Abstract

The ability to manipulate rheological and electrical properties of colloidal carbon black gels makes them attractive in composites for energy applications such as batteries and fuel cells, where they conduct electricity and prevent sedimentation of ‘granular’ active components. While it is commonly assumed that granular fillers have a simple additive effect on the composite properties, new phenomena can emerge unexpectedly, with some composites exhibiting a unique rheological bi-stability between high-yield-stress and low-yield-stress states. Here we report such bi-stability in suspensions of non-Brownian graphite and colloidal carbon black in oil, a model system to mimic composite suspensions for energy applications. Steady shear below a critical stress elicits a transition to a persistent mechanically weak and poorly conducting state, which must be ‘rejuvenated’ using high-stress shear to recover a stronger, high-conductivity state. Our findings highlight the highly tunable nature of binary granular/gel composite suspensions and present new possibilities for optimising mixing and processing conditions for Li-ion battery slurries.

Graphical abstract

Similar content being viewed by others

Introduction

As global energy demand increases (IEA 2022; Barrett et al. 2022), sustainable storage and conversion technologies (solar cells, batteries, fuel cells) are becoming increasingly critical (IEA 2020). These devices are often fabricated from components prepared as slurries combining carbon black and larger granular particles such as graphite or other active components (Entwistle et al. 2022; Wei et al. 2015; Kim et al. 2022). Understanding the rheology of these mixtures is vital to optimise device performance (Richards et al. 2023). As a result, recent efforts have revealed an intimate connection between the size of fractal carbon black agglomerates and shear stress which underlies the reversible thixotropic response of carbon black suspensions under high-shear intensities (Hipp et al. 2021). On the other hand, low-intensity shear drives the densification and anisotropic structuring of agglomerates notably larger and denser than those formed under high-intensity shear (Hipp et al. 2019; Wang and Ewoldt 2022; Varga et al. 2019). Upon cessation of flow, a conductive colloidal gel forms (Helal et al. 2016; Narayanan et al. 2017) which may prevent sedimentation of large granular fillers (Konda et al. 2023). Although these additives improve conductivity (Sullivan and Bose 2022; Don et al. 2022; Phillips et al. 2017; Antunes et al. 2011), they also non-trivially alter the slurry rheology and processability (Kim et al. 2022; King et al. 2008; Kwon et al. 2015).

Here we combine rheometry, electron microscopy and dielectric measurements to examine the mechanical and electrical properties of a model slurry consisting of graphite and carbon black in mineral oil. We show that the material is bi-stable, with shear acting as a switch between a high-conductivity, high-yield-stress state and a low-conductivity, low-yield-stress state, similar to recently reported bi-stability in silica-based binary suspensions (Jiang et al. 2022). Our results show that slurry processing conditions could dramatically impact device performance, and should help guide efforts to optimise mixing and coating processes.

Materials and methods

Suspension preparation

The synthetic graphite (Timrex KS150) and carbon black (Ensaco 250 G) were used as supplied by Imerys Graphite & Carbon (Bodio, Switzerland). The fraction of graphite powder passing through a \(63 \ {\mu m}\) aperture in vibrational sieving was collected for the investigations. Optical microscopy gave a count-based particle size distribution, from which we estimate \(d_\textrm{90} \approx 58 \ {\mu m}\) and \(d_\textrm{50} \approx 24 \ {\mu m}\), with \(d_\textrm{x} = \textrm{y}\) meaning \(\mathrm {x \ \%}\) of the imaged particles have a diameter \(\le \textrm{y}\) (Snow 2020). The assumption in our analysis that the particles are spherical is acceptable given that KS150 graphite has a relatively low aspect ratio. Heavy mineral oil (330760, viscosity \(\eta _0 = {0.16\,\mathrm{\text {Pa}\text {s}}}\) at 23 \({}^{\circ }\text {C}\)) was obtained from Merck.

Carbon black powder was mixed with mineral oil in a sealed 250 mL bottle by hand shaking followed by sonication (Bransonic 5510E-MT, frequency 42 kHz, 135 W) for an hour. To prepare the binary suspensions, the gel was manually and vortex mixed with the graphite powder to obtain a visually homogeneous suspension. Samples were stored at room temperature and shaken and stirred vigorously before being used for rheometry.

