Abstract

The martensite structure of steel is of great importance in mechanical engineering and is usually adjusted by heat treatment. Of particular interest is the morphology of martensite, as it has a significant influence on mechanical properties. In this work, a phase field model is presented, where the order parameter is used to describe the evolution of martensite in order to predict the resulting morphology. In a first step, simulations with two martensite variants with different transformation strains by means of the finite element method in the small strain context show the basic applicability of the model in a two-dimensional environment. With a concept based on the phenomenological theory of martensite crystallography, good agreement with the transformation mechanics of the experiment is achieved. Furthermore, an illustrative three-dimensional simulation takes the crystallographic variants of the Nishiyama–Wasserman orientation relationship into account. The size of the simulation domain corresponds to the size of a prior austenite grain. The calculated block sizes agree with the experimental observations.

Similar content being viewed by others

References

Abeyaratne, R., Knowles, J.K.: On the driving traction acting on a surface of strain discontinuity in a continuum. J. Mech. Phys. Solids 38(3), 345–360 (1990)

Abeyaratne, R., Knowles, J.K.: Evolution of Phase Transitions: A Continuum Theory. Cambridge University Press, Cambridge (2006)

Ahluwalia, R., Lookman, T., Saxena, A., Albers, R.C.: Landau theory for shape memory polycrystals. Acta Mater. 52(1), 209–218 (2004)

Ahluwalia, R., Quek, S.S., Wu, D.T.: Simulation of grain size effects in nanocrystalline shape memory alloys. J. Appl. Phys. 117(24), 244305 (2015)

Alber, H.D., Zhu, P.: Solutions to a model for interface motion by interface diffusion. Proc. R. Soc. Edinb. Sect. A Math. 138(5), 923–955 (2008)

Amos, P.G.K., Schoof, E., Streichan, N., Schneider, D., Nestler, B.: Phase-field analysis of quenching and partitioning in a polycrystalline Fe-C system under constrained-carbon equilibrium condition. Comput. Mater. Sci. 159, 281–296 (2019)

Andersson, J.O., Helander, T., Höglund, L., Shi, P., Sundman, B.: Thermo-calc & dictra, computational tools for materials science. Calphad 26(2), 273–312 (2002)

Artemev, A., Jin, Y.M., Khachaturyan, A.G.K.: Three-dimensional phase field model of proper martensitic transformation. Acta Mater. 49(7), 1165–1177 (2001)

Artemev, A., Wang, Y., Khachaturyan, A.G.: Three-dimensional phase field model and simulation of martensitic transformation in multilayer systems under applied stresses. Acta Mater. 48(10), 2503–2518 (2000)

Aubry, S., Fago, M., Ortiz, M.: A constrained sequential-lamination algorithm for the simulation of sub-grid microstructure in martensitic materials. Comput. Methods Appl. Mech. Eng. 192(26–27), 2823–2843 (2003)

Bachmann, F., Hielscher, R., Schaeben, H.: Texture analysis with MTEX – free and open source software toolbox. In: Klein, H., Schwarzer, R.A. (eds.) Solid State Phenomena, vol. 160, pp. 63–68. Trans Tech Publ (2010)

Bain, E.C., Dunkirk, N.Y.: The nature of martensite. Trans. AIME 70(1), 25–47 (1924)

Balay, S., Abhyankar, S., Adams, M.F., Brown, J., Brune, P., Buschelman, K., Dalcin, L., Dener, A., Eijkhout, V., Gropp, W.D., Karpeyev, D., Kaushik, D., Knepley, M.G., May, D.A., McInnes, L.C., Mills, R.T., Munson, T., Rupp, K., Sanan, P., Smith, B.F., Zampini, S., Zhang, H., Zhang, H.: PETSc Web page (2019). https://www.mcs.anl.gov/petsc

