Abstract

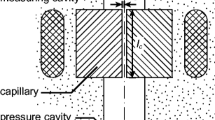

The pressure coefficient of viscosity of poly(α-methylstyrene-co-acrylonitrile) was measured using a high-pressure sliding plate rheometer (HPSPR) and two types of capillary rheometer: a piston-driven device with a throttle at the exit [piston capillary rheometer with throttle (PCRWT)] operated at a fixed flow rate, and a counter-pressure nitrogen capillary rheometer (CPNCR) operated at a fixed pressure drop. In the HPSPR, the pressure, shear rate, density, and viscosity are all uniform throughout the sample, while the analysis of capillary data is complicated by the axial pressure gradient and the radial shear rate gradient. The polymer was found to be piezorheologically simple, and the HPSPR data indicated that the pressure coefficient of viscosity β ≡ dln(a P)/dP decreased slightly with increasing pressure at high pressure. While β from PCRWT data from different laboratories and instruments agreed fairly well, the β values were on average about 2/3 of that from the HPSPR. The CPNCR yields β about 18% lower than that of the HPSPR.

Similar content being viewed by others

References

Altstädt V, Freitas LDL, Schubert WD (2004) Rheological and mechanical properties of poly(α-methylstyrene-co-acrylonitrile)/poly(methylacrylate-co-methyl methacrylate) blends in miscible and phase-separated regimes of various morphologies. Part IV. Influence of the morphology on the mechanical properties. Pure Appl Chem 76:389–413

Bagley EB (1957) End corrections in the capillary flow of polyethylene. J App Phys 28:624–627

Barus C (1883) Isothermals, isopiestics and isometrics relative to viscosity. Am J Sci 45:87–96

Brydson JA (1999) Plastic materials, 7th edn. Butterworth Heinemann, Oxford

Cardinaels R, Van Puyvelde P, Moldenaers P (2007) Evaluation and comparison of routes to obtain pressure coefficients from high-pressure capillary rheometry data. Rheol Acta 46:495–505

Chakravorty S, Rides M, Allen CRG, Brown CS (1996) Polymer melt viscosity increases under pressure: simple new measurement method. Plast Rubber Compos Process Appl 25:260–261

Couch MA, Binding DM (2000) High pressure capillary rheometry of polymeric fluids. Polymer 41:6323–6334

Cross MM (1968) Analysis of flow data on polymer systems under steady or oscillatory shear. In: Wetton RE, Whorlow RW (ed) Polymer systems, deformation and flow: Proc of the 1966 Ann Conf Brit Soc Rheol. Macmillan, London, pp 263–273

Dealy JM (2008) Misuse of the term pressure in rheology. Rheol Bull 77:10–13, 26–27

Denn MM (1981) Pressure drop-flow rate equation for adiabatic capillary flow with a pressure- and temperature dependent viscosity. Polym Eng Sci 21:65–68

Ferry JD (1950) Mechanical properties of substances of high molecular weight. Vi. Dispersion in concentrated polymer solutions and its dependence on temperature and concentration. J Am Chem Soc 72:3746–3752

Ferry JD (1980) Viscoelastic properties of polymers, 3rd edn. Wiley, New York

Ferry JD, Stratton RA (1960) The free volume interpretation of the dependence of viscosities and viscoelastic relaxation times on concentration, pressure and tensile strength. Kolloid-Z 171:107–111

Glasstone S, Laidler KJ, Eyring H (1941) The theory of rate processes. McGraw-Hill, New York

Gleissle W (1994a) Influence of the measuring apparatus and method on the value of the melt index. Appl Rheol 94:13–22

Gleissle W (1994b) Influence of the viscoelastic functions on the melt index. Appl Rheol 94:138–147

Goh SH, Lee SY, Siow KS, Pua CL (1987) Miscibility of poly(styrene-co-acrylonitrile) and poly(α-methyl styrene-co-acrylonitrile) with polymethacrylates containing sterically hindered amine groups. J Appl Poly Sci 33:353–360

Goubert A, Vermant J, Moldenaers P, Göttfert A, Ernst B (2001) Comparison of measurement techniques for evaluating the pressure dependence of the viscosity. Appl Rheol 11:26–37

Günther-Schade K, Schubert DW, Faupel F (2002) Determination of the binodal and spinodal phase separation temperatures in the blend system PαMS0.5-co-AN0.5 (Luran)/PMMA0.95MA0.05 (Lucryl) with positron annihilation lifetime spectroscopy. Macromol 35:9074–9078

