Abstract

This study experimentally investigates the hydrodynamic characteristics of a cylinder with multidegree motion during water entry with different initial horizontal velocities and inclined angles. A mechanical device is designed to provide certain initial conditions for the cylinder, and the cavity evolution and cylinder position are recorded with a high-speed camera. To obtain precise hydrodynamic forces, a new image-processing method is established to detect the center and attitude angle of the cylinder based on a step edge model and the Grubbs criterion. Additionally, an algorithm is employed to correct the refraction effects in the raw data. Using the above methods, the phenomena of asymmetric cavities, cavity pinch-off, double cavities and cavity ripples are observed in the wake region of the cylinder. Before the cavity pinches off, the hydrodynamic force driving the cylinder motion is generated from the pressure difference between the wet and dry parts. After pinch-off, the hydrodynamic force is mainly dominated by the induced lift, which depends on the angular speed, and a high-pressure region created by the pinch-off cavity causes an instantaneous impulse force that causes quick decreases in the cylinder accelerations. In addition, for the cylinder lift coefficient, the average rate of change increases almost linearly with an increasing initial angle of attack during water entry. For the drag coefficient, the average rate of increase rises nearly linearly with increasing absolute value of the initial angle of attack before pinch-off. After cavity pinch-off, this rate increases almost linearly with increasing |v0|/α0L.

Graphic abstract

Similar content being viewed by others

References

Barjasteh M, Zeraatgar H, Javaherian MJ (2016) An experimental study on water entry of asymmetric wedges. Appl Ocean Res 58:292–304

Bell GE (1924) On the impact of a solid spheres with a fluid surface. Phil Mag J Sci 48:753–765

Bergmann R, Meer VD, Devaraj G, Stephan BVD, Arjan LD (2009) Controlled impact of a disk on a water surface: cavity dynamics. J Fluid Mech 633:381–409

Bodily KG, Carlson SJ, Truscott TT (2014) The water entry of slender axisymmetric bodies. Phys Fluids 26:557–561

Chen C, Ma Q, Wei Y, Wang C (2018) Experimental study on the cavity dynamics in high-speed oblique water-entry. Fluid Dyn Res 50:045511

Chen C, Sun T, Wei Y, Wang C (2019) Computational analysis of compressibility effects on cavity dynamics in high-speed water-entry. Int J Nav Archit Ocean Eng 11:495–509

Derakhshanian MS, Haghdel M, Alishahi MM, Haghdel A (2018) Experimental and numerical investigation for a reliable simulation tool for oblique water entry problems. Ocean Eng 160:231–243

Duez C, Ybert C, Clanet C, Bocquet L (2007) Making a splash with water repellency. Nat Phys 3:180–183

El Malki AA, Nême A, Scolan YM (2015) Experimental investigation of hydrodynamic loads and pressure distribution during a pyramid water entry. J Fluids Struct 54:925–935

Enriquez OR, Peters IR, Gekle S, Schmidt LE, Lohse E, van der Meer D (2012) Collapse and pinch-off of a non-axisymmetric impact-created air cavity in water. J Fluid Mech 701:40–58

Epps BP, Truscott TT, Techet AH (2010) Evaluating derivatives of experimental data using smoothing splines, Lisbon, Portugal

Glasheen JW, Mcmahon TA (1996) A hydrodynamic model of locomotion in the Basilisk Lizard. Nature 380:340–342

Gonzalez RC, Woods RE, Eddins SL (2013) Digital image processing using MATLAB. McGraw Hill Education, New York

Grubbs FE (1950) Sample criteria for testing outlying observations. Ann Math Stat 21:27–58

Grumstrup T, Keller JB, Belmonte A (2007) Cavity ripples observed during the impact of solid objects into liquids. Phys Rev Lett 99:114502

Gu X, Moan T (2002) Long-term fatigue damage of ship structures under nonlinear wave loads. Mar Technol 39:95–104

Holland KT, Green AW, Abelev A, Valent PJ (2004) Parameterization of the in-water motions of falling cylinders using high-speed video. Exp Fluids 37:690–700

Hou Z, Sun T, Quan X, Zhang G, Sun Z, Zong Z (2018) Large eddy simulation and experimental investigation on the cavity dynamics and vortex evolution for oblique water entry of a cylinder. Appl Ocean Res 81:76–92

Hurd RC, Belden J, Jandron MA, Tate Fanning D, Bower AF, Truscott TT (2017) Water entry of deformable spheres. J Fluid Mech 824:912–930