Rheometry

Rheological measurements were conducted on a stress-controlled AR-G2 rheometer (TA Instruments) with a crosshatched parallel plate geometry (diameter 40 mm, gap height 800 \(\upmu \)m) and temperature kept at 23 \({}^{\circ }\text {C}\) using a Peltier plate. To erase loading memory, the carbon black gel and binary suspensions were subjected to a shear rate of \(\dot{\gamma } = 1000 \ {s^{-1}}\) for 1200 s and 300 s, respectively. We visually checked for, but never found, sample fracture.

Cryogenic scanning electron microscopy (Cryo-SEM)

The scanning electron microscope (SEM) was a Zeiss Crossbeam 550 FIB-SEM with a Quorum Technologies Ltd PP3010T cryogenic attachment. After rheological measurements, the upper geometry was lifted and a small amount of sample was carefully transferred and spaced between two rivets. The rivets were placed in a sample holder and plunge-frozen into slush nitrogen before being loaded into a Quorum chamber and freeze-fractured at \(-\)140 \({}^{\circ }\text {C}\). Afterwards, a 5 min sublimation at \(-\)90 \({}^{\circ }\text {C}\) removed any surface ice introduced during the freeze-fracture process. The uncoated samples were imaged with at 1 kV acceleration voltage. Simultaneous imaging using a Zeiss ’InLens’ secondary electron detector and a secondary electron secondary ion (SESI) detector allowed differentiation between topography and composition.

Monte Carlo simulations were performed with the software CASINO (v3.3.0.4) to estimate secondary electron yields from sample constituents under our experimental conditions (acceleration voltage 1 kV and beam diameter 1.5 nm). A density of \({2.22\,\mathrm{g \ cm^{-3}}}\) was used for the graphite (from the manufacturer), and paraffins consisting of 14, 29 and 43 carbon atoms were used to model the mineral oil with density \({0.87\,\mathrm{g \ cm^{-3}}}\).

Dielectric spectroscopy

Dielectric spectroscopy measurements were performed in an HR-20 rheometer (TA Instruments) equipped with a smooth parallel plate geometry (diameter 25 mm, gap height 800 \(\upmu \)m). TRIOS software (TA Instruments) provided control of a Keysight E4980A LCR impedance analyser. Short- and open-circuit measurements were conducted to correct the raw data, collected in logarithmically spaced frequency sweeps from 20 Hz to 2 MHz at an amplitude of 100 mV.

In the main text, we consider only the real part of the complex conductivity, \(\textrm{Re} \left( \sigma ^*\right) = \sigma ' = \omega \epsilon _r'' \epsilon _0\), with \(\omega =2\pi f\) the frequency of the applied field, \(\epsilon _r''\) the imaginary part of the complex permittivity, and \(\epsilon _0\) the permittivity of free space. Data for \(\sigma '\left( f \right) \) and \(\epsilon _\textrm{r}''\left( f \right) \) are given in the supplementary information (SI) (Fig. S1). To obtain the low-frequency (dc) conductivity, \(\sigma _\textrm{dc}\), we fit the conductivity spectra by \(\epsilon _\textrm{r}'' = \sigma _\textrm{dc}/ \left( \omega \epsilon _0\right) \) in the frequency range 20–1000 Hz and 20–250 Hz for the composite and gel, respectively, since \(\epsilon _\textrm{r}''\left( \omega \right) \) exhibited a slope of -1 in this frequency range (Schönhals and Kremer 2003). At least two spectra were collected for each sample.

a Shear stress, \(\tau \), as a function of shear rate, \(\dot{\gamma }\), for 6 wt% carbon black in oil (CB6) and 6 wt% carbon black + 24 wt% graphite in oil (CB6/G24). For transient data see Fig. S2. During step-down, the sample is rejuvenated at \(\dot{\gamma }_\textrm{rej} = 1000 \ {s^{-1}}\) for 300 s between each \(\dot{\gamma }\), and \(\tau \) is recorded for 300 s. Ramp-down is performed by progressively lowering \(\dot{\gamma }\) with 300 s at each step. Vertical bars indicate the range of \(\tau \) measured after reaching the maximum stress (squares) at each \(\dot{\gamma }\) when a steady state was not reached. Only bars larger than the marker size are shown. The horizontal dashed red line indicates the yield stress, \(\tau _\textrm{y}^\textrm{H} = 103 \ \textrm{Pa}\), of stepped-down CB6/G24. In b and c, the composite after ramping down and quenching, respectively, is seen on the rheometer tool (diameter 50 mm), prior to collecting material for cryo-SEM imaging. d dc electrical conductivity, \(\sigma _\textrm{dc}\), measured 1000 s after the deformation protocol. The values of \(\sigma _\textrm{dc}\) \(\left( 10^{-5} - 10^{-4} \ {mS \cdot cm^{-1}} \right) \) are comparable to conductivities measured by Helal et al. (2016) in gels of CB with similar specific surface area to ours (\({65\,\mathrm{m^2/g}}\) according to the manufacturer). Error bars denote ± one standard deviation based on measurements of at least two different samples

