Abstract

‘Magic-angled’ structure currently attracts increasing attention from condensed matter physics due to its amazing performance in superconductivity of graphene. The similar pattern formation of nanoparticles will bring about novel physics in nanoscale that causes the next generation nanodevices. However, it remains a challenging task to acquire such patterns by self-assembly process. In this article, we reported a Moiré interference pattern formation of magnetic nanoparticles regulated by a rotational magnetic field. The colloidal concentration, the strength, and the frequency of magnetic field were found to affect the pattern formation. The mechanism lied in a two-step process. First, the magnetic nanoparticles formed bilayers of superlattice driven by hydrophobic interaction of interfacial self-assembly. Then, the bilayers of superlattice yielded asynchronous rotational displacement resulting from the magnetic force so that the Moiré interference pattern of nanoparticles formed. This fabrication methodology based on the field-controlled self-assembly provided a novel and simple means to get ‘magic angled’ structures in nanoscale that will enrich the physical understanding of nanotechnology.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Assembly materials with magnetic nanoparticles have broad application prospects because of their special magnetic effects [1,2,3] and magneto-optical effects [4]. Relationship for the assemblies of nanoparticles among morphology, property and effect has remained a critical issue in multiple scientific fields, such as spin electronics, tissue engineering and theranostic platform [5,6,7]. However, it is arduous to fabricate special patterns consisted of the magnetic nanoparticle with traditional top-down route, such as lithographical technics [8, 9]. Thus, magnetic field is often used to direct the assembly of magnetic nanoparticles. One common case is the formation of 1D chain-like assemblies [10,11,12], where the magnetic field greatly augments controllability of the assembly by inducing strong dipolar interaction between the nanoparticles. Currently, the magnetic field-assisted assembly is already an important approach to fabricate the one-dimensional micro/nano structures. Nevertheless, morphological diversity remains to improve with regard to the magnetic field-assisted assembly. The magnetic nanoparticles generally form the isotropic aggregates and then assemble into one-dimensional chains in the presence of a magnetostatic field. By alteration of the field direction, the nanoparticles can form the hexagonal-packed pattern or the stripe-like pattern [13,14,15]. Furthermore, if the magnetic field is time-varied, the nanoparticles can assemble into fiber-like or disk-like structures [16, 17]. Here, it is seen that the ordered pattern emerges on a relatively large scale rather than at the single nanoparticle level and complex assembly morphology has been seldom reported.

Recently, Moiré interference pattern has received increasing attention from a wide range of areas due to fantastic super-conduction property in “magic angle” bilayer graphene [18, 19]. The well-known “magic angle” structure is the Moiré interference pattern that results from relative displacement of two graphene layers. Given that a single layer of graphene is composed of hexagonal closed carbon atoms, the two layers of hexagonal closed nanoparticle superlattice should also form the Moiré interference pattern. This assembly structure will greatly boost the understanding of nanoscale physics and development of nanodevice. Interfacial self-assembly has shown promising role for the formation of uniform and ordered assembly structure [20, 21]. Based on our experience using rotational magnetic field to direct the assembly of magnetic nanoparticles into disk-like pattern [17], we here for the first time employed a rotational magnetic field to form the Moiré interference pattern of Fe@Fe3O4 nanoparticles during the interfacial self-assembly. Our experimental data further showed this pattern can be tuned by the assembly parameters, especially the field frequency, namely, rotation speed. Fe@Fe3O4 nanoparticle is a type of emerging magnetic nanomaterial that integrates advantages of both Fe3O4 and pure Fe [22]. Bearing resemblance to the intriguing property of “magic angle” graphene, we believe this special assembly pattern of Fe@Fe3O4 nanoparticles will have promising applications in a wide range of areas, including catalysis, spintronics and nanotechnology.