Hurd RC, Belden J, Bower AF, Holekamp S, Jandron MA, Truscott TT (2019) Water walking as a new mode of free surface skipping. Sci Rep 9:6042

Korobkin A (2004) Analytical models of water impact. Eur J Appl Math 15:821–838

Louf J-F, Chang B, Eshraghi J, Chang B, Eshraghi J, Mituniewicz A, Vlachos PP, Jung S (2018) Cavity ripple dynamics after pinch-off. J Fluid Mech 850:611–623

Lu Z, Sun T, Wei Y, Cong W (2018) Experimental investigation on the motion feature of inclined water-entry of a semi-closed cylinder. Chin J Theor Appl Mech 2018:6

Lyu X, Wei Z, Tang H, New TH, Li L (2015) On the motion of a falling circular cylinder in flows after water entry. Int Soc Opt Photon 2015:930233

Mallock A (1918) Sounds produced by drops falling on water. Proc R Soc Lond 95:138–143

Mansoor MM, Marston JO, Vakarelski IU, Thoroddsen ST (2014) Water entry without surface seal: extended cavity formation. J Fluid Mech 743:295–326

Marston J, Truscott T, Mansoor M, Thoroddsen S (2016) Crown sealing and buckling instability during water entry of spheres. J Fluid Mech 794:506–529

May A (1952) Vertical entry of missiles into water. J Appl Phys 23:1362–1372

May A (1975) Water entry and the cavity-running behavior of missiles. In: Navsea Hydroballistics Advisory Committee Silver Spring Md

Moghisi M, Squire PT (1981) An experimental investigation of the initial force of impact on a sphere striking a liquid surface. J Fluid Mech 108:133–146

Panciroli R, Ubertini S, Minak G, Jannelli E (2015) Experiments on the dynamics of flexible cylindrical shells impacting on a water surface. Exp Mech 55:1537–1550

Rouse H, Mcnown JS (1948) Cavitation and pressure distribution: head forms at zero angle of yaw. Proactive Maint Mech Syst 20:169–191

Shams A, Zhao S, Porfiri M (2017) Hydroelastic slamming of flexible wedges: Modeling and experiments from water entry to exit. Phys Fluids 29:037107

Speirs NB, Pan Z, Belden J, Truscott TT (2018) The water entry of multidroplet streams and jets. J Fluid Mech 844:1084–1111

Stubbs SM (1967) Dynamic model investigation of water pressures and accelerations encountered during landings of the apollo spacecraft. In: World Bank Technical Paper

Thoroddsen ST, Etoh TG, Takehara K, Takano Y (2004) Impact jetting by a solid sphere. J Fluid Mech 499:139–148

Truscott TT, Techet AH (2009) Water entry of spinning spheres. J Fluid Mech 625:135–165

Truscott TT, Epps BP, Techet AH (2012) Unsteady forces on spheres during free-surface water entry. J Fluid Mech 704:173–210

Truscott TT, Epps BP, Belden J (2014) Water entry of projectiles. Annu Rev Fluid Mech 46:355–378

Vincent L, Xiao T, Yohann D, Jung S, Kanso E (2018) Dynamics of water entry. J Fluid Mech 846:508–535

Von Karman T (1929) The impact on seaplane floats during landing. In: Technical Report Archive & Image Library

Wang J, Lugni C, Faltinsen OM (2015) Analysis of loads, motions and cavity dynamics during freefall wedges vertically entering the water surface. Appl Ocean Res 51:38–53

Wei Z, Hu C (2014) An experimental study on water entry of horizontal cylinders. J Mar Sci Technol 19:338–350

Wei Z, Hu C (2015) Experimental study on water entry of circular cylinders with inclined angles. J Mar Sci Technol 20(4):722–738

Wei Z, Shi X, Wang Y, Xin Y (2010) The oblique water entry impact of a torpedo and its ballistic trajectory simulation. In: Zhang W, Chen Z, Douglas CC, Tong W (eds) High performance computing and applications. Springer, Berlin Heidelberg, pp 450–455

Worthington AM (1882) On impact with a liquid surface. Proc R Soc Lond 34:217–230

Xia W, Wang C, Wei Y, Li J (2019) Experimental study on water entry of inclined circular cylinders with horizontal velocities. Int J Multiph Flow 118:37–49

Acknowledgements

This work was supported by the National Natural Science Foundation of China (11672094).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations

Electronic supplementary material

Below is the link to the electronic supplementary material.