Results and discussion

Individually, carbon black (CB) particles (diameter \(\approx {300\,\mathrm{\text {n}\text {m}}}\) fused aggregates) in mineral oil form colloidal gels with finite yield stress for weight fractions above a few percent (Trappe and Weitz 2000; Trappe et al. 2007; Gibaud et al. 2010), while the larger graphite (G) particles (size \(\approx {30\,\mathrm{\upmu \text {m}}}\)) in oil is an adhesive, non-Brownian suspension, also with a finite yield stress (Richards et al. 2021; Larsen et al. 2023). So, we might expect the graphite to act simply as an ‘active filler’ enhancing the gel yield stress (Chen and Dickinson 1999). Instead, comparing the flow curves of a binary suspension (6 wt.% CB, 24 wt.% G) to a 6 wt.% CB gel, we find a remarkable dependence on deformation protocol in the binary system that is absent in the CB-only gel, Fig. 1a. When the shear stress, \(\tau (\dot{\gamma })\), is progressively ramped down, the binary suspension displays a weak yield stress (\(\lesssim {5\,\mathrm{\text {Pa}}}\)) in the \(\dot{\gamma }\rightarrow 0\) limit, below that of the un-filled CB-only gel (\(\gtrsim {10\,\mathrm{\text {Pa}}}\)). If we instead rejuvenate the sample by sustained rapid shearing (\(\dot{\gamma } = 1000 \ {s^{-1}}\) for 300 s) between each applied shear rate, the yield stress of the binary suspension increases by over an order of magnitude to \(\tau _\textrm{y}^\textrm{H} = {103\,\mathrm{\text {Pa}}}\). This strong history dependence is evident when we inspect samples in the rheometer after measurement: a rejuvenated sample displays sharp peaks (Fig. 1c) while a ramped-down sample appears liquid-like (Fig. 1b).

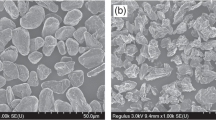

Cryo-SEM images of our carbon black/graphite composite suspension after quenching to 70 Pa \(\left( < \tau _\textrm{y}\right) \) for 200 s following high-shear rejuvenation at \(\dot{\gamma }={1000\,\mathrm{\text {s}^{-1}}}\) (a, b). In a, graphite (G) is seen as large (here \(\sim 10 \ {\mu m}\)), bright flakes, while the bright continuous, narrow lines are fracture lines (FL), not to be confused with graphite. Image b, corresponding to the highlighted region in (a), shows individual carbon black (CB) aggregates, appearing as small bright particles, dispersed throughout the matrix. Images c and d show the CB/G suspension following the shear ramp-down protocol described in Fig. 1a. Image (d) is a closer view at the region highlighted in (c), clearly showing the dense structure of CB blobs

This protocol dependence in mechanical properties is mirrored in electrical properties. Measuring the conductivity at rest following shear cessation, we find a close to order of magnitude larger conductivity in the high-yield-stress composite relative to the ramped-down composite, Fig. 1d. Additionally, the more than an order of magnitude conductivity increase in the high-yield-stress composite compared to the high-yield-stress gel demonstrates CB-G synergism in determining the electrical properties. These observations hold for a range of graphite contents in the composite (Fig. S3).

In contrast to the composites, the ramped-down CB-only gel, although mechanically weaker, exhibits a marginally higher conductivity than the quenched sample. A similar shear-induced rise in conductivity in CB gels (Helal et al. 2016) has been attributed to the formation of ‘log-rolling’ vorticity-aligned flocs (Osuji and Weitz 2008; Grenard et al. 2011) driven by plate confinement (Varga et al. 2019). Rheo-confocal images show similar structures in our CB-only gels, Fig. S5, and we find a strain-dependent conductivity in these gels that correlates with the formation and breakup of these flocs, Fig. S4. So, vorticity-aligned floc formation is probably also responsible for the observed slightly shear-dependent conductivity in our ramped-down CB-only gel.

