\in \) \(\mathscr {V}\) and Neumann boundary conditions Eq. (25.5). After some rearrangements this procedure results into the following weak formulation:

where the bilinear and linear forms are given as

Here the bracket symbol \(<\bullet ,\bullet >_{F}\) denotes the inner product of dual fields integrated over the domain F. Moreover, the rate of macrodeformation tensor \(\textbf{D}_{\delta \textbf{u}}\) induced by the test field \(\delta \textbf{u}\) and the rate of microdeformation tensor \(\varvec{\Lambda }_{\delta {\varvec{\alpha }}}\) induced by the test field \(\delta {\varvec{\alpha }}\) are defined in Table 1. Also, in terms Eq. (28) linear dependent variables are separated from the nonlinear dependent variables by a semicolon. If there is no semicolon as for \(f_u\) and \(f_{\varvec{\alpha }}\) in Eq. (29) the terms in general depend linearly on the variables. These properties are a direct consequence of Remark 1.

2.5 Newton iteration for weak form

For iterative solution of nonlinear residual Eq. (28) we employ a Newton method. Then, with the pair \( \bar{\textbf{z}} = (\textbf{u}\), \({\varvec{\alpha }})\) according to Eq. (26), and the definitions \(\bar{a}_{\bar{\textbf{z}}}[\bar{\textbf{z}};\delta {\bar{\textbf{z}}}]:=\) \(a_u[\textbf{u}, {\varvec{\alpha }}; \delta \textbf{u}]\) \(+a_{\varvec{\alpha }}[\textbf{u}, {\varvec{\alpha }}; \delta {\varvec{\alpha }}]\) and \(\bar{\rho }({\bar{\textbf{z}}};{\delta {\bar{\textbf{z}}}}):=\) \(\rho _{\textbf{u}}[\textbf{u},{\varvec{\alpha }};\delta \textbf{u}] +\) \(\rho _{{\varvec{\alpha }}}[\textbf{u},{\varvec{\alpha }};\delta {\varvec{\alpha }}]\) at the current state \({\bar{\textbf{z}}^*}= [\textbf{u}^*\), \({\varvec{\alpha }}^*]\) a linear equation

is solved. Here the generally unsymmetric tangent bilinear form

is the Gâteaux-derivative in Eq. (11) (\(\textbf{x}\) replaced by \(\bar{\textbf{z}}\)) of \( \bar{a}_{\bar{\textbf{z}}}\) with respect to the first argument. The solution \(\Delta {\bar{\textbf{z}}}\) of Eq. (30) renders the new iterate for the mixed problem as \(\bar{\textbf{z}} = {\bar{\textbf{z}}^*}+ \Delta {\bar{\textbf{z}}}\). A more detailed result for the nonlinear form in Eq. (28) is

In a general setting the stress-like variables may depend explicitly and implicitly on the primary variables \(\bar{\textbf{z}}\) in Eq. (26). In the sequel of this paper the following dependencies will be of interest:

Then, closed-form expressions for the tangent forms in Eq. (32) in terms of the reference configuration are

where we have introduced the algorithmic tangent moduli

3 A prototype model for viscoplasticity

This section aims to apply the thermodynamic framework, presented in Sect. 2, including its micromorphic extension, into the viscoplastic model in [6]. We make concrete formulations for the Helmholtz energy in Eq. (17) and the evolution of internal variables in equations (24). Moreover, we discuss the thermodynamic consistency of the developed model.

