Abstract

Genetic algorithm was applied for optimization of dispersion properties in semiconductor Bragg reflectors for applications in femtosecond lasers. Broadband, large negative group-delay dispersion was achieved in the optimized design: The group-delay dispersion (GDD) as large as \(-3500\,\hbox {fs}^{2}\) was theoretically obtained over a 10-nm bandwidth. The designed structure was manufactured and tested, providing GDD \(-3320\,\hbox {fs}^{2}\) over a 7-nm bandwidth. The mirror performance was verified in semiconductor structures grown with molecular beam epitaxy. The mirror was tested in a passively mode-locked Yb:KYW laser.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Multiple applications of ultra-fast optics in physics, chemistry, biology, and medicine are driving force of extensive development of femtosecond lasers [1, 2]. For its efficient operation, such lasers require strong dispersion compensation elements, which are most efficiently realized with chirped mirrors [3]. Most such mirrors are based on dielectric materials due to their high refractive index contrast and high damage threshold. However, the high refractive index contrast results in low number of distributed Bragg reflector (DBR) pairs and, consequently, constant value of high negative GDD can be hard to achieve over a broad band (around 10 nm near the 1-µm wavelength) with such mirrors. On the other hand, semiconductor chirped mirrors have lower refractive index contrast and, thus, require more DBR pairs, which allows to provide better separation of reflection of different wavelengths and makes it easier to tune constant negative GDD over a broader band. In our previous works [4–6] we have demonstrated tunable semiconductor double-chirped mirrors with negative dispersion for applications in femtosecond lasers operating near 1 µm. We have fabricated them using arsenide-based molecular beam epitaxy (MBE), and with intentionally introduced layer thickness spatial gradient, we were able to make the mirror properties (reflectivity and dispersion) tunable over an 80-nm range across the mirror surface. We demonstrated tunable mode-locked femtosecond operation of an \(\hbox {Yb:KY}(\hbox {WO}_{4})_{2}\) diode-pumped laser oscillator at the 1035-nm wavelength.

We obtained negative group-delay dispersion (GDD), necessary for the femtosecond laser operation in the soliton regime, by using a double chirp of the mirror stack that resulted in different wavelengths being reflected at different depths within the semiconductor stack. In our mirror design, we followed classical approach, using an analytical formula [7]. However, to apply this formula we had to make a number of approximations [8], which resulted in a non-optimal mirror design. Hence, we have decided to focus our research on using exact numerical solutions of Maxwell equations and to perform computer optimization in order to achieve a structure with lower mean GDD spanning over a wider bandwidth with reduced oscillations.

Because of the large number of mirror layers that can be independently tuned by adjusting their thickness, such an approach—and the structure optimization in particular—is not a trivial task. Due to the large problem scale, a blind trial-and-error approach is not feasible. Instead, we may, e.g., use some general formula for the layer thickness and tune its coefficients using classical optimization techniques. This may be an efficient approach, although it does not allow for investigation of new designs beyond the chosen general formula. However, there exist a number of modern global approaches for such problems: simulated annealing [9], swarm intelligence [10] or genetic algorithms [11].

In this article we investigate the feasibility of one of these modern methods—namely genetic algorithm—to find mirror designs providing extremely high negative GDD, below \(-3000\) \(\hbox {fs}^{2}\). Similar approaches have been tried for optimization of chirped mirrors in the past [12, 13]; however, none of them allowed to obtain GDD and reflectivity levels comparable with our results.

In contrast to classical optimization methods, our genetic algorithm allows us to investigate the designs that significantly differ from the smooth chirp with only a minor change in the adjacent layer thickness. At the same time, it allows us to find certain patterns in the layers stack that exhibit the highly dispersive properties of the mirror and combine them together into the optimal structure.