These combined rheological and electrical results show that our CB/G composite switches between stable high-conductivity, high-yield-stress and low-conductivity, low-yield-stress states depending on the shear history. Similar memory and bistability was recently observed in composites of colloidal gels and granular suspensions of silica particles (Jiang et al. 2022), where the transition between solid-like and liquid-like states originated from the collapse of the gel network into compact, disjoint blobs at moderate applied stress. We use cryogenic scanning electron microscopy (cryo-SEM) to visualise the microstructure of our model composite slurry to explore if a similar mechanism exists in our system. In secondary electron images, the conductive filler particles (both large graphite flakes and small carbon black aggregates) appear bright against the insulating oil. This is expected for our low acceleration voltage and consistent with Monte Carlo simulations comparing the secondary electron yield \(\left( \delta \right) \) from graphite (\(\delta \sim 0.9\)) versus various paraffins (to simulate mineral oil, \(\delta \sim 0.3\)). Note that some bright, narrow lines in our micrographs (FL) are fracture lines created during sample preparation. These are clearly seen in secondary electron secondary ion (SESI) images (Fig. S6) that highlight topography, and should not be confused with edges of graphite flakes.

In the high-yield-stress state produced by quenching from high shear, Fig. 2a and b, irregular CB aggregates are evident throughout the sample, well dispersed between the flake-like graphite particles. In contrast, in the low-yield-stress state following shear ramp down, Fig. 2c and d, we find large, isolated blobs \(\left( > 10 \ {\mu m} \right) \) of CB aggregates, with the surrounding fluid largely devoid of CB particles. These CB blobs are notably denser than the well-dispersed CB particles in the high-yield-stress state, compare Figs. 2b with d. Large area images, Fig. 3 (and Figs. S7 and S8 in the SI), confirm the generality of these features. While the composite shows distinct microstructures in the two states, the differences are less obvious in the pure gel after exposing it to identical shear histories (Fig. S9). Importantly, in the absence of the large graphite fillers, carbon black does not phase separate into isolated blobs.

The collapse of the CB gel phase into compact, disjoint blobs in the composite explains the decrease in conductivity and yield stress following the shear ramp down. The microstructure in our low-yield-stress state differs somewhat from that in the fluid-like states in previously described silica-based composites (Jiang et al. 2022). We find dense aggregations of CB particles generally forming around the larger graphite particles, while the small-particle blobs in the silica-based composites were generally disjoint from the larger particles. This suggests significant attraction between the large and small particles in our composites. This is perhaps unsurprising. The interactions in the previously studied model binary silica suspensions were designed to be non-attractive between the small colloids and large grains. In our case, we have clear evidence of attractive interactions in pure CB and G suspensions. Since both CB and G are forms of carbon, we may then also expect attraction between CB and G particles. The resulting close proximity of CB blobs and G flakes allows the latter to act as bridges between the former, Figs. 2c and 3b, which, together with the formation of densely packed blobs with a low intrinsic resistance (Narayanan et al. 2017), may explain why the contrast in conductivity between the two states in our system is less dramatic than the contrast in the yield stress.

Our results so far show that our CB/G slurry exhibits a shear-induced high-yield-stress/low-yield-stress transition similar to the solid/liquid transition previously observed in a mixture of attractive colloids and repulsive granular particles (Jiang et al. 2022). In the previous system, the solid/liquid transition was controlled by two stress scales: the yield stress of the homogeneous solid-like state, \(\tau _\textrm{y}^\textrm{H}\), and a characteristic stress for breakup of the large blobs in the liquid-like state, \(\tau _\textrm{B}\).

To see if this is also the case in our system, we use creep tests to characterise the yield stress of our composites, varying the preshear stress \(\tau _\textrm{pre}^\textrm{ss}\). In these tests, we measure the time-dependent shear rate \(\dot{\gamma }(t)\) for a sequence of increasing fixed stresses \(\tau \), identifying the \(\tau _\textrm{y}\) from the onset of steady flow, \(\dot{\gamma }(t)\approx \mathrm{const.}\), in the long-time limit (see Fig. S10). Prior to each test, the composite is prepared in either a heterogenous or homogenous state, followed by extended shear at the given preshear stress \(\tau _\textrm{pre}^\textrm{ss}\).