2 Experimental section

2.1 Synthesis of Fe@Fe3O4 nanoparticles

The mixed solution of 20 ml octadecene and 0.3 ml oleyl amine (0.9 mmol) was degassed for 30 min at 120 °C under argon to remove the moisture and oxygen. Then the temperature was raised to 180 °C and 0.7 ml pentancarbonyl iron (Fe(CO)5) was rapidly injected into the solution. Vigorous stirring was carried out under argon cladding. The mixture was kept at 180 °C for 30 min and subsequently cooled to room temperature. The supernatant was sucked out and discarded with a pipette, and the suspension containing black products was transferred into a centrifugal tube. The suspension was washed with hexane under nitrogen protection, followed by adding 30 ml isopropanol to precipitate the Fe@Fe3O4 nanoparticles. The nanoparticles were dispersed into hexane and stored at 4 °C refrigerator. The detailed process can be found at Refs. [21, 22].

2.2 Fabrication of nanoparticle superlattices

One drop (5 μl) of pure water was put on a copper grid to form a semi-sphere, and then 1 μl Fe@Fe3O4 nanoparticle suspension (hexane) was dropped on the surface of the droplet. The mixed droplet evaporated at 20 °C in a closed room around which a rotational magnetic field was imposed. The magnetic field was composed of a pair of permanent magnets with 7 cm space. The magnets were driven to rotate by a motor. The field was parallel to the copper grid, and the copper grid was hung to prevent influences from the mechanical vibration.

2.3 Characterization

The nanoparticle and lattice morphological characterization was done by Optical Imaging System (IX71, Olympus Co. Ltd., Japan), transmission electron microscopy (TEM, JEM-2100, Japan) and scanning electron microscopy (SEM, Zeiss Supra 40 Gemini, Germany). We measured the electrical properties of the assembled nanoparticle superlattice by an impedance analyzer (Agilent 4294A, 40 Hz–110 MHz). The surface energy and surface tension were measured by contact angle measurement (AC220V, 50 Hz, JC2000C2, China).

2.4 Micromagnetics simulation

Micromagnetic simulations were performed using the 3D micromagnetic package OOMMF [1]. The model size is 50 × 50 × 20 nm3 and contains eight grains with a diameter of 15 nm. The material parameters used for the calculation are obtained using an interpolation between the values of Fe and Fe3O4 compositions [2, 3]. The anisotropy constant K1 is − 2.75 × 103 J/m3, the saturation magnetization Ms is 7.22 × 105 T, and the exchange integral A is 2.44 × 10–11 J/m. The model was discretized into cell sizes of 1 × 1 × 1 nm3, ensuring that for each mesh the average edge length of all the tetrahedral elements was less than the exchange length.

3 Results and discussion

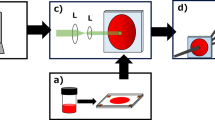

The scheme for interfacial assembly of nanoparticles in the presence of a rotational magnetic field is illustrated in Fig. 1a. The morphological alteration of the droplet was experimentally observed with an Optical Imaging System, as shown in Supporting Information, Fig. S1. With the solvent evaporation, the oil-phased nanoparticles were inclined to form close-packed structure on the copper grid. The distribution of magnetic field intensity and the magnetic force lines between two magnets with 7 cm space were simulated, shown in Fig. 1b, c, respectively. The copper grid was put in the central region between the magnets. The field intensities along the centerline and perpendicular to the centerline in 1 cm range are plotted in Fig. 1c, where the copper grid was used as the original point. It was seen the field can be regarded uniform. The field intensity was simulated to be about 15 mT that was confirmed by experimental measurement. The nanocrystalline structure and magnetic property of synthesized Fe@Fe3O4 nanoparticles were characterized, as shown in Fig. 2. It was seen that the nanoparticles were superparamagnetic owning core–shell structure. The size of nanoparticles was highly uniform with average diameter 13.45 nm.

a Scheme for interfacial self-assembly process of Fe@Fe3O4 nanoparticles in the presence of a rotational magnetic field. b, c Simulation of magnetic field intensity and magnetic force lines between two magnets with 7.5 cm space, respectively. d, e Plotting of simulated field intensity data in 1 cm distance along and perpendicular to the centerline, respectively

