Abstract

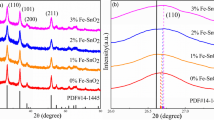

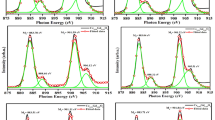

Structural, electronic, optical, and magnetic properties of pristine chromium oxide (Cr2O3) and iron (Fe)-substituted Cr2O3 nanoparticles prepared using wet chemical method were investigated by X-ray diffraction (XRD), micro-Raman spectroscopy, UV–Vis absorption spectroscopy, X-ray photoelectron spectroscopy (XPS), and physical properties measurement system-vibration sample magnetometer (PPMS–VSM). XRD pattern confirmed the formation of the single rhombohedral phase of pristine Cr2O3, and Fe-substituted Cr2O3 nanoparticles having space group R3c. Micro-Raman study demonstrated the creation of magnon with Fe substitution. XPS studies revealed the successful incorporation of Fe cations into the Cr2O3 lattice. It also affirms that with Fe doping, there is the occurrence of mixed oxidation states of Cr, Fe, and oxygen defects, which may be responsible for the origin of magnetism in the as-prepared nanoparticles. UV–Vis studies were also performed to determine optical behavior, which revealed narrowing of bandgap from 2.92 eV to 2.06 eV with Fe doping due to the formation of impurity levels between the forbidden gap. Temperature dependence of magnetization (M–T) studies demonstrated the coexistence of antiferromagnetic (AFM) and ferromagnetic (FM) below cusp transition and dominance of AFM and paramagnetic (PM) state at room temperature, which was fitted together with Curie–Weiss law and 3D-spin wave model below cusp temperature and above cusp temperature to Johnston equation. M–H curves recorded at 300 K confirm that the as-prepared nanoparticles exhibit either PM or AFM magnetic behavior. The observed PM and AFM-dominated magnetization behavior at 300 K is explained by considering the role of mixed oxidation states and oxygen defects which leads to activate bound magnetic polarons (BMP) with nearer Fe or Cr 3d ions. However, at 5 K, all samples show enhanced magnetization with AFM correlation due to frozen antiferromagnetic superexchange interactions due to thermal effect. The narrowing of bandgap and the magnetization behavior with Fe substitution in Cr2O3 lattices reveals the role of oxygen vacancies and their potential for advanced functional applications in semiconductors such as magneto-optics and spintronics devices.

Similar content being viewed by others

References

T. Dietl, Nat. Mater. 9, 965 (2010)

V. Christensen, and N. Pryds, Appl. Phys, D, 120505 (2020)

J.M.D. Coey, M. Venkatesan, C.B. Fitzgerald, Nat. Mater. 4, 173 (2005)

N. Ali, B. Singh, Z.A. Khan, A.R. Vijaya, K. Tarafder, S. Ghosh, Sci. Rep. 9, 3 (2019)

J. Philip, A. Punnoose, B.I. Kim, K.M. Reddy, S. Layne, J.O. Holmes, B. Satpati, P.R. Leclair, T.S. Santos, J.S. Moodera, Nat. Mater. 5, 298 (2006)

N.S. Garnet, V. Ghodsi, L.N. Hutfluss, P. Yin, M. Hegde, P.V. Radovanovic, J. Phys. Chem. C 121, 1918 (2017)

K. Kumar, M. Chitkara, I.S. Sandhu, D. Mehta, S. Kumar, J. Alloys Compd. 588, 681 (2014)

K.S. Ranjith, P. Saravanan, S.H. Chen, C.L. Dong, C.L. Chen, S.Y. Chen, K. Asokan, R.T.R. Kumar, J. Phys. Chem. C 118, 27039 (2014)

J. Singh, V. Verma, R. Kumar, S. Sharma, R. Kumar, Vacuum 159, 282–286 (2019)

E. Winkler, R.D. Zysler, H.E. Troiani, D. Fiorani, Phys. B Condens. Matter 384, 268 (2006)

F.C.O.I. Banerjee, H.K.D. Kim, D. Pisani, K.P. Mohanchandra, and G.P. Carman, J. Alloys Compd. 614, 305 (2014)

J.J. Carey, M. Legesse, M. Nolan, J. Phys. Chem. C 120, 19160 (2016)

H. Sadat Nabi and R. Pentcheva, Phys. Rev. B Condens. Matter Mater. Phys. 83, 2 (2011)

P. Bhardwaj, J. Singh, R. Kumar, R. Kumar, and V. Verma, Solid State Sci. 115, 106581 (2021)

M. Coskun, G. Hassnain Jaffari, S. Manzoor, M. Korkmaz, and S. Ismat Shah, J. Magn. Magn. Mater. 322, 1731 (2010)

M.D. Hossain, S. Dey, R.A. Mayanovic, M. Benamara, MRS Adv. 1, 2387 (2016)

S.H. Yang, S.J. Liu, Z.H. Hua, S.G. Yang, J. Alloys Compd. 509, 6946 (2011)

Z. Yang, J. Zhang, D. Gao, Z. Zhu, G. Yang, and D. Xue, RSC Adv. 1–6, 1 (2010)

R.N. Bhowmik, K.V. Siva, R. Ranganathan, C. Mazumdar, J. Magn. Magn. Mater. 432, 56 (2017)

