Abstract

Agarose hydrogels are poroviscoelastic materials that exhibit a waterlogged-crosslinked microstructure. Despite an extensive use in biotechnologies and numerous studies of the elastic properties of agarose gels, little is known about the compressible behavior and the microstructural changes of such fibrillar hydrogels under compression. The present work investigates the mechanical response of centimeter-sized pre-molded agarose cylinders when applying a compressive strain ramp over an extended range of loading speed and polymer concentration. One of the original contributions is the simultaneous monitoring of the changes in the hydrogel volume to determine the Poisson’s ratio through a spatiotemporal method. The linear poroelastic response of agarose hydrogels shows a compressible behavior at strain rates less than 0.7 % s−1. The critical compressive strain of a few percent at the onset of the non-linear regime and the always positive Poisson’s ratio decrease when applying a slow compressive ramp. The mechanical response in the linear regime is typical of a deformation mode either dominated by the bending of semiflexible strands (enthalpic regime) or by the stretching of the network (entropic regime) at higher agarose concentration. Cyclic linear shear deformations superimposed to a compressive strain from 0.5 up to 40% further give evidence of a compression-softening of the network causing the transition to the non-linear regime without dependence upon the network topology and connectivity. Finally, the buckling-induced aging of the network under a weak compression and the poroviscoelasticity of the hydrogel are shown to impact the relaxation of the normal stress and the equilibrium stress.

Similar content being viewed by others

Notes

The equilibrium height ho of the pre-molded gel is slightly less than the height H of the duralumin mold as the sol-gel transition induces a small water release and a volume retraction of the sample as reported by Mao et al. (2016). Here, the hydrogel under tension in the mold at room temperature undergoes a uniform spontaneous shrinkage when demolding the cylinder with an equilibrium contraction ratio χ = (H − ho)/H which increases linearly with the polymer concentration and reaches a plateau value χ = (3.1 ± 0.2) % at agarose mass concentrations c > 1.5 wt%.

Note that the slow compression of the L3 hydrogel in air causes an early exudation of water from the outer free surface (third column in Fig. 5) and an apparent slight increase in the rate of swelling of the cylinder with a consequent overestimation of the Poisson's ratio as determined by the spatiotemporal method.

The deformation of the agarose hydrogel appears as reversible after a fast or a slow 15 % compressive strain ramp and the material nearly recovers the initial shape within half an hour when removing the load. The hydrogel can further be compressed up to a 90% strain without breaking under an extremely low loading speed dh/dt = 0.1μm/s (dε/dt ≈ 7.1 10−4 % s−1) at agarose concentrations from 0.5 wt% up to 12 wt% as previously reported for gellan gels for polymer concentrations 0.81 wt% < c < 2.5 wt% (Nakamura et al. 2001).

For highly diluted agarose and biopolymer hydrogels close to the percolation threshold (ϕg ≈ 0.1% < ϕ < 0.5%), experimental values of the elastic exponent β are quite dispersed in the range from 1.8 up to 4 (Tokita and Hikichi 1987; Clark and Ross-Murphy 1987; Kawabata et al. 1996; Mohammed et al. 1998; Fujii et al. 2000; Gunasekaran and Yoon 2014). Considering agarose fibers as stiff linear rods, the scalar percolation theory from de Gennes (1980) gives a critical exponent β ≈ 1.9 (Djabourov 1991). On the other hand, a vectorial percolation model taking into account the bending of fibers predicts a higher value β ≈ 3.96 of the elastic exponent (Sahimi 1986). However, the dispersion in the experimental values of the scaling exponent in the close vicinity of the gel point also arises both from loose chains (free chains) that gradually vanish upon increasing the agarose concentration and from a greater sensitivity of the hydrogel elasticity to the molecular weight distribution of the polymer.

One strand of length ξ and cross section r2 in a volume of size ξ corresponds to a fiber volume fraction ϕ - ϕg ∝ r2ξ/ξ3 = r2/ξ2 and a mesh size ξ ∝ r (ϕ - ϕg)λ) with a scaling exponent λ = − 1/2. The scaling relation ξ ∝ (ϕ - ϕg)-1/2 describes the concentration dependence of the pore diameter in agarose hydrogels both for the larger and the smaller free spaces at fiber volume fraction ϕ < 3 wt% (Fig. 16in Appendix 5.1).

The typical mesh size of concentrated agarose hydrogels scales as ξ ∝ εc ∝ (ϕ - ϕg)-0.45 with a scaling exponent λ ≈ − 0.45 less than the expected value λ = − 0.5 for a sparse semiflexible network since the radius r of strands is no longer small enough compared to the mean diameter ξ of pores.