3.1 Helmholtz energy function

We set the order parameter \({\varvec{\alpha }}\) in Eq. (3) as

and specify the Helmholtz energy function in Eq. (17) as

The terms \(\Psi ^{iso}\) and \(\Psi ^{vol}\) take storage quantities related to the elastic strains \({\textbf{E}}^{e}\) into account. The first term considers isochoric elastic deformations, where \({\textbf{E}}^e_\mathrm{{dev}}\) \(=\) \({{\mathbb {I}}}^{dev}:{\textbf{E}}^{e}\) \(=\) \({\textbf{E}}^{e}-({{\,\textrm{tr}\,}}[{\textbf{E}}^{e}]/3)\textbf{1}\) and \({{\,\textrm{tr}\,}}[{\textbf{E}}^{e}] = \textbf{1}: {\textbf{E}}^{e}\). Here, \(\textbf{1}\) is a first-order unit tensor. The second term considers volumetric elastic deformations. For an isotropic material G and K are the shear modulus and the bulk modulus, respectively. The inelastic part \(\Psi ^{p}\) of the Helmholtz energy is defined in Eq. (37.4). It accounts for energy storage due to inelastic deformations, more concretely to combined linear and nonlinear isotropic hardening. \(q_1\) and \(q_2\) are (scalar) internal variables of strain type, such that its number is \(n_{q}=\) 2. \(H_i\), \(i=1,2\) are material parameters. The micropart \(\Psi ^{mic}\) of the Helmholtz energy is defined in Eq. (37.5). It accounts for energy storage due to microstructural properties consisting of a scalar type part and a gradient type part. \(\bar{H}_i\), \(i=1,2\) are micromorphic coupling moduli that force proximity between the macro- and microvariables, leading to the targeted regularization effect. The constant \(M\) is a micromorphic stiffness.

3.2 Thermodynamic forces

With the Helmholtz energy in equations (37) the thermodynamic forces in equations (19) become

Here, both terms of Eq. (38.1) are the deviatoric and volumetric parts of the Hill stress under elastic deformation, and the quantities \(Q_1\) and \(Q_2\) in Eq. (38.2) refer to stress like internal variables and are responsible for the softening and hardening of the material, respectively. Equation (38.3) represents the microforce, and Eq. (38.4) represents the microstress.

3.3 Evolution equations

The main aim of the evolution equations is to simulate the softening/hardening and anisotropy behavior of the material. To this end, we extend the evolution equations presented in [6] by the micromorphic part. By aid of the Hill stress tensor in Eq. (19.1) we define the equivalent von Mises stress, the deviatoric part of the Hill stress and stress like internal variables

Based on the model proposed in [6], the evolution equations for the plastic part \({\textbf{E}}^{p}\) in Eq. (10) and the internal variables \(q_i\) in Eq. (17) are defined as

The quantities \(Q_1\) and \( Q_2\) are the stress like internal variables in Eq. (38.2). The flow multiplier \(\dot{\lambda }\) is defined as

where \(\dot{\lambda }_{0}\) and A are material parameters and \(\theta \) is the absolute temperature. By aid of Eq. (40.1) a rate of equivalent plastic strain \({\dot{e}}_v\) may be defined as

The time derivatives of the thermodynamic forces \(Q_1\) and \(Q_2\) are calculated by inserting evolution Eqs. (40.2) and (40.3) into Eq. (38.2)

In the sequel, we do not exploit the above generality by setting \(\bar{H}_1 =0\) such that \(\bar{q}_1\) is not activated. Moreover, we set \(\bar{H}_2 =\bar{H}\) in view of Eq. (42) and \(\bar{e}_{v}= \bar{q}_2\) to obtain

Remark 2

-

1.

Note that the flow parameter \(\dot{\lambda }\) in Eq. (41) is always non-negative, which has some consequences for the proof on thermodynamic consistency presented below.

-

2.

By aid of the Hill stress \({\textbf{T}}\) and the inelastic strain rate in relations (40.1) we obtain

$$\begin{aligned} 1.~~ {\textbf{T}}: \dot{\textbf{E}}^{p}= \dot{\lambda }\sqrt{\displaystyle \frac{3}{2}} {\textbf{T}}: \displaystyle \frac{{\textbf{T}}_\mathrm{{dev}}}{||{\textbf{T}}_\mathrm{{dev}}||} = \dot{\lambda }\sigma _{v}. \end{aligned}$$(45) -

3.

In Eq. (44), \(Q_1\) and \(Q_2\) define softening and hardening, respectively. For \(Q^{*}_{1}> Q_0\), \(Q_1\) is negative and consequently softening takes place. The quantity \(Q_2\) is a monotonically increasing function and represents hardening.