2 Numerical design method

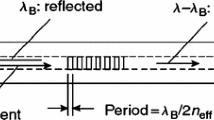

The main idea behind genetic algorithms is the analysis of a large population of chromosomes, i.e., the data representing the investigated problem. Such chromosome can be a sequence of digital bits, an array of numbers or, any other, more complex data structure. Proper choice of the chromosome representation is crucial for successful optimization. In the case of chromosome representing a Bragg mirror, it seems most natural to encode the thicknesses of each epitaxial layer in the mirror stack. This is not, however, the best approach as the reflecting properties of chirped mirrors are characterized by the Bragg numbers (defined as an inverse optical path length of one GaAs/AlAs pair) of all the pairs. Hence, such sequence of Bragg numbers seems to better represent the reflective characteristics of the stack. These Bragg numbers must be accompanied by the relative thickness of the GaAs and AlAs layers within each pair, to give the complete information on the mirror structure.

In our computations we have designed the chromosome as an array of two-element sets, one set per each GaAs/AlAs pair. The first number in the set is the optical path length of the layer pair \(\varLambda\) (inverse of the Bragg number), and the second one is the GaAs fill factor f ranging from 0 (only AlAs layer) to 1 (only GaAs)—Fig. 1a. During the optimization process, both these numbers can be freely varied with a constraint preventing very thin layers (below 4 nm) that are difficult to fabricate with high accuracy using molecular beam epitaxy (MBE) technique without additional calibration process of growth rates for layers of different thicknesses (i.e., growth rate of thick and thin layers differs). This constraint can be relaxed to layer thicknesses below 1 nm if the mentioned additional MBE calibration is performed or if other techniques—e.g., ion beam deposition [14]—are used.

a Schematic diagram of the chromosome representation of a particular mirror design. Each Bragg mirror pair is represented by its optical path length \(\varLambda\) and the GaAs/AlAs ratio f. b Offspring generation. Parts of two chromosomes are interchanged to produce two new members of the next generation

Calculated and measured a reflectivity and b group-delay dispersion of the optimized structure I (dotted lines in the subfigure (a) indicate the wavelength range used in (b)). A broad spectral band with calculated GDD varying between \(-\)2600 and \(-3200\,{\mathrm {fs}}^{2}\) is present; however, the measured GDD does not match the theoretical prediction and as such is not suitable for mode-locked laser

Calculated and measured a reflectivity and b group-delay dispersion of the optimized structure II (dotted lines in the subfigure (a) indicate the wavelength range used in (b)). GDD of this structure has a larger absolute value than in structure I; however, the oscillations are more pronounced (\(-\)3100 to \(-3800\,{\mathrm {fs}}^{2}\)). The measured GDD follows the characteristics of the theoretical one, despite smaller absolute value and the slight blue shift

In our numerical analysis the initial population consists of 1000 chromosomes designed analytically [7] for a constant GDD of \(-3000\,{\mathrm {fs}}^{2}\) in the band between 1030 and 1050 nm, each of them varied, by adding a random value, randomized with Gaussian distribution around 0 with standard deviation 300 nm for \(\varLambda\) and 0.25 for f. This way the calculations commence with sufficiently differentiated elements in the population that still have some relation to a moderately performing structure. The proper optimization with genetic algorithm is performed in the evolution process, where each chromosome is scored and either eliminated or multiplied according to its quality. Then, the next generation is being created by randomly grouping surviving chromosomes into 500 pairs, each of which produces two offsprings, i.e., new members of the next generation: Both chromosomes in the pair are cut in a randomly selected point, and the data representing \(\varLambda\) and f for the layers on both sides from the cutting point are exchanged within the pair. To increase the variety and to test a broad spectrum of the \(\varLambda\)-f pairs, the cutting points for \(\varLambda\) and f are chosen independently. The process is illustrated in Fig. 1b. After creating the offspring, some of the chromosomes are mutated randomly with a small probability of 2 %, which increases the variety and allows to find alternative solutions. The entire cycle is repeated 200 times. Because of the selection process in each generation, both the average and the best score of all of the chromosomes in the population increase. At the end of the evolution process, the best element that appeared through all iterations is chosen as the final optimization result.