Appendices

Appendix: Image processing

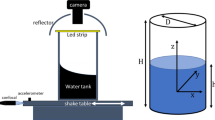

Digital image processing is an important branch of computer vision that can detect the edges and profile of an object according to a grayscale image. This method has been applied to extract the position of the water entry of a rigid body (Truscott and Techet 2009; Truscott et al. 2012; Wei and Hu 2015). To detect the trajectory and attitude angle of the cylinder in an image that has serious interference from the air cavity (Fig. 1), we develop an algorithm based on the grayscale gradient and implement the detection code in MATLAB. As shown in Fig. 17, the image processing includes image pretreatment, edge detection, center position and attitude angle calculations and refraction effect correction. To match the detection coordinate system to a two-dimensional matrix system in MATLAB, a Cartesian coordinate system is established as shown in Fig. 18.

taken from Fig. 26 at t = 120 ms

Schematic of the Cartesian coordinate system used for detecting the edge of the cylinder, where α is the transient attitude angle. The image is

Image pretreatment

Certain positioning coordinates on the edge of the cylinder have to be accurately detected in the image, such as the reference points and the ranges of the rows and columns of the moving cylinder. Inaccurate positioning coordinates may induce extraction error and even failure. In addition, the background noise easily interferes with the positioning information in the image. Therefore, it is necessary to erase the background noise before detecting the positioning coordinates. Note that our goal is to preserve the full morphology of the cylinder and cavity in processing and wipe out the background noise as much as possible. To improve the operation speed of the detection, a RGB image shot by a high-speed camera is first converted to a gray image f(x,y). This gray image includes the full morphological characteristics of the motion target. A classic algorithm for converting an image to grayscale is employed herein (Gonzalez et al. 2013).

where x and y are the row and column pixel coordinates of the image, respectively, and R, G and B represent the red, green and blue components in the original image, respectively. Because the images from the same case have the same background, a matrix Dsub(x,y) is obtained by an operation in which the original image matrix Y(x,y) is subtracted from the background image matrix B(x,y), where B(x,y) represents the image matrix when the cylinder has not entered the camera field of view.

Here, \(1 \le x \le H\) and \(1 \le y \le W\), where H and W are the row and column pixels of the image, respectively, and \(\left\{ {x,y \in I} \right\}\), where I is the set of natural numbers. The larger coordinate value in the difference matrix Dsub(x,y) includes the information of the detection target. However, the smaller value in matrix Dsub(x,y) represents the noise. To improve the resolution of the detection target, a power function is employed to suppress the smaller value and enlarge the larger value in Dsub(x,y); then, an enhanced matrix Denh(x,y) is obtained.

where p and q are constant, p = 0.8, and q = 1.05. Next, a binary matrix Dbin(x,y) is generated by picking a suitable truncated threshold fv with a value of 0.3.

The original image matrix Y(x,y) is multiplied by the binary matrix Dbin(x,y), as shown in Eq. (11), to obtain the clear image Yera(x,y), whose background noise has been erased.

Moreover, a clearer image can be obtained by modulating the image background with the following linear equation.

where Ib is the treated background image, the suppression value is sb = 0.94, and the enhanced value is eb = 0.7. An appropriate rebuilt image Ipaste is obtained by performing the following operation:

A comparison between images without and with image processing is shown in Fig. 19. By contrasting the cylinder profile, cavity shape, splash film and small bubbles, it is obvious that the characteristics of the moving target are completely preserved by our proposed method. The effect of erasing the background noise is significant. The rebuilt image Ipaste is compared in Fig. 19d. Moreover, the images presented in this paper are mostly processed by Eq. (13).

Edge detection

Line detection algorithms mainly include the line segment detector (LSD) and Hough transform. These algorithms are robust but ignore subpixel errors in line detection. Namely, the error of the line detection is at least ± 1 pixel, which may introduce an actual detection error es > ± 1.138 mm in our experiments. This error may induce a relatively large error in velocity that may reach the scale of the experimental velocity or greater. Consequently, we abandon the existing algorithms for line detection and propose a high-precision algorithm to detect the edge of the cylinder profile based on a step edge model.

3.1 Image splitting

The core of the step edge model is to detect the cylinder profile using the morphology gradient edge operator. Therefore, it is necessary to conduct an image interpolation operation to obtain subpixel precision for the edge of the cylinder. When the image is too large, such as in Fig. 19b, the interpolated image is an enlarged image with a huge amount of data, leading to a very high number of calculations needed in the following manipulation. Accordingly, we have to detect, position and split the moving target, so we need only to interpolate the split image.