Large area cryo-SEM images of our CB/G composites a after quenching to 70 Pa \(\left( < \tau _\textrm{y}\right) \) for 200 s following high-shear rejuvenation at \(\dot{\gamma }={1000\,\mathrm{\text {s}^{-1}}}\), and b after the ramp-down protocol. Examples of carbon black (CB) blobs, graphite (G) particles and fracture lines (FL) are indicated by arrows

Yield stresses (open stars) from creep tests (error bars indicate the finite stress step size) on CB6/G24 after steady shear preshearing at the indicated preshear stresses, \(\tau _\textrm{pre}^\textrm{ss}\). The sample was either initially in a homogeneous state (hom.), obtained by pre-preshearing at \(\dot{\gamma } = 1000 \ {s^{-1}}\) for 300 s, or a heterogeneous state (het.) by pre-preshearing at \(\dot{\gamma } = 10 \ {s^{-1}}\) for 1000 s. During subsequent preshearing, the accumulated strain at each \(\tau _\textrm{pre}^\textrm{ss}\) was \(\gamma _\textrm{total} = 20,000\), except at \(\tau _\textrm{pre}^\textrm{ss} \le 90 \ {Pa}\) for CB6/G24 Hom. as the sample did not flow below its yield stress, \(\tau _\textrm{y}^\textrm{H}=103 \ \textrm{Pa}\) estimated from the flow curve in Fig. 1a, and indicated by the vertical dashed red line, so a 200 s preshear was applied instead. For the composite initially in the homogeneous state, the storage modulus \(G'\) (solid circles), measured in the linear viscoelastic region (LVR), strain amplitude \(\gamma _0^\textrm{osc} = 0.001\) and frequency \({10\,\mathrm{rad \ s^{-1}}}\), was obtained by appending a 200 s shear step at 90 Pa after shearing at the indicated \(\tau _\textrm{pre}^\textrm{ss}\). Then, \(G'\) was noted after 100 s in the LVR

At high preshear stresses, Fig. 4, we obtain the yield stress of the homogeneous state, \(\tau _\textrm{y}\approx {100\,\mathrm{\text {Pa}}}\approx \tau _\textrm{y}^\textrm{H}\), irrespective of the initial state prior to applying \(\tau _\textrm{pre}^\textrm{ss}\). For preshear stresses \(\tau _\textrm{pre}^\textrm{ss}\lesssim {200\,\mathrm{\text {Pa}}}\), the \(\tau _\textrm{y}\) steadily decreases with decreasing \(\tau _\textrm{pre}^\textrm{ss}\), roughly halving for \(\tau _\textrm{pre}^\textrm{ss}\) slightly above the homogeneous yield stress. For \(\tau _\textrm{pre}^\textrm{ss}>\tau _\textrm{y}^\textrm{H}\), the yield stress remains independent of the initial state prior to the preshear step. However, preshearing below \(\tau _\textrm{y}^\textrm{H}\) reveals a bistable regime. Initially homogeneous samples retain their yield stress so that \(\tau _\textrm{y}\approx \tau _\textrm{y}^\textrm{H}\approx \textrm{constant}\) for \(\tau _\textrm{pre}^\textrm{ss}<\tau _\textrm{y}^\textrm{H}\), while the yield stress in the initially heterogeneous sample continues to decrease with decreasing \(\tau _\textrm{pre}^\textrm{ss}\).

Thus, our graphite/carbon black composite exhibits similar bi-stable rheology to that observed in the silica composites (Jiang et al. 2022). For preshear stresses above the homogeneous yield stress, \(\tau _\textrm{pre}^\textrm{ss}>\tau _\textrm{y}^\textrm{H}\), the sample response is history-independent but depends on \(\tau _\textrm{pre}^\textrm{ss}\), with \(\tau _\textrm{y}\approx \tau _\textrm{y}^\textrm{H}=\textrm{constant}\) for high preshear stresses but then weakening over a range of moderate preshear stresses, indicating the transition from the homogeneous to the heterogeneous state. However, the yield stress of our composite remains finite in the heterogeneous state, which might be expected given the large-small attraction in our composites. With the large-small attraction absent, or at least dramatically reduced in the composites previously studied (Jiang et al. 2022), the percolated small-particle network that underpins the solid-like response is suddenly lost in the heterogenous blob-like state. However, in our graphite/carbon black composite both graphite-graphite and graphite-blob contacts enable the retention of a connected, albeit weaker, structure in the heterogenous state. In this weaker heterogenous state, the composite’s yield stress should depend on the shape and structure of the blobs, so that \(\tau _\textrm{y}\) varies with the preshear stress in this regime. Thus, while the bi-stable regime below \(\tau _\textrm{y}^\textrm{H}\) is clear in both systems, the transition between heterogeneous and homogeneous states at higher stresses is less clear in our CB/G composites when characterised by the yield stress.

