Abstract

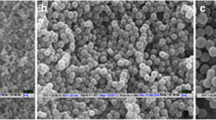

Shear thickening fluids (STFs) are smart materials that change from liquid to solid reversibly when undergoing critical stresses. These materials are good alternatives to improve applications where energy dissipation is important, for example, in the fabrication of liquid body armor and shock absorbing protective gear. However, as much as it is known about the effect of several variables on their properties, such as particle concentration and medium viscosity, the stability of these colloidal dispersions over time and over shearing is not yet well understood. The development and design of new applications depend on predicting for how long the material will keep its properties. In this project, we studied the influence of fumed silica content, ultrasonication energy used during dispersion of the silica particles, and humidity during storage to analyze the changes in properties of STFs. The influence of shearing magnitude on their properties was also studied. STFs with higher amounts of silica and produced using less dispersion energy showed the highest viscosity peak on initial tests, but they were also the least stable over time, due to flocculation of the particles. In stable samples, water absorption led to a large loss of maximum viscosity. The presence of humidity on samples diminished the overall viscosity, but did not prevent the sample from becoming a gel if the parameters used resulted in an unstable STF. Shearing the STF reduced its maximum viscosity, being more evident in samples with higher viscosity.

Graphical abstract

Similar content being viewed by others

References

Barnes HA (1989) Shear-thickening (“Dilatancy”) in suspensions of nonaggregating solid particles dispersed in Newtonian liquids. J Rheol (N Y N Y) 33:329–366. https://doi.org/10.1122/1.550017

Barthel H, Rösch L, Weis J (2008) Fumed silica - production, properties, and applications. Organosilicon Chem I Mol Mater:761–778. https://doi.org/10.1002/9783527620777.ch91a

Bertrand E, Bibette J, Schmitt V (2002) From shear thickening to shear-induced jamming. Phys Rev E Stat Nonlin Soft Matter Phys 66:060401. https://doi.org/10.1103/PhysRevE.66.060401

Birkin PR, Offin DG, Joseph PF, Leighton TG (2005) Cavitation, shock waves and the invasive nature of sonoelectrochemistry. J Phys Chem B 109:16997–17005. https://doi.org/10.1021/jp051619w

Blees MH (2002) Foundations of colloid science. Colloids Surf A Physicochem Eng Asp 210:125. https://doi.org/10.1016/s0927-7757(02)00170-x

Bossis G (1985) The rheology of concentrated suspensions of spheres in simple shear flow by numerical simulation. J Fluid Mech 155:105. https://doi.org/10.1017/S0022112085001732

Brown E, Forman NA, Orellana CS, Zhang H, Maynor BW, Betts DE, DeSimone JM, Jaeger HM (2010) Generality of shear thickening in dense suspensions. Nat Mater 9:220–224. https://doi.org/10.1038/nmat2627

Brown E, Jaeger HM (2012) The role of dilation and confining stresses in shear thickening of dense suspensions. J Rheol 56:875–923. https://doi.org/10.1122/1.4709423

Cao S, He Q, Pang H, Chen K, Jiang W, Gong X (2018) Stress relaxation in the transition from shear thinning to shear jamming in shear thickening fluid. Smart Mater Struct 27:085013. https://doi.org/10.1088/1361-665X/aacbf8

Chatterjee VA, Dey P, Verma SK, Bhattacharjee D, Biswas I, Neogi S (2019) Probing the intensity of dilatancy of high performance shear-thickening fluids comprising silica in polyethylene glycol. Mater Res Express 6. https://doi.org/10.1088/2053-1591/ab1185

Egres RG, Halbach CJ, Decker MJ, et al (2005) Stab performance of shear thickening fluid (STF)-fabric composites for body armor applications. In: International SAMPE Symposium and Exhibition (Proceedings)

Feng X, Li S, Wang Y, Wang Y, Liu J (2014) Effects of different silica particles on quasi-static stab resistant properties of fabrics impregnated with shear thickening fluids. Mater Des 64:456–461. https://doi.org/10.1016/j.matdes.2014.06.060

Freundlich H, Jones AD (1936) Sedimentation volume, dilatancy, thixotropic and plastic properties of concentrated suspensions. J Phys Chem 40:1217–1236. https://doi.org/10.1021/j150378a012

Gedanken A (2003) Sonochemistry and its application to nanochemistry. Curr Sci 85:1720

Gürgen S, Kuşhan MC (2017) The stab resistance of fabrics impregnated with shear thickening fluids including various particle size of additives. Compos Part A Appl Sci Manuf 94:50–60. https://doi.org/10.1016/j.compositesa.2016.12.019

Gürgen S, Li W, Kuşhan MC (2016) The rheology of shear thickening fluids with various ceramic particle additives. Mater Des 104:312–319. https://doi.org/10.1016/j.matdes.2016.05.055

Hoffman RL (1974) Discontinuous and dilatant viscosity behavior in concentrated suspensions. II Theory and experimental tests. J Colloid Interface Sci 46:491–506. https://doi.org/10.1016/0021-9797(74)90059-9

Hoffman RL (1972) Discontinuous and dilatant viscosity behavior in concentrated suspensions. J Rheol 114:10514–10527. https://doi.org/10.1063/1.1373687

