Abstract

We report on the characterization and first laser operation of ceramic Yb:LuScO3 in a thin-disk oscillator. The optical performance achieved with a ceramic Yb:LuScO3 disk is compared to the one obtained with an existing ceramic Yb:Lu2O3 disk for reference. The characterization covers the measurement of the fluorescence spectra, the fluorescence lifetimes, and nomarsky imaging. The investigation on the laser operation covers the measurement of resonator losses, output powers, and thermal behavior during continuous-wave operation in a multimode thin-disk oscillator. An average output power of 149 W and a slope efficiency of 51.8% were achieved with the ceramic Yb:LuScO3 disk which reached a maximum surface temperature of about 150 °C. At the same temperature level, a disk made of the already established ceramic Yb:Lu2O3 delivered 957 W of output power with a slope efficiency of 75.7%.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The development of Yb-doped sesquioxide ceramics for the use as gain media in thin-disk lasers has progressed steadily in the recent years.

Among the sesquioxides, the mixed sesquioxide Yb:LuScO3 offers a broad emission bandwidth of 22 nm [1] (see Table 1), making it a promising gain medium for achieving short pulse durations down to 74 fs [2]. However, due to the disordered crystal structure of Yb:LuScO3, this comes at the expense of the thermal conductivity, which merely amounts to 3.5 W/(m⋅K) [3].

The more established sesquioxide Yb:Lu2O3 offers superior thermal properties with a thermal conductivity of 12 W/(m⋅K) and a small quantum defect of only 5.6% [3]. Thus, Yb:Lu2O3 is suitable for high-power thin-disk oscillators with average output powers reaching into the kW-level [4], but its spectral emission bandwidth amounts to 13 nm [7] which is significantly smaller than that of Yb:LuScO3.

Both materials can be efficiently pumped at their zero-phonon absorption lines at wavelengths around 976 nm [3]. The main band for laser emission is reported to be centered around a wavelength of 1041 nm for Yb:LuScO3 and around a wavelength of 1034 nm for Yb:Lu2O3 [3].

When comparing previously reported average output powers from continuous-wave (cw) oscillators using ceramic Yb:LuScO3 and ceramic Yb:Lu2O3, the highest output power of 1.19 kW and a slope efficiency of 68.6% was demonstrated with ceramic Yb:Lu2O3 in a thin-disk oscillator [4]. With ceramic Yb:LuScO3, up to this date, the highest laser output power of 250 mW and a slope efficiency of 40.3% was achieved using a comparatively thick sample (2.6 mm) in a conventional oscillator [5].

In this letter we report on the performance of the first thin-disk oscillator based on ceramic Yb:LuScO3, which delivered an average output power of 149 W with a slope efficiency of 51.8%. For reference, the results are compared to those obtained with an existing ceramic Yb:Lu2O3 disk.

2 Disk characterization

2.1 Sample Preparation

A 5 at.% Yb:LuScO3 and a 4 at.% Yb:Lu2O3 polycrystalline ceramic disk were used. Both samples were fabricated by a combination of vacuum sintering and hot isostatic pressing of high-purity powders, similar to the approach described in [10].

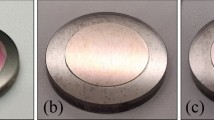

The ceramic Yb:LuScO3 disk was polished to a thickness of 100 µm and the ceramic Yb:Lu2O3 disk to 125 µm. Both samples were coated with an anti-reflective coating at their front face and a highly reflective coating at their rear face for both the pump and the laser wavelength. Subsequently each disk was glued with the highly reflective side on a water-cooled diamond heat sink (radius of curvature RoC = 3.8 m) for an efficient heat dissipation. A photograph of the mounted disks is shown in Fig. 1 a) and b). The ceramics are free of pores and the grain sizes range from 5 µm to 40 µm in diameter for both samples.

2.2 Fluorescence spectra

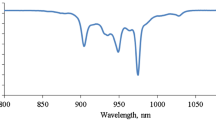

The fluorescence spectra were measured by pumping the disks with a cw diode laser with an emission centered at a wavelength of 976.5 nm. The pump beam was focused on the disks at an angle of incidence of 30°, with a spot size of 1 mm and a power density of 8 W/cm2. The emission spectra were recorded with a spectrometer covering the wavelength range between 900 and 1100 nm, coupled to a multimode fiber facing towards the disks at normal incidence. To separate the signal of the fluorescence from the pump radiation that is scattered at the sample, the pumping was interrupted by an optical chopper with a frequency of 1.5 kHz and the spectrum was recorded in the time between the pump pulses.