Balay, S., Abhyankar, S., Adams, M.F., Brown, J., Brune, P., Buschelman, K., Dalcin, L., Dener, A., Eijkhout, V., Gropp, W.D., Karpeyev, D., Kaushik, D., Knepley, M.G., May, D.A., McInnes, L.C., Mills, R.T., Munson, T., Rupp, K., Sanan, P., Smith, B.F., Zampini, S., Zhang, H., Zhang, H.: PETSc Users Manual. Tech. Rep. ANL-95/11 - Revision 3.12, Argonne National Laboratory (2019)

Balay, S., Gropp, W.D., McInnes, L.C., Smith, B.F.: Efficient management of parallelism in object-oriented numerical software libraries. In:Arge, E., Bruaset, A.M., Langtangen, H.P. (eds.) Modern Software Tools for Scientific Computing, pp. 163–202. Springer (1997)

Barsch, G.R., Krumhansl, J.A.: Twin boundaries in ferroelastic media without interface dislocations. Phys. Rev. Lett. 53(11), 1069 (1984)

Barsch, G.R., Krumhansl, J.A.: Nonlinear and nonlocal continuum model of transformation precursors in martensites. Metall. Trans. A 19(4), 761–775 (1988)

Bartel, T.: Multiskalenmodellierung martensitischer Phasentransformationen in Formgedächtnislegierungen unter Verwendung relaxierter Energiepotenziale. Ph.D. thesis, Ruhr University Bochum (2009)

Bartel, T., Hackl, K.: A novel approach to the modelling of single-crystalline materials undergoing martensitic phase-transformations. Mater. Sci. Eng. A 481, 371–375 (2008)

Bartel, T., Hackl, K.: A micromechanical model for martensitic phase-transformations in shape-memory alloys based on energy-relaxation. ZAMM-J. Appl. Math Mech./Z. Angew. Math. Mech. Appl. Math. Mech. 89(10), 792–809 (2009)

Bartel, T., Menzel, A., Svendsen, B.: Thermodynamic and relaxation-based modeling of the interaction between martensitic phase transformations and plasticity. J. Mech. Phys. Solids 59(5), 1004–1019 (2011)

Bhadeshia, H.K.D.H.: Martensite transformation. In: Encyclopedia of Materials: Science and Technology, pp. 5203–5206. Elsevier (2001)

Bowles, J.S., Mackenzie, J.K.: The crystallography of martensite transformations I. Acta Metall. 2(1), 129–137 (1954)

Cahn, J.W., Hilliard, J.E.: Free energy of a nonuniform system. I. Interfacial free energy. J. Chem. Phys. 28(2), 258–267 (1958)

Callister, W.D., Rethwisch, D.G.: Materials science and engineering, vol. 5. wiley, New York (2011)

Cayron, C.: ARPGE: A computer program to automatically reconstruct the parent grains from electron backscatter diffraction data. J. Appl. Crystallogr. 40(6), 1183–1188 (2007)

Chen, L.Q., Wang, Y., Khachaturyan, A.G.: Kinetics of tweed and twin formation during an ordering transition in a substitutional solid solution. Philos. Mag. Lett. 65(1), 15–23 (1992)

Conti, S., Fonseca, I., Leoni, G.: A \(\Gamma \)-convergence result for the two-gradient theory of phase transitions. Commun. Pure Appl. Math. 55(7), 857–936 (2002)

Cui, S., Cui, Y., Wan, J., Rong, Y., Zhang, J.: Grain size dependence of the martensite morphology-a phase-field study. Comput. Mater. Sci. 121, 131–142 (2016)

Cui, S., Wan, J., Rong, Y., Zhang, J.: Phase-field simulations of thermomechanical behavior of MnNi shape memory alloys using finite element method. Comput. Mater. Sci. 139, 285–294 (2017)

Cui, S., Wan, J., Zhang, J., Chen, N., Rong, Y.: Phase-field study of microstructure and plasticity in polycrystalline MnNi shape memory alloys. Metall. Mater. Trans. A 49(12), 5936–5941 (2018)

Dacorogna, B.: Direct Methods in the Calculus of Variations, vol. 78. Springer, Berlin (2007)

