Abstract

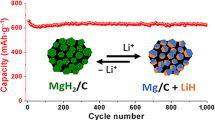

Magnesium batteries provide a promising alternative to traditional energy storage solutions due to their impressive energy density, potential safety features, and cost-effectiveness, making them highly suitable for large-scale applications. The solid state synthesis of MgCoSiO4 is reported in this work. The produced magnesium cobalt silicate nanoparticles are treated with 450 V of DC glow discharge plasma for 15 min of exposure time. The novel aspect of the MgCoSiO4 material generated in a solid state is highlighted in this research work. This material underwent plasma treatment, which changed its surface and improved its performance. Through testing and investigation, these modifications resulted in increased conductivity and overall electrode material efficiency, demonstrating the substantial influence of the treatment material functionality. It enhances the electrochemical characteristics by altering the surface energies, adhesion, and wettability. Thus the as prepared sample was made as the electrode material for further investigation. The sample’s structural, morphological, and chemical makeup was examined using XRD, FTIR, FESEM and wettability. Owning to the exclusive sponge-like morphology and more porous air plasma treated MgCoSiO4 electrode displays higher specific capacitance of 1232 F/g than the pure 296 F/g which can also exhibit 89% of capacitance retention after 6000 cycles. These results suggests that the MgCoSiO4 electrode material treated with air plasma is appropriate for use in energy storage applications.

Similar content being viewed by others

Data availability

The data that has been used in the manuscript is confidential.

Abbreviations

- MgCoSiO4 :

-

Magnesium cobalt silicate

- DC:

-

Direct current

- XRD:

-

X-Ray diffraction

- FTIR:

-

Fourier transforms infrared spectroscopy

- FESEM:

-

Field emission scanning electron microscope

- EDAX:

-

Energy dispersive X-Ray analysis

- F/g:

-

Farad per gram

- Mg:

-

Magnesium

- Li:

-

Lithium

- Na:

-

Sodium

- K:

-

Kelvin

- SiO:

-

Silicon oxide

- SHE:

-

Standard hydrogen electrode

- mAH/g:

-

Milli amps hour per gram

- Mg2So4 :

-

Magnesium sulfate

- MgO:

-

Magnesium oxide

- Co3O4 :

-

Cobalt oxide

- SiO2 :

-

Silicon dioxide

- PVDF:

-

Polyvinidene difluroide

- NMP:

-

N-Methyl2-pyrolidine

- Ag:

-

Silver

- AgCl:

-

Silver chloride

- CV:

-

Cyclic voltammetry

- EIS:

-

Electrochemical impedance spectroscopy

- GCD:

-

Galvanostatic charge discharge

- FWHM:

-

Full width half maximum

- Co:

-

Cobalt

- Si:

-

Silicon

- KOH:

-

Potassium hydroxide

- NaOH:

-

Sodium hydroxide

- Rs:

-

Polarization resistance

- Rct:

-

Charge transfer resistance

References

S.A. Bello et al., Eggshell nanoparticle reinforced recycled low-density polyethylene: a new material for automobile application. J. King Saud Univ. Eng. Sci. 35(6), 406–414 (2023). https://doi.org/10.1016/j.jksues.2021.04.008

Y. Nuli, J. Yang, Y. Li, J. Wang, Mesoporous magnesium manganese silicate as cathode materials for rechargeable magnesium batteries. Chem. Commun. 46(21), 3794–3796 (2010). https://doi.org/10.1039/c002456b

S. Ranjan et al., Nanoscience and nanotechnologies in food industries: opportunities and research trends. J. Nanoparticle Res. (2014). https://doi.org/10.1007/s11051-014-2464-5

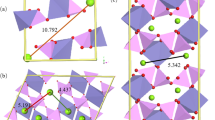

J. Heath, H. Chen, M.S. Islam, MgFeSiO4 as a potential cathode material for magnesium batteries: Ion diffusion rates and voltage trends. J. Mater. Chem. A 5(25), 13161–13167 (2017). https://doi.org/10.1039/c7ta03201c

