Abstract

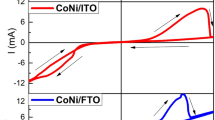

An FTO thin film was first deposited onto a glass substrate via the spray pyrolysis technique. To investigate the influence of the used salt and, consequently, structural properties on electrochemical performance, two precursor solutions were prepared from copper chloride dihydrate and copper acetate monohydrate and spray-deposited onto the FTO thin films. Considerable differences were observed in the physical characteristics of the resulting CuO thin films derived from different precursor solutions. The XRD results were employed to estimate the crystallite size and strain for the prepared CuO thin films via the Williamson–Hall method, as well as lattice parameters. Accordingly, the CuO thin film deposited from chlorine salt showed a greater crystallite size, lower strain, and unit volume cell. The Hall effect measurement revealed that there is slightly less resistivity for the CuO prepared from chlorine salt; however, mobility and carrier concentration were significantly different for the CuO thin films. The Randles–Sevcik equation was used to calculate the diffusion coefficient, and it is found that the structural characteristics of CuO grown from acetate salt (6.43 × 10–6 cm2/s) are in favor of better ion diffusion in compare with chloride salt (4.72 × 10–6 cm2/s). Similarly, the estimated equivalent distribution resistance from the Nyquist plot for CuO thin films spray-deposited from chlorine (250.11 Ω) and acetate (130.01 Ω) confirmed the better ion diffusion for the acetate solution-derived CuO thin film. Capacitance was calculated from cyclic voltammetry, galvanostatic charge–discharge, and electrochemical impedance spectroscopy, all of which confirmed better ion storage performance in CuO deposited from acetate salt due to the superior ion diffusion characteristics of the mentioned thin film.

Similar content being viewed by others

Data and code availability

The data that support the findings of this study are available in the manuscript.

References

Y.K. Jeong, G.M. Choi, J. Phys. Chem. Solids 57, 81 (1996). https://doi.org/10.1016/0022-3697(95)00130-1

Q. Zhang, K. Zhang, D. Xu, G. Yang, H. Huang, F. Nie, C. Liu, S. Yang, Prog. Mater. Sci. 60, 208 (2014). https://doi.org/10.1016/j.pmatsci.2013.09.003

H.Z. Asl, S.M. Rozati, J. Electron. Mater. 46, 5020 (2017). https://doi.org/10.1007/s11664-017-5510-0

T. Terasako, T. Murakami, A. Hyodou, S. Shirakata, Sol. Energy Mater. Sol. Cells 132, 74 (2015). https://doi.org/10.1016/j.solmat.2014.08.023

H.Z. Asl, S.M. Rozati, J. Mater. Sci. Mater. Electron. 29, 4365 (2018). https://doi.org/10.1007/s10854-017-8385-1

D. Wojcieszak, A. Obstarczyk, E. Mańkowska, M. Mazur, D. Kaczmarek, K. Zakrzewska, P. Mazur, J. Domaradzki, Mater. Res. Bull. 147, 111646 (2022). https://doi.org/10.1016/j.materresbull.2021.111646

B.S. Kang, S.-E. Ahn, M.-J. Lee, G. Stefanovich, K.H. Kim, W.X. Xianyu, C.B. Lee, Y. Park, I.G. Baek, B.H. Park, Adv. Mater. 20, 3066 (2008). https://doi.org/10.1002/adma.200702932

S.K. Shinde, S.M. Mohite, A.A. Kadam, H.M. Yadav, G.S. Ghodake, K.Y. Rajpure, D.S. Lee, D.Y. Kim, J. Electroanal. Chem. 850, 113433 (2019). https://doi.org/10.1016/j.jelechem.2019.113433

S.K. Shinde, D.Y. Kim, G.S. Ghodake, N.C. Maile, A.A. Kadam, D.S. Lee, M.C. Rath, V.J. Fulari, Ultrason. Sonochem. 40, 314 (2018). https://doi.org/10.1016/j.ultsonch.2017.07.014

