Abstract

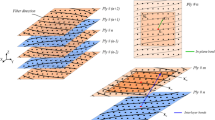

A new peridynamic model for predicting the out-of-plane bending and twisting behavior of composite laminates has been proposed, in which fiber bonds and matrix bonds are distinguished for characterizing anisotropy. The peridynamic formulations are obtained based on the principle of virtual displacements using the Total Lagrange formulation, and the equation of motion is reformulated by the interpolation technique. The critical curvature is adopted as the failure criterion, and a micromodulus reduction method is implemented in the PD algorithm. For multi-layer laminated structures, a new single-layer material point model (SLMPM) is proposed, in which the overall micromodulus is integrated according to all plies in laminates. The capability of the developed PD model was demonstrated by the bending examples of composite laminates with different fiber orientations, and damage analysis was further conducted to demonstrate the strong capability of the proposed PD model in replicating the failure process of composite structures. In addition, the computational efficiency of numerical models can be greatly improved due to the SLMPM.

Similar content being viewed by others

Data availability

The data are available upon reasonable request.

References

Silling SA (2000) Reformulation of elasticity theory for discontinuities and long-range forces. J Mech Phys Solids 48:175–209

Silling SA, Lehoucq RB (2010) Peridynamic theory of solid mechanics. Adv Appl Mech 44:73–168

Silling SA, Askari E (2005) A meshfree method based on the peridynamic model of solid mechanics. Comput Struct 3:1526–1535

Madenci E, Oterkus E (2014) Peridynamic theory and its applications. Springer, New York

Bobaru F, Foster JT, Geubelle PH, Silling SA (2016) Handbook of peridynamic modeling. CRC Press, Boca Raton

Gao C, Zhou Z, Li Z, Li L, Cheng S (2020) Peridynamics simulation of surrounding rock damage characteristics during tunnel excavation. Tunn Undergr Space Technol 97:103289

Qin M, Yang D, Chen W, Yang S (2021) Hydraulic fracturing model of a layered rock mass based on peridynamics. Eng Fract Mech 258:108088

Zhou Z, Li Z, Gao C, Zhang D, Bai S (2021) Peridynamic micro-elastoplastic constitutive model and its application in the failure analysis of rock masses. Comput Geotech 132(1):104037

Yaghoobi A, Chorzepa MG (2017) Fracture analysis of fiber reinforced concrete structures in the micropolar peridynamic analysis framework. Eng Fract Mech 169:238–250

Jin Y, Li L, Jia Y, Shao J, Burlion N (2021) Numerical study of shrinkage and heating induced cracking in concrete materials and influence of inclusion stiffness with Peridynamics method. Comput Geotech 133:103998

Xu C, Yuan Y, Zhang Y, Xue Y (2021) Peridynamic modeling of prefabricated beams post-cast with steelfiber reinforced high-strength concrete. Struct Concr 22:445–456

Zhang H, Qiao P (2018) An extended state-based peridynamic model for damage growth prediction of bimaterial structures under thermomechanical loading. Eng Fract Mech 189:81–97

Zhang H, Zhang X, Liu Y, Qiao P (2022) Peridynamic modeling of elastic bimaterial interface fracture. Comput Methods Appl Mech Eng 390:114458

Alebrahim R (2019) Peridynamic modeling of lamb wave propagation in bimaterial plates. Compos Struct 214:12–22

Bathe K-J, Bolourchi S (1980) A geometric and material nonlinear plate and shell element. Comput Struct 11(1–2):23–48

Bonet J, Wood RD (1997) Nonlinear continuum mechanics for finite element analysis. Cambridge University Press, Cambridge

Hughes TJ, Pister KS, Taylor RL (1979) Implicit-explicit finite elements in nonlinear transient analysis. Comput Methods Appl Mech Eng 17:159–182

Silling SA, Bobaru F (2005) Peridynamic modeling of membranes and fibers. Int J Non Linear Mech 40(2–3):395–409