R. Dastjerdi, M. Montazer, S. Shahsavan, A new method to stabilize nanoparticles on textile surfaces. Colloids Surfaces A Physicochem. Eng. Asp. 345(1–3), 202–210 (2009). https://doi.org/10.1016/j.colsurfa.2009.05.007

P. Saha, M.K. Datta, O.I. Velikokhatnyi, A. Manivannan, D. Alman, P.N. Kumta, Rechargeable magnesium battery: current status and key challenges for the future. Prog. Mater. Sci. 66, 1–86 (2014). https://doi.org/10.1016/j.pmatsci.2014.04.001

R. Shah, V. Mittal, E. Matsil, A. Rosenkranz, Magnesium-ion batteries for electric vehicles: current trends and future perspectives. Adv. Mech. Eng. 13(3), 1–9 (2021). https://doi.org/10.1177/16878140211003398

D.Y. Kim, Y. Lim, B. Roy, Y.G. Ryu, S.S. Lee, Operating mechanisms of electrolytes in magnesium ion batteries: chemical equilibrium, magnesium deposition, and electrolyte oxidation. Phys. Chem. Chem. Phys. 16(47), 25789–25798 (2014). https://doi.org/10.1039/c4cp01259c

M. Asif, S. Kilian, M. Rashad, Uncovering electrochemistries of rechargeable magnesium-ion batteries at low and high temperatures. Energy Storage Mater. 42(July), 129–144 (2021). https://doi.org/10.1016/j.ensm.2021.07.031

D. Aurbach et al., Progress in rechargeable magnesium battery technology. Adv. Mater. 19(23), 4260–4267 (2007). https://doi.org/10.1002/adma.200701495

J. Muldoon et al., Electrolyte roadblocks to a magnesium rechargeable battery. Energy Environ. Sci. 5(3), 5941–5950 (2012). https://doi.org/10.1039/c2ee03029b

C.B. Bucur, T. Gregory, A.G. Oliver, J. Muldoon, Confession of a magnesium battery. J. Phys. Chem. Lett. 6(18), 3578–3591 (2015). https://doi.org/10.1021/acs.jpclett.5b01219

Y. Shao et al., Coordination Chemistry in magnesium battery electrolytes: how ligands affect their performance. Sci. Rep. 3, 4–10 (2013). https://doi.org/10.1038/srep03130

R.C. Massé, E. Uchaker, G. Cao, Beyond Li-ion: electrode materials for sodium- and magnesium-ion batteries. Sci. China Mater. 58(9), 715–766 (2015). https://doi.org/10.1007/s40843-015-0084-8

D. Aurbach et al., A short review on the comparison between Li battery systems and rechargeable magnesium battery technology. J. Power. Sources 97–98, 28–32 (2001). https://doi.org/10.1016/S0378-7753(01)00585-7

Y. Li et al., A high-voltage rechargeable magnesium-sodium hybrid battery. Nano Energy 34, 188–194 (2017). https://doi.org/10.1016/j.nanoen.2017.02.012

Y. Orikasa et al., High energy density rechargeable magnesium battery using earth-abundant and non-toxic elements. Sci. Rep. 4, 1–6 (2014). https://doi.org/10.1038/srep05622

M.S. Whittingham, Materials challenges facing electrical energy storage. MRS Bull. 33(4), 411–419 (2008). https://doi.org/10.1557/mrs2008.82

H.D. Abruña, Y. Kiya, J.C. Henderson, Batteries and electrochemical capacitors. Phys. Today 61(12), 43–47 (2008). https://doi.org/10.1063/1.3047681

A. Afif, S.M. Rahman, A. Tasfiah Azad, J. Zaini, M.A. Islam, A.K. Azad, Advanced materials and technologies for hybrid supercapacitors for energy storage—a review. J. Energy Storage 25, 100852 (2019). https://doi.org/10.1016/j.est.2019.100852

