Abstract

Neutron imaging was employed to track the uptake of Gd\(^{3+}\) ions by the sub 2 nm micropores of charged activated carbon cloth electrodes from an aqueous Gd(NO\(_3\))\(_3\) solution. The transmitted neutron intensity evinces the persistent presence of Gd\(^{3+}\) in the micropores during the discharge cycle, which is caused by the adsorption of oppositely charged ions. The charge efficiency of the activated carbon cloth system was determined by direct comparison with the imaged Gd\(^{3+}\) concentration changes, with which the influence of ion swapping and resistive losses on capacitive deionization cells can be ascertained.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The defining trait of porous carbon materials is their high surface-to-volume ratio, which bestows favourable adsorptive properties upon them. The combination of high electrical conductivity and enormous surface area is suitable for application as electrodes in systems relying on a large electrical double layer in which ions can be stored. This is relevant in the field of energy storage in the form of supercapacitors, but also in the desalination of water. One method that uses the electrical double layer to immobilise a large concentration of ions is capacitive deionization (CDI) [1, 2]. A sketch of the process with porous carbon electrodes is shown in Fig. 1. Pores are classified according to their size: those with widths over 50 nm are called macropores, between 2 and 50 nm mesopores and below 2 nm micropores [3]. An electrical double layer on the electrode surface is formed upon application of a voltage and the ions are pulled in from the bulk solution. Desalinated water can then be withdrawn from the cell. Upon removal of the potential difference between electrodes, the ions are liberated from the pores and diffuse out into the remaining brine. The process is then repeated.

Scheme of a capacitive deionization (CDI) process. a The CDI cell is filled with saline water. b A voltage between the electrodes is applied and the ions are electrosorbed by the porous carbon matrix. Desalinated water can be withdrawn. c The maximum capacity of ions in the pores is reached and the voltage is switched off. The ions are released into the saline solution. However, ions of opposing charge can also enter the pores

Carbon materials with mesoporous and microporous structures are suitable for CDI. Examples of such materials are activated carbon cloths, ordered mesoporous carbons, carbide-derived carbon, carbon nanotubes, carbon black and carbon aerogels [1, 4]. Nonetheless, there is no universal relationship between the pore size distribution or surface area and the CDI capability. Micropores provide a high surface area, but they also lead to overlapping of the electric double layer due to their small size. The associated electrostatic repulsion reduces the actual desalination effect.

A straightforward way to quantify the CDI capability of porous electrodes is to measure the salinity of the water that has passed through the desalination cell. Yet, this does not provide information on the transport of the ions into the porous network that makes up the electrodes. Directly measuring the uptake of the ions by the porous structure of the electrode is possible with a radiographic method such as neutron imaging. Interactions with the nuclei provide different sensitivities compared to other imaging methods such as those relying on X-rays, which interact with the electrons of the atom. The ion concentrations can be mapped by differences in the neutron transmission profile. The individual pores are far beyond the spatial resolution of the technique, which is around 50 µm for the field of view used in this study. Hence, an average over the porous structure is obtained.

Due to the comparatively low volume fraction of ions in solution, a large neutron absorption cross section of the respective species is a prerequisite for successful neutron imaging. Gadolinium has the highest neutron absorption cross section of any naturally occurring element. The absorption cross section is due to the odd-numbered isotopes \({}^{155}\)Gd (\(\sigma _{\rm a}=62\,200\) barn) and \({}^{157}\)Gd (\(\sigma _{\rm a}=249\,800\) barn), with remeasured values for thermal neutrons published in 2019 [5]. Each of these isotopes accounts for around 15% of the natural abundance of Gd [6]. Accordingly, the thermal neutron absorption cross section of elemental Gd is \(\sigma _{\rm a}=46\,700\) barn [7]. The contrast for neutron imaging with Gd is unrivalled, but the neutron absorption by the lanthanides Sm (\(\sigma _{\rm a}=5922\) barn) and Eu (\(\sigma _{\rm a}=4530\) barn) is also substantial [6]. The paramagnetism of Gd solutions also makes them a good choice when magnetic field effects are of interest [7, 8].

Previous studies have applied neutron imaging to monitor the movement of Li\(^+\) ions in batteries [9,10,11] and during CDI by ordered mesoporous carbon electrodes with approximately 10 nm pore size [12,13,14,15]. The first two of the CDI studies employed Gd nitrate solutions [12, 13], whereas the latter two imaged \({}^6\)Li (\(\sigma _{\rm a} = 940\,\) barn) from concentrated LiCl solutions [14, 15]. These experiments used cold neutrons, which possess higher absorption cross sections than thermal neutrons and thus restricted the investigations to low concentrations of Gd\(^{3+}\). In contrast, thermal neutrons were used to study the CDI by carbon aerogel electrodes and the effect of a magnetic field gradient on the ensuing system [8]. Neutron imaging has also been utilized to analyze the harvesting of energy from capacitive double layer expansion [16].

