Abstract

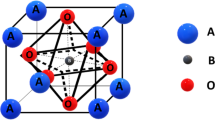

In pursuing enhanced performance for electronic applications, we synthesized ferroelectric materials, specifically Ba(1-x)Nd2x/3TiO3 (BNdTx) nanoceramics, utilizing solid-state reaction techniques coupled with microwave heating treatment. Our investigation involved varying Nd3+-doping levels (x = 0%, 2%, 4%, and 8%) to tailor the material's properties. XRD analysis confirmed the presence of a single-phase tetragonal perovskite structure (space group P4mm). A comprehensive examination of the partial density of states for both undoped and Nd3+-doped BaTiO3 was undertaken to discern the impact of Nd3+-doping on the energy bands. Microscopic analysis revealed the presence of pores in the samples, accompanied by a reduction in grain size with increasing Nd3+ content. The introduction of Nd3+ induced a shift in the Curie temperature (TC) towards room temperature. Simultaneously, the dielectric characteristics exhibited a consistent value above 1900, with a low loss of less than 5% observed across a range of temperatures (30–100 °C). Notably, the sample with x = 4% demonstrated thermally stable dielectric properties, suggesting its potential suitability as a material for Multilayer Ceramic Capacitor (MLCC) applications.

Graphical abstract

Integrating microwave sintering and ball milling techniques is a significant development in advanced materials engineering, specifically in producing Multi-Layer Ceramic Capacitors (MLCC). The practical implementation of these novel methodologies is essential in decreasing particle size, which is a critical determinant in improving thermal stability. Ball milling further refines the particle size distribution, whereas microwave sintering guarantees a more uniform and fine-grained microstructure through its rapid and effective heating capabilities. The capacitors acquire enhanced thermal stability and a more refined material granularity through this synergistic combination. By achieving a more uniform and compact ceramic structure, these processes result in a finer particle size, enhancing the overall performance and dependability of MLCC capacitors. The increasing need for miniaturized and high-performance electronic components has focused on utilizing microwave sintering and ball milling. These processes are at the forefront of technological advancements in the pursuit of improved thermal properties and increased efficiency in manufacturing MLCC capacitors.

Similar content being viewed by others

Data availability

The data used in this article is confidential and analyzed in this manuscript.

References

K. Laadjal, A.J.M. Cardoso, Electronics 12(6), 1297 (2023)

J. Chun, J. Heo, K.S. Lee, B.U. Ye, B.S. Kang, S.-H. Yoon, Sci. Rep. 14, 616 (2024)

M. Feng, Yu. Feng, T. Zhang, J. Li, Q. Chen, Q. Chi, Q. Lei, Adv. Sci. 8(23), 2102221 (2021)

D. Shi, D. Liu, L. Zhao, Qi. Wang, T. Tang, X. Long, L. Yan, B.-P. Zhang, He. Qi, L.-F. Zhu, Chem. Eng. J. 479, 147672 (2024)

Z. Lv, T. Lu, Z. Liu, T. Hu, Z. Hong, S. Guo, Z. Xu et al., Adv. Energy Mater. 2304291 (2024)

W. Dutta, C. Reece, A. Mallik, IET Power Electron. (2023). https://doi.org/10.1049/pel2.12608

J. Torki, C. Joubert, A. Sari, J. Energy Storage 58, 106330 (2023)

P. Yousefian, A. Sepehrinezhad, A.C.T. van Duin, C.A. Randall, APL Mach. Learn. 1, 036107 (2023)

Y. Xiao, Y. Yang, S. Yang, J. Li, D. Liu, Wu. Jie, M. Wang, C. Li, F. Li, Int. J. Appl. Ceram. 20(6), 3735–3742 (2023)

P. Zan, Y. Long, Pu. Linyu, Xu. Huang, J. Liu, J. Mater. Sci. Mater. Electron. 35, 23 (2024)

Y. Wang, Z. Peng, J. Wang, J. Liu, B. Chen, Q. Chai, S. Dang, Z. Zhai, P. Liang, X. Chao, Z. Yang, Ceram. Int. 50(9), 15569–15576 (2024)

W.H. Lee, C.Y. Su, J. Am. Ceram. Soc. 90, 3345–3348 (2007)