M.T. Qureshi et al., Enhanced thermoelectric and optical response of Ag substituted Cu2O compositions for advanced applications. Ceram. Int. 49(12), 19861–19869 (2023). https://doi.org/10.1016/j.ceramint.2023.03.103

J. Shin, J.K. Seo, R. Yaylian, A. Huang, Y.S. Meng, A review on mechanistic understanding of MnO2 in aqueous electrolyte for electrical energy storage systems. Int. Mater. Rev. 65(6), 356–387 (2020). https://doi.org/10.1080/09506608.2019.1653520

N. Ullah et al., Effect of cobalt doping on the structural, optical and antibacterial properties of α-MnO2 nanorods. Appl. Phys. A 127(10), 779 (2021). https://doi.org/10.1007/s00339-021-04926-7

D. Majumdar, T. Maiyalagan, Z. Jiang, Recent progress in ruthenium oxide-based composites for supercapacitor applications. ChemElectroChem 6(17), 4343–4372 (2019). https://doi.org/10.1002/celc.201900668

U.K. Chime et al., Recent progress in nickel oxide-based electrodes for high-performance supercapacitors. Curr. Opin. Electrochem. 21, 175–181 (2020). https://doi.org/10.1016/j.coelec.2020.02.004

M. Asghar et al., Synthesis of biocompatible coating on Ni-Cr alloy by cathodic cage plasma processing technique as anti-pathogenic bacteria for medicinal applications. Phys. Scr. 98(5), 55920 (2023). https://doi.org/10.1088/1402-4896/acc908

L. Lyu et al., Recent development of biomass-derived carbons and composites as electrode materials for supercapacitors. Mater. Chem. Front. 3(12), 2543–2570 (2019). https://doi.org/10.1039/c9qm00348g

M.T. Qureshi et al., Enhanced photocatalytic efficiency and biosensing in plasmonic nanostructures for the detection of bacteria in various analytes. Opt. Quantum Electron. 55(13), 1147 (2023). https://doi.org/10.1007/s11082-023-05345-z

T. Zeeshan et al., A comparative computational and experimental study of Al–ZrO2 thin films for optoelectronic applications. Solid State Commun. 358, 115006 (2022). https://doi.org/10.1016/j.ssc.2022.115006

M. Saleem et al., DFT and experimental investigations on CdTe1-xSex for thermoelectric and optoelectronic applications. J. Alloys Compd. 921, 166175 (2022). https://doi.org/10.1016/j.jallcom.2022.166175

F. Ullah et al., Structural and dielectric studies of MgAl2O4–TiO2 composites for energy storage applications. Ceram. Int. 47(21), 30665–30670 (2021). https://doi.org/10.1016/j.ceramint.2021.07.244

J. Joseph, A.T. Murdock, D.H. Seo, Z.J. Han, A.P. O’Mullane, K. Ken Ostrikov, Plasma enabled synthesis and processing of materials for lithium-ion batteries. Adv. Mater. Technol. 3(9), 1–19 (2018). https://doi.org/10.1002/admt.201800070

S.Y. Jin, J. Manuel, X. Zhao, W.H. Park, J.H. Ahn, Surface-modified polyethylene separator via oxygen plasma treatment for lithium ion battery. J. Ind. Eng. Chem. 45, 15–21 (2017). https://doi.org/10.1016/j.jiec.2016.08.021

H. Long, M. Zhang, Q. Wang, L. Xing, S. Wang, X. Xue, Plasma-treated Co3O4/graphene nanocomposite as high performance anode of lithium-ion battery. J. Alloys Compd. 701, 200–207 (2017). https://doi.org/10.1016/j.jallcom.2017.01.108

R. Swaroop, P. Rani, G. Jamwal, G. Sabavath, H. Kumar, Y. Jewariya, Enhancing the electrochemical performance of TiO2 based material using microwave air plasma treatment with an ECR cavity. Front. Chem. 10(November), 1–16 (2022). https://doi.org/10.3389/fchem.2022.1065153