The present study applies the neutron imaging method to analyze the electrosorption of Gd\(^{3+}\) in microporous activated carbon cloths (ACCs) in situ. These are made up of microporous fibers, which provide enormous surface areas (up to 3500 m\(^2\) g\(^{-1}\) [1]), adsorptive capabilities and display high mechanical stability. ACCs are created by carbonization and activation of a phenol-formaldehyde derived polymer precursor (novoloid). The novoloid is melt-spun into fibers and woven prior to the pyrolysis. Applications of ACCs are centred around gas adsorption and water treatment. A number of publications have investigated the desalination performance of ACC electrodes [17,18,19,20,21,22,23,24,25,26,27,28,29]. Optimization of performance by surface functionalization has been the main direction of the research, although unanswered questions concerning the electrosorption mechanism in the microporous fibers remain. The energy efficiency of the charge process and a link to the movement of ions in the micropores is central for application in CDI, and it is the aim of the neutron imaging experiment to provide information about this. This is particularly pertinent for porous carbon electrodes where the ion movement in the pores can be inefficient and increase the energy cost of desalination.

2 Methods

2.1 Porous material characterization

Activated carbon cloth with brand name ACC-5092-20 was provided by Kynol® Europa GmbH. This material comprises pyrolyzed and activated phenolic fibers [30,31,32], which are arranged in a fabric of 0.55 mm thickness with a ribbed surface.

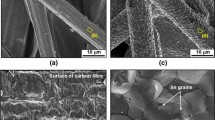

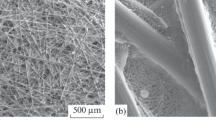

Scanning electron microscope (SEM) images of the ACC at different magnifications are provided in Fig. 2. The morphology shows carbon fibers of approximately 10 µm diameter that form interwoven bundles in a repeating pattern. The diameter of the rope-like bundles is in the order of 500 µm.

The porosity of the microporous (< 2 nm) activated carbon cloths was investigated using nitrogen gas adsorption. The carbon cloth sample was de-gassed for 1 h at 200 °C under vacuum prior to analysis. The measured nitrogen adsorption isotherms of the cloths were of Type-I, which is characterized by an abrupt rise in the pressure due to filling of micropores. Type-I isotherms are observed for the adsorption of a monolayer of adsorbate in materials with pore sizes that are not much larger than the cross-sectional area of the adsorbate. For a N\(_2\) molecule, this is assumed to be 0.162 nm\(^2\). Under such conditions, the commonly employed Brunauer–Emmett–Teller (BET) theory is not applicable and other models for the evaluation of the isotherm are required [33]. One theory that describes the N\(_2\) adsorption isotherms in microporous carbon structures is the N\(_2\)-Carbon Quenched Solid State Density Functional Theory (QSDFT) model [34, 35] for slit-shaped pores. This model can describe carbon materials with pore sizes between 0.35 and 40 nm and was used to extract the pore size distribution from the data presented here. The QSDFT takes into account the surface roughness and inherent heterogeneity of the surface in disordered carbon materials such as the ACCs [34].

The measured cumulative pore volume of the sample is plotted in Fig. 3a. The pore size distribution is shown in Fig. 3b. In QSDFT, the pore size is calculated as pore width with the assumption that the pores behave as slits. The pore width in the ACC sample is exclusively below 2 nm. The specific surface area from the QSDFT analysis is 1960 m\(^2\)g\(^{-1}\), which is similar to previously reported values for this material [28, 29].

2.2 Neutron imaging

The electrosorption of Gd\(^{3+}\) was imaged at the thermal neutron radiography station NEUTRA [36], which is located at the neutron spallation source SINQ in the Paul Scherrer Institute. The energy of the thermal neutrons is described by a 25 meV Maxwellian spectrum. The sample was exposed to a neutron flux of approximately \(1.3\times 10^7\,\textrm{cm}^{-2}\, \textrm{s}^{-1}\). Transmitted neutrons were detected by a combination of a Tb-doped Gadox scintillator (produced by RC-Tritec, Switzerland, in collaboration with PSI) and a CCD camera (Andor, iKon-L). Gadox scintillators detect neutrons by the same neutron capture processes that are exploited in the present absorption study of Gd\(^{3+}\) ions.

Neutron images with 2048\(\times\)2048 pixels and a pixel size of 33.04 µm were recorded. This corresponded to a field of view of 67.67 mm \(\times 67.67\) mm. The exposure and readout time were 10 s and approximately 3 s, respectively.

A sketch of the experiment is shown in Fig. 4(a). The sample holder was a glass cuvette with a path length of 5 mm. This was placed 1 cm in front of the detector. The outside dimensions of the cuvette were 40 mm \(\times\) 23.6 mm \(\times\) 7.5 mm (height \(\times\) width \(\times\) depth).

Porous ACC electrodes were cut to approximately 7 mm wide and 43 mm long stripes for use as electrodes. These were soaked in heavy water (D\(_2\)O) to avoid air bubble formation during the neutron imaging measurement. The cloths were pierced with 100 µm-diameter silver wires and connected to the power leads of a potentiostat (Biologic SP-300). They were then stuck to the inside front window of the cuvette by capillary forces and the cuvette was filled with 3.5 mL 70 mM Gd(NO\(_3\))\(_3\) solution in D\(_2\)O. A direct current (DC) voltage was applied to the cell, while changes in the transmission profile were monitored. The resulting setup can be seen in a neutron image during the first charging process, which is shown in Fig. 4b. This image was dark-current corrected and normalized by the open neutron beam without sample.

Heavy water (\(\sigma _{\textrm{D}_2 \textrm{O}} = 20\) barn) was used to avoid the incoherent scattering by regular water molecules (\(\sigma _{\textrm{H}_2 \textrm{O}} = 169\) barn). The cell was covered with parafilm for minimization of evaporation and D\(_2\)O–H\(_2\)O exchange [37].