Y. Wang, K. Miao, W. Wang, Y. Qin, J. Eur. Ceram. Soc. 37(6), 2385–2390 (2017)

C.H. Kim, K.J. Park, Y.J. Yoon, M.H. Hong, J.O. Hong, K.H. Hur, J. Eur. Ceram. Soc. 28, 1213–1219 (2008)

S. Sumithra, K. Annapoorani, A. Ellmore, B. Vaidhyanathan, Open Ceram. 9, 100214 (2022)

T. Fan, C. Ji, G. Chen, W. Cai, R. Gao, X. Deng, Z. Wang, C. Fu, Mater. Chem. Phys. 250, 123034 (2020)

W. Hu, Z. Chen, Z. Lu, X. Wang, X. Fu, Ceram. Int. 47(17), 24982–24987 (2021)

H.S. Yun, B.G. Yun, H.M. Lee et al., SN Appl. Sci. 1, 1366 (2019)

L. Chen, H. Wang, P. Zhao, Z. Shen, C. Zhu, Z. Cen, L. Li, X. Wang, J. Am. Ceram. Soc. 102(5), 2781–2790 (2019)

S. Sato, Y. Nakano, A. Sato, T. Nomura, J. Eur. Ceram. Soc. 19(6–7), 1061–1065 (1999)

L. Li, J. Yu, Y. Liu, N. Zhang, J. Chen, Ceram. Int. 41(7), 8696–8701 (2015)

M. Wang, K. Xue, K. Zhang, L. Li, Ceram. Int. 48(15), 22212–22220 (2022)

Y. Wang, B. Cui, Y. Liu, X. Zhao, Z. Hu, Q. Yan, T. Wu, L. Zhao, Y. Wang, Scr. Mater. 90–91, 49–52 (2014)

F.D. Morrison, D.C. Sinclair, A.R. Int, J. Inorg. Mater. 3, 1205–1210 (2001)

M. Ganguly, S. Rout, T. Sinha, S. Sharma, H. Park, C. Ahn, I. Kim, J. Alloys Compd. 579, 473–484 (2013)

Z. Yao, H. Liu, Y. Liu, Z. Wu, Z. Shen, Y. Liu, M. Cao, Mater. Chem. Phys. 109, 475–481 (2008)

A.S. Shaikh, R.W. Vest, J. Am. Ceram. Soc. 69, 689–694 (1986)

T.R.N. Kutty, P. Murugaraj, J. Mater. Sci. 22, 3652–3664 (1987)

S.B. Desu, D.A. Payne, J. Am. Ceram. Soc. 73, 3407–3415 (1990)

M.H. Aleinawi, A.U. Ammar, M. Buldu-Akturk, N.S. Turhan, S. Nadupalli, E. Erdem, J. Phys. Chem. C 126(8), 4229–4240 (2022)

S. Mahboob, A. Dutta, C. Prakash, G. Swaminathan, S. Suryanarayana, G. Prasad, G. Kumar, Mater. Sci. Eng. B 134(1), 36–40 (2006)

S. Mahboob, G.R. Prasad et al., Bull. Mater. Sci. 42, 30 (2019)

M.T. Buscaglia, V. Buscaglia, M. Viviani, P. Nanni, J. Am. Ceram. Soc. 84(2), 376–384 (2001)

J. Gardner, F.D. Morrison, Dalton Trans. 43, 11687–11695 (2014)

Z. Yu, C. Ang, R. Guo, Mater. Lett. 61, 326 (2007)

M.S. Alkathy, K.K. Bokinala, K.C. James Raju, J. Mater. Sci. Mater. Electron. 27, 3175–3181 (2016)

M. Tihtih, J.E.F.M. Ibrahim, E. Kurovics, L.A. Gömze, Cryst. Res. Technol. 57, 2100106 (2022)

M. Tihtih et al., ACS Omega 8, 8448–8460 (2023)

S. Mustapha, M.M. Ndamitso, A.S. Abdulkareem, J.O. Tijani, D.T. Shuaib, A.K. Mohammed, A. Sumaila, Adv. Nat. Sci. Nanosci. Nanotechnol. 10, 045013 (2019)

G. Schiller, L. Huisman, A. Ferreira, M. Deluca, K. Reichmann, Structure-property relationships in BaTiO3-BiFeO3–BiYbO3 ceramics. J. Eur. Ceram. Soc. 33, 1457–1468 (2013)