Hoffman RL (1982) Discontinuous and dilatant viscosity behavior in concentrated suspensions III. Necessary conditions for their occurrence in viscometric flows. Adv Colloid Interface Sci 17:161–184. https://doi.org/10.1016/0001-8686(82)80017-1

Hoffman RL (1998) Explanations for the cause of shear thickening in concentrated colloidal suspensions. J Rheol 42:111–123. https://doi.org/10.1122/1.550884

Hunter RJ (2001) Foundations of colloid science (2nd edition)

Khalili F, De Paoli F, Guldiken R (2015) Impact resistance of liquid body armor utilizing shear thickening fluids: a computational study. In: ASME International Mechanical Engineering Congress and Exposition, Proceedings (IMECE)

Laskowski J, Kitchener JA (1969) The hydrophilic-hydrophobic transition on silica. J Colloid Interface Sci 29:670–679. https://doi.org/10.1016/0021-9797(69)90219-7

Lee YS, Wetzel ED, Wagner NJ (2003) The ballistic impact characteristics of Kevlar® woven fabrics impregnated with a colloidal shear thickening fluid. J Mater Sci 38:2825–2833. https://doi.org/10.1023/A:1024424200221

Liu XQ, Bao RY, Wu XJ, Yang W, Xie BH, Yang MB (2015) Temperature induced gelation transition of a fumed silica/PEG shear thickening fluid. RSC Adv 5:18367–18374. https://doi.org/10.1039/c4ra16261g

Maranzano BJ, Wagner NJ (2001) The effects of particle size on reversible shear thickening of concentrated colloidal dispersions. J Chem Phys 114:10514–10527. https://doi.org/10.1063/1.1373687

Metzner AB, Whitlock M (1958) Flow behavior of concentrated (dilatant) suspensions. Trans Soc Rheol 2:239–254. https://doi.org/10.1122/1.548831

Mewis J, Wagner NJ (2012) Colloidal suspension rheology. Cambridge University Press, Cambridge

Negi AS, Osuji CO (2009) New insights on fumed colloidal rheology - shear thickening and vorticity-aligned structures in flocculating dispersions. In: Rheologica Acta

Ohsawa S, Kawamura T, Takamatsu N, Yusa Y (2002) Rayleigh scattering by aqueous colloidal silica as a cause for the blue color of hydrothermal water. J Volcanol Geotherm Res 113:49–60. https://doi.org/10.1016/S0377-0273(01)00250-5

Raghavan SR, Khan SA (1997) Shear-thickening response of fumed silica suspensions under steady and oscillatory shear. J Colloid Interface Sci 185:57–67. https://doi.org/10.1006/jcis.1996.4581

Raghavan SR, Walls HJ, Khan SA (2000) Rheology of silica dispersions in organic liquids: new evidence for solvation forces dictated by hydrogen bonding. Langmuir. 16:7920–7930. https://doi.org/10.1021/la991548q

Reynolds O (1885) LVII. On the dilatancy of media composed of rigid particles in contact. With experimental illustrations. London, Edinburgh, Dublin Philos Mag J Sci 20:469. https://doi.org/10.1080/14786448508627791

Singh M, Verma SK, Biswas I, Mehta R (2019) Rheology of fumed silica and polyethylene glycol shear thickening suspension with nano-clay as an additive. J Polym Eng 39:48–57. https://doi.org/10.1515/polyeng-2018-0054

Song Z, Zhang C, Song M, Wu S (2011) Advanced stab resistance fabrics utilizing shear thickening fluids. In: Advanced Materials Research

Soutrenon M, Michaud V, Manson JAE (2013) Influence of processing and storage on the shear thickening properties of highly concentrated monodisperse silica particles in polyethylene glycol. Appl Rheol 23. https://doi.org/10.3933/ApplRheol-23-54865

Taurozzi JS, Hackley VA, Wiesner MR (2011) Ultrasonic dispersion of nanoparticles for environmental, health and safety assessment issues and recommendations. Nanotoxicology. 5:711–729. https://doi.org/10.3109/17435390.2010.528846

Warren J, Offenberger S, Toghiani H, Pittman CU Jr, Lacy TE, Kundu S (2015) Effect of temperature on the shear-thickening behavior of Fumed silica suspensions. ACS Appl Mater Interfaces 7:18650–18661. https://doi.org/10.1021/acsami.5b05094

Lee YS, Wetzel ED, Egres RG Jr, Wagner NJ (2013) Advanced body armor utilizing shear thickening fluids. J Chem Inf Model. https://doi.org/10.1017/CBO9781107415324.004

Acknowledgments

The authors acknowledge the Multiuser Central Facilities (CEM) at UFABC for the use of SEM and DLS and CAPES for financial support.

Funding

This work was supported by Coordenação de Aperfeiçoamento de Pessoal de Nível Superior–Brasil (CAPES)–Finance Code 001, for the master’s scholarship of D. A. H.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Heinze, D.A., Carastan, D.J. The influence of fumed silica content, dispersion energy, and humidity on the stability of shear thickening fluids. Rheol Acta 59, 455–468 (2020). https://doi.org/10.1007/s00397-020-01216-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00397-020-01216-6