Neutron imaging setup: CDI with activated carbon cloths. a Sketch of the experimental setup (top view). The glass cuvette contained the ACC electrodes and Gd(NO\(_3\))\(_3\) solution. The electrodes were connected to a potentiostat. b Dark-current corrected neutron image (normalized by open beam: \(T=\tfrac{I - I_{\rm dc}}{I_0-I_{\rm dc}})\) of the 5 mm path length cuvette with 70 mM Gd(NO\(_3\))\(_3\) solution: 40 min into first charge at 0.7 V. Right electrode: negative charge (Gd\(^{3+}\)); left electrode: positive charge (NO\(_3^{-}\)). Heightened \(c_\textrm{Gd}\) in the right electrode lowers the neutron transmission and vice versa for the left electrode

The incident neutron intensity \(I_0\) is related to the transmitted neutron intensity I by the Beer–Lambert law

The exponent contains the Avogadro constant \(N_A\) (\(6.022\times 10^{23}\) mol\(^{-1}\)), the concentration \(c_i\), the neutron cross sections \(\sigma _{i}\) , and the path length \(\Delta z\). The sum in the exponent incorporates all isotopes of the material through which the neutron beam passes.

For the analysis of the Gd\(^{3+}\) transport in the ACC electrodes concentration, the time-sequenced neutron images were normalized by the first image of the series. Differences in neutron transmission are directly visible in the difference images in Fig. 5. During electrosorption in the micropores of the ACC electrodes, the concentrations of NO\(_3^{-}\) and Gd\(^{3+}\) ions in the cloths change. The incoherent thermal neutron scattering cross section of NO\(_3^{-}\) is \(\sigma _{\textrm{NO}_3} = 24.2\,\) barn [6], which is three orders of magnitude lower than the neutron absorption cross section of Gd\(^{3+}\). Due to this, the differences in intensity can be assumed to be exclusively due to accumulation or depletion of Gd\(^{3+}\). Thus, the change in Gd\(^{3+}\) concentration (\(\Delta c_{\textrm{Gd}}\)) at two different times can be obtained from the Beer–Lambert law (see Suppl. Information)

The neutron images were converted to maps of \(\Delta _{\textrm{Gd}}\) by this procedure.

3 Results and discussion

Consecutive voltages of 0.7 V, 0 V and \(-0.7\) V were applied to the ACC electrodes and the migration of the Gd\(^{3+}\) ions into the micropores was monitored in situ by variations in the neutron attenuation. Small changes in the transmittance were converted to \(\Delta c_{\textrm{Gd}}\) in the ACC electrodes with Eq. 2. Parasitic electrochemical reactions such as water splitting are unimportant at the chosen voltage.

The \(\Delta c_\textrm{Gd}\) maps resulting from the first charge at 0.7 V, first discharge at 0 V and second charge at \(-0.7\) V are displayed in Fig. 5. The time evolution of the mean \(\Delta c_\textrm{Gd}\) within the activated carbon cloth electrodes is shown in Fig. 6. The accumulation of Gd\(^{3+}\) was measurable within a minute of applying the potential difference. A plateau was reached after 40 min, when further ions stopped entering the micropores.

The micropores of the cloth had a maximum capacity of 14 mM Gd\(^{3+}\) at 0.7 V. Few ions from the bulk solution were adsorbed, which can be appreciated when inspecting Fig. 6. The concentration changes within the two ACC electrodes were rather symmetric and add up to near 0 mM, meaning that the Gd\(^{3+}\) ions were predominately exchanged from one electrode to the other. This implies that changes of Gd\(^{3+}\) concentration in the bulk liquid hardly altered the neutron transmission at a path length of 5 mm in the cuvette, unlike in previous experiments with carbon aerogel electrodes at higher voltages [8]. As a result, the approximation of using the ACC electrode thickness as path length in the calculation of \(\Delta c_\textrm{Gd}\) is accurate and incurs negligible uncertainty.

Neutron images converted to \(\Delta c_{\mathrm {Gd}}\) within 0.55 mm-thick ACC electrodes (full time sequences of the processes in the Suppl. information). The electrodes were in 5 mm path length glass cuvette full of 70 mM Gd(NO\(_3\))\(_3\) solution. The images are restricted to below the liquid surface. a Charge process at 0.7 V. Right electrode: negatively polarized; left electrode: positively polarized. b Discharge process at 0 V. c Charge process at \(-0.7\) V. Right electrode: positively polarized; left electrode: negatively polarized

When desalinating highly concentrated salt water, a commonly faced issue is ions of opposite sign entering the pores during the desorption cycle (see Fig. 1c). This is accompanied by a drop of desalination efficiency, because the expulsion of co-ions (ions of the same charge as the electrode) takes up energy. Regeneration of the electrodes is challenging and requires inversion of the voltage with which the co-ions can be removed from the pores again.