Diewald, F., Kuhn, C., Heier, M., Langenbach, K., Horsch, M., Hasse, H., Müller, R.: Investigating the stability of the phase field solution of equilibrium droplet configurations by eigenvalues and eigenvectors. Comput. Mater. Sci. 141, 185–192 (2018)

Du, G.: Phase-field simulation of lath martensite in low-carbon steel. Ph.D. thesis, Ruhr University Bochum (2017)

Eggbauer, A., Ressel, G., Gruber, M., Prevedel, P., Marsoner, S., Stark, A., Ebner, R.: Different Cooling Rates and Their Effect on Morphology and Transformation Kinetics of Martensite. In: Proceedings of the International Conference on Martensitic Transformations: Chicago, pp. 35–40. Springer (2018)

Engin, C., Urbassek, H.M.: Molecular-dynamics investigation of the fcc \(\rightarrow \) bcc phase transformation in Fe. Comput. Mater. Sci. 41(3), 297–304 (2008)

Entel, P., Meyer, R., Kadau, K.: Molecular dynamics simulations of martensitic transitions. Philos. Mag. B 80(2), 183–194 (2000)

Finel, A., Le Bouar, Y., Gaubert, A., Salman, U.: Phase field methods: microstructures, mechanical properties and complexity. C.R. Phys. 11(3–4), 245–256 (2010)

Fried, E., Grach, G.: An order-parameter-based theory as a regularization of a sharp-interface theory for solid-solid phase transitions. Arch. Ration. Mech. Anal. 138(4), 355–404 (1997)

Fried, E., Gurtin, M.E.: Continuum theory of thermally induced phase transitions based on an order parameter. Physica D 68(3–4), 326–343 (1993)

Fried, E., Gurtin, M.E.: Dynamic solid-solid transitions with phase characterized by an order parameter. Physica D 72(4), 287–308 (1994)

Garcke, H.: On mathematical models for phase separation in elastically stressed solids (2000). Habilitation thesis

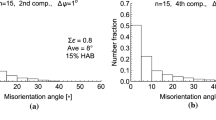

Graf, M., Kuntz, M., Autenrieth, H., Müller, R.: Investigation of size effects due to different cooling rates of as-quenched martensite microstructures in a Low-Alloy Steel. Appl. Sci. 10(15), 5395 (2020)

Greninger, A.B., Troiano, A.R.: The mechanism of martensite formation. Trans AIME 1(9), 590–598 (1949)

Hestenes, M.R., Stiefel, E., et al.: Methods of conjugate gradients for solving linear systems. J. Res. Natl. Bureau Stand. 49(6), 409–436 (1952)

Hildebrand, F., Miehe, C.: A regularized sharp interface model for phase transformation accounting for prescribed sharp interface kinetics. PAMM 10(1), 673–676 (2010)

Hildebrand, F., Miehe, C.: Variational phase field modeling of laminate deformation microstructure in finite gradient crystal plasticity. PAMM 12(1), 37–40 (2012)

Hildebrand, F.E.: Variational multifield modeling of the formation and evolution of laminate microstructure. Ph.D. thesis, University of Stuttgart (2013)

Hildebrand, F.E., Miehe, C.: A phase field model for the formation and evolution of martensitic laminate microstructure at finite strains. Phil. Mag. 92(34), 4250–4290 (2012)

Honda, K., Nishiyama, Z.: On the nature of the tetragonal and cubic martensites. Sci. Rep. Tohoku Imp. Univ. 21, 299–331 (1932)

Huiping, L., Guoqun, Z., Shanting, N., Chuanzhen, H.: FEM simulation of quenching process and experimental verification of simulation results. Mater. Sci. Eng. A 452, 705–714 (2007)

Jacobs, A.E.: Landau theory of structures in tetragonal-orthorhombic ferroelastics. Phys. Rev. B 61(10), 6587 (2000)

Jacobs, A.E., Curnoe, S.H., Desai, R.C.: Simulations of cubic-tetragonal ferroelastics. Phys. Rev. B 68(22), 224104 (2003)