3.4 Thermodynamic consistency

For thermodynamic consistency of the material model under consideration, it is sufficient that Clausius–Plank inequality (22) is fulfilled. Using Eqs. (39.1), (39.3) and evolution equations (40), Clausius–Planck inequality (22) re-writes as

3.5 Summary of constitutive equations

The complete set of equations is summarized in Table 2: The standard additive decomposition of the total strain tensor \({\textbf{E}}\) is introduced in Eq. I. Equation II specifies the energy function \(\Psi \), which is splitted into an elastic volumetric part \(\Psi ^{vol}\), an elastic isochoric part \(\Psi ^{iso}\), a plastic part \(\Psi ^{p}\) and an order related part \(\Psi ^{mic}\). The parameters K and G denote the bulk and shear modulus, respectively, taking into account that \(G=G[E,\nu ]\), where E is Young’s modulus and \(\nu \) is Poisson’s ratio. The thermodynamic forces \(Q_1\) and \(Q_2\) are given in Eq. III, and Eq. IV summarizes the different stress tensors. The evolution of the inelastic strain tensor \(\dot{\textbf{E}}^{p}\) is given in Eq. V, where the flow direction \(\textbf{N}\) is given in Eq. VI. The flow multiplier and the von Mises stress are presented in Eq. VII. Finally, Eq. VIII in Table 4 summarizes all material parameters.

3.6 Strong form for micromorphic viscoplasticity

Upon defining

Based on settings (47) the coupled strong form for initial boundary value problem (25) becomes

Equilibrium conditions (25.1–2) constitute a coupled problem due to the dependence on the primary fields \(\textbf{u}\) and \(\bar{e}_{v}\).

By aid of Eqs. (4.2) and (38.4), (48.2) rewrites as

Here, \(\Delta _\textbf{X}= {\text {Div}}\partial _\textbf{X}\) is the Laplace operator and \(l_c\) is an internal characteristic length scale that governs the gradient effect. This length scale is assumed as real positive, given that the parameters M and \(\bar{H}\) are positive.

4 Numerical implementation

For numerical solution of initial boundary problem (48) with the finite element method combined to a time stepping algorithm the space-time domain \(\mathscr {B}\times \ \mathcal {I}\) is divided into nonoverlapping spatial and temporal elements

where \(n_{\textrm{el}}\) and \(n_T\) are the numbers of finite elements and time steps, respectively.

4.1 Numerical integration scheme in time

This section is concerned with numerical integration of the rate equations for \({\textbf{E}}^{p},{\dot{e}}_v\) in Table 2. Following standard integration procedures in finite element techniques a strain-driven algorithm is considered, where the total gradient \({}^{n+1}\textbf{F}\) at each time step \({}^{n+1}t\) and initial values \(({}^{n}{\textbf{E}}^{p},{}^{n}e_v)\) are given. Then it is the object to find the corresponding quantities \(({}^{n+1}{\textbf{E}}^{p}, {}^{n+1}e_v)\) at time \({}^{n+1}t\) consistent with the constitutive equations in Table 2. In order to alleviate the notation, from now on the index \(n+1\), referring to the actual time step, will be omitted.

For numerical integration of the rate equations for \({\textbf{E}}^{p}\) and \({\dot{e}}_v\) summarized in Table 2 an Euler backward rule, which is unconditionally stable, renders the following update scheme

Upon combining Eqs.(51.1–3) with Eqs. I and IV of Table 2 and exploiting that \({\textbf{T}}_\mathrm{{dev}} \) and \({\textbf{T}}_\mathrm{{dev}}^{tr}\) are coaxial, such that

The Hill stress tensor is obtained from the relations

where \({\textbf{T}}_\mathrm{{dev}}^{tr}\) is typically referred to as the trial stress tensor, see, e.g., Simo and Hughes [21] and references therein. Thus it remains to determine \(\Delta \lambda \) iteratively as described in the following subsection.