The peak-normalized spectra of both ceramic disks are shown in Fig. 2. The inset provides a detailed view of the peaks used for the laser emission. The main emission band of the ceramic Yb:LuScO3 was found to be centered at a wavelength of 1039 nm, while it was measured to be centered at 1033 nm for the ceramic Yb:Lu2O3. It is worth mentioning that the measured emission bands presented in this work are shifted to shorter wavelengths compared to the emission bands of the corresponding single crystals reported on in [3], see Tab 1. On the other hand, the emission spectra of Yb:LuScO3 and Yb:Lu2O3 single crystals shown by Beil et al. seem to be centered at 1039 nm and 1033 nm, respectively [6], which would be in agreement with the spectra presented here.

2.3 Fluorescence lifetime

To measure the fluorescence lifetime, the ceramic disks were excited with a cw diode laser emitting at a wavelength of 976.5 nm. The fluorescence decay signal was recorded immediately after turning off the pumping (falltime < 5 μs) using an ultrafast photodiode (falltime < 50 ps) and a spectral filter (transmission wavelength 1020 nm – 1040 nm). The resulting decay curves are shown in Fig. 3.

The fluorescence lifetime of the ceramic Yb:LuScO3 was measured to be 828 µs. Compared to the reported lifetime of single-crystalline Yb:LuScO3 of 850 µs [1], this is shorter by about 3%, but compared to the previously reported lifetime of 172 µs of ceramic Yb:LuScO3 [5], this manifests a significant improvement in the material quality of the sample.

The fluorescence lifetime of the ceramic Yb:Lu2O3 was measured to be 916 µs, which is 6% lower than the reported value of single-crystalline Yb:Lu2O3 of 975 µs [8].

2.4 Nomarski microscopy

The microstructural homogeneity of the refractive index of the ceramic disks was compared using Nomarski microscopy [11]. Since the surface of the samples is laser-grade polished, i.e. the physical thickness is constant across the sample, the Nomarski images shown in Fig. 4 reveal the variations of the refractive index in the disks.

Some of the grain boundaries are visible in the Nomarski image of the Yb:LuScO3 ceramic. This indicates a slight variation in the refractive index of the individual grains. In contrast, the Nomarski image of the Yb:Lu2O3 ceramic shows virtually no inhomogeneities. Note that both samples have similar grain sizes with diameters ranging from 5 µm to 40 µm.

The variations in the refractive index of the grains of the Yb:LuScO3 ceramic may result from different mixing ratios x of Lutetium and Scandium in the Yb:(LuxSc1-x)2O3 ceramic. The refractive indices of the pure sesquioxides Yb:Lu2O3 and Yb:Sc2O3 were reported to be \({n}_{{Lu}_{2}{O}_{3}} = 1.935\) and \({n}_{{Sc}_{2}{O}_{3}} = 1.994\), respectively, at a wavelength of 589.3 nm [12].

Regardless of the origin of the variations of the refractive index, the scattering that it causes during laser operation is expected to increase the losses in the resonator and thus lower the laser efficiency.

It is also worth noting that this variation in the refractive index is not peculiar to this individual sample, but applies to all Yb:LuScO3 ceramics available to us.

3 Laser experiments

The laser experiments were performed in cw multimode (MM) operation with the experimental setup shown in Fig. 5.

Setup for MM laser operation: Ceramic disks (green) mounted on a water-cooled diamond heat sink, pumping module and V-shaped laser cavity. For the sake of clarity, the drawing of the pump module does neither show all optical components nor the individual beam paths. Power meters (PM) are depicted in blue. The surface temperature of the disk was recorded with a thermal camera

The ceramic disks were mounted inside a multi-pass pumping module with 12 reflections of the pump light at the rear side of the disks. The diameter of the pump spot was 4.4 mm.

A spectrally-stabilized fiber-coupled diode laser with an output power of 2 kW and a 0.4 nm wide emission spectrum (FWHM) centered at a wavelength of 976.5 nm was used for pumping.