To obtain the design of the mirrors with the desired properties, it is crucial to define a good scoring function. In the case of the high-dispersion Bragg mirrors three factors must be taken into account: (1) the maximum absolute value of the negative GDD that—for our mirror—was assumed to be at least \(-3000\,{\mathrm {fs}}^{2}\) [4]; (2) the bandwidth in which this large negative GDD does not oscillate by more than 20 %; and (3) the average value of the mirror reflectivity over the low GDD band, which must not fall below 99 %. This leads to three components of the scoring function, each of which is multiplied by a certain weight. The score for the factor (1) is the negated value of the average GDD in the analyzed range. However, during computing the mean, GDD values smaller than the cap value of 1.5 of the target GDD (which in different experiments varied between \(-\)3000 and \(-4000\,{\mathrm {fs}}^{2}\)) are ignored. The aim of such cap is to suppress the creation of very narrow dips with extremely high negative GDD, which may lead to the undesired oscillations. The score for the factor (2) is a variance of the computed GDD within the band of interest, taken with the negative sign (thus, the lower the variance, the higher the score). Finally, the criterion (3) is ensured by very large negative scoring assigned to all chromosomes that result in the mirror reflectivity lower than 98 % within the analyzed band.

The proper weights corresponding to each of these three scoring functions have to be determined experimentally. In our computations we tried a broad range of the weights. The optimal mirror structure that is presented in Sect. 3 has been obtained with the weight of 40 % for criterion (1) (high mean negative GDD) and 60 % for criterion (2) (low variance). The reflectivity criterion (3) is not considered in the weights as it rather acts as a pass/no-pass filter.

Genetic optimization was repeated few hundred times in total for various scoring weights and target GDD values. From all the optimized results, two mirror structures were selected and fabricated. Details of the epitaxial growth of the high-dispersion Bragg mirrors and their characterization may be found in [4, 5, 15]. The mirror structures were covered with a three-layer anti-reflective coating to avoid strong GDD oscillations, resulting from the intra-mirror cavity.

3 Results

The reflectivity and group-delay dispersion of the initial structure are shown in Fig. 2. In the first analytical approximation, the structure is far from optimized. The minimum GDD is not less than \(-2000\,{\mathrm {fs}}^{2}\), and the mirror fabricated according to this design would be inferior to our previous—manually tuned—structures [4, 5]. For the genetic algorithm, the exact properties of this initial structure are unimportant for the final optimized mirror. What matters is the variability of the first population which is ensured by a strong random alternation of the layer thicknesses and fill factors.

After few hundred repetitions of the genetic optimization, two similarly promising designs have been achieved. Their layer thicknesses are presented in Fig. 3. There is no visible regularity in the mirrors; however, some general rules can be found in both structures. The average total thickness of GaAs/AlAs pairs remains more or less constant through the whole mirror, while GaAs layer thicknesses increase with the layer number (starting from the mirror surface). The first GaAs layers tend to be very thin, i.e., the outer pairs are dominated by the AlAs material. This changes in the deeper parts of the mirrors, where the thicknesses of the GaAs and AlAs layers are comparable.

The most important results are the optical properties of the mirrors. It can be seen in Fig. 4 that they indeed meet the expectations. In both cases a significant plateau of GDD is observed, accompanied by the strong GDD drop at its long wavelength end. This plateau is the key factor for the femtosecond mode-locked laser oscillator performance in the soliton regime.