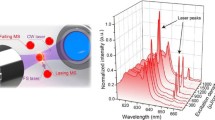

Nanoparticle concentration plays an important role in the formation of superlattice. To form the Moiré interference pattern, we should obtain two layers of nanoparticle superlattice. Thus, we first experimentally investigated the role of nanoparticle concentration. Based on our previous experiment, the rotation speed of magnetic field was set 600 rpm. The results are shown in Fig. 3. It was found that few nanoparticles discretely formed small aggregates. With the increase of nanoparticle concentration, the nanoparticles were inclined to form the close-packed superlattice. At the concentration 7.5 mg/mL, the nanoparticles formed a single layer of superlattice uniformly covering a large scale. When the concentration was above 7.5 mg/mL, the bilayer of superlattice emerged, and the Moiré interference pattern emerged clearly at 10 mg/mL concentration. The assembly patterns of nanoparticle concentration from 7.5 to 15 mg/mL were shown in Supporting Information, Fig. S2. However, it is worth noting that a plethora of nanoparticles were unfavorable for the formation of Moiré interference pattern. Evidently, when the concentration was above 13 mg/mL, the Moiré interference pattern was scarce to find.

To prove that the intriguing pattern formation was directed by the rotational magnetic field, the field intensity and frequency were experimentally investigated. It was observed that the concentration at 10 mg/mL was most suitable for the formation of the Moiré interference pattern. The assembly patterns under field intensity from 0 to 15 mT are shown in Fig. 4. It was seen that in the absence of the rotational magnetic field, the nanoparticles of second layer formed discrete close-packed domains, just like the case of first layer for small concentration. When the field intensity increased, the close-packed area became significantly augmented, which is desirable for the formation of superlattice. When the field intensity reached 10–15 mT, the nanoparticles showed an obvious Moiré interference pattern. However, when the field intensity was 20 mT, the pattern seemed disappeared, showing a compact and uniform structure. If the field intensity was 25 mT, the nanoparticles were to form the bulk-like aggregates. Thus, it is believed that the magnetic field here played dual roles. One was to induce the aggregation of nanoparticles to form superlattice, and the other was to yield displacement of the nanoparticle superlattice. This field-dependent pattern formation also showed the similar tendency in the field frequency experiments (Supporting Information, Fig. S3).

The self-assembly is a process to equipoise multiple forces in nanoscale. Here, it is worth mentioning that the Fe@Fe3O4 nanoparticles were capped by the hydrophobic oleyl amine and dispersed in the hexane. During the assembly process, the hexane floated on the water droplet and volatilized much quicker than the water. Thus, a strong hydrophobic interaction was imposed on the nanoparticles, which led to the attractive force. Also due to the hydrophobic effect, meniscus between the nanoparticles should be convex and the capillary force was repulsive. Moreover, the oleyl amine molecules sterically hindered the aggregation of nanoparticles. For the Fe@Fe3O4 nanoparticles in the presence of magnetic field, the magnetic dipolar interaction is much stronger (over two orders) than the thermal disturbance [23, 24]. Given that the magnetic field was nearly uniform, radial migration of the nanoparticles under field could be neglected. Just owing to the strong repulsive force between the oleyl amine molecules, the nanoparticles kept the monodispersed state so that the magnetic dipolar interaction was too weak to cause the formation of stripe-like aggregation. With the hexane volatilization, the interfacial self-assembly caused the formation of bilayer superlattices. The assembly augmented response of the nanoparticles to the magnetic field. Given the rotating magnetic field effect, the formed superlattice will be given a torque to rotate together. It turns out that the size of the first layer was significantly larger than that of the second layer and their disclination was also different. As a result, the Moiré interference pattern formed. Figure 5a shows a cartoon of two hexagonal-packed sphere array with relative rotation from 0° to 180°. The cartoon exhibited the same interference patterns as assembly experiments under different rotation angles. It seemed there was a certain symmetry between 0°–90° and 100–180°. The cartoon partly proved the formation of Moiré interference pattern as a result of the relative displacement of superlattice bilayers. This possible mechanism is schematically illustrated in Fig. 5b.

a Cartoon of relative rotation between two close-packed layers from 0° to 180°. b Mechanism scheme of the Moiré interference pattern formation. The rotational magnetic field makes the bilayers yield relative displacement, so seen from the top view, the superlattice bilayers were not hexagonal-packed but the Moiré interference patterned