A clearer mapping onto previously found behaviour (Jiang et al. 2022) results when we measure the small-amplitude storage modulus (\(G^\prime \)) of an initially homogeneous composite after appending a low-stress creep step (shearing at \({90\,\mathrm{\text {Pa}}}< \tau _\textrm{y}^\textrm{H}\)) between our pre-shear step at \(\tau _\textrm{pre}^\textrm{ss}\) and our oscillatory measurement, Fig. 4 (filled symbols). Now, we find a sharp jump in elastic modulus with \(G'\gtrsim {e4\,\mathrm{\text {Pa}}}\) above \(\tau _\textrm{pre}^\textrm{ss} \approx {200\,\mathrm{\text {Pa}}}\) and below \(\tau _\textrm{y}^\textrm{H}={103\,\mathrm{\text {Pa}}}\). This is consistent with the initial drop in \(\tau _\textrm{y}\) at intermediate pre-shear stresses, suggesting an estimate for the blob breakup stress \(\tau _\textrm{b}\approx {200\,\mathrm{\text {Pa}}}\). While we do not fully understand why the transition appears sharper when measuring the elastic modulus compared to the yield stress, we might expect adhesive large particle contacts to be broken under small amplitude oscillations (Richards et al. 2020), so that \(G'\) provides a more direct probe of the small particle network. We thus recover the essential rheological features of the granular/gel composites described previously (Jiang et al. 2022), with the homogeneous/heterogeneous (”solid”/”liquid”) transition controlled by two stress scales: the yield stress of the homogeneous composite \(\tau _\textrm{y}^\textrm{H}\) and a characteristic blob breakup stress \(\tau _\textrm{b}\).

Conclusions

We have shown that binary suspensions of graphite and carbon black particles display a similar mechanical bistability as mixtures of granular and colloidal silica particles (Jiang et al. 2022). Prolonged shear of the mixture at high enough applied stress followed by abrupt cessation of shear produces a high-yield-stress solid state – a gel of the smaller particles in which the larger particles are dispersed homogeneously. However, a gradual ramping down of the shear rate produces either a liquid state (silica mixtures) or a low-yield-stress solid (the present system) in which the smaller particles are aggregated into discrete blobs. Such structure-rheology correlations in cathode slurries have been reported before (Park et al. 2022; Komoda et al. 2022), with some evidence for history dependence (Park et al. 2022), so that bistability may be generic to binary suspensions of large grains dispersed in colloidal gels.

In our case, we find that the mechanically stronger composite also has higher electrical conductivity. This finding in our model system can be directly compared with a similar correlation between higher conductivities and discharge capacities in more elastic anode slurries for Li-ion batteries (Sullivan and Bose 2022). Our cryo-SEM images provide a direct, particle-level explanation of the link between mechanical strength and electrical conductivity: the higher-performance samples are produced using a shearing protocol that completely homogenises the system, while lower-performance samples are associated with a highly heterogeneous distribution of CB particles. A recent study using SEM and energy-dispersive X-ray spectroscopy (Saraka et al. 2020) points to a similar conclusion for the relation between microstructure and performance in dried slurry coatings used as electrodes in Li-ion batteries. This study does not, however, discuss the relative importance of slurry processing and the subsequent processes of coating and drying in determining the microstructure. Our results suggest that slurry processing certainly plays a key role. Future work may therefore fruitfully examine how the bistability of the slurry may also influence the outcome of the coating and drying process.

Data availability

The presented data can be accessed via https://doi.org/10.7488/ds/7538.