In addition, the algorithm of the step edge model can obtain only a few points on the edge of the cylinder when the cylinder has a smaller inclined angle, especially when the cylinder is close to horizontal. This effect likely induces larger errors in calculating the trajectory and inclined angle of the cylinder. To improve the detection precision and reduce the calculation load, a MATLAB function, imrotate, is employed to rotate the original image Y and clear image Yera by a preset inclined angle α0. Moreover, an interpolation method, bicubic, is employed for interpolation when rotating the image. Then, an expected image in which the cylinder axis is almost vertical is obtained.

The reference points on the cylinder are first detected from the clear image before splitting with a rectangular window. In the clear images, there are sets of natural numbers \(I_{x} = \left\{ {x_{1} ,x_{2} , \ldots ,x_{H} } \right\}\) and \(I_{y} = \left\{ {y_{1} ,y_{2} , \ldots ,y_{W} } \right\}\) satisfying \(Y_{{{\text{era}}}} \left( {I_{x} ,I_{y} } \right) < 255\) for the morphological characteristics of the moving cylinder, where xH and yW are the height and the width of the image, respectively. An ordinate xbc near the center point of the bottom can be found by the following equation:

Similarly, there is a corresponding yxbc (\(y_{xbc} \in I_{y}\)) satisfying\(Y_{{{\text{era}}}} \left( {x_{bc} ,y_{xbc} } \right) < 255\), and the corresponding abscissa ybc is obtained.

Here, we set the width of the split image to three times the diameter of the cylinder. Based on the center point of the bottom of the cylinder, the ranges of the rectangular window, ordinates xw \(\left( {x_{w} \subset Ix} \right)\) and yw \(\left( {y_{w} \subset Iy} \right)\), can be calculated as:

where Dpixel is the cylinder diameter in the image before the cylinder impacts the free surface. As presented in Fig. 20, the cylinder is included in the split image Ycut. In this figure, (a) is the original image, (b) is the rotated image by the function imrotate, and (c) is the split image. These figures indicate that the moving cylinder can be split accurately by the above algorithm.

3.2 Detecting points on the edge

Before detecting the edge of the cylinder, the split image Ycut experiences a k order interpolation by function interp2 offered in MATLAB. The dimension of the interpolated image Yinp is substantially large because the dimension is 2k times that of Ycut. Hence, we detect only a limited number of points on the edge of the cylinder. In addition, according to the center point of the bottom in the interpolated image Yinp, Eq. (19) can be used to determine the distribution of the original points.

where ndet is the number of detection points, and Linp is the length of the cylinder in the interpolated image.

In our study, cubic interpolation, k = 3, is employed, and the number of interpolation points is ndet = 100. Figure 21 demonstrates the grayscale curves of the interpolated image for ndet = 10, where Wcut is the width of the interpolated image and G is the normalized gray value. At different locations, the grayscale curve presents a significant step at the edge of the cylinder. Therefore, the step edge model can be used to detect the edge of the cylinder with confidence.

In addition, the step edge model has a favorable feature for positioning the object edge. When the data have heavy noise interference, a large-size template can be used to smooth the data. The original function of the step edge model is presented as follows:

where c is the step edge. The positions of the double extrema of \(f^{\prime}\left( x \right)\) form the detection boundary. According to the features of the grayscale curve, a step function g(x) has to be constructed, where the range of the independent variable is \(x \in [0,3D_{{{\text{pixel}}}} ]\). In addition, the independent variable is \(x \in [0,\left( {L + 2D} \right)D_{{{\text{pixel}}}} /D]\) when we detect the point on the bottom edge.

where fup and fdown are the up and down thresholds of the gray value, respectively, and are defined in the following equations:

For the construction function g(x) in Eq. (21), the derivative function \(g^{\prime}(x)\) has a truncated step. Consequently, a MATLAB function, smooth, is used to smooth the data of g(x), and then, \(g^{\prime}(x)\) is obtained by taking the first derivative of g(x). The constructed function and the corresponding derivative are shown in Fig. 22, where the construction function is plotted in Fig. 22a and the corresponding first derivative is plotted in Fig. 22b. According to the variation in \(g^{\prime}(x)\) and using x = 0 as a demarcation line, it is easy to find that the first extreme points on the left and right are the detection points on the edge of the cylinder by the following equation:

where \(\, x_{{_{{{\text{ext}}}} }}^{i} \in \left\{ {\left[ {g^{\prime\prime}\left( x \right)} \right]^{i} = 0} \right\},i = 1,2, \ldots ,n_{{\det}}.\)