O’Grady J, Foster J (2014) Peridynamic plates and flat shells: a non-ordinary, state-based model. Int J Solids Struct 51(25–26):4572–4579

Diyaroglu C, Oterkus E, Oterkus S, Madenci E (2015) Peridynamics for bending of beams and plates with transverse shear deformation. Int J Solids Struct 69–70:152–168

Nguyen CT, Oterkus S (2019) Peridynamics for the thermomechanical behavior of shell structures. Eng Fract Mech 219:106623

Nguyen CT, Oterkus S (2020) Ordinary state-based peridynamic model for geometrically nonlinear analysis. Eng Fract Mech 224:106750

Nguyen CT, Oterkus S (2021) Ordinary state-based peridynamics for geometrically nonlinear analysis of plates. Theor Appl Fract Mec 112:102877

Shen G, Xia Y, Hu P, Zheng G (2021) Construction of peridynamic beam and shell models on the basis of the micro-beam bond obtained via interpolation method. Eur J Mech-A/Solids 86:104174

Oterkus E, Madenci E (2012) Peridynamic analysis of fiber-reinforced composite materials. J Mech Mater Struct 7(1):45–84

Hu W, Ha YD, Bobaru F (2012) Peridynamic model for dynamic fracture in unidirectional fiber-reinforced composites. Comput Methods Appl Mech Eng 217–220:247–261

Sun C, Huang Z (2016) Peridynamic simulation to impacting damage in composite laminate. Compos Struct 138:335–341

Hu YL, Yu Y, Wang H (2014) Peridynamic analytical method for progressive damage in notched composite laminates. Compos Struct 108:801–810

Hu YL, Carvalho N, Madenci E (2015) Peridynamic modeling of delamination growth in composite laminates. Compos Struct 132:610–620

Diyaroglu C, Madenci E, Phan N (2019) Peridynamic homogenization of microstructures with orthotropic constituents in a finite element framework. Compos Struct 227:111334

Diyaroglu C, Oterkus E et al (2016) Peridynamic modeling of composite laminates under explosive loading. Compos Struct 144:14–23

Silling SA, Epton M, Weckner O, Xu J, Askari E (2007) Peridynamic states and constitutive modeling. J Elast 88:151–184

Silling SA (2017) Stability of peridynamic correspondence material models and their particle discretizations. Comput Methods Appl Mech Eng 322:42–57

Gao Y, Oterkus S (2019) Fully coupled thermomechanical analysis of laminated composites by using ordinary state based peridynamic theory. Compos Struct 207:397–424

Gao Y, Oterkus S (2021) Coupled thermo-fluid-mechanical peridynamic model for analysing composite under fire scenarios. Compos Struct 255:113006

Hattori G, Trevelyan J, Coombs WM (2018) A non-ordinary state-based peridynamics framework for anisotropic materials. Comput Methods Appl Mech Eng 339:416–442

Fang G, Liu S et al (2021) A stable non‐ordinary state‐based peridynamic model for laminated composite materials. Int J Numer Methods Eng 122:403–430

Shang S, Qin XD, Li H et al (2019) An application of non-ordinary state-based peridynamics theory in cutting process modelling of unidirectional carbon fiber reinforced polymer material. Compos Struct 226:111194

Hu YL, Madenci E (2016) Bond-based peridynamic modeling of composite laminates with arbitrary fiber orientation and stacking sequence. Compos Struct 153:139–175

Hu YL, Yu Y, Madenci E (2020) Peridynamic modeling of composite laminates with material coupling and transverse shear deformation. Compos Struct 253:112760

Hu YL, Madenci E (2017) Peridynamics for fatigue life and residual strength prediction of composite laminates. Compos Struct 160:169–184

Jiang XW, Wang H (2018) Ordinary state-based peridynamics for open-hole tensile strength prediction of fiber-reinforced composite laminates. J Mech Mater Struct 13(1):53–82

Jiang XW, Wang H, Guo S (2019) Peridynamic open-hole tensile strength prediction of fiber-reinforced composite laminate using energy-based failure criteria. Adv Mater Sci Eng 2019:7694081

