Abstract

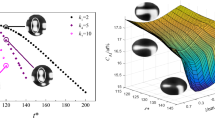

The inseparability of material macroscopic properties and microstructure has prompted scholars to continuously delve into microstructural studies. The phase-field method has become an important basis for modern microstructure simulation techniques. The difficulty of the phase-field method lies in the modeling and parameter input. In this paper, the evolution mechanism of carbide precipitation in the process of plasma cladding of nickel-based alloy on phosphorus removal roll is investigated by the method of phase-field modeling and finite-element coupling. A Ni–Cr–C ternary phase-field precipitation model is developed, and the Ni40A macroscopic solidification process is simulated by ProCAST software, and then the boundary conditions are input into the phase-field model to simulate the carbide precipitation process in the solidification of nickel-based alloy. The simulated atomic diagram shows that the carbide is a core–shell structure, consisting of a Cr-rich core and a C-rich shell, and the carbide morphology changes significantly after coupling the elastic energy. The simulation results are in good agreement with the experimental results, which verifies the feasibility and accuracy of the phase-field method.

Similar content being viewed by others

Data availability

Data supporting the findings of this study are available in Thermodynamic evaluation of the Cr-Ni-C system. These data were derived from the following resources available in the public domain: https://link.springer.com/article/10.1007/BF02646072. Kajihara M, Hillert M. Thermodynamic evaluation of the Cr-Ni-C system [J]. Metallurgical Transactions A, 1990, 21(10):2777–2787.

References

Z. Shengli, Optimization of the construction of a phosphorus removal box before hot rolling finishing of steel. Powder Metall. Mater. Sci. Eng. 24(6), 6 (2019)

A.H. Li, J.N. Ren, C.W. Huang et al., Progress in the study of the interfacial evolution of the phase field method for the precipitation process of nickel-based alloys. Therm. Process. Technol. 40(14), 1–3 (2011). https://doi.org/10.14158/j.cnki.1001-3814.2011.14.034

Ju. Du Xinglin, M.H. Quan et al., Precipitation behavior of M23C6-type carbides of GH3230 alloy. Metal Heat Treat. 002, 046 (2021)

S. Luo, W. Wang et al., Numerical Simulation of Dendritic Growth of Fe-C Binary Alloy Using Cellular Automation Model (John Wiley and Sons Inc, 2017)

S. Luo, W. Wang, M. Zhu, Cellular automaton modeling of dendritic growth of Fe-C binary alloy with thermosolutal convection. Int. J. Heat Mass Transf. 116, 940–950 (2018). https://doi.org/10.1016/j.ijheatmasstransfer.2017.09.074

O. Zinovieva, A. Zinoviev, V. Ploshikhin, Three-dimensional modeling of the microstructure evolution during metal additive manufacturing. Comput. Mater. Sci. 141, 207–220 (2018). https://doi.org/10.1016/j.commatsci.2017.09.018

C. Rui, X. Qingyan et al., A modified cellular automaton model for the quantitative prediction of equiaxed and columnar dendritic growth. J. Mater. Sci. Technol. (2014). https://doi.org/10.1016/j.jmst.2014.06.006

Y. Lian, Z. Gan, C. Yu et al., A cellular automaton finite volume method for microstructure evolution during additive manufacturing. Mater. Des. (2019). https://doi.org/10.1016/j.matdes.2019.107672

H. Yin, S.D. Felicelli, Dendrite growth simulation during solidification in the LENS process. Acta Mater. 58(4), 1455–1465 (2010). https://doi.org/10.1016/j.actamat.2009.10.053

Y. Liu, L. Cheng, Q. Zeng et al., Monte Carlo simulation of polycrystalline microstructures and finite element stress analysis. Mater. Des. 55, 740–746 (2014). https://doi.org/10.1016/j.matdes.2013.10.047

H.L. Wei, J.W. Elmer, T. Debroy, Three-dimensional modeling of grain structure evolution during welding of an aluminum alloy. Acta Mater. 126, 413–425 (2017). https://doi.org/10.1016/j.actamat.2016.12.073

S. Mordechai, Applications of Monte Carlo Method in Science and Engineering (InTech, 2011)

C. Yang, X. Wang, H.M. Jafri et al., Fe-C peritectic solidification of polycrystalline ferrite by phase-field method. Comput. Mater. Sci. 178, 109626 (2020)