Javanbakht, M., Levitas, V.I.: Interaction between phase transformations and dislocations at the nanoscale. Part 2: phase field simulation examples. J. Mech. Phys. Solids 82, 164–185 (2015)

Ji, H., Chopp, D., Dolbow, J.E.: A hybrid extended finite element/level set method for modeling phase transformations. Int. J. Numer. Meth. Eng. 54(8), 1209–1233 (2002)

Jin, Y.M., Artemev, A., Khachaturyan, A.G.: Three-dimensional phase field model of low-symmetry martensitic transformation in polycrystal: simulation of \(\zeta \)’2 martensite in AuCd alloys. Acta Mater. 49(12), 2309–2320 (2001)

Karypis, G., Kumar, V.: A fast and high quality multilevel scheme for partitioning irregular graphs. SIAM J. Sci. Comput. 20(1), 359–392 (1998)

Kitahara, H., Ueji, R., Ueda, M., Tsuji, N., Minamino, Y.: Crystallographic analysis of plate martensite in Fe-28.5 at.% Ni by FE-SEM/EBSD. Mater. Charact. 54(4–5), 378–386 (2005)

Kochmann, J., Wulfinghoff, S., Reese, S., Mianroodi, J.R., Svendsen, B.: Two-scale FE-FFT- and phase-field-based computational modeling of bulk microstructural evolution and macroscopic material behavior. Comput. Methods Appl. Mech. Eng. 305, 89–110 (2016)

Kohn, R.V., Strang, G.: Optimal design and relaxation of variational problems, I. Commun. Pure Appl. Math. 39(1), 113–137 (1986)

Kohn, R.V., Strang, G.: Optimal design and relaxation of variational problems, II. Commun. Pure Appl. Math. 39(2), 139–182 (1986)

Kohn, R.V., Strang, G.: Optimal design and relaxation of variational problems, III. Commun. Pure Appl. Math. 39(3), 353–377 (1986)

Koistinen, D.P., Marburger, R.E.: A general equation prescribing the extent of the austenite-martensite transformation in pure iron-carbon alloys and plain carbon steels. Acta Metall. 7(1), 59–60 (1959)

Kružík, M., Mielke, A., Roubíček, T.: Modelling of microstructure and its evolution in shape-memory-alloy single-crystals, in particular in CuAlNi. Meccanica 40(4–6), 389–418 (2005)

Kuhn, C.: Numerical and Analytical Investigation of a Phase Field Model for Fracture. doctoralthesis, Technische Universität Kaiserslautern (2013)

Kurdjumov, G., Sachs, G.: Over the mechanisms of steel hardening. Z. Phys. 64, 325–343 (1930)

Levitas, V.I., Javanbakht, M.: Interaction between phase transformations and dislocations at the nanoscale. Part 1. General phase field approach. J. Mech. Phys. Solids 82, 287–319 (2015)

Levitas, V.I., Lee, D.W., Preston, D.L.: Interface propagation and microstructure evolution in phase field models of stress-induced martensitic phase transformations. Int. J. Plast 26(3), 395–422 (2010)

Levitas, V.I., Roy, A.M., Preston, D.L.: Multiple twinning and variant-variant transformations in martensite: phase-field approach. Phys. Rev. B 88(5), 054113 (2013)

Luskin, M.: On the computation of crystalline microstructure. Acta Numer. 5, 191–257 (1996)

Málek, J., Strakos, Z.: Preconditioning and the Conjugate Gradient Method in the Context of Solving PDEs, vol. 1. SIAM, Philadelphia (2014)

Malik, A., Amberg, G., Borgenstam, A., Ågren, J.: Phase-field modelling of martensitic transformation: the effects of grain and twin boundaries. Modell. Simul. Mater. Sci. Eng. 21(8), 085003 (2013)

Malik, A., Yeddu, H.K., Amberg, G., Borgenstam, A., Ågren, J.: Three dimensional elasto-plastic phase field simulation of martensitic transformation in polycrystal. Mater. Sci. Eng., A 556, 221–232 (2012)