Constructed function g(x) a and corresponding derivative function \(g^{\prime}(x)\) b used to detect the points on the edge of the cylinder, where the data are the same as in Fig. 21

The points (xedge, yedge) detected in the interpolated image have to be translated to the scale of the rotated image by the following equation:

The points on either the cylinder right edge or left edge can be accurately detected through the above algorithm, and a standard deviation is employed to judge the optimal side or bottom. Moreover, the Grubbs criterion (Grubbs 1950) is applied to exclude data outliers on the edge of the bubble. In particular, when the cylinder is enveloped by the cavity, the left and right edges of the cylinder near the bottom should be preserved, and then, the center line is calculated between these two edges.

Position and attitude angle calculations

The split image is a part of the original image that has experienced an image rotation by the preset inclined angle α0. As a result, the sides and bottom of the cylinder are not strictly vertical and horizontal, respectively. To simplify the calculation of the center point and correct the attitude angle, a coordinate transformation, defined in Eq. (24), is performed on the detected points.

where \(\theta = - \;\arctan k_{l}\), where kl is the linear fitting slope of the detected points on the edge of the cylinder. Therefore, we obtain the ultimate attitude angle as follows:

In Fig. 23 shows the schematic diagram of the image-processing principle for detecting the cylinder center. For the cases where the length of the wet-surface edge is greater than 0.6 L, it is only necessary to translate the optimal side edge and the bottom edge by 0.5 Dpixel and 0.5 Lpixel to the cylinder region, respectively. The intersection of the translated lines is the cylinder center (Fig. 23a). When the cylinder is totally enveloped by the water-entry cavity or the length of the wet-surface edge is less than 0.4 L, the center line between the left and right edges of the cylinder is calculated. The center line passes through the center of the cylinder. And the bottom edge is translated by 0.5 Lpixel into the cylinder region. Then, the intersection of the center line and the translated bottom edge is the cylinder center (Fig. 23b). The ordinate of the cylinder center is obtained by an operation, defined in Eq. (26):

where npoint is the number of left points and kside is a parameter of the optimal side: when the left edge is adopted, this parameter is kside = 1; conversely, kside = − 1, and ncc is the parameter of the cylinder covered by the cavity: when the cylinder is enveloped by the cavity, this parameter is ncc = 0; conversely, ncc = 1. Similarly, we can calculate the abscissa as follows:

The center of the cylinder calculated by Eqs. (26) and (27) is first rotated and translated, and then the center position of the cylinder in the original image can be obtained using Eqs. (28) and (29).

where \({\varvec{\varUpsilon}}= \left[ {\begin{array}{*{20}c} {\cos \alpha_{0} } & {\sin \alpha_{0} } \\ { - \sin \alpha_{0} } & {\cos \alpha_{0} } \\ \end{array} } \right]\).

Refraction correction

Our algorithm can accurately detect the center of the cylinder from a sequence of images. However, the effect of the refraction effect on the center has to be corrected after the cylinder penetrates the free surface. Accordingly, a correction algorithm is used to correct the center position in this study, and the algorithm, defined in Eq. (30), has been applied to correct the extraction data for a water-entry problem (Lu et al. 2018).

where lc is the distance from the lens of the high-speed camera to the wall of the water tank, lt is the distance from the cylinder axis to the wall of the water tank, smeasure is the distance from the detection point to the lens coordinate, sreal is the real pixel distance of detection, and n is the refractive index. The constant parameters are lc = 1.02 m, lt = 0.5 m and n = 1.333. Note that lc and lt have to be translated into pixel dimensions since the coordinates of the cylinder center are in pixel dimensions. Eventually, the pixel coordinates of the cylinder center are multiplied by the pixel ratio D/Dpixel to obtain the real coordinates. Furthermore, the real coordinates are translated to right-handed coordinates.

The cylinder trajectories with and without correction are plotted in Fig. 24. The initial vertical and horizontal velocities of this cylinder are v0 = 2.36 m s−1 and u0 = 1.38 m s−1, respectively, and the initial inclined angle is α0 = 90.47°. The correction effect of the cylinder trajectory is favorable, and the corrected vertical and horizontal displacements are smaller than those without correction. In particular, when the center of the cylinder penetrates the water surface, the horizontal displacement sharply increases due to the refraction effect. The algorithm is proven to be powerful for correcting the trajectory.

