Abstract

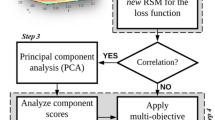

Laser beam machining (LBM) is a promising manufacturing process that exhibits several desirable quality characteristics. Given a large number of objective functions, the level of complexity increases in an optimization problem. Therefore, this study presents a multivariate application of the normal boundary intersection (NBI) method to reduce dimensionality in optimization problems of the LBM process. Such an approach is capable of exploring the entire solution space with only a small number of Pareto points, and generating equispaced frontiers based on the objective functions written in terms of principal component scores. Hence, a design of experiment with three input parameters and six quality characteristics was undertaken to appropriately model the process requirements applied to AISI 314S steel. The results indicate that the proposed methodology is capable of achieving optimal values for interest characteristics. In addition, this approach shows a reduction in computational effort of approximately 91.89% (from 259 to 21 subproblems) in obtaining the best solution for rough operation.

Similar content being viewed by others

References

Meijer J (2004) Laser beam machining (LBM), state of the art and new opportunities. J Mater Process Technol 149:2–17. https://doi.org/10.1016/j.jmatprotec.2004.02.003

Dubey AK, Yadava V (2008) Laser beam machining-A review. Int J Mach Tools Manuf 48:609–628. https://doi.org/10.1016/j.ijmachtools.2007.10.017

Gomes GF, de Almeida FA, da Silva Lopes Alexandrino P et al (2018) A multiobjective sensor placement optimization for SHM systems considering Fisher information matrix and mode shape interpolation. Eng Comput 10:1–17. https://doi.org/10.1007/s00366-018-0613-7

Saghatforoush A, Monjezi M, Shirani Faradonbeh R, Jahed Armaghani D (2016) Combination of neural network and ant colony optimization algorithms for prediction and optimization of flyrock and back-break induced by blasting. Eng Comput 32:255–266. https://doi.org/10.1007/s00366-015-0415-0

Chen XL, Fu JP, Yao JL, Gan JF (2018) Prediction of shear strength for squat RC walls using a hybrid ANN–PSO model. Eng Comput 34:367–383. https://doi.org/10.1007/s00366-017-0547-5

Gomes GF, de Almeida FA, da Cunha SS et al (2018) An estimate of the location of multiple delaminations on aeronautical CFRP plates using modal data inverse problem. Int J Adv Manuf Technol 99:1155. https://doi.org/10.1007/s00170-018-2502-z

MiarNaeimi F, Azizyan G, Rashki M (2017) Multi-level cross entropy optimizer (MCEO): an evolutionary optimization algorithm for engineering problems. Eng Comput. https://doi.org/10.1007/s00366-017-0569-z

Gomes GF, da Cunha SS, Ancelotti AC (2018) A sunflower optimization (SFO) algorithm applied to damage identification on laminated composite plates. Eng Comput. https://doi.org/10.1007/s00366-018-0620-8

Dubey A, Yadava V (2008) Robust parameter design and multi-objective optimization of laser beam cutting for aluminium alloy sheet. Int J Adv Manuf Technol 38:268–277. https://doi.org/10.1007/s00170-007-1105-x

Kasman Ş, Etem Saklakoglu I (2012) Determination of process parameters in the laser micromilling application using Taguchi method: a case study for AISI H13 tool steel. Int J Adv Manuf Technol 58:201–209. https://doi.org/10.1007/s00170-011-3371-x

Ghosal A, Manna A (2013) Optics & laser technology response surface method based optimization of ytterbium fiber laser parameter during machining of Al/ Al2O3 -MMC. Opt Laser Technol 46:67–76. https://doi.org/10.1016/j.optlastec.2012.04.030

Parandoush P, Hossain A (2014) A review of modeling and simulation of laser beam machining. Int J Mach Tools Manuf 85:135–145. https://doi.org/10.1016/j.ijmachtools.2014.05.008

Li CH, Tsai MJ (2009) Multi-objective optimization of laser scribing for the isolation process of solar cell wafers using grey relational analysis. IEEE Int Symp Ind Electron 41:1154–1159. https://doi.org/10.1109/ISIE.2009.5218137

Teixidor D, Ferrer I, Ciurana J, Özel T (2013) Optimization of process parameters for pulsed laser milling of micro-channels on AISI H13 tool steel. Robot Comput Integr Manuf 29:209–218

Childs THC, Hauser C, Badrossamay M (2004) Mapping and modelling single scan track formation in direct metal selective laser melting. CIRP Ann Manuf Technol 53:191–194. https://doi.org/10.1016/S0007-8506(07)60676-3