During the discharge of the electrodes at 0 V, roughly half of the Gd\(^{3+}\) ions remained trapped in the micropores (see Fig. 5b). Evidently, NO\(_3^-\) ions quickly compensated the charge of the Gd\(^{3+}\) in the micropores before these could desorb and diffuse out into the bulk solution. The converse is true for the electrode containing NO\(_3^-\). Blocking of the micropores after adsorption of co-ions degrades the ACCs. Both ACCs kept half their adsorbed ions with \(\Delta c_\textrm{Gd}=7\) mM after the first discharge. The charging processes following the first did not recover the Gd\(^{3+}\) adsorption capability of 14 mM with respect to the initial concentration distribution. However, the ACC electrodes were always able to transfer approximately 14 mM Gd\(^{3+}\) to the negatively charged cloth. The initial two charges are symmetric around the y-axis with \(\Delta c_\textrm{Gd}=0\). At the second discharge at 0 V, the left electrode lost all its adsorbed Gd\(^{3+}\) with respect to the initial concentration.

After the last charging process at 0.7 V, the potential was changed to \(-0.7\) V without a discharge at 0 V. This rapidly expelled all the ions from the micropores, which can be seen in the sharp descent of \(\Delta c_\textrm{Gd}\), after which the ions transferred onto the oppositely charged side.

Neutron imaged mean Gd\(^{3+}\) concentration change in the ACC electrodes. The change is with respect to the initial situation prior to the application of a voltage. The neutron images corresponding to the first cycles at 0.7 V, 0 V and \(-0.7\,\)V are shown in Fig. 5 after conversion to \(\Delta c_{\textrm{Gd}}\). A comparison between the measured \(\Delta c_\textrm{Gd}\) and data from the potentiostat is shown in Fig. 7. The gaps in the data were caused by an attempt to correct for scattering contributions with a black-body grid [38]. This correction was not used in the end

The quantitative data extracted from the neutron images can be used to gauge the efficiency of the process. This is accomplished by comparing the Gd\(^{3+}\) ion concentration attributed to adsorption in the micropores of the ACC to the charge expected from the current readout from the potentiostat. The comparison is shown in Fig. 7. The top two panels show the applied potential and measured current. The charge resulting from the integrated current signal is shown in Fig. 7c. The left y-axis indicates the value in coulombs and on the right converted to a concentration of trivalent ions. Division by Faraday’s constant (\(F = 96\,485\) C mol\(^{-1}\)) and the activated carbon cloth electrode volume (\(V \approx 0.12\) mL) leads to this value. Thus, a charge of 2 C is equivalent to 57.6 mM of trivalent ions. The charge efficiency \(\Lambda = \tfrac{3 \Delta c_\textrm{Gd}}{\Delta Q}\) can be calculated from these values and is summarized in Table 1. The ratios during the discharge processes are also shown for comparison.

Comparison of the readout from the potentiostat and \({\Delta c_{\mathrm{Gd}}}\) detected by neutron imaging. a, b The cell voltage and the measured current. c The integrated current shows the charge Q, which can be converted to a concentration of trivalent ions (see right y-axis). d The neutron imaged \(\Delta c_{\textrm{Gd}}\) in the right electrode (see Fig. 5). The charge efficiency \(\Lambda _\textrm{Gd}\) based solely on the capture of Gd\(^{3+}\) is 0.24 during the first two charges, but then drops to around 0.18 in the subsequent charging processes (see Tab. 1)

The \(\Lambda\) values were around 24% during the first two charging processes and fell to 18% for the third and fourth charge. These values are low, but not unusual for CDI with microporous electrodes where the electrical double layer from adjacent pores can overlap. A considerable amount of the current is consumed by the expulsion of co-ions from the electrode before counterions (ions with opposite charge to the electrode) are adsorbed. The neutron images only show the change in the Gd\(^{3+}\) concentration and are insensitive to NO\(_3^-\).

Avraham et al. reported \(\Lambda \approx 36\) % for a cell voltage of 0.6 V [18]. They were able to double the efficiency of the system by never allowing the ACC electrodes to fully discharge, which was accomplished by successive switching between 0.4 and 0.6 V. The choice of this potential window effectively quashes migration of counterions into the electrodes during the desorption phase. Kim et al. also reported charge efficiencies below 40% for ACC CDI electrodes operated at 0.6 V [28]. This study also contains \(\Lambda\) values for ACC CDI cells without current collectors that usually consist of a metallic backing frame to which the electrodes are attached. The absence of a current collector led to a 26% drop in charge efficiency with the higher electrical resistance. The electrical resistivity of activated carbon cloths is around \(4\times 10^{-4}\) \(\Omega\) m [28], an order of magnitude lower than regular graphite.

4 Conclusion and outlook

The presented study shows that the ion movement in microporous materials can be analyzed quantitatively with an acceptable temporal resolution by neutron imaging with thermal neutrons. The transfer of Gd\(^{3+}\) ions from a 70 mM Gd(NO\(_3\))\(_3\) solution into and out of the micropores of 0.55 mm-thick ACC electrodes was imaged with neutrons. The low charge efficiency of around 0.25 at 0.7 V with a 70 mM Gd(NO\(_3\))\(_3\) solution can be partially explained by resistive losses. However, ion swapping between the electrodes caused by co-ion expulsion at the beginning of the charging step is the critical factor. To avoid the debilitating co-ion adsorption in the porous matrix of carbon electrodes, ion exchange membranes can be inserted into CDI cells [1, 39, 40]. These block co-ions from entering the porous structure to neutralise the adsorbed counterions. A new approach has been the advent of Faradaic electrodes in CDI cells [41,42,43,44,45,46,47]. Such electrodes avoid the issues encountered with the electrosorption in the double layer of porous carbon. A neutron imaging study such as the one performed here would improve understanding of the ion movement in a more efficient process with a Faradaic electrode in which the ions are captured by intercalation [44].