D.H. Kim et al., Facile enhancement of electrochemical performance of solid-state supercapacitor via atmospheric plasma treatment on PVA-based gel-polymer electrolyte. Gels (2023). https://doi.org/10.3390/gels9040351

B. Xu, H. Shen, J. Ge, Q. Tang, Improved cycling performance of SiOx/MgO/Mg2SiO4/C composite anode materials for lithium-ion battery. Appl. Surf. Sci. 546, 148814 (2021). https://doi.org/10.1016/j.apsusc.2020.148814

Y.S. Su, K.C. Hsiao, P. Sireesha, J.Y. Huang, Lithium silicates in anode materials for li-ion and li metal batteries. Batteries 8(1), 1–17 (2022). https://doi.org/10.3390/batteries8010002

S. Kumar, N. Munichandraiah, Magnesium cobalt silicate as a bifunctional catalyst for the O2 electrode and its application in Li-O2 cells. Catal. Sci. Technol. 6(17), 6716–6725 (2016). https://doi.org/10.1039/c6cy00029k

S. Saveetha, K.A. Vijayalakshmi, Influence of Low temperature Plasma on activated bamboo charcoal employed in energy storage system. Xidian Univ. 16(1001), 12–22 (2022)

K.A. Vijayalakshmi, K. Vignesh, N. Karthikeyan, Synthesis and surface characterization of bamboo charcoal carbon using low temperature plasma treatment. Mater. Technol. 30(A2), A99–A103 (2015). https://doi.org/10.1179/17535557A15Y.000000005

J.Z. Sun, Sol-gel synthesis of cathode material MgMnSiO 4 for magnesium cells. J. Chem. Soc. Pak. 34(3), 611–614 (2012)

K.A. Vijayalakshmi, M. Vimala, Impact of non-thermal plasma on SiO 2 nano particles synthesized by rice husk. Digest J Nanomater. Biostruct. 17(3), 1073–1078 (2022)

S. Saveetha, K.A. Vijayalakshmi, The morphological study of FePO4/plasma treated bamboo charcoal composite act as cathode material in energy storage devices. Dig. J. Nanomater. Biostructures 16(4), 1359–1363 (2021). https://doi.org/10.15251/djnb.2021.164.1359

S. Hoseini, N. Rahemi, S. Allahyari, M. Tasbihi, Application of plasma technology in the removal of volatile organic compounds (BTX) using manganese oxide nano-catalysts synthesized from spent batteries. J. Clean. Prod. 232, 1134–1147 (2019). https://doi.org/10.1016/j.jclepro.2019.05.227

C. Bai et al., Plasma treated carbon paper electrode greatly improves the performance of iron-hydrogen battery for low-cost energy storage. Chin. Chem. Lett. 33(2), 1095–1099 (2022). https://doi.org/10.1016/j.cclet.2021.07.008

A. Feng, B.J. McCoy, Z.A. Munir, D. Cagliostro, Wettability of transition metal oxide surfaces. Mater. Sci. Eng. A 242(1–2), 50–56 (1998). https://doi.org/10.1016/s0921-5093(97)00527-3

N.T. Oxide et al., Wettability of nanostructured transition-metal oxide (Al 2 O 3, CeO 2, and AlCeO 3) powder surfaces. Materials (Basel) 15(5485), 1–12 (2022)

R. Sangiorgi, M.L. Muolo, D. Chatain, N. Eustathopoulos, Wettability and work of adhesion of nonreactive liquid metals on silica. J. Am. Ceram. Soc. 71(9), 742–748 (1988). https://doi.org/10.1111/j.1151-2916.1988.tb06407.x

S.Z. Bai et al., Preparation and characterization of BCN. Gaodeng Xuexiao Huaxue Xuebao/Chemical J. Chinese Univ. 26(5), 811–815 (2005)