Havermeyer F, Schubert DW (2002) Consistent analysis of cloud points and spinodal-compatibility of P(αMS-CO-AN) and P(MA-CO-MMA). Mater Res Innov 6:185–188

Hay G, Mackay ME, Awati KM, Park Y (1999) Pressure and temperature effects in slit rheometry. J Rheol 43:1099–1116

Kadijk SE, Van Den Brule BHAA (1994) On the pressure dependency of the viscosity of molten polymers. Pol Eng Sci 34:1535–1546

Karl V-H (1979) Pressure dependence of viscoelastic and physicochemical properties of polymers. 8. Viscosity of polyethylene up to 5000 bar. Angew Makromol Chem 79:11–19

Koran F, Dealy JM (1999) A high pressure sliding plate rheometer for polymer melts. J Rheol 43:1279–1290

Laun HM (1986) Prediction of elastic strains of polymer melts in shear and elongation. J Rheol 30:459–501

Laun HM (1998) Rheological and mechanical properties of poly(α-methylstyrene-co-acrylonitrile)/poly(methylmethacrylate) blends in miscible and phase separated regimes of various morphologies. Part 1. Characterization of constituents, blend preparation, and overview on blend morphology. Pure Appl Chem 70:1547–1566

Laun HM (2003) Pressure dependent viscosity and dissipative heating in capillary rheometry of polymer melts. Rheol Acta 42:295–308

Laun HM (2004) Capillary rheometry for polymer melts revisited. Rheol Acta 43:509–528

Laun HM, Lyngaae-Jörgensen J, Altstädt V, Schytt V (1997) Rheological and mechanical properties of PαMSAN/PMMA blends in miscible and phase separated regimes of various morphologies. Part 2. Limits of miscibility in the quiescent state and during flow. Polym Netw Blends 7:77–86

Park HE, Dealy JM (2006) Effects of pressure and supercritical fluids on the viscosity of polyethylene. Macromol 39:5438–5452

Park HE, Dealy J, Münstedt H (2006) Influence of long-chain branching on the time-pressure and time-temperature shift factors for polystyrene and polyethylene. Rheol Acta 46:153–159

Sato Y, Yurugi M, Fujiwara K, Takishima S, Masuoka H (1996) Solubilities of carbon dioxide and nitrogen in polystyrene under high temperature and pressure. Fluid Phase Equilib 125:129–138

Schubert DW (2001) Compatibility of poly(α-methylstyrene-co-acrylonitrile) with PMMA: a neutron and cloud point study. Mater Res Innov 4:353–359

Tait PG (1888) Report on some of the physical properties of fresh water and sea-water. In: Report on the scientific results of the voyage of H.M.S. challenger during the years 1873–1876: Physics and Chemistry, vol. 2, part IV. H.M. Stationery Office, London, pp 1–68

Vinckier I, Laun HM (1999) Manifestation of phase separation processes in oscillatory shear: droplet-matrix systems versus co-continuous morphologies. Rheol Acta 38:274–286

Vinckier I, Laun HM (2000) Manifestation of spinodal decomposition in oscillatory shear measuremest. Macromol Symp 149:151–156

Vinckier I, Laun HM (2001) Assessment of the Doi–Ohta theory for co-continuous blends under oscillatory flow. J Rheol 45:1373–1385

Vinckier I, Schweizer T, Laun HM (2002) Interfacial tension in a LCST blend: effect of temperature, blend composition and deformation of the interphase. J Polym Sci Part B 40:679–690

Wohl A (1921) Untersuchungen über die Zustandsgleichung. IV. Die kompressionsgleichung der flüssigkeiten (Zustandsgleichung stark verdichteter stoffe). Z Phys Chem 99:234–241

Xu J, Costeux S, Dealy JM, De Decker MN (2007) Use of a sliding plate rheometer to measure the first normal stress difference at high shear rates. Rheol Acta 46:815–824

Zhang ZI, Zhang HD, Yang YL, Vinckier I, Laun HM (2001) Rheology and morphology of phase-separating polymer blends. Macromol 34:416–1429

Zoller P, Bolli P, Pahud V, Ackermann H (1976) Apparatus for measuring pressure-volume-temperature relationships of polymers to 350 degrees C and 2200 kg/cm2. Rev Sci Instrum 47:948–952