T.Z. Gong, Y. Chen, W.Y. Hao et al., Modeling segregation of Fe–C alloy in solidification by phase-field method coupled with thermodynamics. Metals 13(6), 1148 (2023)

Y. He, L.-W. Zhang, J. Niu, CA method and its application in mesoscopic simulation of materials. Met. Heat Treat. 30(5), 6 (2005). https://doi.org/10.3969/j.issn.0254-6051.2005.05.021

C. Li-Li, Multi-scale simulation of the organization of TIG welded joints of nickel-based alloys based on CA method. Nanjing Univ. Aeronaut. Astronaut (2020). https://doi.org/10.27239/d.cnki.gnhhu.2020.001577

W.U. Zhouzhi, Numerical simulation study of powder sintering process based on thermal-force-diffusion coupling model. Chongqing Univ. (2021). https://doi.org/10.27670/d.cnki.gcqdu.2021.001451

A. Lingmin, Multi-Field Coupled Simulation of Solidification Process of Polyalloys by Phase Field Method (Lanzhou University of Technology, 2014)

B.I. Halperin, P.C. Hohenberg, S.K. Ma, Renormalization-group methods for critical dynamics: I. Recursion relations and effects of energy conservation. Phys. Rev. B (1974). https://doi.org/10.1103/physrevb.10.139

A.A. Wheeler, W.J. Boettinger, G.B. Mcfadden, Phase-field model for isothermal phase transitions in binary alloys. Phys. Rev. (1991). https://doi.org/10.1103/PhysRevA.45.7424

S.G. Kim, W.T. Kim, T. Suzuki, Phase-field model for binary alloys. Phys. Rev. E 60(6), 7186 (1999)

I. Steinbach, F. Pezzolla, A Generalized Field Method for Multiphase Transformations Using Interface Fields (Elsevier Science Publishers BV, 1999). https://doi.org/10.1016/S0167-2789(99)00129-3

T. Jinjun, Simulation and experimental validation of microstructure of Al-Cu eutectic alloy based on Thermo-Calc thermodynamic calculation. Harbin Inst. Technol. (2010). https://doi.org/10.7666/d.D269139

Li. Leiji, Li. Wanming, C. Ming et al., Current status of the application of phase field method in metal solidification process. J. Iron Steel Res. 32(10), 13 (2020). https://doi.org/10.13228/j.boyuan.issn1001-0963.20200079

R. Poduri, L.Q. Chen, Computer simulation of atomic ordering and compositional clustering in the pseudobinary Ni_3Al-Ni_3V system. Acta Mater. 46(5), 1719–1729 (1998)

He. Bo, T. Yao, Z. Yan et al., Three-dimensional phase field study of γ’ phase coarsening behavior of Ni-Al alloy based on KKS model. Shanghai Metals 39(5), 7 (2017). https://doi.org/10.3969/j.issn.1001-7208.2017.05.017

Y.H. Zhao, H. Hou, J. Ren, Microphase field of Ni-Mo tetra-neighboring interaction energy on the precipitation behavior of Ni_(75)Al_(14)Mo_(11) alloy. J. Cent. South Univ. 43(8), 9 (2012)

C.H.U. Zhong, C.H.E.N. Zheng, W.A.N.G. Yongxin et al., Progress of microstructure simulation of alloys by microphase field method. Mater. Guide 18(z2), 204–206 (2004). https://doi.org/10.3321/j.issn:1005-023X.2004.z2.062

Y.-Y. Sun, Phase Field Method to Study the Elastic Field and Trace Element Modulation of Cu-Rich Phase Precipitation Process in Fe-Cu-Mn-Ni-Al Alloy (North Central University, 2023)

T. Wang, An Integrated Approach for Microstructure Simulation: Application to Ni-Al-Mo Alloys (Springer, 2006)

S.B. Biner, Programming Phase-Field Modeling (Springer International Publishing, 2017)

S.J. Lee, D.K. Matlock, C.J.V. Tyne, An empirical model for carbon diffusion in austenite incorporating alloying element effects. ISIJ Int. 51(11), 1903–1911 (2011)

E.J. Ku, K. Stránsky, Diffusion in iron, iron solid solutions and steels. Mater. Sci. Eng. 52(1), 1–38 (1982)