The forced permeation time t* ∝ η R2/(E k) of a solvent through a semiflexible hydrogel under compression scales as the square of the cylinder radius R and as the inverse of the elastic modulus E of the soft material where k ∝ ξ2 is the hydraulic permeability of the network and η the viscosity of the solvent (Doi 2009).

A minimum compressive strain ε = 4% is required for an accurate determination of the drained Poisson’s ratio using the spatiotemporal method.

References

Armstrong CG, Lai WM, Mow VC (1984) An analysis of the unconfined compression of articular cartilage. J Biomech Eng 165:106–173. https://doi.org/10.1115/1.3138475

Arnott S, Fulmer A, Scott WE, Dea ICM, Moorhouse R, Rees DA (1974) The agarose double helix and its function in agarose gel structure. J Mol Biol 90(2):273–284. https://doi.org/10.1016/0022-2836(74)90372-6

Ashby MF (2005) The properties of foams and lattices. Phil Trans R Soc A 364:15–30. https://doi.org/10.1098/rsta.2005.1678

Aymard P, Martin DR, Plucknett K, Foster TJ, Norton IT (2001) Influence of thermal history on the structural and mechanical properties of agarose gels. Biopolymers 59(3):131–144. https://doi.org/10.1002/1097-0282(200109)59:3<131::AID-BIP1013>3.0.CO;2-8

Ayyad O, Muñoz-Rojas D, Agulló N, Borrós S, Gómez-Romero P (2010) High-concentration compact agar gels from hydrothermal synthesis. Soft Matter 6(11):2389–2391. https://doi.org/10.1039/b926713a

Baczynski K, Lipowsky R, Kierfeld J (2007) Stretching of buckled filaments by thermal fluctuations. Phys Rev E 76:061914. https://doi.org/10.1103/PhysRevE.76.061914

Bertula K, Martikainen L, Munne P, Hietala S, Klefstrȍm J, Ikkala O, Nonappa (2019) Strain-stiffening of agarose gels. ACS Macro Lett 8(6):670–675. https://doi.org/10.1021/acsmacrolett.9b00258

Biot M (1941) General theory of three dimensional consolidation. J Appl Phys 12(2):155–164. https://doi.org/10.1063/1.1712886

Bouzid M, Del Gado E (2018) Network topology in soft hydrogels: hardening and Softening materials. Langmuir 34(3):773–781. https://doi.org/10.1021/acs.langmuir.7b02944

Broedersz CP, Mao X, Lubensky TC, MacKintosh FC (2011) Criticality and isostaticity in fiber networks. Nat Phys 7(12):983–988. https://doi.org/10.1038/nphys2127

Caccavo D, Cascone S, Poto S, Lamberti G, Barba AA (2017) Mechanics and transport phenomena in agarose-based hydrogels studied by compression-relaxation tests. Carbohydr Polym 176:136–144. https://doi.org/10.1016/j.carbpol.2017.03.027

Cai S, Hu Y, Zhao X, Suo Z (2010) Poroelasticity of a covalently crosslinked alginate hydrogel under compression. J Appl Phys 108:113514. https://doi.org/10.1063/1.3517146

Chan EP, Hu Y, Johnson PM, Suo Z, Stafford CM (2012) Spherical indentation testing of poroelastic relaxations in thin hydrogel layer. Soft Matter 8(5):1492–1498. https://doi.org/10.1039/c1sm06514a

Chaudhuri O, Parekh SH, Fletcher DA (2007) Reversible stress softening of actin networks. Nature 445(7125):295–298. https://doi.org/10.1038/nature05459

Clark AH, Ross-Murphy SB (1987) Structural and mechanical properties of biopolymer gels. In: Biopolymers. Advances in Polymer Science, vol 83. Springer, Berlin Heidelberg, pp 157–192. https://doi.org/10.1007/BFb0023332

Cocks ACF, Ashby MF (2000) Creep-buckling of cellular solids. Acta Mater 48(13):3395–3400. https://doi.org/10.1016/S1359-6454(00)00139-7

Coviello T, Kajiwara K, Burchard W, Dentini M, Crescenzi V (1986) Solution properties of xanthan. 1. Dynamic and static light scattering from native and modified xanthans in dilute solutions. Macromolecules 19(11):2826–2831. https://doi.org/10.1021/ma00165a027

de Gennes PG (1980) Scaling concepts in polymer physics, vol 32. Cornell University Press, Ithaca, p 290. https://doi.org/10.1002/actp.1981.010320517