We further simulated evolution of the magnetic moments for the assemblies in the presence of rotation magnetic field by Object Oriented Micromagnetic Framework (OOMMF). Since the size of Fe@Fe3O4 nanoparticles is smaller than the critical size of a single domain, the magnetic moments in each nanoparticle can be regarded as a single domain. The arrangement of magnetic moments was modulated by the external magnetic field. As shown in Fig. 6, when the applied rotating magnetic field was small, the magnetic moments in the nanoparticles were randomly oriented. Thus, the nanoparticles were unable to agglomerate significantly. When the rotating magnetic field was around 5–12 mT, the orientation of the magnetic moments in adjacent nanoparticles changed under the action of the rotating magnetic field. Overall, the magnetic moments in nanoparticle assemblies exhibited a chiral arrangement that approximated a vortex. The critical magnetic field in the simulation was about 5 mT, which was basically consistent with the experimental result. From the perspective of energy, Gibbs free energy of the system first decreased (5 ~ 12 mT) and then was raised with increase of the field intensity (> 15 mT).

4 Conclusions

In summary, the Moiré interference pattern of Fe@Fe3O4 nanoparticles was fabricated for the first time by rotational magnetic field-directed interfacial self-assembly of bilayer superlattices. This special pattern was experimentally proved to be tuned by the colloidal concentration, field intensity and field frequency. The underlying mechanism may lie in a two-stage process. The first stage was to form bilayer superlattices mainly induced by the hydrophobic interaction and steric hindrance of oleyl amine molecules. The second stage was the asynchronous rotation of the two superlattice layers caused by the rotational magnetic field. Moreover, the micromagnetics simulation also showed the underlying alteration of the magnetic property for the assemblies. The assembly pattern in our experiments bore some resemblance to the well regarded “magic angle” graphene, signifying this structure may contain great promises for scientific endeavors. We believe this work could serve as a feasible route for automatic, rapid, and green fabrication of regular and complex micro/nano structures, thus paving the way for exploring frontiers of spintronics.

References

M. Iranmanesh, J. Hulliger, Magnetic separation: its application in mining, waste purification, medicine, biochemistry and chemistry [J]. Chem. Soc. Rev. 46(19), 5925–5934 (2017)

I. Conde-Leboran, D. Baldomir, C. Martinez-Boubeta et al., A single picture explains diversity of hyperthermia response of magnetic nanoparticles [J]. J. Phys. Chem. C 119(27), 15698–15706 (2015)

G. Angelovski, E. Toth, Strategies for sensing neurotransmitters with responsive MRI contrast agents[J]. Chem. Soc. Rev. 46(2), 324–336 (2017)

Q. Maqbool, A. Jung, S. Won, J. Cho et al., Chiral magneto-optical properties of supra-assembled Fe3O4 nanoparticles [J]. ACS Appl. Mater. Interfaces 13(45), 54301–54307 (2021)

G. Song, M. Ranjbar, D.R. Daughton, R.A. Kiehl, Nanoparticle-induced anomalous Hall effect in graphene [J]. Nano Lett. 19(10), 7112–7118 (2019)

J.P. Armstrong, M.M. Stevens, Using remote fields for complex tissue engineering [J]. Trends Biotechnol. 38(3), 254–263 (2020)

C. Song, W. Sun, Y. Xiao et al., Ultrasmall iron oxide nanoparticles: synthesis, surface modification, assembly, and biomedical applications [J]. Drug Discov. Today 24(3), 835–844 (2019)

P. Genoni, F. Genuzio, T.O. Menteş et al., Magnetic patterning by electron beam-assisted carbon lithography. ACS Appl. Mater. Interfaces. 10(32), 27178–27187 (2018)

Y. Guang, Y. Peng, Z. Yan et al., Electron beam lithography of magnetic skyrmions. Adv. Mater. 32(39), 2003003 (2020)

S.S. Park, Z.J. Urbach, C.A. Brisbois et al., DNA and field mediated assembly of magnetic nanoparticles into high aspect ratio crystals [J]. Adv. Mater. 32(4), 1906626 (2020)

