Abstract

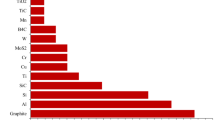

One of the ways to strengthen and prevent damage to the copper tube mold in continuous steel casting is to cover its inner surface. In this research, the surface of the copper plate is coated with nickel and graphene oxide by the electroplating method. Investigation of the mechanical properties of the coated plates showed that the addition of 30 cc of graphene oxide colloidal solution to the electrolyte solution, with the formation of 30 nm nanoparticles and cauliflower structure, achieved the highest hardness of 780 Vickers. In this sample, the adhesive and sheet abrasion mechanism was dominant and the lowest value of friction coefficient was obtained compared to other samples. In order to evaluate the performance of the coatings, the wetting angle and surface tension of the coatings in contact with the molten drops of aluminum and steel were calculated and compared. This study showed that in the sample containing 30 cc of graphene oxide colloidal solution, the aluminum drop had an angle of 130° with the surface tension of 24 × 10–6 N/m and a steel drop of an angle of 120° with the surface tension of 120 × 10–6 N/m.

Similar content being viewed by others

References

S. Mizoguchi, T. Ohashi, T. Saeki, Continuous casting of steel. Ann. Rev. Mater. Sci. 11(1), 151–169 (1981)

L. Cheng, H. Wu, X. Ye, Special purpose equipment design of crystallizer copper tube for inner hole plating, in Proceedings of the 2015 6th International Conference on Manufacturing Science and Engineering (Atlantis Press, New York, 2015).

Y. Xiao, et al, Numerical calculation about influence of crystallizer structure on the stress evolution process of horizontal continuous casting of copper tubes. J. Pressure Vessel Technol. (2021)

K. Ranjbar, Effect of flow induced corrosion and erosion on failure of a tubular heat exchanger. Mater. Des. 31(1), 613–619 (2010)

J. Zhou et al., Interactive effect of ant nest corrosion and stress corrosion on the failure of copper tubes. Eng. Fail. Anal. 83, 9–16 (2018)

S. Tjong, K. Lau, Tribological behaviour of SiC particle-reinforced copper matrix composites. Mater. Lett. 43(5–6), 274–280 (2000)

C.D. Association, The Copper Tube Handbook (2010)

D. K. Crampton, M.L. Wood, Process for tin-coating the interiors of copper tubes. Google Patents (1949)

S. Barella et al., Investigation of failure and damages on a continuous casting copper mould. Eng. Fail. Anal. 36, 432–438 (2014)

A. Michau et al., High-temperature oxidation resistance of chromium-based coatings deposited by DLI-MOCVD for enhanced protection of the inner surface of long tubes. Surf. Coat. Technol. 349, 1048–1057 (2018)

H.V. Dirk Rode, Molds for a continuous casting system. Canada (1997)

B. Fotovvati, N. Namdari, A. Dehghanghadikolaei, On coating techniques for surface protection: a review. J. Manuf. Mater. Process. 3(1), 28 (2019)

A. Gupta, C. Srivastava, Optimum amount of graphene oxide for enhanced corrosion resistance by tin-graphene oxide composite coatings. Thin Solid Films 661, 98–107 (2018)

J. Wang et al., Effect of current density on microstructure and corrosion resistance of Ni-graphene oxide composite coating electrodeposited under supercritical carbon dioxide. Surf. Coat. Technol. 358, 765–774 (2019)

K. Rajkumar, S. Aravindan, Tribological behavior of microwave processed copper-nanographite composites. Tribol. Int. 57, 282–296 (2013)

D. Kuang et al., Graphene-nickel composites. Appl. Surf. Sci. 273, 484–490 (2013)

Q.-L. Rao et al., Microstructure evolution of electroless Ni-B film during its depositing process. Appl. Surf. Sci. 240(1–4), 28–33 (2005)

M. Kiani, M. Bahrololoom, Investigation of influence of electrodeposition parameters on the morphology and surface roughness of nickel-carbon composite coatings, in Eleventh Congress of the Iranian Metallurgical Society (2007)

S. Sadik, Morphology of the curd of cauliflower. Am. J. Bot. 49(3), 290–297 (1962)

A. Rahimi, M.R. Vaezi, M. Yari, Effect of tempertureon properties and corrosion behavior of electroplated nickel-graphene composite coating (2016)

R. Askarnia et al., Fabrication of high strength aluminum-graphene oxide (GO) composites using microwave sintering. Adv. Compos. Mater. 30(3), 271–285 (2021)

W.-M. Tian et al., Graphene-reinforced aluminum matrix composites prepared by spark plasma sintering. Int. J. Min. Metall. Mater. 23(6), 723–729 (2016)