Delaine-Smith RM, Burney S, Balkwill FR, Knight MM (2016) Experimental validation of a flat punch indentation methodology calibrated against unconfined compression tests for determination of soft tissue biomechanics. J Mech Behav Biomed Mater 60:401–415. https://doi.org/10.1016/j.jmbbm.2016.02.019

Delavoipière J, Tran Y, Verneuil E, Chateauminois A (2016) Poroelastic indentation of mechanically confined hydrogel layers. Soft Matter 12(38):8049–8058. https://doi.org/10.1039/C6SM01448H

Divoux T, Mao B, Snabre P (2015) Syneresis and delayed detachment of agar plates. Soft Matter 11(18):3677–3685. https://doi.org/10.1039/c5sm00433k

Djabourov M (1991) Gelation – A review. Polym Int 25(3):135–143. https://doi.org/10.1002/pi.4990250302

Djabourov M, Clark AH, Rowlands DW, Ross-Murphy SB (1989) Small-angle X-ray scattering characterization of agarose sols and gels. Macromolecules 22(1):180–188. https://doi.org/10.1021/ma00191a035

Djabourov M, Nishinari K, Ross-Murphy S (2013) Helical structures from neutral biopolymers. In: Physical Gels from Biological and Synthetic Polymers. Cambridge University Press, pp 182–221. https://doi.org/10.1017/CBO9781139024136

Doi M (2009) Gel dynamics. J Phys Soc Jpn 78(5):052001. https://doi.org/10.1143/JPSJ.78.052001

Dormoy Y, Candau S (1991) Transient electric birefringence study of highly dilute agarose solutions. Biopolymers 31(1):109–117. https://doi.org/10.1002/bip.360310110

Eldridge JE, Ferry JD (1954) Studies of the cross-linking process in gelatin gels: III. Dependence of melting point on concentration and molecular weight. J Phys Chem 58(11):992–995. https://doi.org/10.1021/j150521a013

Feke GT, Prins W (1974) Spinodal phase separation in a macromolecular sol → gel transition. 7(4):527–530. https://doi.org/10.1021/ma60040a022

Foord SA, Atkins EDT (1989) New X-ray diffraction results from agarose: Extended single helix structures and implications for gelation mechanism. 28(8):1345–1365. https://doi.org/10.1002/bip.360280802

Forte AE, D’Amico F, Charalambides MN, Dini D, Williams JG (2015) Modelling and experimental characterization of the rate dependent fracture of gelatine gels. Food Hydrocoll 46:180–190. https://doi.org/10.1016/j.foodhyd.2014.12.028

Foucard LC, Price JK, Klug WS, Levine AJ (2015) Cooperative buckling and the nonlinear mechanics of nematic semiflexible networks. Nonlinearity 28(9):R89–R112. https://doi.org/10.1088/0951-7715/28/9/R89

Fujii T, Yano T, Kumagai H, Miyawaki O (2000) Scaling analysis on elasticity of agarose gel near the sol-gel transition temperature. Food Hydrocoll 14(4):359–363. https://doi.org/10.1016/S0268-005X(00)00012-6

Gibson LJ (2005) Biomechanics of cellular solids. J Biomech 38(3):377–399. https://doi.org/10.1016/j.jbiomech.2004.09.027

Gibson LJ, Easterling KE, Ashby MF (1981) The structure and mechanics of cork. Proc R Soc Lond A377:99–117. https://doi.org/10.1098/rspa.1981.0117

Greaves GN, Greer AL, Lakes RS, Rouxel T (2011) Poisson’s ratio and modern materials. Nat Mater 10(11):823–837. https://doi.org/10.1038/nmat3134

Gunasekaran S, Yoon WB (2014) Investigation of elastic modulus of xanthan and locust bean gum at different concentrations of mixture using cascade model. J Texture Stud 45(1):80–87. https://doi.org/10.1111/jtxs.12040

Hay JL, Wolff PJ (2001) Small correction required when applying the. Hertzian contact model to instrumented indentation data 16(5):1280–1286. https://doi.org/10.1557/JMR.2001.0179

Hayashi A, Kinoshita A, Kuwano M (1977) Studies of the agarose gelling system by the fluorescence polarization method. I Polym J 9(2):219–225. https://doi.org/10.1295/polymj.9.219

Hu Y, Suo Z (2012) Viscoelasticity and poroelasticity in elastomeric gels. Acta Mechanica Solida Sinica 25(5):441–458. https://doi.org/10.1016/S0894-9166(12)60039-1

Hu Y, Zhao X, Vlassak JJ, Suo Z (2010) Using indentation to characterize the poroelasticity of gels. Appl Phys Lett 96(12):112904. https://doi.org/10.1063/1.3370354

