Abstract

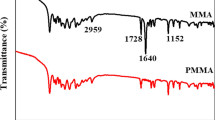

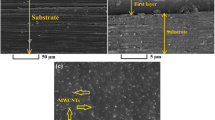

Using two different types of protective coatings, we examined the protection of magnesium alloy (AZ61) with composition of Mg(93)–Al(6) –Zn(1) against corrosion in neutral 3.5% NaCl solution. We treated the alloy with a novel silane polymer coating that demonstrated viable in protecting the surface against corrosion. The hybrid protecting film is composed of 1,2 bis(triethoxysilyl)ethane-poly(vinyl alcohol). Also we examined an alternative approach to coat the magnesium-based alloy with a layer containing nickel and TiO2 nanoparticles and followed by applying a protective silane film. The silane film was synthesized from a silane precursor (1,2-bis(triethoxysilyl)ethane) using a sol–gel cross-linking method. The surface of the bare and coated Mg alloy was evaluated before and after exposure to the corrosive medium using structural, surface and electrochemical techniques. Structural techniques include X-ray photoelectron spectroscopy. Scanning electron microscopy/energy-dispersive X-ray spectroscopy analysis was used to explore the surface morphologies and structures. The electrochemical techniques used were potentiodynamic polarization and electrochemical impedance spectroscopy. The Mg alloy coated with the hybrid films has been tested for prolonged exposure to the chloride solution, and both coatings have proved effective in protecting the Mg alloy.

Similar content being viewed by others

References

B.L. Mordike, T. Ebert, Magnesium: properties—applications—potential. Mater. Sci. Eng. A 302, 37–45 (2001). Doi: https://doi.org/10.1016/S0921-5093(00)01351-4.

E. Ghali, W. Dietzel, K.-U. Kainer, General and localized corrosion of magnesium alloys: a critical review. J. Mater. Eng. Perform. 13, 7–23 (2004). https://doi.org/10.1361/10599490417533

M.K. Kulekci, Magnesium and its alloys applications in automotive industry. Int. J. Adv. Manuf. Technol. 39, 851–865 (2008). https://doi.org/10.1007/s00170-007-1279-2

C.D. Gu, W. Yan, J.L. Zhang, J.P. Tu, Corrosion resistance of AZ31B magnesium alloy with a conversion coating produced from a choline chloride—Urea based deep eutectic solvent. Corros. Sci. 106, 108–116 (2016). https://doi.org/10.1016/j.corsci.2016.01.030

X. Jiang, R. Guo, S. Jiang, Evaluation of self-healing ability of Ce–V conversion coating on AZ31 magnesium alloy. J. Magnesium Alloys 4, 230–241 (2016). https://doi.org/10.1016/j.jma.2016.06.003

M.A. Deyab, R. Ouarsal, A.M. Al-Sabagh, M. Lachkar, B. El Bali, Enhancement of corrosion protection performance of epoxy coating by introducing new hydrogenphosphate compound. Prog. Org. Coat. 107, 37–42 (2017). Doi: https://doi.org/10.1016/j.porgcoat.2017.03.014

S. Khalifeh, T.D. Burleigh, Super-hydrophobic stearic acid layer formed on anodized high purified magnesium for improving corrosion resistance of bioabsorbable implants. J. Magnesium Alloys 6, 327–336 (2018). https://doi.org/10.1016/j.jma.2018.08.003

Z. Shi, G. Song, A. Atrens, Influence of anodising current on the corrosion resistance of anodised AZ91D magnesium alloy. Corros. Sci. 48, 1939–1959 (2006). https://doi.org/10.1016/j.corsci.2005.08.004

Y.-R. Zhou, S. Zhang, L.-L. Nie, Z.-J. Zhu, J.-Q. Zhang, F.-H. Cao, J.-X. Zhang, Electrodeposition and corrosion resistance of Ni–P–TiN composite coating on AZ91D magnesium alloy. Trans. Nonferrous Met. Soc. China 26, 2976–2987 (2016). https://doi.org/10.1016/S1003-6326(16)64428-X