Childs THC, Hauser C, Badrossamay M (2005) Selective laser sintering (melting) of stainless and tool steel powders: experiments and modelling. Proc Inst Mech Eng Part B J Eng Manuf 219:339–357

Pandey AK, Dubey AK (2012) Taguchi based fuzzy logic optimization of multiple quality characteristics in laser cutting of Duralumin sheet. Opt Lasers Eng 50:328–335. https://doi.org/10.1016/j.optlaseng.2011.11.005

Mistry V, James S (2017) Finite element analysis and simulation of liquid-assisted laser beam machining process. Int J Adv Manuf Technol 2325–2331. https://doi.org/10.1007/s00170-017-1009-3

Darwish S, Ahmed N, Alahmari AM, Mufti NA (2017) A study of micro-channel size and spatter dispersion for laser beam micro-milling. Mater Manuf Process 32:171–184. https://doi.org/10.1080/10426914.2016.1176188

Darwish S, Ahmed N, Alahmari AM, Mufti NA (2016) A comparison of laser beam machining of micro-channels under dry and wet mediums. Int J Adv Manuf Technol 83:1539–1555. https://doi.org/10.1007/s00170-015-7658-1

Pan LK, Wang CC, Wei SL, Sher HF (2007) Optimizing multiple quality characteristics via Taguchi method-based Grey analysis. J Mater Process Technol 182:107–116. https://doi.org/10.1016/j.jmatprotec.2006.07.015

Schweier M, Heins JF, Haubold MW, Zaeh MF (2013) Spatter formation in laser welding with beam oscillation. Phys Procedia 41:20–30. https://doi.org/10.1016/j.phpro.2013.03.047

Rao RV, Kalyankar VD (2014) Optimization of modern machining processes using advanced optimization techniques: a review. Int J Adv Manuf Technol 73:1159–1188. https://doi.org/10.1007/s00170-014-5894-4

Almeida FA de, Gomes GF, De Paula VR et al (2018) A weighted mean square error approach to the robust optimization of the surface roughness in an AISI 12L14 free-machining steel-Turning process. Stroj Vestnik/J Mech Eng 64:147–156. https://doi.org/10.5545/sv-jme.2017.4901

Yu X, Zhang S, Johnson E (2003) A discrete post-processing method for structural optimization. Eng Comput 19:213–220. https://doi.org/10.1007/s00366-003-0259-x

Almeida FA, Gomes GF, Sabioni RC, Gomes JHF, Paula VR, Paiva AP et al (2018) A gage study applied in shear test to indentify variation causes from a resistance spot welding measurement system. Stroj Vestnik/J Mech Eng 63:621–631

Fabiano Luis N, Tayana Incerti P, Pedro Paulo B et al (2017) Multivariate normal boundary intersection based on rotated factor scores: a multiobjective optimization method for methyl orange treatment. J Clean Prod 143:413–439

Manjoth S, Keshavamurthy R, Kumar GSP (2016) Optimization and analysis of laser beam machining parameters for Al7075-TiB < inf> 2</inf> in-situ composite. IOP Conf Ser Mater Sci Eng 149:12013. https://doi.org/10.1088/1757-899X/149/1/012013

Ahmed N, Alahmari AM, Darwish S, Khan AA (2016) Experimental investigation of micro-channels produced in aluminum alloy (AA 2024) through laser machining. Appl Phys A 122:948. https://doi.org/10.1007/s00339-016-0463-3

Umer U, Mohammed MK, Al-Ahmari A (2017) Multi-response optimization of machining parameters in micro milling of alumina ceramics using Nd:YAG laser. Meas J Int Meas Confed 95:181–192. https://doi.org/10.1016/j.measurement.2016.10.004

Prakash C, Kansal HK, Pabla BS, Puri S (2016) Multi-objective optimization of powder mixed electric discharge machining parame- ters for fabrication of biocompatible layer on β -Ti alloy using NSGA-II coupled with Taguchi based response surface methodology †. J Mech Sci Technol 30:4195–4204. https://doi.org/10.1007/s12206-016-0831-0

Costa DMD, Belinato G, Brito TG et al (2016) Weighted principal component analysis combined with Taguchi’s Signal-to-noise ratio to the multiobjective optimization of dry end milling process: a comparative study. J Brazilian Soc Mech Sci Eng. https://doi.org/10.1007/s40430-016-0614-7