L. Chen, B. Su, L. Jiang, Recent advances in one-dimensional assembly of nanoparticles. Chem. Soc. Rev. 48(1), 8–21 (2019)

D. Lisjak, A. Mertelj, Anisotropic magnetic nanoparticles: a review of their properties, syntheses and potential applications [J]. Prog. Mater Sci. 95, 286–328 (2018)

J.G. Lee, V. Porter, W.A. Shelton et al., Magnetic field-driven convection for directed surface patterning of colloids [J]. Langmuir 34(50), 15416–15424 (2018)

Z. Li, F. Yang, Y. Yin, Smart materials by nanoscale magnetic assembly [J]. Adv. Func. Mater. 30(2), 1903467 (2020)

Q. Cao, Q. Fan, Q. Chen et al., Recent advances in manipulation of micro-and nano-objects with magnetic fields at small scales [J]. Mater. Horiz. 7(3), 638–666 (2020)

J.F. Sun, Y. Zhang, Z.P. Chen et al., Fibrous aggregation of magnetite nanoparticles induced by a time-varied magnetic field [J]. Angew. Chem. Int. Ed. 46(25), 4767–4770 (2007)

F. Fan, J. Sun, B. Chen et al., Rotating magnetic field-controlled fabrication of magnetic hydrogel with spatially disk-like microstructures[J]. Sci. China Mater. 61(8), 1112–1122 (2018)

Sun Z, Hu YH. How magical is magic-angle graphene? [J] Matter 2(5):1106–1114 (2020).

Y. Cao, V. Fatemi, S. Fang et al., Unconventional superconductivity in magic-angle graphene superlattices [J]. Nature 556, 43–50 (2018)

K.N. Al-Milaji, R.R. Secondo, T.N. Ng et al., Interfacial self-assembly of colloidal nanoparticles in dual-droplet inkjet printing [J]. Adv. Mater. Interfaces 5(10), 1701561 (2018)

G. Zhu, Z. Huang, Z. Xu et al., Tailoring interfacial nanoparticle organization through entropy [J]. Acc. Chem. Res. 51(4), 900–909 (2018)

H. Liang, J. Guo, Y. Shi et al., Porous yolk-shell Fe/Fe3O4 nanoparticles with controlled exposure of highly active Fe (0) for cancer therapy [J]. Biomaterials 268, 120530 (2021)

K. Cheng, S. Peng, C. Xu et al., Porous hollow Fe3O4 nanoparticles for targeted delivery and controlled release of cisplatin [J]. J. Am. Chem. Soc. 131(30), 10637–10644 (2009)

M. J. Donahue and D. G. Porter, OOMMF User’s Guide, version 1.0, Interagency Report NISTIR 6376, National Institute of Standards and Technology, Gaithersburg, MD, (1999).

Y. Zhang, Q.Q. Zhou, J.J. Ding et al., Electric field control of exchange-spring behavior [J]. J. Appl. Phys. 117, 124105 (2015)

B. Leighton, N.M. Vargas, D. Altbir et al., Tailoring the magnetic properties of Fe asymmetric nanodots [J]. J. Mag. Mag. Mater. 323, 1563–1567 (2011)

Y. Lalatonne, J. Richardi, M.P. Pileni, Van der Waals versus dipolar forces controlling mesoscopic organizations of magnetic nanocrystals[J]. Nat. Mater. 3(2), 121–125 (2004)

Acknowledgements

This work is financially supported by the Science Center of the National Science Foundation of China (52088101), National Key Research and Development Program of China (2021YFB3501202), the National Natural Science Foundation of China (Grant No. 52001012); and the Beijing Municipal Natural Science Foundation (Grant No. 2214070).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Ethical statement

It is declared that no animal experiment was conducted for this study. No funding was received to assist with the preparation of this manuscript. All authors certify that they have no affiliations with or involvement in any organization or entity with any financial interest or non-financial interest in the subject matter or materials discussed in this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Han, Y., Fan, F., PengWang et al. A Moiré interference pattern formation of magnetic nanoparticles by rotational magnetic field controlled interfacial self-assembly. Appl. Phys. A 128, 457 (2022). https://doi.org/10.1007/s00339-022-05586-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-022-05586-x