Both structure I and II were fabricated with the molecular beam epitaxy (MBE) and topped with a three-layer (SiN, \(\hbox {TiO}_{2}\), \(\hbox {SiO}_{2}\)) anti-reflective coating. The MBE is the most frequently used technique for semiconductor structures deposition. Due to high accuracy of 0.5 % and small layer roughness of 1–2 monolayers it is the most desirable technique to obtain chirped mirrors with smooth GDD spectral characteristics without oscillations. After manufacturing, the reflectivity and GDD have been measured for both structures (Fig. 5) using the same setups and methods as in our earlier works [4]. As for the reflectivity, the position of the sharp reflectivity dip around 1050 nm can be used to match the calculated and experimental layer thicknesses, as the latter can be proportionally scaled at different locations on the wafer. The spectral characteristics of GDD are much more sensitive to any non-uniformity than these of the reflectivity. In Fig. 5b the experimental GDD curve for the structure I differs from the theoretical values: The GDD spectrum is red-shifted with the minimum value higher than expected from the calculations. The most important feature, which unambiguously disqualifies the mirror for laser application, is the lacking GDD plateau around the lasing wavelength. Its likely reason is the inaccuracy in the mirror fabrication, probably of the anti-reflective coating rather than the epitaxial layers: The inaccuracy of the anti-reflective layers thickness is \(\pm 3\)–5 nm, while MBE roughness is of order of two molecular layers. In the case of the structure II, the measured GDD dependence is similar to the theoretical prediction except of a small blue shift. In the 1033–1040 nm range the GDD has a plateau with the variations of ±100 \(\hbox {fs}^{2}\). The minimum value is \(-\)3320 \(\hbox {fs}^{2}\), slightly lower than calculated.

In order to test the sensitivity of the mirror characteristics to fabrication errors, we have computed the change of the reflectivity and GDD spectral shape for structure II with the proportional change of the layer thicknesses. The results are presented in Fig. 6, where the calculated reflectivity and GDD are shown for all layer thicknesses varied from 97 to 100 % of the optimized values. Measured structure II GDD (Fig. 5b) reveals a shift toward shorter wavelengths of around 8 nm, which corresponds to the layer thickness reduced by 0.5 %, which is at the limit of the MBE technique accuracy.

Both mirrors have been tested in a femtosecond Yb:KYW laser with a standard X-type cavity, pumped with a 750-mW, 980-nm single-mode fiber-coupled laser diode [16]. Structure II provided stable, passive Kerr-lens mode-locked operation with more than 100 mW average output power. Pulses as short as 600 fs FWHM were measured with an interferometric autocorrelator, and the laser spectrum was centered at 1031 nm and spanned 2.5 nm (FWHM).

4 Conclusions

We have presented the application of genetic algorithm for numerical optimization of high-dispersion Bragg mirrors. This approach allowed us to obtain a structure with broadband reflectivity and GDD characteristics, suitable for femtosecond mode-locked laser operation. We investigated the importance of the scoring function choice, taking into account the average dispersion as well as its oscillations within the spectral band of interest.

Genetic algorithms are intrinsically heuristic methods, relying on random pairing and mutations of the chromosomes. They may find promising designs of the previously unknown form, but do not guarantee that the final solution will be the best one. In practice, it is usually better than the designs obtained with classical (analytical) methods. In our case this can be seen as a broadband flat region of the high negative GDD with suppressed oscillations in structure II.

Although the mirror structure is more complicated than the classical design and, hence, more difficult to fabricate, our approach enables novel designs with the properties previously inaccessible with classical methods.

References

S. Rivier, V. Petrov, A. Gross, S. Vernay, V. Wesemann, D. Rytz, U. Griebner, Diffusion bonding of monoclinic Yb:KY(WO4)2/KY(WO4)2 and its continuous-wave and mode-locked laser performance. Appl. Phys. Express 1, 112601 (2008)

U. Keller, K. Weingarten, F. Kartner, D. Kopf, B. Braun, I. Jung, R. Fluck, C. Honninger, N. Matuschek, J. Aus der Au, Semiconductor saturable absorber mirrors (SESAM’s) for femtosecond to nanosecond pulse generation in solid-state lasers. IEEE J. Sel. Top. Quantum Electron. 2, 435–453 (1996)