A recent development that may benefit the study of ions in porous materials is neutron dark-field imaging [48, 49], which involves the detection of small-angle scattering signals and their conversion to a real space image. Small-angle neutron scattering can resolve particles in the range of 1–100 nm. The pores of carbon-based CDI electrodes fall in this range and have been previously studied with this scattering method [50,51,52,53,54,55,56,57].

CDI electrodes can be modified to favour the removal of a specific species of ion [58,59,60,61,62]. The mechanism by which this can be achieved is still under active investigation. Charge, ionic radii, hydration ratios, and mobilities of the ions have an effect on ionic transport inside porous electrodes. Neutron imaging may serve to distinguish cations of different elements, especially rare-earth ions that have greatly varying neutron absorption cross sections. Furthermore, the versatility of neutron imaging allows upscaling to larger systems with flow through cells or the extension to three-dimensional imaging with a tomographic setup. The main requirement for a successful time-resolved experiment is that the dynamics to be observed occur at timescales compatible with the neutron detection, which is ultimately limited by the neutron flux and detector readout.

Data availibility

The datasets generated and analyzed during the current study are available in the Zenodo repository [63].

References

S. Porada, R. Zhao, A. van der Wal, V. Presser, P. Biesheuvel, Review on the science and technology of water desalination by capacitive deionization. Prog. Mater. Sci. 58, 1388 (2013). https://doi.org/10.1016/j.pmatsci.2013.03.005

M.E. Suss, S. Porada, X. Sun, P.M. Biesheuvel, J. Yoon, V. Presser, Water desalination via capacitive deionization: what is it and what can we expect from it? Energy Environ. Sci. 8, 2296 (2015). https://doi.org/10.1039/C5EE00519A

B. Zdravkov, J. Čermák, M. Šefara, J. Jank\(\mathring{\rm u}\), Pore classification in the characterization of porous materials: A perspective: Cent. Eur. J. Chem. 5, 385 (2007). https://doi.org/10.2478/s11532-007-0017-9

Y. Liu, C. Nie, X. Liu, X. Xu, Z. Sun, L. Pan, Review on carbon-based composite materials for capacitive deionization. RSC Adv. 5, 15205 (2015). https://doi.org/10.1039/C4RA14447C

n_TOF Collaboration, M. Mastromarco, A. Manna, et al., Cross section measurements of \({}^{155,157}\)Gd(n,\(\gamma\)) induced by thermal and epithermal neutrons, Eur. Phys. J. A 55, 9 ( 2019) https://doi.org/10.1140/epja/i2019-12692-7

V.F. Sears, Neutron scattering lengths and cross sections. Neutron News 3, 26 (1992). https://doi.org/10.1080/10448639208218770

T.A. Butcher, G.J.M. Formon, P. Dunne, T.M. Hermans, F. Ott, L. Noirez, J.M.D. Coey, Neutron imaging of liquid-liquid systems containing paramagnetic salt solutions. Appl. Phys. Lett. 116, 022405 (2020). https://doi.org/10.1063/1.5135390

T.A. Butcher, L. Prendeville, A. Rafferty, P. Trtik, P. Boillat, J.M.D. Coey, Neutron imaging of paramagnetic ions: electrosorption by carbon aerogels and macroscopic magnetic forces. J. Phys. Chem. C 125, 21831 (2021). https://doi.org/10.1021/acs.jpcc.1c06031

J.P. Owejan, J.J. Gagliardo, S.J. Harris, H. Wang, D.S. Hussey, D.L. Jacobson, Direct measurement of lithium transport in graphite electrodes using neutrons. Electrochim. Acta 66, 94 (2012). https://doi.org/10.1016/j.electacta.2012.01.047

B. Song, I. Dhiman, J.C. Carothers, G.M. Veith, J. Liu, H.Z. Bilheux, A. Huq, Dynamic lithium distribution upon dendrite growth and shorting revealed by operando neutron imaging. ACS Energy Lett. 4, 2402 (2019). https://doi.org/10.1021/acsenergylett.9b01652

N.S. Nazer, M. Strobl, A. Kaestner, P.J. Vie, V.A. Yartys, Operando neutron imaging study of a commercial Li-ion battery at variable charge-discharge current densities. Electrochim. Acta 427, 140793 (2022). https://doi.org/10.1016/j.electacta.2022.140793

K. Sharma, H.Z. Bilheux, L.M.H. Walker, S. Voisin, R.T. Mayes, J.O. Kiggans Jr., S. Yiacoumi, D.W. DePaoli, S. Dai, C. Tsouris, Neutron imaging of ion transport in mesoporous carbon materials. Phys. Chem. Chem. Phys. 15, 11740 (2013). https://doi.org/10.1039/C3CP51310F

K. Sharma, R.T. Mayes, J.O. Kiggans, S. Yiacoumi, H.Z. Bilheux, L.M. Walker, D.W. DePaoli, S. Dai, C. Tsouris, Enhancement of electrosorption rates using low-amplitude, high-frequency, pulsed electrical potential. Sep. Purif. Technol. 129, 18 (2014). https://doi.org/10.1016/j.seppur.2014.03.016