Huisman EM, Lubensky TC (2011) Internal stresses, normal modes, and nonaffinity in three dimensional biopolymer networks. Phys Rev Lett 106:088301. https://doi.org/10.1103/PhysRevLett.106.088301

Ichinose N, Ura H (2020) Concentration dependence of the sol-gel phase behavior of agarose-water system observed by the optical bubble pressure tensiometry. Sci Rep 10:2620. https://doi.org/10.1038/s41598-020-58905-8

Jansen KA, Licup AJ, Sharma A, Rens R, MacKintosh FC, Koenderink GH (2018) The role of network architecture in collagen mechanics. Biophys J 114(11):2665–2678. https://doi.org/10.1016/j.bpj.2018.04.043

Joly-Duhamel C, Hellio D, Ajdari A, Djabourov M (2002) All gelatin networks: 2. The master curve for elasticity. Langmuir 18(19):7158–7166. https://doi.org/10.1021/la020190m

Jones JL, Marques CM (1990) Rigid polymer network models. J Phys France 51(11):1113–1127. https://doi.org/10.1051/jphys:0199000510110111300

Kaneda I (2018) Effects of sweeteners on the solvent transport behaviour of mechanically-constrained agarose gels. Gels 4(23):1–9. https://doi.org/10.3390/gels4010023

Kaneda I, Iwasaki S (2015) Solvent transportation behavior of mechanically constrained agarose gels. Rheol Acta 54(5):437–443. https://doi.org/10.1007/s00397-015-0842-2

Kawabata A, Akuzawa S, Ishii Y, Yazaki T, Otsubo Y (1996) Sol-gel transition and elasticity of starch. Biosci Biotechnol Biochem 60(4):567–570. https://doi.org/10.1271/bbb.60.567

Kim OV, Litvinov RI, Weisel JW, Alber MS (2014) Structural basis for the non linear mechanics of fibrin networks under compression. Biomaterials 35(25):6739–6749. https://doi.org/10.1016/j.biomaterials.2014.04.056

Kirkpatrick FH, Dumais MM, White HW, Guiseley KB (1993) Influence of the agarose matrix in pulsed-field electrophoresis. Electrophoresis 14(1):349–354. https://doi.org/10.1002/elps.1150140159

Kunitz M (1928) Syneresis and swelling of gelatin. The Journal of General Physiology 12(2):289–312. https://doi.org/10.1085/jgp.12.2.289

Lang NR, Műnster S, Metzner C, Krauss P, Schűrmann S, Lange J, Aifantis KE, Friedrich O, Fabry B (2013) Estimating the 3D pore size distribution of biopolymer networks from directionally biased date. Biophys J 105(9):1967–1975. https://doi.org/10.1016/j.bpj.2013.09.038

Laurent TC (1967) Determination of the structure of agarose gels by gel permeation chromatography. Biochim Biophys Acta 136(2):199–205. https://doi.org/10.1016/0304-4165(67)90064-5

Maaloum M, Pernodet N, Tinland B (1998) Agarose gel structure using atomic force microscopy: Gel concentration and ionic strength effects. Electrophoresis 19(10):1606–1610. https://doi.org/10.1002/elps.1150191015

Manno M, Palma MU (1997) Fractal morphogenesis and interacting processes in gelation. PRL 79(21):4286–4288. https://doi.org/10.1103/PhysRevLett.79.4286

Mao B, Divoux T, Snabre P (2016) Normal force controlled rheology applied to agar gelation. J Rheol 60(3):473–489. https://doi.org/10.1122/1.4944994

Mao B, Divoux T, Snabre P (2017a) Impact of saccharides on the drying kinetics of agarose gels measured by in-situ interferometry. Sci Rep 7:41185. https://doi.org/10.1038/srep41185

Mao B, Bentaleb A, Louerat F, Divoux T, Snabre P (2017b) Heat-induced aging of agar solutions: Impact on the structural and mechanical properties of agar gels. Food Hydrocoll 64:59–69. https://doi.org/10.1016/j.foodhyd.2016.10.020

Mao B, Bouchaudy A, Salmon JB, Divoux T, Snabre P (2017c) Time-resoved rheological monitoring of viscoelastic materials under drying. AERC 2017. 11th Annual European Rheology Conference, Copenhagen, Denmark. Abstract number GS19. https://nordicrheologysociety.org/content/aerc/2017/images/AERC2017-AbstractBook-20170322.pdf. Accessed 24 november 2020

Matsuhashi T (1990) Agar. In: Harris P (ed) Food gels. Elsevier Applied Science, New York, pp 1–51