4.2 Local iteration

The unknown value \(\Delta \lambda \) appearing in Eq. (51) is obtained from a one-dimensional nonlinear equation as follows: Taking the norm on both sides of Eq. (53.3) renders

By use of Eq. (51.4) the following nonlinear one-dimensional equation

This equation can be solved iteratively with a Newton method

where k is the iteration number and

is the Jacobian of the residual in Eq. (41). We define \(\Delta \lambda \) as

Consequently, the term \(\displaystyle \frac{\partial \Delta \lambda }{\partial ||{\textbf{T}}_\mathrm{{dev}}||}\) is obtained as

Inserting Eq. (59) in Eq. (57) the Jacobian is calculated. Having solved above local problem Eq. (55), relation (51) is used for an update of the history variables \(({\textbf{E}}^{p}, e_v)\), and the Hill stresses \({\textbf{T}}\) are calculated according to Eq. (53).

4.3 Algorithmic tangent moduli

This section intends to derive the algorithmic tangent moduli in Eq. (35), necessary for iterative solution of residuals Eq. (28) with a Newton method according to Eq. (30).

4.3.1 Algorithmic tangent moduli \(\mathbbm {C}^1\)

Given the relation between the second Piola-Kirchhoff \(\textbf{S}\) stress and the Hill stress \({\textbf{T}}\) in Eq. (21.2) the following result is obtained for the algorithmic tangent modulus in Eq. (35.1) by formal application of the chain rule (see [14, 22]):

In addition to the projection tensor \({\mathbb {P}}\) in Eq. (7.2) we have defined the sixth-order tensor \({\mathbb {L}}\), see [14]. Straightforward differentiation of the stress tensor \({\textbf{T}}\) renders the consistent stress–strain tangent modulus \({\mathbb {H}}\)

where the term \( \displaystyle \frac{\textrm{d} \Delta \lambda }{\textrm{d} {\textbf{E}}}\) is obtained as

In order to obtain the quantity \(\displaystyle \frac{\partial ||{\textbf{T}}_\mathrm{{dev}}||}{\partial {\textbf{E}}}\) we consider local problem Eq. (55) as an implicit function and conclude

where J is the Jacobian defined in Eq. (56.b). The expression for \( \displaystyle {\partial r }/ {\partial {\textbf{E}}} \) is obtained as a partial derivative of the residual r defined in Eq. (55) with respect to the total strain tensor \({\textbf{E}}\)

Inserting Eqs. (59) and (63.c) into Eq. (62) renders

4.3.2 Algorithmic tangent modulus \(\mathbbm {C}^2\)

In view of the setting for the prototype model in Eq. (47) the tangent modulus \(\mathbbm {C}^2\) according to Eq. (35.2) becomes

The term \(\displaystyle \frac{\partial {\Delta \lambda }}{\partial { \bar{e}_{v}}}\) is calculated as a partial derivative of \(\Delta \lambda \) in Eq. (59)

where \(\displaystyle \frac{\partial {\Delta \lambda } }{\partial { Q}}\) and \(\displaystyle \frac{\partial {Q} }{\partial { \bar{e}_{v}}} \) are obtained as

The term \(\displaystyle \frac{\partial {\Delta \lambda } }{\partial { ||{\textbf{T}}_\mathrm{{dev}}||}} \) is obtained from Eq. (59). On the other hand, the term \(\displaystyle \frac{\partial {||{\textbf{T}}_\mathrm{{dev}}||} }{\partial { \bar{e}_{v}}}\) is calculated by taking the derivative of the implicit function in Eq. (55) with respect to \( \bar{e}_{v}\) as

Here, \(\displaystyle \frac{\partial r }{\partial \bar{e}_{v}}\) is obtained as a derivative of the residual r defined in Eq. (55) with respect to the microequivalent plastic strain \(\bar{e}_{v}\) as

4.3.3 Algorithmic tangent moduli \(\mathbbm {C}^{31}\) and \(\mathbbm {C}^{32}\)

In view of the setting for the prototype model in Eq. (38.4) the tangent modulus \(\mathbbm {C}^{31}\) according to Eq. (35.3) becomes

Straightforward differentiation of the microforce in Eq. (47.1) renders the tangent modulus in Eq. (35.4)

Here, \(\displaystyle \frac{d \Delta \lambda }{d {\textbf{E}}}\) is given in Eq. (65) and \({\mathbb {P}}\) is the projection tensor in Eq. (7.2).

