Abstract

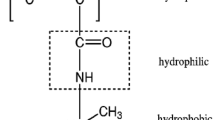

A novel procedure for the preparation of superhydrophilic poly(styrene-co-acrylate)/SiO2 composite materials was prepared from conventional emulsion polymerization in the presence of colloidal silica. TEM photos revealed that poly(styrene-co-acrylate) latexes exhibited a clear core–shell structure, and the electrostatic repulsion and hydrogen bonds between poly(styrene-co-acrylate) latexes and SiO2 nanoparticles guaranteed the uniform dispersion of silica nanoparticles. The average diameter data indicated that the particle size of composite latexes (78 nm) was slightly smaller than that of polymer (82 nm), although the slight aggregation of SiO2 nanoparticles had increased the average diameter to 87 nm. FTIR spectra confirmed that hydrogen bonds were formed and gel reaction of –OH groups occurred during film formation. Two kinds of Si–O bonds were found in XPS spectra with a weight ratio addition of 20.0% SiO2, which one was related to the Si–OH groups of colloidal silica nanoparticles, while the other was attributed to the Si–O-Si groups obtained from the gel reaction. SEM and AFM images displayed that the formation of micro/nano structure from the gel reaction had increased the roughness of the composite films. The water contact angle (WCA) of the composite films was found to decrease from 45 to 3º (3 s) and exhibit superhydrophilicity.

Graphical abstract

Similar content being viewed by others

References

Castro LD, Pessan NM (2018) Thin Solid Films 651:138–144

Chen PY, Hu Y, Wei CH (2012) Appl Surf Sci 258:4334–4338

Yu QJ, Yin YQ, Yang YC, Han YY, Liu YJ, Li BX, Weng LJ, Sol-Gel J (2018) Sci Techn 87:749–759

Chen JJ, Zhang L, Zeng ZX, Wang G, Liu GM, Zhao WJ, Ren TH, Xue QJ (2016) Colloids Surf A Physicochem Eng Asp 509:149–157

Lin YH, Su KL, Tsai PS, Chuang FL, Yang YM (2011) Thin Solid Films 519:5450–5455

Geng Z, He JH, Xu LG (2012) Mater Res Bull 47:1562–1567

Deng WS, Wang G, Tang L, Zeng ZX, Ren TH, Colloid J (2022) Interf Sci 608:186–192

Zhang S, Zhao X, Wang P, Xiao P, Luo J, Jiang B (2019) J Sol Gel Sci Techn 92:598–606

Chang CC, Lin ZM, Cheng LP (2019) J Appl Polym Sci 136. https://doi.org/10.1002/APP.48144

Alam K, Ali S, Saboor A, Salman M, Humayun MM, Sadiq M, Arif M (2019) Coatings 9:497

Dong HC, Ye PL, Zhong MJ, Pietrasik J, Drumright R, Matyjaszewski K (2010) Langmuir 19:15567–15573

Aghaei R, Eshaghi A (2017) J Alloy Compd 699:112–118

Wenzel RN (1936) Ind Eng Chem 28:988–994

Cassie ABD, Baxter S (1944) Trans. Faraday Soc 40:546–551

Ganjoo S, Azimirad R, Akhavan O, Moshfegh AZ (2009) J Phys D Appl Phys 42:0253022

Liao WB, Zuo LY, Zheng SN, Huang XX, Ye LY, Zhong GY (2021) J Coat Technol Res 18:107–116

Ye LY, Ma GH, Zheng SN, Huang XX, Zhao LL, Luo HB, Liao WB (2019) J Coat Technol Res 16:1243–1252

Li W, l'Abee RM, Goossens JG (2013) Macromol Chem Phys 214:2705–2715

Bao Y, Zhang Y, Liu P, Ma J, Zhang W, Liu C, Simion D (2019) J Colloid Interf Sci 553:83–90

Liao WB, Qu JQ, Li Z, Chen HQ (2011) Polym Mater Sci Eng 11:4–8

Huang XX, Liao WB, Ye LY, Zhang N, Lan SH, Fan HB, Qu JQ (2017) Micropor Mesopor Mat 243:311–318

Liao WB, Teng HP, Qu JQ, Masuda T (2011) Prog Org Coatings 71:376–383

Zhu BF, Liu J, Chen Y, Liu YW, Yang ZN (2017) Z. Surf Coat Tech 331:40–47

Li XY, Shi B, Li MM, Mao LQ (2015) J Porous Mater 22:201–210

Funding

This work was financially supported by the “Guangdong Basic and Applied Basic Research Foundation” (2020A1515110881) and the “Social Development Science Technology Foundation of Dongguan” (20211800904612, 20211800901532).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Supplementary file1 (MP4 311987 KB)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liao, W., Wu, W., Zhong, G. et al. Facile fabrication of superhydrophilic poly(styrene-co-acrylate)/SiO2 composite materials by conventional emulsion polymerization. Colloid Polym Sci 301, 957–966 (2023). https://doi.org/10.1007/s00396-023-05114-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-023-05114-0