References

Antunes RA, de Oliveira MC, Ett G et al (2011) Carbon materials in composite bipolar plates for polymer electrolyte membrane fuel cells: a review of the main challenges to improve electrical performance. J Power Sources 196:2945–2961. https://doi.org/10.1016/j.jpowsour.2010.12.041

Barrett J, Pye S, Betts-Davies S et al (2022) Energy demand reduction options for meeting national zero-emission targets in the United Kingdom. Nat Energy 7:726–735. https://doi.org/10.1038/s41560-022-01057-y

Chen J, Dickinson E (1999) Effect of surface character of filler particles on rheology of heat-set whey protein emulsion gels. Colloids Surf B: Biointerfaces 12:373–381. https://doi.org/10.1016/S0927-7765(98)00091-5

Don MF, Ekanayake P, Jennings JR et al (2022) Graphite/carbon black counter electrode deposition methods to improve the efficiency and stability of hole-transport-layer-free perovskite solar cells. ACS Omega 7:22830–22838. https://doi.org/10.1021/acsomega.2c02555

Entwistle J, Ge R, Pardikar K et al (2022) Carbon binder domain networks and electrical conductivity in lithium-ion battery electrodes: a critical review. Renew Sustain Energy Rev 166:112624. https://doi.org/10.1016/j.rser.2022.112624

Gibaud T, Frelat D, Manneville S (2010) Heterogeneous yielding dynamics in a colloidal gel. Soft Matter 6:3482–3488. https://doi.org/10.1039/C000886A

Grenard V, Taberlet N, Manneville S (2011) Shear-induced structuration of confined carbon black gels: steady-state features of vorticity-aligned flocs. Soft Matter 7:3920–3928. https://doi.org/10.1039/C0SM01515F

Helal A, Divoux T, McKinley GH (2016) Simultaneous rheoelectric measurements of strongly conductive complex fluids. Phys Rev Appl 6:064004. https://doi.org/10.1103/PhysRevApplied.6.064004

Hipp JB, Richards JJ, Wagner NJ (2019) Structure-property relationships of sheared carbon black suspensions determined by simultaneous rheological and neutron scattering measurements. J Rheol 63:423–436. https://doi.org/10.1122/1.5071470

Hipp JB, Richards JJ, Wagner NJ (2021) Direct measurements of the microstructural origin of shear-thinning in carbon black suspensions. J Rheol 65:145. https://doi.org/10.1122/8.0000089

IEA (2020) Energy technology perspectives 2020. https://www.iea.org/reports/energy-technology-perspectives-2020. Accessed 30 Oct 2023

IEA (2022) World total final consumption by source, 1973-2018. https://www.iea.org/data-and-statistics/charts/world-total-final-consumption-by-source-1973-2018. Accessed 30 Oct 2023

Jiang Y, Makino S, Royer JR et al (2022) Flow-switched bistability in a colloidal gel with non-brownian grains. Phys Rev Lett 128:248002. https://doi.org/10.1103/PhysRevLett.128.248002

Kim Y, Kim S, Kim BS et al (2022) Yielding behavior of concentrated lithium-ion battery anode slurry. Phys Fluids 34:123112. https://doi.org/10.1063/5.0128872

King JA, Tambling TM, Morrison FA et al (2008) Effects of carbon fillers on the rheology of highly filled liquid-crystal polymer based resins. J Appl Polym Sci 108:1646–1656. https://doi.org/10.1002/app.27755

Komoda Y, Ishibashi K, Kuratani K et al (2022) Rheological interpretation of the structural change of LiB cathode slurry during the preparation process. JCIS Open 5:100038. https://doi.org/10.1016/j.jciso.2021.100038

Konda K, Jacob MS, Seth JR et al (2023) Capacity degradation of lithium-ion cell: the role of free carbon black content in the slurry and drying induced cracks in lifepo4 electrode. J Energy Storage 74:109477. https://doi.org/10.1016/j.est.2023.109477

Kwon YI, Kim JD, Song YS (2015) Agitation effect on the rheological behavior of lithium-ion battery slurries. J Electron Mater 44:475–481. https://doi.org/10.1007/s11664-014-3349-1

Larsen T, Søbye AL, Royer JR et al (2023) Rheology of polydisperse nonspherical graphite particles suspended in mineral oil. J Rheol 67:81–89. https://doi.org/10.1122/8.0000511