C. Koventhan, V. Vinothkumar, S. Chen, P. Veerakumar, K. Lin, Polyol-assisted synthesis of spinel-type magnesium cobalt oxide nanochains for voltammetric determination of the antipsychotic drug thioridazine. J. Electroanal. Chem. (2021). https://doi.org/10.1016/j.jelechem.2021.115600

R. Boopathiraja, M. Parthibavarman, A.N. Begum, Hydrothermal induced novel CuCo 2 O 4 electrode for high performance supercapacitor applications. Vacuum 165(April), 96–104 (2019). https://doi.org/10.1016/j.vacuum.2019.04.013

R. Boopathiraja, M. Parthibavarman, The cost-effective asymmetric supercapacitor from binary MnCo2O4 electrodes with nanofiber and nanocube-like morphology. J. Mater. Sci. Mater. Electron. (2020). https://doi.org/10.1007/s10854-020-03560-y

S. Saveetha, V. Ka, Exploring the electrochemical behaviour of DC glow discharge plasma exposed activated bamboo charcoal incorporated with FePO 4 nanoparticles in energy storage applications. Mater. Technol. 00(00), 1–10 (2022). https://doi.org/10.1080/10667857.2022.2086768

B.P. Ajayi, A.K. Thapa, U. Cvelbar, J.B. Jasinski, M.K. Sunkara, Atmospheric plasma spray pyrolysis of lithiated nickel-manganese-cobalt oxides for cathodes in lithium ion batteries. Chem. Eng. Sci. 174, 302–310 (2017). https://doi.org/10.1016/j.ces.2017.09.022

Z. Li, Q. Jiang, Z. Ma, Q. Liu, Z. Wu, S. Wang, Oxygen plasma modified separator for lithium sulfur battery. RSC Adv. 5(97), 79473–79478 (2015). https://doi.org/10.1039/c5ra17629h

J. Meng et al., Enhancing electrochemical performance of graphene fiber-based supercapacitors by plasma treatment. ACS Appl. Mater. Interfaces 10(16), 13652–13659 (2018). https://doi.org/10.1021/acsami.8b04438

Q. Jiang, Z. Li, S. Wang, H. Zhang, A separator modified by high efficiency oxygen plasma for lithium ion batteries with superior performance. RSC Adv. 5(113), 92995–93001 (2015). https://doi.org/10.1039/c5ra18457f

T. Nakajima et al., Electrochemical behavior of plasma-fluorinated graphite for lithium ion batteries. J. Power. Sources 104(1), 108–114 (2002). https://doi.org/10.1016/S0378-7753(01)00895-3

J. Profili et al., Toward more sustainable rechargeable aqueous batteries using plasma-treated cellulose-based li-ion electrodes. ACS Sustain. Chem. Eng. (2020). https://doi.org/10.1021/acssuschemeng.9b07125

Q. D. Truong, M. K. Devaraju, and I. Honma, “Rechargeable Mg-ion Batteries,” pp. 1–20.

Y. Nuli, Y. Zheng, Y. Wang, J. Yang, J. Wang, Electrochemical intercalation of Mg2+ in 3D hierarchically porous magnesium cobalt silicate and its application as an advanced cathode material in rechargeable magnesium batteries. J. Mater. Chem. 21(33), 12437–12443 (2011). https://doi.org/10.1039/c1jm10485c

Y. Zheng, Y. Nuli, Q. Chen, Y. Wang, J. Yang, J. Wang, Magnesium cobalt silicate materials for reversible magnesium ion storage. Electrochim. Acta 66, 75–81 (2012). https://doi.org/10.1016/j.electacta.2012.01.037

Author information

Authors and Affiliations

Contributions

Judith fennila T first author and original draft writing of the manuscript. Dr K A Vijayalakshmi corresponding author and supervision of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The author declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Fennila, T.J., Vijayalakshmi, K.A. Outstanding specific capacitance of air plasma exposed MgCoSiO4 cathode in the rechargeable magnesium batteries. Appl. Phys. A 130, 392 (2024). https://doi.org/10.1007/s00339-024-07551-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-024-07551-2