F. Maxim, P. Ferreira, P.M. Vilarinho, I. Reaney, Hydrothermal synthesis and crystal growth studies of BaTiO3 using Ti nanotube precursors Cryst. Growth Des 8(9), 3309–3315 (2008)

Y. Shiratori, C. Pithan, J. Dornseiffer, R. Waser, Raman scattering studies on nanocrystalline BaTiO3 Part I-isolated particles and aggregates. J. Raman Spectrosc. 38(10), 1288–1299 (2007)

Y. Shiratori, C. Pithan, J. Dornseiffer, R. Waser, Raman scattering studies on nanocrystalline BaTiO3 Part II-consolidated polycrystalline ceramics. J. Raman Spectrosc. 38, 1300–1306 (2007)

V. Pal, O.P. Thakur, R.K. Dwivedi, Investigation of MPB region in lead-free BLNT-BCT system through XRD and Raman spectroscopy. J. Phys. D Appl. Phys. 48, 05530 (2015)

J. Kreisel, A.M. Glazer, G. Jones, P.A. Thomas, L. Abello, G. Lucazeau, J. Phys. Condens. Matter 12, 3267 (2000)

J. Kreisel, A.M. Glazer, P. Bouvier, G. Lucazeau, High-pressure Raman study of a relaxor ferroelectric: the Na0.5Bi0.5TiO3 perovskite. Phys. Rev. B (2001). https://doi.org/10.1103/PhysRevB.63.174106

M.S. Alkathy, M.H. Lente, J. Eiras, Mater. Chem. Phys. 257, 123791 (2021)

S. Sasikumar, T.K. Thirumalaisamy, S. Saravanakumar et al., J. Mater. Sci. Mater. Electron. 31, 1535–1546 (2020)

R.D. Shannon, Acta Crystallogr. 32(5), 751–767 (1976)

C.C. Parhi et al., ACS Omega 8(41), 37752–37768 (2023)

M. Saleem, M.S. Butt, A. Maqbool, M.A. Umer, M. Shahid, F. Javaid, R.A. Malik, H. Jabbar, H.M. Waseem Khalil, L.D. Hwan, M. Kim, B. Koo, S. Jeong, J. J. Alloys Compd. 822, 153525 (2020)

M. Mostafa, M.J. Rahman, S. Choudhury, Sci. Eng. Compos. Mater. 26(1), 62–69 (2019)

A. Semenov et al., Materials 12(21), 3592 (2019)

K. Manfred, J. Am. Ceram. Soc. 54, 455 (1971)

T.M. Harkulich, J. Magder, M.S. Vukasovich, R.J. Lockhart, J. Am. Ceram. Soc. 49(6), 295 (1966)

A. Yamaji, Y. Enomoto, K. Kinoshita, T. Mrakami, J. Am. Ceram. Soc. 60, 97 (1977)

M. Kahn, J. Am. Ceram. Soc. 54, 452 (1971)

D.A. Payne, H.U. Anderson, J. Am. Ceram. Soc. 50, 491 (1967)

A.C. Caballero, J.C. Fernandez, C. Moure, P. Duran, J. Eur. Ceram. Soc. 17, 513 (1997)

G. Arlt, D. Hennings, G. de With, J. Appl. Phys. 58, 1619 (1985)

W.R. Buessem, L.E. Cross, A.K. Goswami, J. Am. Ceram. Soc. 49, 33 (1966)

W.R. Buessem, L.E. Cross, A.K. Goswami, J. Am. Ceram. Soc. 49, 36 (1966)

A.J. Bell, A.J. Moulson, L.E. Cross, Ferroelectrics 54, 147 (1984)

M.S. Alkathy, J.A. Eiras, F.L. Zabotto et al., J. Mater. Sci. Mater. Electron. 32, 12828–12840 (2021)

S. Hu, C. Luo, P. Li et al., J. Mater. Sci. Mater. Electron. 28, 9322–9327 (2017)

B. Sandeep, K.R. Kambale, A. Ghorpade, A. Halikar, R. Gaikwad, H. Panda, J. Asian Ceram. Soc. 7(4), 407–416 (2019)

Q. Yin, B. Zhu, H. Zeng, Microstructure Property and Processing of Functional Ceramics (Springer, Berlin, 2010)

Y. Park, W.-J. Lee, H.-G. Kim, J. Condens. Matter Phys 9(43), 9445 (1997)

Y. Park et al., J. Phys. 9, 9445 (1997)

K. Keizer, A.J. Burggraaf, Phys. Status Solidi A 3, 561 (1974)

Z. Zhao, V. Buscaglia, M. Viviani et al., Phys. Rev. B 70, 024107 (2004)

W. Hu, X. Tan, K. Rajan, J. Eur. Ceram. Soc. 31, 801–807 (2011)

R.E. Eitel, C.A. Randall, T.R. Shrout et al., Jpn. J. Appl. Phys. 40, 5999–6002 (2001)

