Abstract

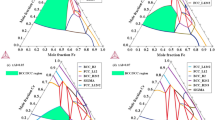

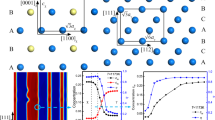

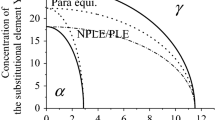

The simulation of microstructural evolution in multi-principal element alloys is still challenging although for alloy development it is of high importance. In the work, a phase-field model linked with CALPHAD thermodynamic databases is utilized to explore the microstructural evolution during diffusion-controlled phase separation in the Fe–Ni–Cr–Co–Cu high-entropy alloy system with elastic lattice misfit. The compositional fluctuation and temperature effect on the elemental distribution and the kinetics of Cu-enriched phase formation are systematically investigated. The simulated results show that the Cu-enriched phase has a complicated core–shell structure consisting of a Cu-enriched core and a Ni/Fe shell. The latter as a buffer layer possesses retardant effect on the formation of Cu-enriched precipitates. Furthermore, the high Ni/Fe concentration delays the phase separation, growth and coarsening of the Cu-enriched phase, leading to particle refinement and the increasing width of the Ni/Fe shell. Besides, high temperature accelerates the phase separation and simultaneously promotes the growth and coarsening of nanoscale Cu-enriched precipitates. The present work expands the knowledge of phase separation in multicomponent alloy systems and provides insights to optimize material microstructure and properties.

Similar content being viewed by others

References

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, S.Y. Chang, Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Adv. Eng. Mater. 6, 299–303 (2004)

B. Cantor, I. Chang, P. Knight, A. Vincent, Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 375, 213–218 (2004)

D.B. Miracle, O.N. Senkov, A critical review of high entropy alloys and related concepts. Acta Mater. 122, 448–511 (2017)

Z. Li, S. Zhao, R.O. Ritchie, M.A. Meyers, Mechanical properties of high-entropy alloys with emphasis on face-centered cubic alloys. Prog. Mater Sci. 102, 296–345 (2019)

G. Laplanche, A. Kostka, O. Horst, G. Eggeler, E. George, Microstructure evolution and critical stress for twinning in the CrMnFeCoNi high-entropy alloy. Acta Mater. 118, 152–163 (2016)

L. Zhang, J. Fan, D. Liu, M. Zhang, P. Yu, Q. Jing, M. Ma, P. Liaw, G. Li, R. Liu, The microstructural evolution and hardness of the equiatomic CoCrCuFeNi high-entropy alloy in the semi-solid state. J. Alloy. Compd. 745, 75–83 (2018)

X. Xu, P. Liu, S. Guo, A. Hirata, T. Fujita, T. Nieh, C. Liu, M. Chen, Nanoscale phase separation in a fcc-based CoCrCuFeNiAl0 5 high-entropy alloy. Acta. Mater. 84, 145–152 (2015)

G. Qin, Z. Li, R. Chen, H. Zheng, C. Fan, L. Wang, Y. Su, H. Ding, J. Guo, H. Fu, CoCrFeMnNi high-entropy alloys reinforced with Laves phase by adding Nb and Ti elements. J. Mater. Res. 34, 1011–1020 (2019)

A. Verma, P. Tarate, A. Abhyankar, M. Mohape, D. Gowtam, V. Deshmukh, T. Shanmugasundaram, High temperature wear in CoCrFeNiCux high entropy alloys: The role of Cu. Scripta Mater. 161, 28–31 (2019)

K. Lin, C. Wei, Y. He, C. Li, P. Zhang, J. Li, J. Wang, Formation of core-shell structure in immiscible CoCrCuFe1 5Ni0 5 high-entropy alloy. Mater. Lett. (2022). https://doi.org/10.1016/j.matlet.2022.132452

Y.K. Kim, B.J. Lee, S.-K. Hong, S.I. Hong, Strengthening and fracture of deformation-processed dual fcc-phase CoCrFeCuNi and CoCrFeCu1 71Ni high entropy alloys. Mater. Sci. Eng., A 781, 1392 (2020)

C.-M. Lin, H.-L. Tsai, Effect of annealing treatment on microstructure and properties of high-entropy FeCoNiCrCu0. 5 alloy. Materials Chem Phys 128, 50–56 (2011)