Mamivand, M., Zaeem, M.A., El Kadiri, H.: A review on phase field modeling of martensitic phase transformation. Comput. Mater. Sci. 77, 304–311 (2013)

Marder, A.R., Benscoter, A.O., Krauss, G.: Microcracking sensitivity in Fe-C plate martensite. Metall. Trans. 1(6), 1545–1549 (1970)

Mecozzi, M.G., Eiken, J., Santofimia, M.J., Sietsma, J.: Phase field modelling of microstructural evolution during the quenching and partitioning treatment in low-alloy steels. Comput. Mater. Sci. 112, 245–256 (2016)

Moelans, N.: A quantitative and thermodynamically consistent phase-field interpolation function for multi-phase systems. Acta Mater. 59(3), 1077–1086 (2011)

Moelans, N., Blanpain, B., Wollants, P.: An introduction to phase-field modeling of microstructure evolution. Comput. Coupling Phase Diagr. Thermochem 32(2), 268–294 (2008)

Morito, S., Tanaka, H., Konishi, R., Furuhara, T., Maki, T.: The morphology and crystallography of lath martensite in Fe-C alloys. Acta Mater. 51(6), 1789–1799 (2003)

Müller, R.: A phase field model for the evolution of martensite microstructures in metastable austenites. Ph.D. thesis, University of Kaiserslautern (2016)

Nishiyama, Z.: X-ray investigation of the mechanism of the transformation from face centered cubic lattice to body centered cubic. Sci. Rep. Tohoku Univ. 23, 637 (1934)

Nishiyama, Z.: Martensitic Transformation. Elsevier, Amsterdam (2012)

Olson, G., Cohen, M.: A perspective on martensitic nucleation. Annu. Rev. Mater. Sci. 11(1), 1–32 (1981)

Ou, X.: Molecular dynamics simulations of fcc-to-bcc transformation in pure iron: a review. Mater. Sci. Technol. 33(7), 822–835 (2017)

Petryk, H., Stupkiewicz, S.: Interfacial energy and dissipation in martensitic phase transformations. Part I: theory. J. Mech. Phys. Solids 58(3), 390–408 (2010)

Petryk, H., Stupkiewicz, S., Maciejewski, G.: Interfacial energy and dissipation in martensitic phase transformations. Part II: size effects in pseudoelasticity. J. Mech. Phys. Solids 58(3), 373–389 (2010)

Rasmussen, K.Ø., Lookman, T., Saxena, A., Bishop, A.R., Albers, R.C., Shenoy, S.R.: Three-dimensional elastic compatibility and varieties of twins in martensites. Phys. Rev. Lett. 87(5), 055704 (2001)

Rezaee-Hajidehi, M., Stupkiewicz, S.: Phase-field modeling of multivariant martensitic microstructures and size effects in nano-indentation. Mech. Mater. 141, 103267 (2020)

Roumi, F.: Shape changing transformations: interactions with plasticity and electrochemical processes. Ph.D. thesis, California Institute of Technology (2010)

Rubini, S., Ballone, P.: Quasiharmonic and molecular-dynamics study of the martensitic transformation in Ni-Al alloys. Phys. Rev. B 48(1), 99 (1993)

Rubini, S., Ballone, P.: Erratum: Quasiharmonic and molecular-dynamics study of the martensitic transformation in Ni-Al alloys. Phys. Rev. B 49(21), 15428 (1994)

Sandoval, L., Urbassek, H.M.: Transformation pathways in the solid-solid phase transitions of iron nanowires. Appl. Phys. Lett. 95(19), 191909 (2009)

Schäfer, B.J., Song, X., Sonnweber-Ribic, P., Hartmaier, A., et al.: Micromechanical modelling of the cyclic deformation behavior of martensitic SAE 4150—a comparison of different kinematic hardening models. Metals 9(3), 368 (2019)