L. Filipovic, S. Selberherr, G.C. Mutinati, E. Brunet, S. Steinhauer, A. Köck, J. Teva, J. Kraft, J. Siegert, F. Schrank, Microelectron. Eng. 117, 57 (2014). https://doi.org/10.1016/j.mee.2013.12.025

S. RahemiArdekani, A. Sabour RouhAghdam, M. Nazari, A. Bayat, E. Yazdani, E. Saievar-Iranizad, J. Anal. Appl. Pyrolysis 141, 104631 (2019). https://doi.org/10.1016/j.jaap.2019.104631

H.Z. Asl, S.M. Rozati, J. Electron. Mater. 47, 3568 (2018). https://doi.org/10.1007/s11664-018-6201-1

S. Jongthammanurak, M. Witana, T. Cheawkul, C. Thanachayanont, Mater. Sci. Semicond. Process. 16, 625 (2013). https://doi.org/10.1016/j.mssp.2012.11.009

R.J. Deokate, A.V. Moholkar, G.L. Agawane, S.M. Pawar, J.H. Kim, K.Y. Rajpure, Appl. Surf. Sci. 256, 3522 (2010). https://doi.org/10.1016/j.apsusc.2009.12.102

C. Abdelmounaïm, Z. Amara, A. Maha, D. Mustapha, Mater. Sci. Semicond. Process. 43, 214 (2016). https://doi.org/10.1016/j.mssp.2015.12.019

H.Z. Asl, S.M. Rozati, J. Mater. Sci. Mater. Electron. 31, 2537 (2020). https://doi.org/10.1007/s10854-019-02790-z

H.Z. Asl, S.M. Rozati, Appl. Phys. A 125, 689 (2019). https://doi.org/10.1007/s00339-019-2943-8

H.Z. Asl, S.M. Rozati, Mater. Res. Ibero. Am. J. (2018). https://doi.org/10.1590/1980-5373-MR-2017-0754

H.Z. Asl, S.M. Rozati, J. Electron. Mater. 49, 1534 (2019). https://doi.org/10.1007/s11664-019-07858-4

T.Y. Tiong, C.F. Dee, A.A. Hamzah, B.Y. Majlis, S. Abdul Rahman, Sens. Actuators B Actuators B 202, 1322 (2014). https://doi.org/10.1016/j.snb.2014.05.126

D. Nath, F. Singh, R. Das, Mater. Chem. Phys. 239, 122021 (2020). https://doi.org/10.1016/j.matchemphys.2019.122021

I. Singh, R.K. Bedi, Appl. Surf. Sci. 257, 7592 (2011). https://doi.org/10.1016/j.apsusc.2011.03.133

H. Liu, X. Wang, M. Li, S. Yu, R. Zheng, Ceram. Int. 45, 14347 (2019). https://doi.org/10.1016/j.ceramint.2019.04.149

Y. Kajikawa, J. Appl. Phys. 114, 053707 (2013). https://doi.org/10.1063/1.4817243

D. Wu, Q. Zhang, M. Tao, Phys. Rev. B 73, 235206 (2006). https://doi.org/10.1103/PhysRevB.73.235206

R. Shabu, A.M.E. Raj, C. Sanjeeviraja, C. Ravidhas, Mater. Res. Bull. 68, 1 (2015). https://doi.org/10.1016/j.materresbull.2015.03.016

T. Parvathy, N.A. Muhammed Sabeer, N. Mohan, P.P. Pradyumnan, Opt. Mater. 125, 112031 (2022). https://doi.org/10.1016/j.optmat.2022.112031

H.Z. Asl, S.M. Rozati, J. Mater. Sci. Mater. Electron. 31, 14537 (2020). https://doi.org/10.1007/s10854-020-04014-1

H. Mersian, M. Alizadeh, Ceram. Int. 46, 17197 (2020). https://doi.org/10.1016/j.ceramint.2020.03.275

W. Li, J.D. Patterson, Phys. Rev. B 50, 14903 (1994). https://doi.org/10.1103/PhysRevB.50.14903

H. Zare Asl, S.M. Rozati, Chem. Phys. Lett. Phys. Lett. 815, 140364 (2023). https://doi.org/10.1016/j.cplett.2023.140364

G. Wang, J. Huang, S. Chen, Y. Gao, D. Cao, J. Power. Sources 196, 5756 (2011). https://doi.org/10.1016/j.jpowsour.2011.02.049