Meunier V, Nicolai T, Durand D (2000) Structure and kinetics of aggregating κ-carrageenan studied by light scattering. Macromolecules 33(7):2497–2504. https://doi.org/10.1021/ma991433t

Mezzenga R, Schurtenberger P, Burbidge A, Michel M (2005) Understanding foods as soft materials. Nat Mater 4:729–740. https://doi.org/10.1038/nmat1496

Mitsuiki M, Mizuno A, Motoki M (1999) Determination of molecular weight of agars and effect of the molecular weight on the glass transition. J Agric Food Chem 47(2):473–478. https://doi.org/10.1021/jf980713p

Mohammed ZH, Hember MWN, Richardson RK, Morris ER (1998) Kinetic and equilibrium processes in the formation and melting of agarose gels. Carbohydr Polym 36(1):15–26. https://doi.org/10.1016/S0144-8617(98)00011-3

Molginer A, Rubinstein B (2005) The physics of filipodial protrusion. Biophys J 89(2):782–795. https://doi.org/10.1529/biophysj.104.056515

Morita T, Narita T, Mukai S, Yanagisawa M, Tokita M (2013) Phase behaviors of agarose gel. AIP Advances 3(4):042128:1-12. https://doi.org/10.1063/1.4802968

Nakamura K, Shinoda E, Tokita M (2001) The influence of compression velocity on strength and structure for gellan gels. Food Hydrocoll 15(3):247–252. https://doi.org/10.1016/S0268-005X(01)00021-2

Nitta T, Endo Y, Haga H, Kawabata K (2003) Microdomain structure of agar gels observed by mechanical-scanning probe microscopy. J Electron Microsc 52(3):277–281. https://doi.org/10.1093/jmicro/52.3.277

Normand V, Lootens DL, Amici E, Plucknett KP, Aymard P (2000) New insight into agarose gel mechanical properties. Biomacromolecules 1(4):730–738. https://doi.org/10.1021/bm005583j

Normand V, Aymard P, Lootens DL, Amici E, Plucknett KP, Frith WJ (2003) Effect of sucrose on agarose gels mechanical behaviour. Carbohydr Polym 54(1):83–95. https://doi.org/10.1016/S0144-8617(03)00153-X

Ogston AG (1958) The spaces in a uniform random suspension of fibres. Trans Faraday Soc 54:1754–1757. https://doi.org/10.1039/TF9585401754

Ouellet S, Cronin D, Worswick M (2006) Compressive response of polymeric foams under quasi-static, medium and high strain rate conditions. Polym Test 25(6):731–743. https://doi.org/10.1016/j.polymertesting.2006.05.005

Pernodet N, Maaloum M, Tinland B (1997) Pore size of agarose gels by atomic force microscopy. Electrophoresis 18(1):55–58. https://doi.org/10.1002/elps.1150180111

Ramzi M, Rochas C, Guenet JM (1998) Structure-properties relation for agarose thermoreversible gels in binary solvents. Macromolecules 31(18):6106–6111. https://doi.org/10.1021/ma9801220

Righetti G, Brost BCW, Snyder RS (1981) On the limiting pore size of hydrophilic gels for electrophoresis and isoelectric focussing. J BiochemBiophys Methods 4(5-6):347–363. https://doi.org/10.1016/0165-022x(81)90075-0

Rinaudo M (2008) Main properties and current applications of some polysaccharides as biomaterials. Polym Int 57(3):397–430. https://doi.org/10.1002/pi.2378

Rochas C, Brûlet A, Guenet JM (1994) Thermally reversible gelation of agarose in water/dimethyl sulfoxide mixtures. Macromolecules 27(14):3830–3835. https://doi.org/10.1021/ma00092a023

Rochas C, Hecht AM, Geissler E (1996) Swelling properties of agarose gels. J Chim Phys 93:850–857. https://doi.org/10.1051/jcp/1996930850

Sahimi M (1986) Relation between the critical exponent of elastic percolation networks and the conductivity and geometrical exponents. J Phys C Solid State Phys 19(4):L79–L83. https://doi.org/10.1088/0022-3719/19/4/004

San Biagio PL, Madonia F, Sciortino F, Palma-Vitorelli MB, Palma MU (1984) Cooperative interaction of polysaccharide molecules in water: A role of connectivity properties of H-Bonds within the solvent? J Phys 45(C7):225–233. https://doi.org/10.1051/jphyscol:1984725

San biagio PL, Bulone D, Emanuele A, Palma-Vitorelli MB, Palma MU (1996) Spontaneous symmetry-breaking pathways: time-resolved study of agarose gelation. Food Hydrocoll 10(1):91–97. https://doi.org/10.1016/S0268-005X(96)80059-2