C.-M. Lin, H.-L. Tsai, Equilibrium phase of high-entropy FeCoNiCrCu0. 5 alloy at elevated temperature. J Alloys Compounds. 489, 30–35 (2010)

S.M. Oh, S.I. Hong, Microstructural stability and mechanical properties of equiatomic CoCrCuFeNi, CrCuFeMnNi, CoCrCuFeMn alloys. Mater. Chem. Phys. 210, 120–125 (2018)

H. Zheng, R. Chen, G. Qin, X. Li, Y. Su, H. Ding, J. Guo, H. Fu, Microstructure evolution, Cu segregation and tensile properties of CoCrFeNiCu high entropy alloy during directional solidification. J. Mater. Sci. Technol. 38, 19–27 (2020)

C. Du, L. Hu, Q. Pan, K. Chen, P. Zhou, G. Wang, Effect of Cu on the strengthening and embrittling of an FeCoNiCr-xCu HEA. Mater. Sci. Eng. A 832, 142413 (2022)

K. Kadirvel, Z. Kloenne, J.K. Jensen, H. Fraser, Y. Wang, Phase-field modelling of transformation pathways and microstructural evolution in multi-principal element alloys. Appl. Phys. Lett. 119, 171905 (2021)

N. Shah, M. Rahul, G. Phanikumar, Accelerated design of eutectic high entropy alloys by ICME approach. Metall. and Mater. Trans. A. 52, 1574–1580 (2021)

Y. Sun, Y. Zhao, B. Zhao, Z. Guo, X. Tian, W. Yang, H. Hou, Multi-component phase-field simulation of microstructural evolution and elemental distribution in Fe–Cu–Mn–Ni–Al alloy. Calphad 69, 101759 (2020)

A.M. Jokisaari, P. Voorhees, J.E. Guyer, J. Warren, O. Heinonen, Benchmark problems for numerical implementations of phase field models. Comput. Mater. Sci. 126, 139–151 (2017)

A. Choudhury, M. Kellner, B. Nestler, A method for coupling the phase-field model based on a grand-potential formalism to thermodynamic databases. Curr. Opin. Solid State Mater. Sci. 19, 287–300 (2015)

J. Li, Z. Li, Q. Wang, C. Dong, P. Liaw, Phase-field simulation of coherent BCC/B2 microstructures in high entropy alloys. Acta Mater. 197, 10–19 (2020)

D. Schwen, C. Jiang, L. Aagesen, A sublattice phase-field model for direct CALPHAD database coupling. Comput. Mater. Sci. 195, 110466 (2021)

Y.A. Coutinho, N. Vervliet, L. De Lathauwer, N. Moelans, Combining thermodynamics with tensor completion techniques to enable multicomponent microstructure prediction. npj. Comput. Mater. 6, 1–11 (2020)

S. Chatterjee, N. Moelans, A grand-potential based phase-field approach for simulating growth of intermetallic phases in multicomponent alloy systems. Acta Mater. 206, 116630 (2021)

X. Zuo, Y. Coutinho, S. Chatterjee, N. Moelans, Phase field simulations of FCC to BCC phase transformation in (Al) CrFeNi medium entropy alloys. Materials Theory 6, 1–24 (2022)

N. Valizadeh, T. Rabczuk, Isogeometric analysis of hydrodynamics of vesicles using a monolithic phase-field approach. Comput. Methods Appl. Mech. Eng. 388, 114191 (2022)

J. López, N. Valizadeh, T. Rabczuk, An isogeometric phase–field based shape and topology optimization for flexoelectric structures. Comput. Methods Appl. Mech. Eng. 391, 114564 (2022)

M. Ashour, N. Valizadeh, T. Rabczuk, Isogeometric analysis for a phase-field constrained optimization problem of morphological evolution of vesicles in electrical fields. Comput. Methods Appl. Mech. Eng. 377, 113669 (2021)

F. Amiri, S. Ziaei-Rad, N. Valizadeh, T. Rabczuk, On the use of local maximum entropy approximants for Cahn-Hilliard phase-field models in 2D domains and on surfaces. Comput. Methods Appl. Mech. Eng. 346, 1–24 (2019)

X. Yang, Y. Zhang, Prediction of high-entropy stabilized solid-solution in multi-component alloys. Mater. Chem. Phys. 132, 233–238 (2012)