Narayanan A, Mugele F, Duits MHG (2017) Mechanical history dependence in carbon black suspensions for flow batteries: a rheo-impedance study. Langmuir 33:1629–1638. https://doi.org/10.1021/acs.langmuir.6b04322

Osuji CO, Weitz DA (2008) Highly anisotropic vorticity aligned structures in a shear thickening attractive colloidal system. Soft Matter 4:1388–1392. https://doi.org/10.1039/B716324J

Park JH, Sung SH, Kim S et al (2022) Significant agglomeration of conductive materials and the dispersion state change of the Ni-rich NMC-based cathode slurry during storage. Ind Eng Chem Res 61:2100–2109. https://doi.org/10.1021/acs.iecr.1c04205

Phillips C, Al-Ahmadi A, Potts SJ et al (2017) The effect of graphite and carbon black ratios on conductive ink performance. J Mater Sci 52:9520–9530. https://doi.org/10.1007/s10853-017-1114-6

Richards JA, Guy BM, Blanco E et al (2020) The role of friction in the yielding of adhesive non-Brownian suspensions. J Rheol 64:405–412. https://doi.org/10.1122/1.5132395

Richards JA, O’Neill RE, Poon WCK (2021) Turning a yield-stress calcite suspension into a shear-thickening one by tuning inter-particle friction. Rheol Acta 60:97–106. https://doi.org/10.1007/s00397-020-01247-z

Richards JJ, Ramos PZ, Liu Q (2023) A review of the shear rheology of carbon black suspensions. Front Phys 11. https://doi.org/10.3389/fphy.2023.1245847

Saraka RM, Morelly SL, Tang MH et al (2020) Correlating processing conditions to short- and long-range order in coating and drying lithium-ion batteries. ACS Appl Energy Mater 3:11681–11689. https://doi.org/10.1021/acsaem.0c01305

Schönhals A, Kremer F (2003) Analysis of dielectric spectra. In: Kremer F, Schönhals A (eds) Broadband dielectric spectroscopy. Springer-Verlag, Berlin Heidelberg, pp 59–96. https://doi.org/10.1007/978-3-642-56120-7

Snow Z (2020) Metal powder production and powder size and shape distribution. In: Bourell D, Frazier W, Kuhn H, et al (eds) Additive manufacturing processes. ASM International, p 167–171. https://doi.org/10.31399/asm.hb.v24.a0006567

Sullivan JP, Bose A (2022) On the connection between slurry rheology and electrochemical performance of graphite anodes in lithium-ion batteries. Electrochem Commun 141:107353. https://doi.org/10.1016/j.elecom.2022.107353

Trappe V, Weitz DA (2000) Scaling of the viscoelasticity of weakly attractive particles. Phys Rev Lett 85:449–452. https://doi.org/10.1103/PhysRevLett.85.449

Trappe V, Pitard E, Ramos L et al (2007) Investigation of \(q\)-dependent dynamical heterogeneity in a colloidal gel by x-ray photon correlation spectroscopy. Phys Rev E 76:051404. https://doi.org/10.1103/PhysRevE.76.051404

Varga Z, Grenard V, Pecorario S et al (2019) Hydrodynamics control shear-induced pattern formation in attractive suspensions. Proc Natl Acad Sci USA 116:12193–12198. https://doi.org/10.1073/pnas.1901370116

Wang Y, Ewoldt RH (2022) New insights on carbon black suspension rheology-Anisotropic thixotropy and antithixotropy. J Rheol 66:937–953. https://doi.org/10.1122/8.0000455

Wei TS, Fan FY, Helal A et al (2015) Biphasic electrode suspensions for li-ion semi-solid flow cells with high energy density, fast charge transport, and low-dissipation flow. Adv Energy Mater 5:1500535. https://doi.org/10.1002/aenm.201500535

Acknowledgements

Graphite and carbon black powders were kindly provided by Imerys Graphite & Carbon.

Funding

Open access funding provided by Aalborg University. ThL was funded by Advent Technologies A/S and a grant from the Industrial PhD programme, Innovation Fund Denmark, project 8053-00063B.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Larsen, T., Royer, J.R., Laidlaw, F.H.J. et al. Controlling the rheo-electric properties of graphite/carbon black suspensions by ‘flow switching’. Rheol Acta 63, 283–289 (2024). https://doi.org/10.1007/s00397-024-01439-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00397-024-01439-x