V. Pervak, C. Teisset, A. Sugita, S. Naumov, F. Krausz, A. Apolonski, High-dispersive mirrors for femtosecond lasers. Opt. Express 16, 10220–10233 (2008)

A. Jasik, M. Dems, P. Wnuk, P. Wasylczyk, A. Wójcik-Jedlińska, K. Regiński, L. Zinkiewicz, K. Hejduk, Design and fabrication of highly dispersive semiconductor double-chirped mirrors. Appl. Phys. B Lasers Opt. 116, 141–146 (2013)

A. Jasik, P. Wasylczyk, M. Dems, P. Wnuk, A. Wójcik-Jedlińska, K. Regiński, L. Zinkiewicz, K. Hejduk, A passively mode-locked, self-starting femtosecond Yb:KYW laser with a single highly dispersive semiconductor double-chirped mirror for dispersion compensation. Laser Phys. Lett. 10, 085302 (2013)

P. Wnuk, P. Wasylczyk, L. Zinkiewicz, M. Dems, K. Hejduk, K. Reglińskiski, A. Wójcik-Jedlińska, A. Jasik, Continuously tunable Yb:KYW femtosecond oscillator based on a tunable highly dispersive semiconductor mirror. Opt. Express 22, 18284–18289 (2014)

N. Matuschek, F. Kartner, U. Keller, Analytical design of double-chirped mirrors with custom-tailored dispersion characteristics. IEEE J. Quantum Electron. 35, 129–137 (1999)

N. Matuschek, F. Kartner, U. Keller, Theory of double-chirped mirrors. IEEE J. Sel. Top. Quantum Electron. 4, 197–208 (1998)

S. Kirkpatrick, C.D. Gelatt, M.P. Vecchi, Optimization by simulated annealing. Science 220, 671–680 (1983)

K. Parsopoulos, M. Vrahatis, Nat. Comput. 1, 235–306 (2002)

D.E. Goldberg, Genetic Algorithms in Search, Optimization, and Machine Learning (Addison-Wesley Publishing Company, Boston, 1989)

V. Yakovlev, G. Tempea, Optimization of chirped mirrors. Appl. Opt. 41, 6514–6520 (2002)

A. Wonisch, U. Neuhäusler, N.M. Kabachnik, T. Uphues, M. Uiberacker, V. Yakovlev, F. Krausz, M. Drescher, U. Kleineberg, U. Heinzman, Design, fabrication, and analysis of chirped multilayer mirrors for reflection of extreme-ultraviolet attosecond pulses. Appl. Opt. 45, 4147–4156 (2006)

A. Guggenmos, R. Rauhut, M. Hofstetter, S. Hertrich, B. Nickel, J. Schmidt, E.M. Gullikson, M. Seibald, W. Schnick, U. Kleineberg, Aperiodic CrSc multilayer mirrors for attosecond water window pulses. Opt. Express 21, 21728–21740 (2013)

A. Jasik, P. Wasylczyk, P. Wnuk, M. Dems, A. Wojcik-Jedlinska, K. Reginski, L. Zinkiewicz, K. Hejduk, Tunable semiconductor double-chirped mirror with high negative dispersion. IEEE Photonics Technol. Lett. 26, 14–17 (2014)

P. Wasylczyk, C. Radzewicz, Design and alignment criteria for a simple, robust, diode-pumped femtosecond Yb:KYW oscillator. Laser Phys. 19, 129 (2009)

Acknowledgments

This work was partially supported by the National Centre for Research and Development (NCBiR) under Project 02-0009-10/2011. P. Wnuk acknowledges a Mobility Plus fellowship from the Polish Ministry of Science and Higher Education.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Dems, M., Wnuk, P., Wasylczyk, P. et al. Optimization of broadband semiconductor chirped mirrors with genetic algorithm. Appl. Phys. B 122, 266 (2016). https://doi.org/10.1007/s00340-016-6540-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00340-016-6540-7