Z. Shao, Z. Cai, R. Hu, S. Wei, The study of electroless nickel plating directly on magnesium alloy. Surf. Coat. Technol. 249, 42–47 (2014). https://doi.org/10.1016/j.surfcoat.2014.03.043

M. Yekehtaz, F. Sittner, R. Ugas-Carrión, S. Flege, J. Brötz, W. Ensinger, Characterization of protective sol–gel coatings on magnesium based on phenyl-triethoxysilane precursor. Thin Solid Films 518, 5223–5226 (2010). https://doi.org/10.1016/j.tsf.2010.04.040

N. Karthik, Y.R. Lee, M.G. Sethuraman, Hybrid sol-gel/thiourea binary coating for the mitigation of copper corrosion in neutral medium. Prog. Org. Coat. 102, 259–267 (2017). https://doi.org/10.1016/j.porgcoat.2016.10.024

H. Uchiyama, T. Bando, H. Kozuka, Effect of the amount of H2O and HNO3 in Ti(OC3H7i)4 solutions on the crystallization of sol-gel-derived TiO2 films. Thin Solid Films 669, 157–161 (2019). https://doi.org/10.1016/j.tsf.2018.10.050

A.J. López, A. Ureña, J. Rams, Wear resistant coatings: Silica sol–gel reinforced with carbon nanotubes. Thin Solid Films 519, 7904–7910 (2011). https://doi.org/10.1016/j.tsf.2011.05.076

A.A. El-Hadad, V. Barranco, A. Samaniego, I. Llorente, F.R. García-Galván, A. Jiménez-Morales, J.C. Galván, S. Feliu, Influence of substrate composition on corrosion protection of sol–gel thin films on magnesium alloys in 0.6M NaCl aqueous solution. Prog. Org. Coat. 77, 1642–1652 (2014). Doi: https://doi.org/10.1016/j.porgcoat.2014.05.026.

X. Guo, K. Du, Q. Guo, Y. Wang, F. Wang, Experimental study of corrosion protection of a three-layer film on AZ31B Mg alloy. Corros. Sci. 65, 367–375 (2012). https://doi.org/10.1016/j.corsci.2012.08.055

L. Zeng, S. Yang, W. Zhang, Y. Guo, C. Yan, Preparation and characterization of a double-layer coating on magnesium alloy AZ91D. Electrochim. Acta 55, 3376–3383 (2010). https://doi.org/10.1016/j.electacta.2010.01.041

X. Fan, Y. Wang, B. Zou, L. Gu, W. Huang, X. Cao, Preparation and corrosion resistance of MAO/Ni–P composite coat on Mg alloy. Appl. Surf. Sci. 277, 272–280 (2013). https://doi.org/10.1016/j.apsusc.2013.04.044

G. Bierwagen, The physical chemistry of organic coatings revisited—viewing coatings as a materials scientist. J. Coat. Technol. Res. 5, 133–155 (2008). https://doi.org/10.1007/s11998-007-9066-4

G. Grundmeier, W. Schmidt, M. Stratmann, Corrosion protection by organic coatings: electrochemical mechanism and novel methods of investigation. Electrochim. Acta 45, 2515–2533 (2000). https://doi.org/10.1016/S0013-4686(00)00348-0

N. Scharnagl, C. Blawert, W. Dietzel, Corrosion protection of magnesium alloy AZ31 by coating with poly(ether imides) (PEI). Surf. Coat. Technol. 203, 1423–1428 (2009). https://doi.org/10.1016/j.surfcoat.2008.11.018

F.L. Miguel, R. Müller, S. Mathur, F. Mücklich, Microstructure and mechanical properties of electrodeposited Ni and Ni–matrix-nanocomposite thin films. Mater. Sci. Eng. A 646, 254–262 (2015). Doi: https://doi.org/10.1016/j.msea.2015.08.069.

L. Benea, E. Danaila, J.-P. Celis, Influence of electro-co-deposition parameters on nano-TiO2 inclusion into nickel matrix and properties characterization of nanocomposite coatings obtained. Mater. Sci. Eng. A 610, 106–115 (2014). Doi: https://doi.org/10.1016/j.msea.2014.05.028.