T. Leist, T. Granzow, W. Jo, J. Rödel, J. Appl. Phys. 108, 014103 (2010)

M.S. Alkathy, K.C. JamesRaju, J. Electroceram. 38, 63–73 (2017)

Z. Li, J. Yu, S. Hao, P. Janolin, J. Eur. Ceram. Soc. 42(12), 4693–4701 (2022). https://doi.org/10.1016/j.jeurceramsoc.2022.05.023

V.F. Michel, T. Esswein, N.A. Spaldin, J. Mater. Chem. C 9(27), 8640–8649 (2021)

C. Ludt, D.C. Meyer, M. Zschornak, Materials 17(5), 1023 (2024)

A. Rani, J. Kolte, P. Gopalan, Ceram. Int. 41(10), 14057–14063 (2015)

X. Guo, Y. Sun, L. Liu, Z. Yu, J. Liu, Int. J. Appl. Ceram. (2024). https://doi.org/10.1111/ijac.14666

H. Wu, W. Cai, Z. Liu, D. Chen, R. Gao, G. Chen, X. Deng, Z. Wang, X. Lei, C. Fu, Ceram. Int. 50(4), 6845–6853 (2024)

A. Thakre, A. Kumar, M.-Y. Lee, D.R. Patil, S.-H. Kim, J. Ryu, J. Mater. Chem. C 9(10), 3403–3411 (2021)

A. Kumar, S.R. Emani, K.C. James Raju, J. Ryu, A.R. James, Energies 13(23), 6457 (2020)

V. Polinger, P. Garcia-Fernandez, I. Bersuker, Phys. B Condens. Matter. 457, 296–309 (2015)

B.W. Zhou, J. Zhang, X.B. Ye, G.X. Liu, X. Xu, J. Wang, Z.H. Liu et al., Phys. Rev. Lett.. Lett. 130, 146101 (2023)

Y. Zhou, S. Dong, C. Shan, K. Ji, J. Zhang, Phys. Rev. B 105, 075408 (2022)

S.Y. Chen, R. Liu, Y.P. Zheng, Y.J. Shi, S.T. Dang, Y.C. Shi, F. Yang et al., J. Alloys Compd. 936, 168015 (2023)

P. Bhatt, A. Kumar, C. Ritter, S.M. Yusuf, J. Phys. Chem. C 124, 19228–19239 (2020)

Acknowledgements

The authors express their sincere gratitude for the financial support provided by the Sao Paulo Research Foundation (FAPESP: Grant no. 2017/13769-1) and (FAPESP: Grant no. 2023/05716-6). Dr. Mansor thanks the researchers supporting project number (RSP2024R393) at King Saud University in Riyadh, Saudi Arabia, for his financial support. Prof. K.C James Raju acknowledges the funds received from the Institution of Eminence (IoE) program under sanction number UoH/IoE/RC1/RC1-20-013.

Author information

Authors and Affiliations

Contributions

Mahmoud Alkathy: Writing, Correction, formal analysis, and original draft preparation. Flavio Paulo Milton: investigator. Mansour K. Gatasheh: Resources. Fabio Zabotto: Investigator. H. A. Kassim: Synthetization, Methodology, SEM measurements, and Formal Analysis. Prof. James Raju: Supervise and correct the original draft. Prof Jose Eiras: Correctional, supervision, and approval of the final version.

Corresponding author

Ethics declarations

Conflict of interest

The authors confirm no conflict of interest or competing interest in this work.

Ethical statement

This article contains no studies with human participants or animals performed by authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Alkathy, M.S., Milton, F.P., Gatasheh, M.K. et al. Enhancing dielectric properties and thermal stability in microwave-synthesized Nd-modified barium titanate nanoceramics for possible MLCC applications. Appl. Phys. A 130, 402 (2024). https://doi.org/10.1007/s00339-024-07566-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-024-07566-9