Abstract

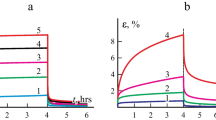

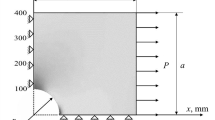

Many materials exhibit the stress range dependent creep behavior. The power law creep observed for a certain stress range changes to the viscous type creep as the stress value decreases. Recently published experimental data for advanced heat resistant steels indicate that the high creep exponent (in the range 7–12) may decrease to the low value of approximately unity within the stress range relevant for engineering structures. The aim of this paper is to analyze the influence of the stress range dependent power-law-viscous creep transition on the behavior of structures at elevated temperature. A constitutive model for the minimum creep rate is introduced to describe both the linear and the power law creep depending upon the stress level. To demonstrate basic features of the stress range dependent creep modeling, several elementary examples from structural mechanics are presented. They include a stress relaxation problem, a beam subjected to pure bending and a pressurized thick-walled cylinder. Based on the uni-axial transition stress the transition value of the external load is estimated such that above this value the power law can be applied. For the loading levels below this value the character of the stress distribution as well as the stress values are essentially influenced by the viscous creep.

Similar content being viewed by others

References

ABAQUS, Benchmarks Manual (2006)

Altenbach H., Gorash Y., Naumenko K.: Steady-state creep of a pressurized thick cylinder in both the linear and the power law ranges. Acta Mech. 195, 263–274 (2008)

Becker A.A., Hyde T.H., Sun W., Andersson P.: Benchmarks for finite element analysis of creep continuum damage mechanics. Comp. Mat. Sci. 25, 34–41 (2002)

Betten J.: Creep Mechanics. Springer, Berlin (2005)

Boyle J.T., Spence J.: Stress Analysis for Creep. Butterworth, London (1983)

Dyson B.F., McLean M.: Micromechanism-quantification for creep constitutive equations. In: Murakami, S., Ohno, N. (eds) IUTAM Symposium on Creep in Structures, pp. 3–16. Kluwer, Dordrecht (2001)

Frost H.J., Ashby M.F.: Deformation-Mechanism Maps. Pergamon, Oxford (1982)

Hult J.A.: Creep in Engineering Structures. Blaisdell Publishing Company, Waltham (1966)

Kloc, L., Sklenička, V.: Transition from power-law to viscous creep beahviour of P-91 type heat-resistant steel. Mater. Sci. Eng. A234–A236:962–965 (1997)

Kloc, L., Sklenička, V.: Confirmation of low stress creep regime in 9% chromium steel by stress change creep experiments. Mater. Sci. Eng. A387–A389:633–638 (2004)

Kloc, L., Sklenička, V., Ventruba, J.: Comparison of low creep properties of ferritic and austenitic creep resistant steels. Mater. Sci. Eng. A319–A321:774–778 (2001)

Kowalewski Z.L., Hayhurst D.R., Dyson B.F.: Mechanisms-based creep constitutive equations for an aluminium alloy. J. Strain. Anal. 29(4), 309–316 (1994)

Malinin, N.N.: Raschet na polzuchest’ konstrukcionnykh elementov (Creep calculations of structural elements, in Russ.). Mashinostroenie, Moskva (1981)

Naumenko K., Altenbach H.: Modelling of Creep for Structural Analysis. Springer, Berlin (2007)

Odqvist F.K.G.: Mathematical Theory of Creep and Creep Rupture. Oxford University Press, Oxford (1974)

Penny R.K., Mariott D.L.: Design for Creep. Chapman & Hall, London (1995)

Perrin I.J., Hayhurst D.R.: Creep constitutive equations for a 0.5Cr–0.5Mo–0.25V ferritic steel in the temperature range 600–675°C. J. Strain. Anal. 31(4), 299–314 (1994)

Rabotnov Y.N.: Creep Problems in Structural Members. North-Holland, Amsterdam (1969)

Reiner M.: Deformation and Flow. An Elementary Introduction to Rheology, 3rd edn. H.K. Lewis & Co., London (1969)

Rieth, M.: A comprising steady-state creep model for the austenitic AISI 316 L(N) steel. J. Nucl. Mater. 360–370(2):915–919 (2007)

Rieth, M., Falkenstein, A., Graf, P., Heger, S., Jäntsch, U., Klimiankou, M., Materna-Morris, E., Zimmermann, H.: Creep of the austenitic steel AISI 316 L(N). experiments and models. Tech. rep., Forschungszentrum Karlsruhe, FZKA 7065, Karlsruhe (2004)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Naumenko, K., Altenbach, H. & Gorash, Y. Creep analysis with a stress range dependent constitutive model. Arch Appl Mech 79, 619–630 (2009). https://doi.org/10.1007/s00419-008-0287-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00419-008-0287-5