Schänzel, M., Shakirov, D., Ilin, A., Ploshikhin, V.: Coupled thermo-mechanical process simulation method for selective laser melting considering phase transformation steels. Comput. Math. Appl. 78, 2230–2246 (2019)

Schmidt, S., Dornisch, W., Müller, R.: A phase field model for martensitic transformation coupled with the heat equation. GAMM-Mitteilungen 40(2), 138–153 (2017)

Schmidt, S., Müller, R.: Heat conduction in a phase field model for martensitic transformation. PAMM 17(1), 561–562 (2017)

Schmitt, R., Kuhn, C., Müller, R.: On a phase field approach for martensitic transformations in a crystal plastic material at a loaded surface. Continuum Mech. Thermodyn. 29(4), 957–968 (2017)

Schmitt, R., Kuhn, C., Müller, R., Bhattacharya, K.: Crystal plasticity and martensitic transformations—a phase field approach. Tech. Mech. 34(1), 23–38 (2014)

Schmitt, R., Kuhn, C., Skorupski, R., Smaga, M., Eifler, D., Müller, R.: A combined phase field approach for martensitic transformations and damage. Arch. Appl. Mech. 85(9–10), 1459–1468 (2015)

Schmitt, R., Müller, R., Kuhn, C.: A phase field model for martensitic transformations. PAMM 12(1), 261–262 (2012)

Schmitt, R., Müller, R., Kuhn, C., Urbassek, H.M.: A phase field approach for multivariant martensitic transformations of stable and metastable phases. Arch. Appl. Mech. 83(6), 849–859 (2013)

Schmitt, R., Müller, R., Skorupski, R., Smaga, M., Eifler, D.: A phase field approach for martensitic transformations in elastoplastic materials. PAMM 13(1), 213–214 (2013)

Schmitt, R., Wang, B., Urbassek, H.M., Müller, R.: Modeling of martensitic transformations in pure iron by a phase field approach using information from atomistic simulation. Tech. Mech. 33, 119–130 (2013)

Schneider, D., Schoof, E., Tschukin, O., Reiter, A., Herrmann, C., Schwab, F., Selzer, M., Nestler, B.: Small strain multiphase-field model accounting for configurational forces and mechanical jump conditions. Comput. Mech. 61(3), 277–295 (2018)

Schoof, E., Herrmann, C., Schneider, D., Hötzer, J., Nestler, B.: Multiphase-Field Modeling and Simulation of Martensitic Phase Transformation in Heterogeneous Materials. In: Nagel, W.E., Kröner, D.H., Resch, M.M. (eds.) High Performance Computing in Science and Engineering’18, pp. 475–488. Springer (2019)

Schoof, E., Herrmann, C., Streichhan, N., Selzer, M., Schneider, D., Nestler, B.: On the multiphase-field modeling of martensitic phase transformation in dual-phase steel using \(J_2\)-viscoplasticity. Model. Simul. Mater. Sci. Eng. 27(2), 025010 (2018)

Schoof, E., Schneider, D., Streichhan, N., Mittnacht, T., Selzer, M., Nestler, B.: Multiphase-field modeling of martensitic phase transformation in a dual-phase microstructure. Int. J. Solids Struct. 134, 181–194 (2018)

Schrade, D., Mueller, R., Xu, B.X., Gross, D.: Domain evolution in ferroelectric materials: a continuum phase field model and finite element implementation. Comput. Methods Appl. Mech. Eng. 196(41–44), 4365–4374 (2007)

Schwenk, M.: Numerische Modellierung der Induktiven Ein-und Zweifrequenzrandschichthärtung. KIT Scientific Publishing, Karlsruhe (2014)

Shchyglo, O., Du, G., Engels, J.K., Steinbach, I.: Phase-field simulation of martensite microstructure in low-carbon steel. Acta Mater. 175, 415–425 (2019)

Taylor, R.L.: FEAP - finite element analysis program (2014). http://www.ce.berkeley/feap

Urbassek, H.M., Sandoval, L.: Molecular dynamics modeling of martensitic transformations in steels. In:Pereloma, E., Edmonds, D.V. (eds.) Phase transformations in steels, pp. 433–463. Elsevier (2012)