K. Sharma, Y.-H. Kim, J. Gabitto, R.T. Mayes, S. Yiacoumi, H.Z. Bilheux, L.M.H. Walker, S. Dai, C. Tsouris, Transport of ions in mesoporous carbon electrodes during capacitive deionization of high-salinity solutions. Langmuir 31, 1038 (2015). https://doi.org/10.1021/la5043102

Y.-H. Kim, K. Tang, J. Chang, K. Sharma, S. Yiacoumi, R. Mayes, H. Bilheux, L. Santodonato, C. Tsouris, Potential limits of capacitive deionization and membrane capacitive deionization for water electrolysis. Sep. Sci. Technol. 54, 2112 (2019). https://doi.org/10.1080/01496395.2019.1608243

K. Sharma, Y.-H. Kim, S. Yiacoumi, J. Gabitto, H. Bilheux, L. Santodonato, R. Mayes, S. Dai, C. Tsouris, Analysis and simulation of a blue energy cycle. Renew. Energ. 91, 249 (2016). https://doi.org/10.1016/j.renene.2016.01.044

E. Avraham, Y. Bouhadana, A. Soffer, D. Aurbach, Limitation of charge efficiency in capacitive deionization. J. Electrochem. Soc. 156, P95 (2009). https://doi.org/10.1149/1.3115463

E. Avraham, M. Noked, Y. Bouhadana, A. Soffer, D. Aurbach, Limitations of charge efficiency in capacitive deionization. J. Electrochem. Soc. 156, P157 (2009). https://doi.org/10.1149/1.3193709

Y. Bouhadana, E. Avraham, A. Soffer, D. Aurbach, Several basic and practical aspects related to electrochemical deionization of water. AIChE J. 56, 779 (2010). https://doi.org/10.1002/aic.12005

E. Avraham, M. Noked, A. Soffer, D. Aurbach, The feasibility of boron removal from water by capacitive deionization. Electrochim. Acta 56, 6312 (2011). https://doi.org/10.1016/j.electacta.2011.05.037

Y. Bouhadana, E. Avraham, M. Noked, M. Ben-Tzion, A. Soffer, D. Aurbach, Capacitive deionization of NaCl solutions at non-steady-state conditions: inversion functionality of the carbon electrodes. J. Phys. Chem C 115, 16567 (2011). https://doi.org/10.1021/jp2047486

M.T.Z. Myint, J. Dutta, Fabrication of zinc oxide nanorods modified activated carbon cloth electrode for desalination of brackish water using capacitive deionization approach. Desalination 305, 24 (2012). https://doi.org/10.1016/j.desal.2012.08.010

G. Wang, Q. Dong, Z. Ling, C. Pan, C. Yu, J. Qiu, Hierarchical activated carbon nanofiber webs with tuned structure fabricated by electrospinning for capacitive deionization. J. Mater. Chem. 22, 21819 (2012). https://doi.org/10.1039/C2JM34890J

I. Cohen, E. Avraham, Y. Bouhadana, A. Soffer, D. Aurbach, The effect of the flow-regime, reversal of polarization, and oxygen on the long term stability in capacitive de-ionization processes. Electrochim. Acta 153, 106 (2015). https://doi.org/10.1016/j.electacta.2014.12.007

K. Laxman, M. T. Z. Myint, M. Al Abri, P. Sathe, S. Dobretsov, and J. Dutta, Desalination and disinfection of inland brackish ground water in a capacitive deionization cell using nanoporous activated carbon cloth electrodes, Desalination 362, 126 (2015) https://doi.org/10.1016/j.desal.2015.02.010

X. Gao, S. Porada, A. Omosebi, K.-L. Liu, P. Biesheuvel, J. Landon, Complementary surface charge for enhanced capacitive deionization. Water Res. 92, 275 (2016). https://doi.org/10.1016/j.watres.2016.01.048

M. Gineys, R. Benoit, N. Cohaut, F. Béguin, S. Delpeux-Ouldriane, Behavior of activated carbon cloths used as electrode in electrochemical processes. Chem. Eng. J. 310, 1 (2017). https://doi.org/10.1016/j.cej.2016.10.018

C. Kim, P. Srimuk, J. Lee, S. Fleischmann, M. Aslan, V. Presser, Influence of pore structure and cell voltage of activated carbon cloth as a versatile electrode material for capacitive deionization. Carbon 122, 329 (2017). https://doi.org/10.1016/j.carbon.2017.06.077

M. Lenz, J. Zabel, M. Franzreb, New approach for investigating diffusion kinetics within capacitive deionization electrodes using electrochemical impedance spectroscopy. Front. Mater. 7, 229 (2020). https://doi.org/10.3389/fmats.2020.00229

M. Shimada, S. Takigami, Y. Nakamura, Y. Abe, T. Iizuka, N. Makiyama, Efficiently activated carbon fiber derived from grafted novoloid fiber. J. Appl. Polym. Sci. 48, 1121 (1993). https://doi.org/10.1002/app.1993.070480618

J. S. Hayes Jr, Nanostructure of activated carbon fibers and kinetics of adsorption/desorption, in Proceedings of the Air & Waste Management Association’s Annual Conference & Exhibition, 95th, pp. 23–27 (2002)

D. Saha, H. Grappe, 5 - adsorption properties of activated carbon fibers, in Activated Carbon Fiber and Textiles, Woodhead Publishing Series in Textiles, edited by J. Y. Chen ( Woodhead Publishing, Oxford, 2017) pp. 143–165 https://doi.org/10.1016/B978-0-08-100660-3.00005-5