The absorption of the pump light after 12 reflections at the rear side of the disks was measured by inserting a thin uncoated glass plate at an angle of 45° into the beam path outside the pump module (see Fig. 5). The absorption at maximum pump power was measured to be 92% for the Yb:LuScO3 ceramic and 96.5% for the Yb:Lu2O3 ceramic.

The V-shaped laser cavity consisted of a highly reflective concave end mirror (radius of curvature RoC = 3 m), the disk (RoC = 3.8 m), and a plane output coupler (OC). Considering these values and the diameter of the pump spot, this cavity nominally generates a laser beam with a beam propagation factor of M2 ≈ 10.

3.1 Resonator losses

The resonator losses in cw MM operation were measured using the method introduced by Caird et al. [13], as shown in Fig. 6.

According to the model introduced by Caird et al. [14], the slope efficiency would increase continuously with increasing output coupling. However, this is not always true for Yb-doped laser media, as reported by Wolter et al. [15] in the case of Yb:YAG. The slope efficiencies presented in Fig. 6 at some point also decrease with increasing output coupling (symbols in brackets), which is why these data points were ignored for the linear fits.

The resonator losses given by the slope of the shown linear fits were found to be 0.46% for the Yb:Lu2O3 ceramic (which is consistent with a previously reported value of 0.48% [9]) and 2.1% for the Yb:LuScO3 ceramic. Since the other losses (such as scattering on the optical surfaces) in the resonator are typically much smaller, the significant difference in the measured losses are attributed mainly to scattering at the grain boundaries caused by their above-mentioned variation of the refractive index in the microstructure of the Yb:LuScO3 ceramic.

3.2 High-power multimode operation

For high-power MM operation, OCs with transmissions of 3% and 4% were used for the Yb:LuScO3 and Yb:Lu2O3 ceramics, respectively. These values of the output coupling resulted in the highest slope efficiencies for both disks, as shown in Fig. 6.

The laser output power and the optical efficiency is shown in Fig. 7 with respect to the absorbed pump power.

The spectra of the output beams are shown in the inset in Fig. 7, for both disks at their maximum output power. The laser emission was centered at 1039 nm for the Yb:LuScO3 ceramic and at 1033 nm for the Yb:Lu2O3 ceramic.

A maximum output power of 149 W and a slope efficiency of 51.8% were reached with the Yb:LuScO3 ceramic disk with a maximum pump power of 382 W. Since the temperature of the disk was close to 150 °C at this power, as shown in Fig. 8 and discussed in more details in the next Sect. 3.3, no further power increase was made to avoid thermally induced damage.

At the same temperature level, a maximum output power of 958 W and a slope efficiency of 75.7% was achieved with the Yb:Lu2O3 ceramic disk.

The lower slope efficiency of the Yb:LuScO3 ceramic in comparison to the Yb:Lu2O3 ceramic is attributed to the relatively high scattering losses.

3.3 Thermal behavior

The distribution of the surface temperature of both disks during MM operation was recorded with a thermal camera and is shown in Fig. 8. The insets show the thermal images of the disks at their maximum output power.

The temperature increase ΔT for a given increase of absorbed pump power ΔPabs (ΔT/ΔPabs) was obtained from the linear fits and amounts to 283 K/kW for the Yb:LuScO3 disk and to 82 K/kW for the Yb:Lu2O3 disk. Thus, the temperature rise of the Yb:LuScO3 ceramic is more than three times higher than that of the Yb:Lu2O3 ceramic.

The significant difference in the slopes ΔT/ΔPabs is partly attributed to the significant difference in the thermal conductivity of the two ceramics (see Tab. 1) and partly to parasitic processes such as non-radiative decay and scattering in the case of the Yb:LuScO3 ceramic. Further investigations will be pursued to identify the actual heating mechanisms and their corresponding contributions.

4 Conclusions

In summary, we have presented the first laser operation of an Yb:LuScO3 ceramic in a thin-disk oscillator in comparison to that of the already established ceramic Yb:Lu2O3. An output power of 149 W with a slope efficiency of 51.8% was achieved with the Yb:LuScO3 ceramic gain medium. The factors limiting the output power were found to be a reduced slope efficiency and an excessive temperature rise of the Yb:LuScO3 ceramic compared to the Yb:Lu2O3 ceramic.