Wang, B., Sak-Saracino, E., Gunkelmann, N., Urbassek, H.M.: Molecular-dynamics study of the \(\alpha \leftrightarrow \gamma \) phase transition in Fe-C. Comput. Mater. Sci. 82, 399–404 (2014)

Wang, B., Urbassek, H.M.: Phase transitions in an Fe system containing a bcc/fcc phase boundary: an atomistic study. Phys. Rev. B 87(10), 104108 (2013)

Wang, Y., Khachaturyan, A.G.: Three-dimensional field model and computer modeling of martensitic transformations. Acta Mater. 45(2), 759–773 (1997)

Wang, Y., Khachaturyan, A.G.: Multi-scale phase field approach to martensitic transformations. Mater. Sci. Eng. A 438, 55–63 (2006)

Wassermann, G.: Über den Mechanismus der \(\alpha \)-\(\gamma \)-Umwandlung des Eisens. Verlag Stahleisen, Düsseldorf (1935)

Wechsler, M.S., Lieberman, D.S., Read, T.A.: On the theory of the formation of martensite. Trans. AIME 197, 1503–1515 (1953)

Xie, C.L., Ghosh, S., Groeber, M.: Modeling cyclic deformation of HSLA steels using crystal plasticity. J. Eng. Mater. Technol. 126(4), 339–352 (2004)

Yamanaka, A., Takaki, T., Tomita, Y.: Elastoplastic phase-field simulation of self-and plastic accommodations in cubic tetragonal martensitic transformation. Mater. Sci. Eng. A 491(1–2), 378–384 (2008)

Yamanaka, A., Takaki, T., Tomita, Y., Yoshino, M.: Crystal plasticity phase-field simulation of deformation behavior and microstructure evolution in polycrystalline material. In: Proceedings of X International Conference on Computational Plasticity-COMPLAS X (CD-ROM), vol. 462, pp. 1–4 (2009)

Yeddu, H.K.: Phase-field modeling of austenite grain size effect on martensitic transformation in stainless steels. Comput. Mater. Sci. 154, 75–83 (2018)

Yeddu, H.K., Borgenstam, A., Hedström, P., Ågren, J.: A phase-field study of the physical concepts of martensitic transformations in steels. Mater. Sci. Eng. A 538, 173–181 (2012)

Yeddu, H.K., Malik, A., Ågren, J., Amberg, G., Borgenstam, A.: Three-dimensional phase-field modeling of martensitic microstructure evolution in steels. Acta Mater. 60(4), 1538–1547 (2012)

Zhang, W., Jin, Y.M., Khachaturyan, A.G.: Phase field microelasticity modeling of heterogeneous nucleation and growth in martensitic alloys. Acta Mater. 55(2), 565–574 (2007)

Zhang, X., Shen, G., Li, C., Gu, J.: Analysis of interface migration and isothermal martensite formation for quenching and partitioning process in a low-carbon steel by phase field modeling. Modell. Simul. Mater. Sci. Eng. 27(7), 075011 (2019)

Acknowledgements

Marius Graf is very grateful to Cyril Cayron for providing the new version of ARPGE. Furthermore, Marius Graf would like to thank Sanjay Govindjee and Robert L. Taylor for their support via the FEAP user forum (http://feap.berkeley.edu/forum/). Felix Diewald and Ralf Müller would like to thank the DFG (Deutsche Forschungsgemeinschaft—German Research Foundation) for financial support—Projektnummer 172116086 - SFB 926.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Appendices