Schafer SE, Stevens ES (1995) A reexamination of the double-helix model for agarose gels using optical rotation. Biopolymers 36(1):103–108. https://doi.org/10.1002/bip.360360109

Schneider CA, Rasband WS, Eliceiri KW (2012) NIH Image to ImageJ: 25 years of image analysis. Nat Methods 9:671–675. https://doi.org/10.1038/nmeth.2089

Stanley NF (2006) Agars. In: Stephen AM, Philips GO (eds) Food polysaccharides and their Applications, 2nd edn. CRC Press, Boca Raton, pp 217–238

Strange DGT, Fletcher TL, Tonsomboon K, Brawn H, Zhao X, Oyen ML (2013) Separating poroviscoelastic deformation mechanisms in hydrogels. Appl Phys Lett 102:03913. https://doi.org/10.1063/1.4789368

Tokita M, Hikichi K (1987) Mechanical studies of sol-gel transition: Universal behaviour of elastic modulus. Phys Rev A 35(10):4329–4333. https://doi.org/10.1103/physreva.35.4329

van Oosten ASG, Vahabi M, Licup AJ, Sharma A, Galie PA, MacKintosh FC, Janmey PA (2016) Uncoupling shear and uniaxial elastic moduli of semiflexible biopolymer networks: compression-softening and stretch-stiffening. Sci Rep 6:19270. https://doi.org/10.1038/srep19270

von Terzaghi K (1925) Erdbaumechanik auf bodenphysikalischer Grundlage. Leipzig and Vienna, Franz Deuticke, 399 pages

Waki S, Harvey JD, Bellamy AR (1982) Study of agarose gels by electron microscopy of freeze-fractured surfaces. Biopolymers 21(9):1909–1926. https://doi.org/10.1002/bip.360210917

Watase M, Nishinari K (1983) Rheological properties of agarose gels with different molecular weights. Rheol Acta 22(6):580–587. https://doi.org/10.1007/BF01351404

Wen Q, Basu A, Janmey PA, Yodh AG (2012) Non-affine deformations in polymer hydrogels. Soft Matter 8(31):8039–8049. https://doi.org/10.1039/c2sm25364j

Xiong JY, Narayanan J, Liu XY, Chong TK, Chen SB, Chung TS (2005) Topology evolution and gelation mechanism of agarose gel. J Phys Chem B 109(12):5638–5643. https://doi.org/10.1021/jp044473u

Yamaue T, Doi M (2004) Swelling dynamics of constrained thin-plate gels under an external force. Phys Rev E Stat Nonlinear Soft Matter Phys 70(1 Pt 1):011401. https://doi.org/10.1103/PhysRevE.70.011401

Yamaue T, Doi M (2005) The stress diffusion coupling in the swelling dynamics of cylindrical gels. J Chem Phys 122:084703. https://doi.org/10.1063/1.1849153

Zhang Y, Fu X, Duan D, Xu J, Gao X (2019) Preparation and characterization of agar, agarose, and agaropectin from the red alga Ahnfeltia plicata. J Ocean Limnol 37(3):815–824. https://doi.org/10.1007/s00343-019-8129-6

Acknowledgements

The authors gratefully acknowledge M Benelmostafa for stimulating discussions, D Dahmani for supplying the Setexam agarose, the expertise center PLACAMAT in Talence (France) for the Cryo-SEM observations and B Mao (BioMérieux Craponne) for the molecular weight characterization of agarose samples by size exclusion chromatography.

Funding

This work was supported by annual funding from the CNRS (Centre National de la Recherche Scientifique) in France and the University Mohammed Premier in Oujda (Morocco).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Mean pore diameter of agarose hydrogels