H. Goldasteh, S. Rastegari, The influence of pulse plating parameters on structure and properties of Ni–W–TiO2 nanocomposite coatings. Surf. Coat. Technol. 259, 393–400 (2014). https://doi.org/10.1016/j.surfcoat.2014.10.064

E. Beltowska-Lehman, P. Indyka, A. Bigos, M.J. Szczerba, M. Kot, Effect of hydrodynamic conditions of electrodeposition process on microstructure and functional properties of Ni-W/ZrO2 nanocomposites. J. Electroanal. Chem. 775, 27–36 (2016). https://doi.org/10.1016/j.jelechem.2016.05.003

H. Gül, F. Kılıç, M. Uysal, S. Aslan, A. Alp, H. Akbulut, Effect of particle concentration on the structure and tribological properties of submicron particle SiC reinforced Ni metal matrix composite (MMC) coatings produced by electrodeposition. Appl. Surf. Sci. 258, 4260–4267 (2012). https://doi.org/10.1016/j.apsusc.2011.12.069

V.S. Saji, Review of rare-earth-based conversion coatings for magnesium and its alloys. J. Mater. Res. Technol. 8, 5012–5035 (2019). https://doi.org/10.1016/j.jmrt.2019.08.013

S. Zhang, Q. Li, J. Fan, W. Kang, W. Hu, X. Yang, Novel composite films prepared by sol–gel technology for the corrosion protection of AZ91D magnesium alloy. Prog. Org. Coat. 66, 328–335 (2009). https://doi.org/10.1016/j.porgcoat.2009.08.011

A.J. López, J. Rams, A. Ureña, Sol–gel coatings of low sintering temperature for corrosion protection of ZE41 magnesium alloy. Surf. Coat. Technol. 205, 4183–4191 (2011). https://doi.org/10.1016/j.surfcoat.2011.03.011

N. Hellgren, R.T. Haasch, S. Schmidt, L. Hultman, I. Petrov, Interpretation of X-ray photoelectron spectra of carbon-nitride thin films: New insights from in situ XPS. Carbon 108, 242–252 (2016). https://doi.org/10.1016/j.carbon.2016.07.017

G.F. Cerofolini, C. Galati, L. Renna, Si 2p XPS spectrum of the hydrogen-terminated (100) surface of device-quality silicon. Surf. Interface Anal. 35, 968–973 (2003). https://doi.org/10.1002/sia.1632

A.F. Orliukas, T. Šalkus, A. Kežionis, V. Venckutė, V. Kazlauskienė, J. Miškinis, G. Laukaitis, J. Dudonis, XPS and impedance spectroscopy of some oxygen vacancy conducting solid electrolyte ceramics. Solid State Ionics 188, 36–40 (2011). https://doi.org/10.1016/j.ssi.2010.11.001

A.P. Grosvenor, M.C. Biesinger, R.S.C. Smart, N.S. McIntyre, New interpretations of XPS spectra of nickel metal and oxides. Surf. Sci. 600, 1771–1779 (2006). https://doi.org/10.1016/j.susc.2006.01.041

R. Shvab, E. Hryha, L. Nyborg, Surface chemistry of the titanium powder studied by XPS using internal standard reference. Powder Metall. 60, 42–48 (2017). https://doi.org/10.1080/00325899.2016.1271092

Acknowledgements

Instrumentation facilities through grants GS01/01, GS02/08, Science Analytical Facilities (Department of Chemistry), RSPU instrumentation facilities, are all highly appreciated.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Appendix A: supplementary material:

Appendix A: supplementary material:

The following are the Supplementary data to this article: Supplementary data 1.

Rights and permissions

About this article

Cite this article

BinSabt, M.H., Abditon, M. & Galal, A. Highly efficient nanocomposite-containing coatings for the protection of Mg alloy against corrosion in chloride containing electrolytes. Appl. Phys. A 128, 151 (2022). https://doi.org/10.1007/s00339-021-05248-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-021-05248-4