J. Rouquerol, P. Llewellyn, F. Rouquerol, Is the BET equation applicable to microporous adsorbents? Stud. Surf. Sci. Catal. 160, 49 (2007). https://doi.org/10.1016/S0167-2991(07)80008-5

A.V. Neimark, Y. Lin, P.I. Ravikovitch, M. Thommes, Quenched solid density functional theory and pore size analysis of micro-mesoporous carbons. Carbon 47, 1617 (2009). https://doi.org/10.1016/j.carbon.2009.01.050

G.Y. Gor, M. Thommes, K.A. Cychosz, A.V. Neimark, Quenched solid density functional theory method for characterization of mesoporous carbons by nitrogen adsorption. Carbon 50, 1583 (2012). https://doi.org/10.1016/j.carbon.2011.11.037

E.H. Lehmann, P. Vontobel, L. Wiezel, Properties of the radiography facility NEUTRA at SINQ and its potential for use as European reference facility. Nondestr. Test. Eval. 16, 191 (2001). https://doi.org/10.1080/10589750108953075

J.K. Im, L. Jeong, J. Crha, P. Trtik, J. Jeong, High-resolution neutron imaging reveals kinetics of water vapor uptake into a sessile water droplet. Matter 4, 2083 (2021). https://doi.org/10.1016/j.matt.2021.04.013

P. Boillat, C. Carminati, F. Schmid, C. Grünzweig, J. Hovind, A. Kaestner, D. Mannes, M. Morgano, M. Siegwart, P. Trtik, P. Vontobel, E. Lehmann, Chasing quantitative biases in neutron imaging with scintillator-camera detectors: a practical method with black body grids. Opt. Express 26, 15769 (2018). https://doi.org/10.1364/OE.26.015769

Y.-J. Kim, J.-H. Choi, Enhanced desalination efficiency in capacitive deionization with an ion-selective membrane. Sep. Purif. Technol. 71, 70 (2010). https://doi.org/10.1016/j.seppur.2009.10.026

P. Biesheuvel, A. van der Wal, Membrane capacitive deionization. J. Membr. Sci. 346, 256 (2010). https://doi.org/10.1016/j.memsci.2009.09.043

M. Pasta, C.D. Wessells, Y. Cui, F. La Mantia, A desalination battery. Nano Lett. 12, 839 (2012). https://doi.org/10.1021/nl203889e

J. Lee, S. Kim, C. Kim, J. Yoon, Hybrid capacitive deionization to enhance the desalination performance of capacitive techniques. Energy Environ. Sci. 7, 3683 (2014). https://doi.org/10.1039/C4EE02378A

P. Srimuk, F. Kaasik, B. Krüner, A. Tolosa, S. Fleischmann, N. Jäckel, M.C. Tekeli, M. Aslan, M.E. Suss, V. Presser, Mxene as a novel intercalation-type pseudocapacitive cathode and anode for capacitive deionization. J. Mater. Chem. A 4, 18265 (2016). https://doi.org/10.1039/C6TA07833H

M.E. Suss, V. Presser, Water desalination with energy storage electrode materials. Joule 2, 10 (2018). https://doi.org/10.1016/j.joule.2017.12.010

M. Torkamanzadeh, L. Wang, Y. Zhang, O. Budak, P. Srimuk, V. Presser, Mxene/activated-carbon hybrid capacitive deionization for permselective ion removal at low and high salinity. ACS Appl. Mater. Interfaces 12, 26013 (2020). https://doi.org/10.1021/acsami.0c05975

P. Srimuk, X. Su, J. Yoon, D. Aurbach, V. Presser, Charge-transfer materials for electrochemical water desalination, ion separation and the recovery of elements. Nat. Rev. Mater 5, 517–538 (2020). https://doi.org/10.1038/s41578-020-0193-1

Q. Li, Y. Zheng, D. Xiao, T. Or, R. Gao, Z. Li, M. Feng, L. Shui, G. Zhou, X. Wang, Z. Chen, Faradaic electrodes open a new era for capacitive deionization. Adv. Sci. 7, 2002213 (2020). https://doi.org/10.1002/advs.202002213

B. Betz, R.P. Harti, M. Strobl, J. Hovind, A. Kaestner, E. Lehmann, H. Van Swygenhoven, C. Grünzweig, Quantification of the sensitivity range in neutron dark-field imaging. Rev. Sci. Instrum. 86, 123704 (2015). https://doi.org/10.1063/1.4937616

M. Siegwart, R.P. Harti, V. Manzi-Orezzoli, J. Valsecchi, M. Strobl, C. Grünzweig, T.J. Schmidt, P. Boillat, Selective visualization of water in fuel cell gas diffusion layers with neutron dark-field imaging. J. Electrochem. Soc. 166, F149 (2019). https://doi.org/10.1149/2.1011902jes

E. Hoinkis, M. Ziehl, A small-angle neutron scattering study of activated carbon fibers. Carbon 41, 2047 (2003). https://doi.org/10.1016/S0008-6223(03)00201-X

P. Pendleton, L. Chen, Small-angle neutron scattering study of activated carbon cloth and ammonium persulfate-modified activated carbon cloth: effect of oxygen content. Physica B Condens. Matter 385–386, 644 (2006). https://doi.org/10.1016/j.physb.2006.06.120