Cryo-SEM micrographs of agarose hydrogels show random fibrillar networks with a typical mean pore diameter d decreasing with the mass concentration of the polymer from a micrometer size at c ≈ 0.3 wt% down to a few hundreds of nanometers at c ≈ 3 wt% (Fig. 2). The pore size distribution is broad with a factor of about 10 between the mean smaller diameter dmin and the mean larger diameter dmax of pores in the network (full black and red circles in Fig. 16). Mechanical-scanning probe microscopy indeed gives evidence of the inhomogeneous microstructure of agarose hydrogels at low concentrations 0.5 wt % < c < 2 wt% with a log-normal distribution of the local shear modulus, while a simple Gaussian distribution describes the histogram of local elastic moduli values in thermal gels made of flexible chains such as polyacrylamide (Nitta et al. 2003). As expected for a fibrillar semiflexible network with a mesh size larger than the strand diameter, the mean pore diameter of agarose hydrogels scales as (c − cg)λ with λ ≈ − 0.5 at 0.3 wt% < c < 3 wt% whatever one considers either the larger or the smaller free spaces (Fig. 16). Note that the scaling exponent λ ≈ − 0.5 takes slightly more negative values when considering the mass concentration in place of the deviation concentration c − cg from the percolation threshold (Maaloum et al. 1998; Righetti et al. 1981). Atomic force microscopic observations from Maaloum et al. (1998) or studies of the electrophoretic mobility of latex particles in agarose hydrogels from Righetti et al. (1981) indeed lead to a similar scaling exponent λ ≈ − 0.5 provided that the mean pore diameter is plotted versus the deviation concentration c − cg from the percolation point (Fig. 16). The length scale explored in sparsely connected networks is further very sensitive to the choice of the investigation method due to the broad pore size distribution of biopolymer hydrogels.

Logarithmic plot of the mean pore diameter d versus the agarose mass concentration c - cg with a gelation threshold cg = 0.1 wt%. Full black circles and red circles refer to the mean smaller diameter dmin and the mean larger diameter dmax of pores extracted from Cryo-SEM micrographs of Setexam hydrogels at polymer mass concentrations c ≈ 0.3 wt% (L0.3), c ≈ 0.99 wt% (L1) and c ≈ 2.9 wt% (L3). Full green squares and full blue squares, respectively, stand for the experimental data of Maaloum et al. (1998) and Righetti et al. (1981). Full color lines are the best power law fits of (d, c − cg) data and the dotted black line highlights the common slope of the power law fits with an indication of the value of the scaling exponent λ ≈ − 0.5

Compression–tension of agarose hydrogels

The reversibility of the hydrogel response is studied by applying a compression–tension cycle at a speed dh/dt = 100 µm/s with a maximum compressive strain εm of either 2% (black curves in Fig. 17) or 10% (red curves in Fig. 17). The stress–strain response appears as nearly reversible in the linear regime for a maximum compressive εm ≈ 2% less than the critical strain εc as water exudation remains negligible during a fast compression–tension cycle (black curves in Fig. 17). A more detailed examination of σ(ε) curves nevertheless shows a weak hysteresis and a slope (dσ/dε)(ε = εm) less important at the end of the compressive ramp compared to the beginning of the tension ramp, especially at low agarose concentration (L1 sample in Fig. 17a). The asymmetry observed in the response of agarose hydrogels to a compression–tension cycle in the linear regime likely results from the deformation mode of strands since it is easier to bend a fiber during compression than to stretch the fiber during extension.

Normal stress σ versus the compressive strain ε of L1 (a), L3 (b), and L9 (c) hydrogels when applying a compression–tension cycle at a loading speed dh/dt = 100 µm/s with a maximum amplitude εm ≈ 2% (black curves) or εm ≈ 10% of the strain ramp (red curves). Dashed vertical full lines show the critical compressive strain εc delimiting the transition to the non-linear regime. Setexam agarose hydrogels with polymer mass concentration c ≈ 0.99 wt% (L1), c ≈ 2.9 wt% (L3), and c ≈ 8.3 wt% (L9)

As expected, the hysteresis becomes more significant in the non-linear regime for a maximum compressive strain εm ≈10 % > εc (full red lines in Fig. 17) as the unbuckling of strands and the breaking of some weak bonds require longer timescales during the extension phase. The degree of hysteresis increases somewhat with the polymer concentration (Fig. 17), and the gel cylinder almost recovers the initial height ho ≈14 mm after a time period from a few minutes to a few hours when removing the load which confirms the dominant elastic behavior of agarose hydrogels. The compression-softening of the fibrillar network thus appears as nearly reversible even for very large compressive strain at very low loading speed as long as the hydrogel remains intact without any stress-induced microfractures. A second compression–tension cycle is necessary to observe a fully reversible deformation of the agarose hydrogel (data not shown) likely as a result of the formation of some extra irreversible bonds between buckled strands during the first compression ramp (paper in preparation).