Comparison of trajectories with (red dotted line) and without (black continuous line) index-of-refraction correction, where the vertical and horizontal displacements are normalized by the cylinder diameter D. The horizontal velocity, vertical velocity and initial inclined angle are v0 = 2.36 m s−1, u0 = 1.38 m s−1 and α0 = 90.47°, respectively

Error analysis

The displacement and attitude angle of the cylinder in the air are detected by our method, in which the initial inclined angle of the cylinder is α0 = 119° and the horizontal velocity is u0 = 0 m s−1, and this basis is used to analyze and compare the errors. Here, the first detected point in the raw data is regarded as the original point, and the corresponding parameters, including the time and horizontal and vertical displacements, are set to zero. In Fig. 25, the vertical and horizontal displacements and attitude angle are plotted with the corresponding fitting residuals. The detection results of the displacement and attitude angle are relatively stable.

The measurement errors are calculated by the formula \(\varepsilon = \sqrt {{{E_{{{\text{cr}}}} } \mathord{\left/ {\vphantom {{E_{{{\text{cr}}}} } {N\Delta t}}} \right. \kern-\nulldelimiterspace} {N\Delta t}}}\) (Epps et al. 2010), where N is the number of points, Δt is the time interval between neighboring points, and Ecr is the critical tolerance used in the quantic smoothing spline scheme. Table 2 provides the measurement errors of all the cases in our experiments. Note that the case in the previous paragraph is a repeat experiment that was conducted by Wei and Hu (2015). Here, the measurement errors of the trajectory and of the angle are ε = 0.041 mm and εα = 0.018°, respectively. These errors are much lower than the measurement error of the trajectory ε = 1.40 mm and angle εα = 0.4° in the study by Wei, who employed a template-matching method to detect the center and attitude angle of a cylinder. The results show the superiority of our proposed method for detecting the position and angle of the cylinder. Moreover, this method addresses object profiles with heavy interference from the impact cavity. Additionally, the detection precision is improved.

Validity analysis

The velocity and acceleration of the cylinder are determined by taking the first and second derivatives of the raw data detected with our algorithm, respectively. As is known, any measurement error of raw data is amplified when the finite difference method (u(t) = Δy/Δt) is employed to take a derivative. Therefore, an advanced fitting technology, a quintic smoothing spline scheme, with a certain critical error tolerance is proposed to fit the discrete data (Epps et al. 2010). This technology can obtain the most accurate smooth curve to represent the raw data with minimized roughness and at the same time minimize the effect of the measurement error.

To verify the accuracy of the detected raw data and the validity of the quintic smoothing spline fitting method, we conduct a large eddy simulation of the water entry of a cylinder with an initial horizontal velocity of u0 = 1.38 m s−1, a vertical velocity of v0 = 2.47 m s−1 and an inclined angle of α0 = 90.5°. Then, the results are compared with the experimental data. The details of the numerical simulation method are provided in the research of Hou et al. (2018). The impact cavities in the experiment and the simulation are presented in Fig. 26. The local structures of the cavity in the figure, such as the cavity size at each moment, evolution of the cavity crown, critical surface seal and deep seal, agree well with each other. The results demonstrate that the numerical simulation method is reliable.

In Fig. 27, time is taken as the abscissa, and certain experimental and numerical results, including x- and y- displacement, velocities and accelerations, attitude angle, angular speed and angular acceleration, are compared. Here, the experimental raw data of the displacement and attitude angle are directly compared, while the velocity, acceleration, angular speed and angular acceleration are determined by the quintic smoothing spline method to fit the raw data. The numerical results are exported from CFD software. As shown in these figures, the curves of the position and attitude angle of the experiment are smooth, which indicates the stability of the present detection method. In addition, the experiment and simulation agree well, which demonstrates the reliability of the detection, correction and quintic smoothing spline algorithms. However, the impact load cannot be captured well by our effort because of the extremely short duration of the impact load, for example, the vertical acceleration of the cylinder shown in Fig. 27.

Rights and permissions

About this article

Cite this article

Xia, W., Wang, C., Wei, Y. et al. Position detection method and hydrodynamic characteristics of the water entry of a cylinder with multidegree motion. Exp Fluids 61, 57 (2020). https://doi.org/10.1007/s00348-020-2887-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00348-020-2887-y