Zuo M, Peng M, Zhen Q (2005) Investigation on the early and late stage phase-separation dynamics of poly(methyl methacrylate)/poly(α-methyl styrene-co-acrylonitrile) blends through rheological and scattering functions. Polymer 46:11085–11092

Acknowledgements

The authors would like to thank Dr. Ingolf Hennig (BASF) for providing the PVT data. Peter Schuler (BASF) is thanked for the design of the counter-pressure arrangement to the ANCR rheometer, as well as for the CPNCR measurements.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

Equation 26 should be concave-up in a semi-log plot, while Eq. 22 gives a linear prediction. However, both predictions by Eqs. 22 and 26 look straight in Fig. 15, and one can thus ask two questions: (1) why two different equations give similar straight predictions in a semi-log plot and (2) why β throttle and β, obtained by fitting to each equation giving the same prediction, are different.

-

(1)

Both \({\mathrm{d}\ln \left( {\Delta P} \right)} \mathord{\left/ {\vphantom {{\mathrm{d}\ln \left( {\Delta P} \right)} {\mathrm{d}P_\mathrm{e} }}} \right. \kern-\nulldelimiterspace} {\mathrm{d}P_\mathrm{e} }\) and \({\mathrm{d}^2\ln \left( {\Delta P} \right)} \mathord{\left/ {\vphantom {{\mathrm{d}^2\ln \left( {\Delta P} \right)} {\mathrm{d}P_\mathrm{e}^2 }}} \right. \kern-\nulldelimiterspace} {\mathrm{d}P_\mathrm{e}^2 }\) of Eq. 26 are positive, so that the solid line predicted by Eq. 26 in a semi-log plot is mathematically concave-up and rising, having certain curvature, but this looks straight in Fig. 15, to the eye. At high P e (above 100 MPa), the prediction by Eq. 26 with the same parameters shows an upswing, so that the prediction of Eq. 26 will not seem straight any longer.

-

(2)

Since \(\Delta P_0 \beta _{\mathrm{sr}} \exp \left( {\beta _{\mathrm{sr}} P_\mathrm{e} } \right)<0.2\) in Eq. 26, we can use the Maclaurin series expansion of the natural logarithm in Eq. 26, and Eq. 26 becomes Eq. 35:

$$\label{Equ35} \begin{array}{lll} \Delta P&=&\frac{1}{\beta _{\mathrm{sr}} }\sum\limits_{j=1}^\infty {\frac{\left[ {\Delta P_0 \beta _{\mathrm{sr}} \exp \left( {\beta _{\mathrm{sr}} P_\mathrm{e} } \right)} \right]^j}{j}} \\ &=&\Delta P_0 \exp \left( {\beta _{\mathrm{sr}} P_\mathrm{e} } \right)+\beta _{\mathrm{sr}} \frac{\left[ {\Delta P_0 \exp \left( {\beta _{\mathrm{sr}} P_\mathrm{e} } \right)} \right]^2}{2} \\ &&+{\kern2pt}\beta _{\mathrm{sr}}^2 \frac{\left[ {\Delta P_0 \exp \left( {\beta _{\mathrm{sr}} P_\mathrm{e} } \right)} \right]^3}{3}+\cdot \cdot \cdot \end{array} $$(35)The first term of Eq. 35 is the same as the right-hand side of Eq. 22:

$$ \label{Equ36} \Delta P=\Delta P_0 \exp \left( {\beta _{\mathrm{throttle}} P_\mathrm{e} } \right) $$(22)If β sr = β throttle, the sum of the terms after the first term in Eq. 35 must be zero or negligible because Eqs. 22 and 35 show the almost same prediction for ΔP. However, this summation is well larger than zero, and thus β sr < β throttle to give the same prediction. It should be noted that the straight prediction of Eq. 26 in Fig. 15 is not because Eq. 26 can approximate to the first term of Eq. 35 but because the prediction of the whole Eq. 26 can look straight to the human scale even though it is not mathematically.

Rights and permissions

About this article

Cite this article

Park, H.E., Lim, S.T., Laun, H.M. et al. Measurement of pressure coefficient of melt viscosity: drag flow versus capillary flow. Rheol Acta 47, 1023–1038 (2008). https://doi.org/10.1007/s00397-008-0296-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00397-008-0296-x