S. Yuanyang, Z. Yuhong, Z. Baojun et al., Phase-field modeling of microstructure evolution of Cu-rich phase in Fe–Cu–Mn–Ni–Al quinary system coupled with thermodynamic databases. J. Mater. Sci. 54(16), 11263–11278 (2019). https://doi.org/10.1007/s10853-019-03678-3

L.Q. Chen, J. Shen, Applications of semi-implicit Fourier-spectral method to phase field equations. Comput. Phys. Commun. 108(2), 147–158 (1998). https://doi.org/10.1016/S0010-4655(97)00115-X

Y.A.N.G. Fang-Fang, Y.A.N.G. Bin-Xin, Non-isothermal Fourier spectral phase field simulation of the precipitation behavior of quaternary alloys. J. Taiyuan Univ. Sci. Technol. 002, 043 (2022)

Y. Yi, Theoretical Study of Carbide Stability and High-Temperature Elastic Properties in Nickel-Based Alloys (Xiamen University, 2023)

Y.C. Zhang, J.C. Wang, Y.J. Yang et al., Simulation of elastic field effects on nucleation and microstructure in precipitated phase transformation by phase field method. Chin. J. Aeronaut. (Engl. Ed.) 20(2), 107–110 (2007)

J.Z. Zhu et al., Three-dimensional phase-field simulations of coarsening kinetics of γ′ particles in binary Ni–Al alloys. Acta Mater. (2004). https://doi.org/10.1016/j.actamat.2004.02.032

Y. Peng, Y. Du, M. Stratmann et al., Precipitation of γ′ in the γ binder phase of WC-Al-Co-Ni cemented carbide: a phase-field study. Calphad (2020). https://doi.org/10.1016/j.calphad.2019.101717

L. Liu, Y. Zhao et al., Phase-field study on effects of antiphase domain and elastic energy on evolution of γ′ precipitates in nickel-based superalloys. Comput. Mater. Sci. 129, 211–219 (2017). https://doi.org/10.1016/j.commatsci.2016.11.036

F. Schleifer, M. Holzinger, Y.Y. Lin et al., Phase-field modeling of γ/γ" microstructure formation in Ni-based superalloys with high γ" volume fraction. Intermetallics (2020). https://doi.org/10.1016/j.intermet.2020.106745

W. Sun, S. Cui, L. Zhang et al., Phase-field simulation of microstructural evolution of γ precipitate in γ’ matrix in binary Ni-Al alloys. IUMRS Int. Conf. Asia (2011). https://doi.org/10.1016/j.proeng.2012.03.031

X. Zheng, Y. Zhao, H. Hou et al., Effect of elastic distortion energy on the whole process of L12 phase precipitation by microscopic phase field simulation. Chin. J. Nonferrous Met. 27(10), 7 (2017). https://doi.org/10.19476/j.ysxb.1004.0609.2017.10.17

M. Kajihara, M. Hillert, Thermodynamic evaluation of the Cr-Ni-C system. Metall. Trans. A 21(10), 2777–2787 (1990)

B.I. Leonovich, Thermodynamic analysis and phase equilibria in the Ni-Cr-C system. Steel Transl. 41(5), 371 (2011)

B.J. Lee, On the stability of Cr carbides. Calphad 16(2), 121–149 (1992)

Funding

This research was supported by the National Key Research and Development Program (No. 2021YFB3702003).

Author information

Authors and Affiliations

Contributions

Conceptualization: M.C. and S.L.; methodology: J.J. and M.C.; validation: J.J. and C.Z.; formal Analysis: J.J. and C.Z.; experiment: C.Z.; resources: M.C.; Supervision: M.C.; writing—original draft preparation: J.J.; funding acquisition: Z.X.

Corresponding author

Ethics declarations

Conflict of interest

All the authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

In this paper, in constructing the phase-specific molar free energy of the ternary system through the sub-point solvation model, a thermodynamic evaluation of the ternary alloy system is required, and its corresponding Gibbs free energy and interaction coefficients are queried through the literature [45,46,47], and its specific thermodynamic and kinetic parameters are shown as follows:

Liquid phase

BCC phase

FCC phase

Graphite

M23C6 phase

SYMBOLS

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ji, J., Zhang, C., Li, S. et al. Simulation of M23C6 precipitation mechanism during solidification of Ni40A coated on phosphorus removal roll by phase field method. Appl. Phys. A 129, 618 (2023). https://doi.org/10.1007/s00339-023-06872-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-023-06872-y