4.3.4 Algorithmic tangent moduli \(\mathbbm {C}^{41}\) and \(\mathbbm {C}^{42}\)

Straightforward differentiation of the microstress in Eq. (38) renders the tangent modulus \(\mathbbm {C}^{41}\) in Eq. (35.5)

where \({\mathbb {I}}\) is a fourth-order unit tensor. Straightforward differentiation of the microforce in Eq. (47.2) renders for the tangent modulus \(\mathbbm {C}^{42}\) in Eq. (35.6)

4.4 Finite element discretization in space

The geometries of each spatial element with respect to the reference and the actual configuration are approximated as

where \(\textrm{node}\) is the number of nodes per element, \({(\bullet )^e}_{a}\) are the ansatz constants, \(N_{a}(\underline{\xi })\) are the ansatz functions, and \(\underline{\xi }= [\{\xi _j \}_{j=1}^{n_{\textrm{dim}}}\), \( \xi _j \in [-1,1], j = 1,...,n_{\textrm{dim}}\) are the natural coordinates. The gradients in Eq. (4) become

On the right-hand side of both equations in (77) the representations \({\textbf{x}^e}_{a} = {x_{i}^e}_{a} \textbf{e}_{i} \), \({{\varvec{\alpha }}^e}_{a} = {\alpha _{i}^e}_{a} \textbf{e}_{i}\) and \(\partial _\textbf{X}N_{a}(\underline{\xi }) = N_{a,I}(\underline{\xi }) \textbf{e}_{I}\) are used, where the comma in front of a variable means the derivative with respective this variable. Moreover, for convenience the summation symbol has been omitted, i.e., from now on the indices \(a,b\) range from 1 to \(\textrm{node}\). With these notations, and the spatial gradients

some kinematic variables in Table 1, induced by macroscopic quantities, material variation \(\delta \textbf{u}\) and material increment \(\delta \textbf{u}\) as well by its microscopic counterparts material variation \(\delta {\varvec{\alpha }}\) and material increment \(\delta {\varvec{\alpha }}\) are summarized in Table 3.

Then, bilinear and linear forms Eq. (29) are given for each finite element \(\mathscr {B}_{e}\)

By use of the algorithmic tangent moduli of (35) in index notation

the tangent forms in equations (34) in terms of the reference configuration for each element e are

5 Numerical examples

We investigate the regularization of shear band within a polycarbonate material using uniaxial and biaxial specimens. In our experimental investigation in [23], the specimens are made from the material Makrofol DE 1-1 000000. The uniaxial tests are conducted on a rectangular-shaped specimen, while the biaxial tests are performed on a cross-shaped specimen as depicted in Fig. 1a, b, respectively. Both tests are conducted using MTS machines. The force–displacement data are transferred to a digital image correlation system (DIC) provided by GOM GmbH. The DIC system is supported by two cameras that capture the 3D-deformations, testing controllers, a lighting system and high-performance computers, see [24].

The uniaxial rectangular-shaped specimen has edge lengths \(b_{0} =\) 50 mm, \(l_{0} = \) 50 mm, and a clamping region of \(l_\textrm{clamp} = 30\,\hbox {mm}\), as depicted in Fig. 1a. In order to simulate the underlying softening behavior, the boundary conditions are applied by prescribed displacements \(\bar{u}_y = 12\,\hbox {mm}\) at the upper boundary, while the lower boundary remains fixed. The applied loading is illustrated in Fig. 1c.

The cross-shaped biaxial specimen, depicted in Fig. 1b, features a central hole to localize strains and establish a correlation between the two loading axes. A similar geometry is utilized in [25] for biaxial investigations of PVC and HDPE materials, where the authors reduce the thickness in the middle of the specimen to localize the strains in this area. All specimen arms are clamped with a length of \(l_\textrm{clamp} = 20\,\hbox {mm}\) and subjected to monotonic loads in x-direction with \(\bar{u}_{x1} = \bar{u}_{x2} = \bar{u}_x\) and y-direction with \(\bar{u}_{y1} = u_{y2} = \bar{u}_y\), as illustrated in Fig. 1c.

The material parameters used in the simulations are provided in Table 4, with the internal length scale \(l_c\) in Eq. (49) ranging from 0 to 0.57 mm. This variation allows the examination of the impact of \(l_c\) on the numerical results, where \(l_c = 0\) corresponds to no regularization.