The reduced slope efficiency is attributed to scattering losses induced by variations of the refractive index in the microstructure of the Yb:LuScO3 ceramic.

The excessive temperature rise is more than three times higher than for the Yb:Lu2O3 ceramic and is assumed to be subject to parasitic heating.

Further work will be dedicated to identify the scattering and heating mechanisms in both kinds of ceramics and in testing the Yb:LuScO3 ceramics in a mode-locked thin-disk oscillator.

Data availability

No datasets were generated or analysed during the current study.

References

R. Peters et al., A new mixed sesquioxide Yb: LuScO3: spectroscopic properties and highly efficient thin-disk laser operation. Advanced solid-state photonics (Optica Publishing Group, 2009)

A. Schmidt et al., Diode-pumped mode-locked Yb: LuScO3 single crystal laser with 74 fs pulse duration. Opt. Lett. 35(4), 511–513 (2010)

R. Peters et al., Thermal analysis and efficient high power continuous-wave and mode-locked thin disk laser operation of Yb-doped sesquioxides. Appl. Phys. B 102, 509–514 (2011)

S. Esser et al., Ceramic Yb:Lu2O3 thin-disk laser oscillator delivering an average power exceeding 1 kW in continuous-wave operation. Opt. Lett. 46(24), 6063–6066 (2021)

W. Jing et al., Spectroscopy and laser operation of highly-doped10 at.% Yb:(Lu, Sc)2O3 ceramics. Opt. Mater. 117, 111128 (2021)

K. Beil et al., Yb-doped mixed sesquioxides for ultrashort pulse generation in the thin disk laser setup. Appl. Phys. B 113, 13–18 (2013)

V. Petrov et al., Continuous-wave and mode-locked lasers based on cubic sesquioxide crystalline hosts. Laser source and system technology for defense and security II. Vol. 6216 (SPIE, 2006)

R. Peters et al., Crystal growth by the heat exchanger method, spectroscopic characterization and laser operation of high-purity Yb:Lu2O3. J. Cryst. Growth 310(7–9), 1934–1938 (2008)

S. Esser et al., Single-crystal and ceramic Yb:Lu2O3 gain media for thin-disk oscillators. Appl. Phys. B 129(10), 160 (2003)

D. Yin et al., Fabrication of Er:Y2O3 transparent ceramics for 2.7 µm mid-infrared solid-state lasers. J. Eur. Ceram. Soc. 40(2), 444–448 (2020)

W. Lang, Nomarski differential interference-contrast microscopy (Carl Zeiss, Oberkochen, 1982)

O. Medenbach et al., Refractive index and optical dispersion of rare earth oxides using a small-prism technique. J. Opt. A Pure Appl. Opt. 3(3), 174 (2001)

W. Wang et al., Broadening emission band of Yb: LuScO3 transparent ceramics for ultrashort pulse laser. J. Am. Ceram. Soc. 104(11), 6064–6073 (2021)

J. Caird et al., Quantum electronic properties of the Na3Ga2Li3F12:Cr3+ laser. IEEE J. Quantum Electron. 24(6), 1077–1099 (1988)

U. Wolters et al., Thermal Effects and Inversion Density in Yb:YAG Thin-Disk Lasers-Examination of Nonlinear Losses in Single Crystals and Ceramics Advanced Solid State Lasers. (Optica Publishing Group, London, 2013)

Funding

Open Access funding enabled and organized by Projekt DEAL. Deutsche Forschungsgemeinschaft (No. 410806665) and National Natural Science Foundation of China (No. 61861136007).

Deutsche Forschungsgemeinschaft, No. 410806665, No. 410806665, No. 410806665, National Natural Science Foundation of China, No. 61861136007, No. 61861136007.

Author information

Authors and Affiliations

Contributions

Stefan Esser performed all measurements and wrote the manuscript. Wei Jinga and Xiaodong Xu where involved in the fabrication of the ceramics. Thomas Graf and Marwan Abdou Ahmed assisted in the preparation of the manuscript. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Esser, S., Jing, W., Xu, X. et al. First thin-disk oscillator with ceramic Yb:LuScO3 in comparison to the operation with ceramic Yb:Lu2O3. Appl. Phys. B 130, 98 (2024). https://doi.org/10.1007/s00340-024-08231-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00340-024-08231-y