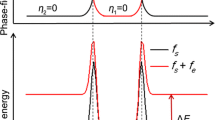

Weighting factors of the phase field potential

Consider the standard equilibrium case (\(\varDelta g = 0\)) of an indefinitely extended one-dimensional continuum, which consists of two phases as depicted in Fig. 14. In equilibrium state, the order parameter function

solves the Euler–Lagrange equation

of the variational problem

Multiplying Eq. (43) with \(\varphi ^\prime \) and utilizing the identity

lead to

From Eq. (46) follows

The constant c is found to be \(c=0\) by evaluation of Eq. (47) regarding the specific order parameter \(\varphi =0\) with \(\psi (\varphi =0) = 0\) and \(\left. \frac{d \varphi }{d x} \right| _{\varphi =0} = 0\). Analogous to Eq. (8), it is

Inserting Eq. (48) in (47) leads to

With Eq. (49), the integral with respect to x in Eq. (44) can be rewritten as an integral with respect to \(\varphi \). Eventually,

is obtained. Evaluation of the integral leads to

Furthermore, Eq. (49) can be used to derive

By solving Eqs. (51) and (52), the parameters \(\alpha ^*\) and \(\beta ^*\) according to Eq. (9) are determined.

Numerical implementation with two spatial dimensions

For the sake of simplicity, the two-dimensional plane strain case is considered. The weak forms

and

of Eqs. (12) and (13) are used. A domain \(\varOmega \) with the continuous volume V is approximated by \(N_{{\mathrm {el}}}\) elements. The assembly of the system is described by

where \(\varOmega _e\) occupies the element domain. Using the following equations, the displacement \({\varvec{u}}\) as well as the order parameters \(\varphi _i\) and their rates \(\dot{\varphi _i}\) are discretized,

Here, \(N_I\) is the bilinear shape function of node I and \(n_{{\mathrm {el}}}\) is the total number of nodes per element. The superimposed hat \(\hat{\left( \bullet \right) }\) indicates nodal quantities. With the matrices

the gradients are discretized by

In Eq. (58), Voigt notation is applied for the symmetrical strain tensor \({\varvec{\varepsilon }}= \frac{1}{2} \left( {\varvec{\nabla u}} + ({\varvec{\nabla u}})^T \right) \). Analogously, the virtual field variables

are approximated. According to the isoparametric concept, the geometry of the element is approximated with identical shape functions.

Applying discretization to the weak forms by inserting Eqs. (56), (58) and (59) in Eqs. (53) and (54) yields the nodal element residuals

for the \(i^{{{\mathrm {th}}}}\) phase field and

for the mechanical field. With the nodal residual vector \( {\varvec{R}}_I = \begin{pmatrix} {\varvec{R^u}}_I,&R_I^{\varphi _i},&\cdots ,&R_I^{\varphi _N} \end{pmatrix}^T \) and the residual vector of an element \( {\varvec{R}}_e = \begin{pmatrix} {\varvec{R}}_I,&\cdots ,&{\varvec{R}}_{n_{{\mathrm {el}}}} \end{pmatrix}^T\), the residual of the model

is assembled. The nodal residual vector \({\varvec{R}}_{I}\) depends on the nodal degrees of freedom \( \hat{{\varvec{d}}} = \begin{pmatrix} {\varvec{u}},&\varphi _i,&\cdots ,&\varphi _N \end{pmatrix}^T \) and their rates. In order to solve the nonlinear equation system \({\varvec{R}}={\varvec{0}}\) at each time step, the backward Euler method is utilized for discretization in time. The degrees of freedom \(\hat{{\varvec{d}}}\) in the current time step are computed with the Newton–Raphson method. This requires a system matrix consisting of a stiffness component and a damping component.

The nodal stiffness matrix \({\varvec{K}}_{IJ} \) reads

where the matrix entries are

Note the symmetry of \({\varvec{K}}_{IJ} \). The corresponding damping matrix reads

which concludes the discretization of the problem. As common in the finite element method, the Gaussian quadrature rule is used for numeric evaluation of the integrals.

Shape deformation according to the PTMC

Rights and permissions

About this article

Cite this article

Graf, M., Kuntz, M., Autenrieth, H. et al. Simulation of martensitic microstructures in a low-alloy steel. Arch Appl Mech 91, 1641–1668 (2021). https://doi.org/10.1007/s00419-020-01845-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00419-020-01845-6