In the numerical examples, we use an 8-noded nonlinear element and conduct three sets of simulations. In the first set, we perform two simulations with different length scales, namely \(l_c=0\) and \(l_c=0.57\). For numerical effectiveness, we simulate only a quarter of the uniaxial specimen depicted in Fig. 2a. We investigate three different mesh densities, with 400, 1600 and 6400 elements representing coarse, medium and dense meshes, respectively. In the thickness direction, two elements are utilized.

The behavior of the specimen with \(l_c=0\) is depicted in Fig. 4a. Initially, the specimen behaves elastically, followed by a transition to plastic behavior characterized by softening. This softening leads to the formation and localization of shear bands. Eventually, a hardening plateau develops where the shear band is fully formed. It is demonstrated in the zoomed-in part of Fig. 4a that the reaction forces exhibit mesh dependence in both softening and hardening domains. However, it is observed in Fig. 3 that for the homogeneous material response, softening is followed by hardening. Furthermore, the localization of the equivalent plastic strain \(e_v\) is observed by mesh refinement, leading to the occurrence of some instabilities as the double X-shaped shear bands in medium and dense meshes, see Fig. 4d, e. This phenomenon has been previously mentioned in [26] and observed in [27, 28]. Additionally, Fig. 4b shows that the distributions of \(e_v\) along the path AB depicted in Fig. 4d, are not converging for the three mesh densities. By activating micromorphic regularization with \(l_c=0.57\), we observe in Fig. 5a that the force versus displacement curves become convergent for all mesh densities, and the width of shear band converges as seen in Fig. 5c–e with the disappearance of the X-shaped shear bands. Moreover, we observe in Fig. 5b that the distribution of \(e_v\) along the path AB is converging.

In the second set of simulations, we perform a single simulation with \(l_c=0.57\) to compare the strain distribution between the experiment and the simulation. In our experimental investigations of polycarbonate, we observed that the shape of the shear band may vary from an experiment to another due to the random distributions of polymer chains. Furthermore, the shear bands did not exhibit a perfect X-shape as seen in the simulation, which is attributed to difficulties in clamping the specimen in an aligned manner due to its small thickness, or potential imperfections introduced during the cutting process. By introducing some imperfections in the geometry of the simulation, we can achieve a similar effect as in the experiment. Here, we simulate half of the geometry using symmetry conditions as depicted in Fig. 2b. The results in Figs. 4a and 5a reveal that our model softens earlier than the experiment, causing the formation of a shear band at \(t=60s\). A similar model error is observed in [29,30,31]. However, the simulation results exhibit good agreement with the experiment for \(t=150s\), as shown in Fig. 6.

Uniaxial specimen: results of three different meshes for \(l_c=0\): a reaction force versus displacement curve with zoom from the softening zone, b distribution of the equivalent plastic strain \(e_v\) along path AB at \(t= 65\,\hbox {s}\). Contour plot of \(e_v\) at \(t= 65\,\hbox {s}\), c coarse mesh, d medium mesh, e fine mesh

Uniaxial specimen: results of three different meshes for \(l_c = 0.57\): a reaction force versus displacement curve with zoom from the softening zone, b distribution of the equivalent plastic strain \(e_v\) along path AB at \(t = 65 s\). Contour plot of \(e_v\) at \(t = 65 s\), c coarse mesh, d medium mesh, e fine mesh

In the final set of simulations, a quarter of the biaxial sample in Fig. 2c is simulated using three different mesh densities, which include coarse, medium and dense with 210, 620 and 3060 elements, respectively. The force–displacement curves of the three meshes depicted in Fig. 7a do not converge in the softening and hardening domains when \(l_c=0\), indicating that the results are mesh dependent. Furthermore, the width of the shear band varies depending on the mesh density and instability is observed in the zoomed-in part within fine mesh, see Fig. 7c–e. Moreover, the equivalent plastic strain \(e_v\) distributions along the path AB of the different mesh configurations are not converging, as shown in Fig. 7b.