Almeida FA, De Paula TI, Leite RR, Gomes GF, Gomes JHF, Paiva APBP (2018) A multivariate GR&R approach to variability evaluation of measuring instruments in resistance spot welding process. J Manuf Process 36:465–479. https://doi.org/10.1016/j.jmapro.2018.10.030

Montgomery DC (2016) Design and analysis of experiments, 9th edn. Wiley, New York

Myers RH, Montgomery DC, Anderson-Cook CM (2009) Response surface methodology, 3rd ed. Taylor & Francis, Routledge

Singh D, Rao PV (2007) A surface roughness prediction model for hard turning process. Int J Adv Manuf Technol 32:1115–1124

Skrypnyk R, Nielsen JCO, Ekh M, Pålsson BA (2018) Metamodelling of wheel–rail normal contact in railway crossings with elasto-plastic material behaviour. Eng Comput. https://doi.org/10.1007/s00366-018-0589-3

Amaral FF, Almeida FA, Costa SC, Leme RCPA (2018) Application of the response surface methodology for optimization of the resistance spot welding process in AISI 1006 galvanized steel. Soldag Inspeção 32:129–142

Camposeco-Negrete C (2015) Optimization of cutting parameters using response surface method for minimizing energy consumption and maximizing cutting quality in turning of AISI 6061 T6 aluminum. J Clean Prod 91:109–117

Asiltürk I, Neşeli S, Ince MA (2016) Optimisation of parameters affecting surface roughness of Co28Cr6Mo medical material during CNC lathe machining by using the Taguchi and RSM methods. Measurement 78:120–128

Cukor G, Jurković Z, Sekulić M (2011) Rotatable central composite design of experiments versus Taguchi method in the optimization of turning. Metalurgija 50:17–20

Al-Ahmari AMA (2007) Predictive machinability models for a selected hard material in turning operations. J Mater Process Technol 190:305–311

Noordin MY, Venkatesh VC, Sharif S et al (2004) Application of response surface methodology in describing the performance of coated carbide tools when turning AISI 1045 steel. J Mater Process Technol 145:46–58

Johnson RA, Wichern DW (2007) Applied multivariate statistical analysis, 6th edn. Prentice Hall, New Jersey

Das I, Dennis JE (1998) Normal-boundary intersection: a new method for generating the pareto surface in nonlinear multicriteria optimization problems. SIAM J Optim 8:631–657. https://doi.org/10.1137/S1052623496307510

Brito TG, Paiva AP, Ferreira JR et al (2014) A normal boundary intersection approach to multiresponse robust optimization of the surface roughness in end milling process with combined arrays. Precis Eng 38:628–638. https://doi.org/10.1016/j.precisioneng.2014.02.013

Lopes LGD, Brito TG, Paiva AP et al (2016) Robust parameter optimization based on multivariate normal boundary intersection. Comput Ind Eng 93:55–66. https://doi.org/10.1016/j.cie.2015.12.023

Abdollah A, Hadi M, Ali Esmaeel N et al (2015) Multi-objective economic emission dispatch considering combined heat and power by normal boundary intersection method..2015.07.011. Electr Power Syst Res 129:32–43

Gomes JHF, Paiva a P, Costa SC et al (2013) Weighted Multivariate Mean Square Error for processes optimization: a case study on flux-cored arc welding for stainless steel claddings. Eur J Oper Res 226:522–535. https://doi.org/10.1016/j.ejor.2012.11.042

Gaudêncio JHD, Almeida FA, Sabioni RC, Turrioni JB, Paiva AP, Campos PHS (2018) Fuzzy multivariate mean square error in equispaced pareto frontiers considering manufacturing process optimization problems. Eng Comput. https://doi.org/10.1007/s00366-018-0660-0

Rocha LCS, De Paiva AP, Balestrassi PP et al (2015) Entropy-based weighting for multiobjective optimization: an application on vertical turning. Math Probl Eng. https://doi.org/10.1155/2015/608325

Shannon CE (1948) A mathematical theory of communication. Bell Syst Tech J 27:379–423

Acknowledgements

The authors gratefully acknowledge the IDMEC/UL, Associated Laboratory for Energy, Transports and Aeronautics (LAETA), IST/University of Lisbon, the SMART2 program from ERASMUS MUNDUS, FAPEMIG, CAPES, CNPq and IFSULDEMINAS.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Belinato, G., de Almeida, F.A., de Paiva, A.P. et al. A multivariate normal boundary intersection PCA-based approach to reduce dimensionality in optimization problems for LBM process. Engineering with Computers 35, 1533–1544 (2019). https://doi.org/10.1007/s00366-018-0678-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00366-018-0678-3