J. Rodríguez-Carvajal, Manual 1, 1 (2001)

K.N. Patel, M.P. Deshpande, V.P. Gujarati, S. Pandya, V. Sathe, S.H. Chaki, Mater. Res. Bull. 106, 187 (2018)

B.Y.R.D. Shannon, M.H.N.H. Baur, O.H. Gibbs, M. Eu, V. Cu, Acta. Cryst. A 32, 751 (1976)

S. Khamlich, E. Manikandan, B.D. Ngom, J. Sithole, O. Nemraoui, I. Zorkani, R. McCrindle, N. Cingo, M. Maaza, J. Phys. Chem. Solids 72, 714 (2011)

M.I. Baraton, G. Busca, M.C. Prieto, G. Ricchiardi, V. Sanchez Escribano, J. Solid State Chemistry 112, 9–14 (1994)

S. Rajagopal, M. Bharaneswari, D. Nataraj, O.Y. Khyzhun, Y. Djaoued, Mater. Res. Express 3, 1 (2016)

T.C. Kaspar, P.V. Sushko, M.E. Bowden, S.M. Heald, A. Papadogianni, C. Tschammer, O. Bierwagen, and S.A. Chambers, Phys. Rev. B 94 (2016)

J. Singh, R. Kumar, V. Verma, and R. Kumar, J. Alloys Compd. 847 (2020)

H. Liu, J. Yang, Y. Zhang, and L. Yang, 145803 (n.d.)

T. Yamashita and P. Hayes, 254, 2441 (2008)

B. Bharti, S. Kumar, H.N. Lee, R. Kumar, Sci. Rep. 6, 1 (2016)

B. Pal, P.K. Giri, J. Nanosci. Nanotechnol. 11, 9167 (2011)

M.C. Biesinger, B.P. Payne, A.P. Grosvenor, L.W.M. Lau, A.R. Gerson, R.S.C. Smart, Appl. Surf. Sci. 257, 2717 (2011)

V. Gandhi, R. Ganesan, H.H. Abdulrahman Syedahamed, and M. Thaiyan, J. Phys. Chem. C 118, 9717 (2014)s

K.R. Kittilstved, W.K. Liu, D.R. Gamelin, Nat. Mater. 5, 291 (2006)

M.A. Hassan, F. Ahmad, and Z.M. Abd El-Fattah, J. Alloys Compd. 750, 320 (2018)

A. Almontasser, A. Parveen, M. Hashim, A. Ul, H. Ameer, Appl. Nanosci. 11, 583 (2021)

J. Singh, R. Kumar, V. Verma, and R.Kumar, Ceram. Int. (2020)

K. Punia, G. Lal, S. Dalela, S.N. Dolia, P.A. Alvi, S.K. Barbar, K.B. Modi, and S. Kumar, J. Alloys Compd. 868, 159142 (2021)

U. Ilyas, R.S. Rawat, T.L. Tan, P. Lee, R. Chen, H.D. Sun, L. Fengji, and S. Zhang, J. Appl. Phys. 111 (2012)

C. Bárcena, A.K. Sra, J. Gao, Nanoscale Magn. Mater. Appl. 167, 591 (2009)

S. Layek, H.C. Verma, J. Magn. Magn. Mater. 397, 73 (2016)

Y.W. Jun, J.W. Seo, J. Cheon, Acc. Chem. Res. 41, 179 (2008)

A.P. Safronov, I.V. Beketov, S.V. Komogortsev, G.V. Kurlyandskaya, A.I. Medvedev, D.V. Leiman, A. Larrañaga, and S.M. Bhagat, AIP Adv. 3, 0 (2013)

N. Ali, A.R. Vijaya, Z.A. Khan, K. Tarafder, and A. Kumar, Sci. Rep. 1 (2019).

V. Gandhi, R. Ganesan, H. Hameed, A. Syedahamed, and M. Thaiyan, (2014).

K.R. Kittilstved, W.K. Liu, D. R. Gamelin 5, 291 (2006)

V. Verma and M. Katiyar, J. Phys. D. Appl. Phys. 48 (2015)

S. Bedanta and W. Kleemann, J. Phys. D. Appl. Phys. 42 (2009)

B. Kisan, J. Kumar, and P. Alagarsamy, J. Alloys Compd. 868, 159176 (2021)

B. G. Ganga, M. R. Varma, and P. N. Santhosh, 7086 (2015)

S. Kunj, J. Ind. Eng. Chem. (2020)

B. J. Sarkar, J. Mater. Sci. Mater. Electron. (2020)

D.C. Johnston, J. Magn. Magn. Mater. 100, 218 (1991)

B.J. Sarkar, M. Dalal, A. Mitra, J. Mandal, A. Bandyopadhyay, P.K. Chakrabarti, J. Alloys Compd. 752, 448 (2018)

O.P. Sushkov, Nat. Phys. 10, 339 (2014)

K. Punia, G. Lal, S. K. Barbar, S. Narain, P. Ahmad, S. Dalela, and S. Kumar, Vacuum 184, 109921 (2021)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bhardwaj, P., Singh, J., Kumar, R. et al. Oxygen defects induced tailored optical and magnetic properties of FexCr2−xO3 (0 ≤ x ≤ 0.1) nanoparticles. Appl. Phys. A 128, 135 (2022). https://doi.org/10.1007/s00339-021-05233-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-021-05233-x