For \(l_c=0.57\), the convergence of the reaction force versus displacement curves, as well as the convergence of the width of shear bands and the distribution of \(e_v\) along path AB for the three different meshes, can be observed in Fig. 8a–e, respectively.

Biaxial specimen: results of three different meshes for \(l_c=0\): a reaction force versus displacement curve with zoom from the softening zone, b distribution of the equivalent plastic strain \(e_v\) along path AB at \(t= 30\,\hbox {s}\). Contour plot of \(e_v\) at \(t= 30\,\hbox {s}\), c coarse mesh, d medium mesh, e fine mesh

Biaxial specimen: results of three different meshes for \(l_c=0.57\): a reaction force versus displacement curve with zoom from the softening zone, b distribution of the equivalent plastic strain \(e_v\) along path AB at \(t= 30\,\hbox {s}\). Contour plot of \(e_v\) at \(t= 30\,\hbox {s}\), c coarse mesh, d medium mesh, e fine mesh

The biaxial simulation and experimental results are compared based on the equivalent strain. Figure 9 depicts that the simulation results show an earlier softening of the specimen compared to the experiment at \(t=20\) s. However, starting from a time of \(t=40\) s, the experimental and numerical results show good agreement.

6 Conclusion

In this paper, we have implemented a micromorphic model for glassy polymer based on the micromorphic theory presented in [5]. Our model implementation has proven effective in regularizing shear bands localization and reaction force–displacement curves under strain softening conditions, for both uniaxial and biaxial loading. The micromorphic regularization is more advantageous over the viscous regularization presented in [27, 32], as strain localization still occurs for high dense meshes in those works. Despite this advantage, the physical meaning of the microequivalent plastic strain \(\bar{e}_{v}\) and the internal length scale \(l_c\) is still unclear. In future work, we will identify the material parameters for the current model and compare the numerical results with various experimental scenarios.

References

Wcisło, B., Pamin, J., Kowalczyk-Gajewska, K., Menzel, A.: Numerical analysis of ellipticity condition for large strain plasticity. In: AIP Conference Proceedings, vol. 1922. AIP Publishing (2018)

Sladek, J., Sladek, V., Bažant, Z.P.: Non-local boundary integral formulation for softening damage. Int. J. Numer. Methods Eng. 57(1), 103–116 (2003)

Peerlings, R.H., Borst, R., Brekelmans, W.M., Vree, J.: Gradient enhanced damage for quasi-brittle materials. Int. J. Numer. Methods Eng. 39(19), 3391–3403 (1996)

Engelen, R.A., Geers, M.G., Baaijens, F.P.: Nonlocal implicit gradient-enhanced elasto-plasticity for the modelling of softening behaviour. Int. J. Plast. 19(4), 403–433 (2003)

Forest, S.: Micromorphic approach for gradient elasticity, viscoplasticity, and damage. J. Eng. Mech. 135(3), 117–131 (2009)

Mahnken, R., Dammann, C.: Simulation of strain-induced anisotropy for polymers with weighting functions. Arch. Appl. Mech. 84, 21–41 (2014)

Abatour, M., Forest, S., Ammar, K., Ovalle, C., Osipov, N., Quilici, S.: Toward robust scalar-based gradient plasticity modeling and simulation at finite deformations. Acta Mech. 234(3), 911–958 (2023)

Abatour, M., Forest, S.: Strain gradient plasticity based on saturating variables. Eur. J. Mech.-A/Solids, 105016 (2023)

Hencky, H.: Über die Form des Elastizitätsgesetzes bei ideal elastischen Stoffen. Zeit. Tech. Phys. 9, 215–220 (1928)

Seth, B.R.: Generalized strain measure with application to physical problems, plasticity and fluid dynamics. In: Reiner, M., Abir, D. (eds.) Second Order Effects in Elasticity, pp. 162–172. Pergamon Press, Oxford (1964)

Ogden, R.W.: Non-linear Elastic Deformations. Ellis Horwood, Chichester (1984)

Silhavy, M.: The Mechanics and Thermodynamics of Continuous Media. Springer, Berlin (1997)