Guo J, Gao W et al (2019) Study of dynamic brittle fracture of composite lamina using a bond-based peridynamic lattice model. Adv Mater Sci Eng 2019:3748795

Braun M, Ariza MP (2019) New lattice models for dynamic fracture problems of anisotropic materials. Compos Part B-Eng 172:760–768

Braun M, Iváñez I, Ariza MP (2021) A numerical study of progressive damage in unidirectional composite materials using a 2D lattice model. Eng Fract Mech 249:107767

Braun M, Ariza MP (2020) A progressive damage based lattice model for dynamic fracture of composite materials. Compos Sci Technol 200:108335

Braun M, Aranda-Ruiz J, Fernández-Sáez J (2021) Mixed mode crack propagation in polymers using a discrete lattice method. Polymers 13(8):1290

Hu YL, Wang JY, Madenci E et al (2022) Peridynamic micromechanical model for damage mechanisms in composites. Compos Struct 301:116182

Buryachenko VA (2020) Generalized effective fields method in peridynamic micromechanics of random structure composites. Int J Solids Struct 202:765–786

Tastan A, Yolum U et al (2016) A 2D peridynamic model for failure analysis of orthotropic thin plates due to bending. Procedia Struct Integr 2:261–268

Ugur Y et al (2020) On the peridynamic formulation for an orthotropic Mindlin plate under bending. Math Mech Solids 25(2):263–287

Underwood PG (1983) Dynamic relaxation a review. In: Computational Methods for Transient Dynamic Analysis, vol 1. American Society of Mechanical Engineers, pp 245–265

Kilic B, Madenci E (2010) An adaptive dynamic relaxation method for quasi-static simulations using the peridynamic theory. Theor Appl Fract Mech 53(3):194–204

Qian Y (2018) Study on damage of laminates due to impact bending. Master’s thesis, Southeast University

Zaccariotto M, Mudric T, Tomasi D et al (2018) Coupling of FEM meshes with Peridynamic grids. Comput Methods Appl Mech Eng 330:471–497

Budzik MK, Jumel J, Shanahan MER (2012) On the crack front curvature in bonded joints. Theor Appl Fract Mech 59(1):8–20

Jiang Z, Wan S, Zhong Z et al (2015) Effect of curved delamination front on mode-I fracture toughness of adhesively bonded joints. Eng Fract Mech 138:73–91

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1: PD material parameters

The geometric relationship between material points x(k) and x(j) can be obtained by Taylor expansion as:

where the higher-order terms of Taylor expansion are ignored, and the expressions in Eq. (77) can be further written as:

1.1 Lamina subjected to simple twisting

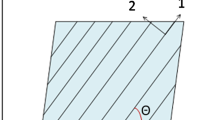

For a lamina subjected to simple twisting, \(\kappa_{12} = \kappa\), as shown in Fig. 25. The constitutive relation can be expressed as:

The strain energy density based on CCM at material point x(k) can be defined as:

The relative curvature between material points x(j) and x(k) in the deformed state can be expressed as:

The strain energy density can be calculated as:

or

The PD strain energy density at material point x(k) must be equal to the counterpart from CCM, Eqs. (80) and (82b), as follows

1.2 Lamina subjected to uniaxial bending

For a lamina subjected to uniaxial bending in the fiber direction, \(\kappa_{11} = \kappa ,{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} \kappa_{22} = 0\), as shown in Fig. 26. The constitutive relation can be expressed as:

where D11 and D12 represent the bending stiffness coefficients of orthotropic materials which can be expressed as:

where

The dilatation and strain energy density based on CCM at material point x(k) can be defined as:

The relative curvature between material points x(j) and x(k) in the deformed state can be expressed as:

Due to uniaxial bending deformation, the dilatation can be calculated as

or

The dilatation at material point x(k) must be equal to the counterpart from CCM, Eqs. (87a) and (89b), as follows:

The strain energy density of the lamina subjected to uniaxial bending can be calculated as:

or

Substituting Eq. (83) into Eq. (91b) and the integral value can be obtained as:

The strain energy density at material point x(k) must be equal to the counterpart from CCM, Eqs. (87b) and (92), as follows:

Similarly, for a lamina subjected to uniaxial bending in the transverse direction, \(\kappa_{11} = 0,{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} \kappa_{22} = \kappa\), as shown in Fig. 27. The expression can also be obtained as:

1.3 Lamina subjected to biaxial bending

For a lamina subjected to biaxial bending, \(\kappa_{11} = \kappa ,{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} \kappa_{22} = \kappa\), as shown in Fig. 28. The constitutive relation can be expressed as:

The strain energy density based on CCM at material point x(k) can be defined as:

The relative curvature between material points x(j) and x(k) in the deformed state can be expressed as:

The strain energy density of the lamina subjected to biaxial bending can be calculated as

Substituting Eq. (83) into Eq. (98) and the integral value can be obtained as:

The strain energy density at material point x(k) must be equal to the counterpart from CCM, Eqs. (96) and (99), as follows:

The PD material parameters of the lamina can be obtained by solving Eqs. (93–94) and (100), as:

In bond-based peridynamics (BBPD), the material parameter a associated with dilatation needs to vanish. Therefore, these elastic constants of lamina are limited as:

The nonvanishing PD parameters, cf and cft, can be presented as:

where cf and cft represent the bending micromodulus of PD bonds in the fiber and arbitrary directions, respectively.

Appendix 2: Surface corrections

Similar to other PD models, the PD material parameters need to be corrected for those material points located in the boundary region. These correction factors can be determined by comparing the strain energy densities obtained from PD and CCM, and the corresponding moment–curvature relations can be modified.

When a lamina is subjected to constant curvature in the fiber and transverse direction, \({{\partial \theta_{\alpha } } \mathord{\left/ {\vphantom {{\partial \theta_{\alpha } } {\partial x_{\alpha } }}} \right. \kern-0pt} {\partial x_{\alpha } }} = \kappa\) with \(\left( {\alpha = 1,2} \right)\), the deformation field at material point x can be described as:

The PD strain energy density associated with x(k) can be decomposed as:

where \(W_{{\alpha {\text{f}}}}^{{{\text{PD}}}}\) and \(W_{{\alpha {\text{ft}}}}^{{{\text{PD}}}}\) represent strain energy densities of fiber bonds and matrix bonds, respectively. Each term in Eq. (105) can be calculated as:

The corresponding strain energy density in CCM associated with material point x(k) can also be defined as:

which can be decomposed as:

where \(W_{{\alpha {\text{f}}}}^{{{\text{CM}}}}\) and \(W_{{\alpha {\text{ft}}}}^{{{\text{CM}}}}\) represent strain energy densities in the fiber direction and arbitrary directions, respectively.

For a lamina subjected to uniaxial bending in the fiber direction, each component of strain energy density can be expressed as:

For a lamina subjected to uniaxial bending in the transverse direction, each component of strain energy density can be expressed as:

Hence, for the uniaxial bending in the fiber direction, the correction factor components at material point x(k) can be defined as:

When a lamina is subjected to uniaxial bending in the transverse direction, the correction factor components at material point x(k) can be defined as:

These correction factors in Eqs. (111–112) can be written in a vector form as:

Since these correction factors are only based on deformation in the fiber and transverse directions. To solve the correction factors in any direction, a unit relative position vector between material points x(k) and x(j) needs to be introduced, which can be expressed as:

Therefore, the correction factor between material points x(k) and x(j) can be obtained as:

The total correction factor between material points x(k) and x(j) can be determined by projecting the correction factor components on the relative position vector as:

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yang, X., Gao, W., Liu, W. et al. Peridynamics for out-of-plane damage analysis of composite laminates. Engineering with Computers (2023). https://doi.org/10.1007/s00366-023-01903-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00366-023-01903-x