Agarose molecular weight and elasticity of agarose hydrogels

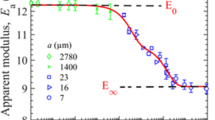

Compression experiments were performed using the Brookfield texture analyzer and agarose hydrogels prepared at different concentrations 0.5 wt% ≤ c ≤ 9 wt% with two different powders supplied either by Setexam or Sigma (Section 2.1). The stress–strain curves of Sigma and Setexam agarose hydrogels considered as incompressible when applying a fast 15% strain ramp at a loading speed dh/dt = 100 µm/s exhibit similar features (Figs. 10a and 18a). As expected, the agarose average molecular weight weakly influences the scaling exponents β ≈ 2.15 ± 0.05 or β ≈ 1.36 ‐ 1.41 representative of either the enthalpic or the entropic elasticity (Fig. 18b). However, Fig. 18b gives evidence of higher values of the Young modulus Eo of Sigma agarose hydrogels (Mw ≈ 3.05 105 g/mol) compared to that of Setexam agarose hydrogels (Mw ≈ 1.88 105 g/mol) regardless of the agarose concentration. The power law fits of the fiber volume fraction dependence of the Young modulus Eo(ϕ - ϕg) of Sigma and agarose hydrogels in the enthalpic and entropic elastic regimes, respectively, give \( {E}_o\approx {M}_w^{0.8} \). The Young modulus of biopolymer fibrillar networks is usually reported to scale as \( {E}_o\approx {M}_w^2 \) for lower average molecular weight 3 104 g/mol < Mw < 7 104 g/mol (Eldridge and Ferry 1954). The dependence on Mw of the elastic modulus of agarose hydrogels is expected to be lower for higher average molecular weight and higher polymer concentrations as the number of dangling ends not involved in the elasticity of the network becomes less (Normand et al. 2000).

(a) Normal stress σ versus the compressive strain ε for Hα hydrogels in water when applying a 15% strain ramp at a loading speed dh/dt = 100 µm/s in the Brookfield texture analyzer. The insert is a zoom in the low-strain region where dotted lines are best linear fits of σ(ε) data in the limit of low compressive strain ε < εc and dashed vertical lines show the critical compressive strain εc. (b) Semilogarithmic plot of the Young modulus Eo of the hydrogel assumed as incompressible versus the fiber volume fraction ϕ - ϕg with ϕg = 0.1% either for Sigma (square symbols) or Setexam (circle symbols) agarose cylinders rapidly compressed in air (open symbols) or in water (full blue symbols). Full black and grey lines are the best power law fits of (Eo, ϕ - ϕg) data for Sigma and Setexam agarose hydrogels, respectively, in the concentration regimes 0.4 % ≤ ϕ - ϕg ≤ 2.8 % and 3.75 % ≤ ϕ - ϕg ≤ 8.2%. Dotted black lines and dotted grey lines highlight the respective slopes of power law fits with an indication of the value of the elastic exponent β either in the enthalpic or in the entropic elastic regime

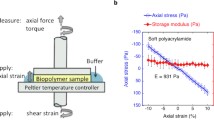

Viscoelasticity of agarose hydrogels

The shear stress relaxation response of quasi-equilibrium agarose hydrogels was monitored in the linear regime when applying a low compressive strain ε ≈ 2% (Section 2.4). The characteristic viscoelastic time t2 at short timescale decreases from 2 min down to 16 seconds when increasing the agarose concentration 0.5 wt% < c < 7 wt% as the hydrogel becomes stiffer (Fig. 19). The retarded elastic response (G2 + G3)/G0 of about 10% to 15% for agarose concentration c > 1 wt% surprisingly takes on a much larger value (G2 + G3)/G0 ≈ 48% for a diluted 0.5 wt% agarose hydrogel (L0.5 sample in Fig. 19 and Table 4). Such a sharp increase in the apparent viscoelasticity of a diluted agarose hydrogel probably results from the buckling-induced aging of the sparsely connected network on long timescale and the gradual emergence of non-linear effects.

Time relaxation of the dimensionless shear stress modulus G(t)/Go of quasi-equilibrium hydrogels L0.5 (grey color), L1 (green color), L3 (blue color), and L7 (brown color) weakly compressed in water when superimposing a shear strain in the linear regime. Before the stress relaxation test, a fast 4% compressive strain ramp is imposed at a loading speed dh/dt = 100 µm/s and the static strain ε = 4% is hold for 15min. Dotted red curves correspond to a second-order generalized Maxwell model (Eq. (1)) fitted to data with the parameter values shown in Table 4. Setexam agarose hydrogels with a polymer mass concentration c ≈ 0.5 wt% (L0.5), c ≈ 0.99 wt% (L1), c ≈ 2.9 wt% (L3), and c ≈ 6.5 wt% (L7)

Rights and permissions

About this article

Cite this article

Ed-Daoui, A., Snabre, P. Poroviscoelasticity and compression-softening of agarose hydrogels. Rheol Acta 60, 327–351 (2021). https://doi.org/10.1007/s00397-021-01267-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00397-021-01267-3