Ch. Miehe, S.G., Diez, J.M.: Finite viscoplasticity of amorphous glassy polymers in the logarithmic strain space. Int. J. Solids Struct. 46, 181–202 (2009)

Miehe, C., Lambrecht, M.: Algorithms for computation of stresses and elasticity moduli in terms of Seth–Hill’s family of generalized strain tensors. Commun. Num. Methods Eng. 48, 323–365 (2000)

Mahnken, R.: Anisotropy in geometrically non-linear elasticity with generalized Seth–Hill strain tensors projected to invariant subspaces. Commun. Numer. Methods Eng. 21, 405–418 (2005)

Mahnken, R., Shaban, A.: Finite elasto-viscoplastic modeling of polymers including asymmetric effects. Arch. Appl. Mech. 83, 53–71 (2013)

Marsden, J.E., Hughes, T.J.R.: Mathematical Foundations of Elasticity. Dover Publications Inc, New York (1994)

Mahnken, R., Stein, E.: Parameter identification for finite deformation elasto-plasticity in principal directions. Comput. Methods Appl. Mech. Eng. 147, 17–39 (1997)

Mahnken, R.: Void growth in finite deformation elasto-plasticity due to hydrostatic stress states. Comput. Methods Appl. Mech. Eng. 194(34–35), 3689–3709 (2005)

Haupt, P.: Continuum Mechanics and Theory of Materials. Springer, Heidelberg (2002)

Simo, J.C., Hughes, T.J.: Computational Inelasticity, vol. 7. Springer, New York (2006)

Friedlein, J., Mergheim, J., Steinmann, P.: Efficient gradient enhancements for plasticity with ductile damage in the logarithmic strain space. Eur. J. Mech.-A/Solids 99, 104946 (2023)

Hamdoun, A., Mahnken, R.: Experimental investigations of uniaxial and biaxial cold stretching within pc-films and bars using optical measurements. PAMM e202300114 (2023)

Gom, A., Manual, U.: The Basics of Strain. GOM–Gesellschaft für Optische Messtechnik. Braunschweig, Germany (2011)

Ognedal, A.S., Clausen, A.H., Polanco-Loria, M., Benallal, A., Raka, B., Hopperstad, O.S.: Experimental and numerical study on the behaviour of PVC and HDPE in biaxial tension. Mech. Mater. 54, 18–31 (2012)

Anand, L., Aslan, O., Chester, S.A.: A large-deformation gradient theory for elastic-plastic materials: strain softening and regularization of shear bands. Int. J. Plast. 30, 116–143 (2012)

Lima, R.S., Quevedo, R., Carvalho, B.R., Roehl, D.: Numerical modeling of shear bands in rocks using fem and a viscous regularization technique

Tang, J., Chen, X., Cui, L., Liu, Z.: Strain localization of Mohr–Coulomb soils with non-associated plasticity based on micropolar continuum theory. J. Rock Mech. Geotech. Eng. (2023)

Parsons, E., Boyce, M., Parks, D.: An experimental investigation of the large-strain tensile behavior of neat and rubber-toughened polycarbonate. Polymer 45(8), 2665–2684 (2004)

Holopainen, S.: Modeling of the mechanical behavior of amorphous glassy polymers under variable loadings and comparison with state-of-the-art model predictions. Mech. Mater. 66, 35–58 (2013)

Narayan, S., Anand, L.: Fracture of amorphous polymers: a gradient-damage theory. J. Mech. Phys. Solids 146, 104164 (2021)

Geers, M., Brekelmans, W., De Borst, R.: Viscous regularization of strain-localisation for damaging materials: viscous and rate-dependent constitutive models. In: DIANA Computational Mechanics ‘94: Proceedings of the First International Diana Conference on Computational Mechanics, pp. 127–138. Springer (1994)

Acknowledgements

The authors appreciate the financial support of the project under Grant MA 1979/27-1 from Deutsche Forschungsgemeinschaft (DFG).

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Contributions

Authors have contributed equally to the work.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hamdoun, A., Mahnken, R. A large deformation gradient theory for glassy polymers by means of micromorphic regularization. Arch Appl Mech 94, 1221–1242 (2024). https://doi.org/10.1007/s00419-024-02570-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00419-024-02570-0