B. Li, L. Zhang, C. Li, Q. Li, J. Chen, G. Shu, Y. Weng, B. Xu, S. Hu, W. Liu, The effect of Mn/Ni on thermodynamic properties of critical nucleus in Fe-Cu-Mn (Ni) ternary alloys. J. Nucl. Mater. 507, 59–67 (2018)

N. Saunders, A.P. Miodownik, CALPHAD (calculation of phase diagrams): a comprehensive guide (Elsevier, Amsterdam, 1998)

J. Zhu, L.-Q. Chen, J. Shen, V. Tikare, Coarsening kinetics from a variable-mobility Cahn-Hilliard equation: Application of a semi-implicit Fourier spectral method. Phys. Rev. E 60, 3564 (1999)

T. He, Y. Ji, Y. Qi, L.-Q. Chen, M. Feng, Stress-dependence of dislocation dissociation, nucleation and annihilation in elastically anisotropic Cu. Int. J. Plast 138, 102927 (2021)

T. Koyama, H. Onodera, Phase-field simulation of phase decomposition in Fe− Cr− Co alloy under an external magnetic field. Met. Mater. Int. 10, 321–326 (2004)

T. Koyama, H. Onodera, Computer simulation of phase decomposition in Fe–Cu–Mn–Ni quaternary alloy based on the phase-field method. Mater. Trans. 46, 1187–1192 (2005)

S. Guo, C. Ng, Z. Wang, C. Liu, Solid solutioning in equiatomic alloys: limit set by topological instability. J. Alloy. Compd. 583, 410–413 (2014)

C. Li, R. Dedoncker, L. Li, F. Sedghgooya, F. Zighem, V. Ji, D. Depla, P. Djemia, D. Faurie, Mechanical properties of CoCrCuFeNi multi-principal element alloy thin films on Kapton substrates. Surf. Coat. Technol. 402, 126474 (2020)

Q. Shen, X. Xiong, T. Li, H. Chen, Y. Cheng, W. Liu, Effects of co-addition of Ni and Al on precipitation evolution and mechanical properties of Fe-Cu alloy. Mater. Sci. Eng., A 723, 279–286 (2018)

S. Shu, P.B. Wells, N. Almirall, G.R. Odette, D.D. Morgan, Thermodynamics and kinetics of core-shell versus appendage co-precipitation morphologies: an example in the Fe-Cu-Mn-Ni-Si system. Acta Mater. 157, 298–306 (2018)

C. Kuehmann, P. Voorhees, Ostwald ripening in ternary alloys. Metall. and Mater. Trans. A. 27, 937–943 (1996)

Y. Zhao, H. Chen, Z. Lu, T. Nieh, Thermal stability and coarsening of coherent particles in a precipitation-hardened (NiCoFeCr) 94Ti2Al4 high-entropy alloy. Acta Mater. 147, 184–194 (2018)

I.M. Lifshitz, V.V. Slyozov, The kinetics of precipitation from supersaturated solid solutions. J. Phys. Chem. Solids 19, 35–50 (1961)

C. Wagner, Theorie der alterung von niederschlägen durch umlösen (Ostwald-reifung), Zeitschrift für Elektrochemie, Berichte der Bunsengesellschaft für physikalische. Chemie 65, 581–591 (1961)

K.E. Yoon, R.D. Noebe, D.N. Seidman, Effects of rhenium addition on the temporal evolution of the nanostructure and chemistry of a model Ni–Cr–Al superalloy I: experimental observations. Acta Mater. 55, 1145–1157 (2007)

Acknowledgements

The authors would like to deeply appreciate the support from the National Natural Sciences Foundation of China (U2067220 and 82000980) and the LingChuang Research Project of China National Nuclear Corporation and the Young Talent Project of China National Nuclear Corporation.

Author information

Authors and Affiliations

Contributions

TH contributed to conceptualization, methodology, writing, reviewing and editing. XC was involved in conceptualization, reviewing and editing. YQ contributed to conceptualization, methodology, reviewing and editing. MF was involved in conceptualization, methodology, funding acquisition and supervision.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

He, T., Chen, X., Qi, Y. et al. Phase-field simulation of phase separation coupled with thermodynamic databases in FeNiCrCoCu high-entropy alloys. Appl. Phys. A 128, 987 (2022). https://doi.org/10.1007/s00339-022-06101-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-022-06101-y