M. Divagar, N. Ponpandian, C. Viswanathan, Mater. Sci. Eng. B. Sci. Eng. B 270, 115229 (2021). https://doi.org/10.1016/j.mseb.2021.115229

R. Kumar, A. Agrawal, T. Bhuvana, A. Sharma, Electrochim. Acta 270, 87 (2018). https://doi.org/10.1016/j.electacta.2018.03.076

D. Shen, K. Steinberg, R. Akolkar, J. Electrochem. Soc. 165, E808 (2018). https://doi.org/10.1149/2.1011814jes

A.M. Teli, T.S. Bhat, S.A. Beknalkar, S.M. Mane, L.S. Chaudhary, D.S. Patil, S.A. Pawar, H. Efstathiadis, J. Cheol Shin, Chem. Eng. J. Eng. J. 430, 133138 (2022). https://doi.org/10.1016/j.cej.2021.133138

M.A. Yewale, R.A. Kadam, N.K. Kaushik, L.N. Nguyen, U.T. Nakate, L.P. Lingamdinne, J.R. Koduru, P.S. Auti, S.V.P. Vattikuti, D.K. Shin, Colloids Surf. A 653, 129901 (2022). https://doi.org/10.1016/j.colsurfa.2022.129901

A. Hagfeldt, M. Graetzel, Chem. Rev. 95, 49 (1995). https://doi.org/10.1021/cr00033a003

J.A. Rajesh, J.Y. Park, S.H. Kang, K.-S. Ahn, Electrochim. Acta 414, 140203 (2022). https://doi.org/10.1016/j.electacta.2022.140203

M.R. Waikar, A.A. Shaikh, R.G. Sonkawade, Vacuum 161, 168 (2019). https://doi.org/10.1016/j.vacuum.2018.12.034

X. Liu, Z. Chang, L. Luo, T. Xu, X. Lei, J. Liu, X. Sun, Chem. Mater. 26, 1889 (2014). https://doi.org/10.1021/cm4040903

H. Behzad, F.E. Ghodsi, J. Mater. Sci. Mater. Electron. 27, 6096 (2016). https://doi.org/10.1007/s10854-016-4535-0

H.Z. Asl, S.M. Rozati, J. Alloys Compd. 928, 167211 (2022). https://doi.org/10.1016/j.jallcom.2022.167211

H. Behzad, F.E. Ghodsi, H. Karaağaç, Ionics 23, 2429 (2017). https://doi.org/10.1007/s11581-017-2081-2

I.V. Esarev, D.V. Agafonov, Y.V. Surovikin, S.N. Nesov, A.V. Lavrenov, Electrochim. Acta 390, 138896 (2021). https://doi.org/10.1016/j.electacta.2021.138896

B.-A. Mei, O. Munteshari, J. Lau, B. Dunn, L. Pilon, J. Phys. Chem. C 122, 194 (2018). https://doi.org/10.1021/acs.jpcc.7b10582

H. Wang, L. Pilon, Electrochim. Acta 76, 529 (2012). https://doi.org/10.1016/j.electacta.2012.05.039

C. Lei, F. Markoulidis, Z. Ashitaka, C. Lekakou, Electrochim. Acta 92, 183 (2013). https://doi.org/10.1016/j.electacta.2012.12.092

Acknowledgements

The authors thanks Behbahan Khatam Alanbia university of technology for financial support (Grant Numbers 3.2.5560).

Author information

Authors and Affiliations

Contributions

HZA: conceptualization, methodology, validation, investigation, resources, writing—original draft preparation, visualization. SMR: conceptualization, resources, writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Asl, H.Z., Rozati, S.M. Influence of structural properties on the electrochemical performance of FTO/CuO double-layer thin-film spray-deposited from different precursor solutions. Appl. Phys. A 129, 786 (2023). https://doi.org/10.1007/s00339-023-07070-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-023-07070-6