Jafaripour, M., H. Koohestani, and B. Ghasemi, Characterization of aluminum matrix composites reinforced with Al2O3, SiC and graphene fabricated by spark plasma sintering. Iran. J. Mater. Sci. Eng. (2021)

J. Li et al., Microstructure and tensile properties of bulk nanostructured aluminum/graphene composites prepared via cryomilling. Mater. Sci. Eng. A 626, 400–405 (2015)

Y. Tian, Z. Bi, G. Cui, Study on the corrosion resistance of graphene oxide-based epoxy zinc-rich coatings. Polymers 13(10), 1657 (2021)

K. Niihara, New design concept of structural ceramics ceramic nanocomposites. J. Ceram. Soc. Jpn 99(1154), 974–982 (1991)

D. Lin, C.R. Liu, G.J. Cheng, Single-layer graphene oxide reinforced metal matrix composites by laser sintering: microstructure and mechanical property enhancement. Acta Mater. 80, 183–193 (2014)

D.J. Kim et al., Ultrahigh-strength multi-layer graphene-coated Ni film with interface-induced hardening. Carbon 178, 497–505 (2021)

D. Chen, H. Feng, J. Li, Graphene oxide: preparation, functionalization, and electrochemical applications. Chem. Rev. 112(11), 6027–6053 (2012)

Z. Ren et al., Mechanical properties of nickel-graphene composites synthesized by electrochemical deposition. Nanotechnology 26(6), 065706 (2015)

J. Liu et al., Microstructure and mechanical properties of graphene oxide-reinforced titanium matrix composites synthesized by hot-pressed sintering. Nanoscale Res. Lett. 14(1), 1–12 (2019)

G. Cieślak, M. Trzaska, Structure and properties of Ni-B/graphene oxide composite coatings produced by chemical reduction method. J. Mater. Eng. Perform. 29(3), 1550–1557 (2020)

A. Ghazaly, B. Seif, H. Salem, Mechanical and tribological properties of AA2124-graphene self lubricating nanocomposite, in Light Metals 2013. (Springer, New York, 2016). p. 411–415.

D. Berman, A. Erdemir, A.V. Sumant, Reduced wear and friction enabled by graphene layers on sliding steel surfaces in dry nitrogen. Carbon 59, 167–175 (2013)

D. Deng et al., Microstructures and wear performance of PTAW deposited Ni-based coatings with spherical tungsten carbide. Metals 5(4), 1984–1996 (2015)

K.C. Ludema, O.O. Ajayi, Friction, wear, lubrication: a textbook in tribology (CRC Press, New York, 2018)

G. Stachowiak, A.W. Batchelor, Engineering tribology. Butterworth-Heinemann (2013)

S.M. Kabeb et al., Effect of graphene nanoplatelets on flame retardancy and corrosion resistance of epoxy nanocomposite coating. Malaysian J. Fund. Appl. Sci. 15(4), 543–547 (2019)

M.-J. Hwang et al., Cathodic electrophoretic deposition (EPD) of phenylenediamine-modified graphene oxide (GO) for anti-corrosion protection of metal surfaces. Carbon 142, 68–77 (2019)

H. Sharifi et al., Effect of magnesium and nickel coatings on the wetting behavior of alumina toughened zirconia by molten Al-Mg alloy. Int. J. Min. Metall. Mater. 19(1), 77–82 (2012)

G. Liu et al., Survey on wetting of SiC by molten metals. Ceram. Int. 36(4), 1177–1188 (2010)

J. Padday, Sessile drop profiles: corrected methods for surface tension and spreading coefficients. Proc. R. Soc. Lond. A Math. Phys. Sci. 330(1583), 561–572 (1972)

Miller, R., Physical properties of liquid metals. Liquid Metals Handbook, 1952: p. 38.

S. Ebnesajjad, C. Ebnesajjad, Surface treatment of materials for adhesive bonding. William Andrew (2013)

T. Van Hau et al., Electrodeposited nickel–graphene nanocomposite coating: effect of graphene nanoplatelet size on its microstructure and hardness. RSC Adv. 10(37), 22080–22090 (2020)

H. Algul et al., The effect of graphene content and sliding speed on the wear mechanism of nickel-graphene nanocomposites. Appl. Surf. Sci. 359, 340–348 (2015)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Malayeri, M.A., Koohestani, H. & Tajally, M. Investigation of wettability of copper plate with nickel-graphene oxide coating produced by electroplating method. Appl. Phys. A 128, 143 (2022). https://doi.org/10.1007/s00339-022-05274-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-022-05274-w