T.X. Nguyen, S.K. Bhatia, Characterization of accessible and inaccessible pores in microporous carbons by a combination of adsorption and small angle neutron scattering. Carbon 50, 3045 (2012). https://doi.org/10.1016/j.carbon.2012.02.091

S. Boukhalfa, L. He, Y.B. Melnichenko, G. Yushin, Small-angle neutron scattering for in situ probing of ion adsorption inside micropores. Angew. Chem. Int. Ed. 52, 4618 (2013). https://doi.org/10.1002/anie.201209141

S. Boukhalfa, D. Gordon, L. He, Y.B. Melnichenko, N. Nitta, A. Magasinski, G. Yushin, In situ small angle neutron scattering revealing ion sorption in microporous carbon electrical double layer capacitors. ACS Nano 8, 2495 (2014). https://doi.org/10.1021/nn406077n

S. Mascotto, D. Kuzmicz, D. Wallacher, M. Siebenbürger, D. Clemens, S. Risse, J. Yuan, M. Antonietti, M. Ballauff, Poly(ionic liquid)-derived nanoporous carbon analyzed by combination of gas physisorption and small-angle neutron scattering. Carbon 82, 425 (2015). https://doi.org/10.1016/j.carbon.2014.10.086

C. Prehal, D. Weingarth, E. Perre, R.T. Lechner, H. Amenitsch, O. Paris, V. Presser, Tracking the structural arrangement of ions in carbon supercapacitor nanopores using in situ small-angle x-ray scattering. Energy Environ. Sci. 8, 1725 (2015). https://doi.org/10.1039/C5EE00488H

C.J. Jafta, A. Petzold, S. Risse, D. Clemens, D. Wallacher, G. Goerigk, M. Ballauff, Correlating pore size and shape to local disorder in microporous carbon: a combined small angle neutron and x-ray scattering study. Carbon 123, 440 (2017). https://doi.org/10.1016/j.carbon.2017.07.046

C.J. Gabelich, T.D. Tran, I.H.M. Suffet, Electrosorption of inorganic salts from aqueous solution using carbon aerogels. Environ. Sci. Technol. 36, 3010 (2002). https://doi.org/10.1021/es0112745

Y. Li, C. Zhang, Y. Jiang, T.-J. Wang, H. Wang, Effects of the hydration ratio on the electrosorption selectivity of ions during capacitive deionization. Desalination 399, 171 (2016). https://doi.org/10.1016/j.desal.2016.09.011

M.R. Cerón, F. Aydin, S.A. Hawks, D.I. Oyarzun, C.K. Loeb, A. Deinhart, C. Zhan, T.A. Pham, M. Stadermann, P.G. Campbell, Cation selectivity in capacitive deionization: elucidating the role of pore size, electrode potential, and ion dehydration. ACS Appl. Mater. Interfaces 12, 42644 (2020). https://doi.org/10.1021/acsami.0c07903

X. Zhang, K. Zuo, X. Zhang, C. Zhang, P. Liang, Selective ion separation by capacitive deionization (CDI) based technologies: a state-of-the-art review. Environ. Sci.: Water Res. Technol 6, 243 (2020). https://doi.org/10.1039/C9EW00835G

J.G. Gamaethiralalage, K. Singh, S. Sahin, J. Yoon, M. Elimelech, M.E. Suss, P. Liang, P.M. Biesheuvel, R.L. Zornitta, L.C.P.M. de Smet, Recent advances in ion selectivity with capacitive deionization. Energy Environ. Sci. 14, 1095 (2021). https://doi.org/10.1039/D0EE03145C

T.A. Butcher, L. Prendeville, A. Rafferty, P. Trtik, P. Boillat, J.M.D. Coey, Activated carbon cloth electrodes for capacitive deionization: a neutron imaging study (2023). https://doi.org/10.5281/zenodo.10065736

Acknowledgements

This work is based on experiments performed at the Swiss spallation neutron source SINQ, Paul Scherrer Institute, Villigen, Switzerland. Support from the European Commission under Contract No. 766007 for the MAMI Marie Curie International Training Network is acknowledged. L. Prendeville acknowledges support from the Irish Research Council under Grant No. GOIPG/2019/4430. The authors would like to thank Niclas Teichert for performing SEM characterization at the CRANN Advanced Microscopy Laboratory.

Funding

Open Access funding provided by the IReL Consortium

Author information

Authors and Affiliations

Contributions

T.A.B. conceived the project. T.A.B., L.P. and P.T. carried out neutron imaging experiments with support from P.B. T.A.B. analyzed the data. A.R. characterized the ACC. J.M.D.C. supervised and secured funding for the project. T.A.B. wrote the manuscript with input from all authors.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Time-sequenced images of \(\Delta c_{\textrm{Gd}}\) during charge and discharge processes are shown in Fig. 5. There is a detailed explanation of quantitative analysis of \(\Delta c_{\textrm{Gd}}\) from the neutron images.

Supplementary file 2 (avi 1152 KB)

Supplementary file 2 (avi 1186 KB)

Supplementary file 4 (avi 446 KB)

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Butcher, T.A., Prendeville, L., Rafferty, A. et al. Activated carbon cloth electrodes for capacitive deionization: a neutron imaging study. Appl. Phys. A 130, 218 (2024). https://doi.org/10.1007/s00339-024-07343-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-024-07343-8