Abstract

Non-linear dielectric spectroscopy (NLDS) is employed as an effective tool to study relaxation processes and phase transitions of a poly(vinylidenefluoride-trifluoroethylene-chlorofluoroethylene) (P(VDF-TrFE-CFE)) relaxor-ferroelectric (R-F) terpolymer in detail. Measurements of the non-linear dielectric permittivity \({\varepsilon _{2}^{'}}\) reveal peaks at 30 and 80\(\,^\circ\)C that cannot be identified in conventional dielectric spectroscopy. By combining the results from NLDS experiments with those from other techniques such as thermally stimulated depolarization and dielectric-hysteresis studies, it is possible to explain the processes behind the additional peaks. The former peak, which is associated with the mid-temperature transition, is found in all other vinylidene fluoride-based polymers and may help to understand the non-zero \(\varepsilon _\mathrm {2}^{'}\) values that are detected on the paraelectric phase of the terpolymer. The latter peak can also be observed during cooling of P(VDF-TrFE) copolymer samples at 100\(\,^\circ\)C and is due to conduction and space-charge polarization as a result of the accumulation of real charges at the electrode–sample interface.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In recent years, terpolymers that are based on vinylidene fluoride (VDF) and tri-fluoroethylene (TrFE), but that have an additional fluorine-containing monomer, receive more and more attention due to their unique properties. In contrast to their ferroelectric counterparts such as the homopolymer polyvinylidene fluoride (PVDF) or its well-known copolymers with tri-fluoroethylene (P(VDF-TrFE)), tetrafluoro-ethylene (P(VDF-TFE)), and hexa-fluoropropylene (P(VDF-HFP)), the terpolymers exhibit relaxor-ferroelectric (R-F) behavior which leads to a significantly wider spectrum of useful properties. In R-F terpolymers, a slim polarization versus electric-field hysteresis curve and a very large electrostriction coefficient are often available [1, 2]. A narrow hysteresis loop with a low coercive field \(E_\text {c}\) and a high saturation polarization \(P_\text {s}\) leads to advantages, e.g. in energy-storage devices [2]. In addition, a lower coercive field \(E_\text {c}\) yields lower switching voltages, which is very useful for memory applications [3]. The ability to be cast into very thin films makes R-F terpolymers very attractive for use in flexible and stretchable electronics [4, 5].

Addition of a third fluorine-containing co-monomer such as chlorofluoroethylene (CFE) or chlorotrifluoroethylene (CTFE) into P(VDF-TrFE) copolymer chains can break the long-range interaction within the ferroelectric dipolar regions and may reduce them to nano-domains [1, 6]. Such a nano-structure forces the majority of the copolymer units to adopt gauche-containing \(TG^\text {+}TG^\text {--}\) and \(T_\text {3}G^\text {+}T_\text {3}G^\text {--}\) conformations [7, 8]. As a result, the ferroelectric-to-paraelectric (F-P) or Curie transition temperature (\(T_\text {C}\)) of the terpolymer is found close to room temperature (RT) [1, 9]. The reduced interactions between the dipoles allow them to be more easily oriented in an applied electric field, which results in a characteristic reduction of the coercive field \(E_\text {c}\) and also in a high saturation polarization \(P_{\text {s}}\). The dielectric permittivity of the relaxor-ferroelectric terpolymers is very high compared to that of other ferroelectric polymers and can reach values of up to 60 in P(VDF-TrFE-CFE) (at RT and a frequency of 0.1 Hz) [9].

Previously, conventional dielectric relaxation spectroscopy (DRS) and thermally stimulated depolarization (TSD) were employed to study relaxations and transitions in P(VDF-TrFE-CFE) [1, 9,10,11]. However, recording and evaluating the complex non-linear dielectric permittivities \(\varepsilon _\text {2}^\mathrm {*}\) and \(\varepsilon _\text {3}^\mathrm {*}\) of P(VDF-TrFE-CFE) can provide more information about relaxations and transitions that cannot be clearly seen in more conventional \(\varepsilon _\text {1}^\mathrm {*}\) measurements. In particular, NLDS may help us to better understand the mid-temperature transition and additional peaks due to charges, which had been observed during differential scanning calorimetry (DSC) and TSD measurements, respectively [11, 12]. Hence, in this study, NLDS measurements were performed on spin-coated and annealed P(VDF-TrFE-CFE) films and for comparison also on annealed P(VDF-TrFE) copolymer films that show typical ferroelectric properties. In this paper, we combine results from non-linear dielectric measurements with complementary insight from conventional DRS, TSD and dielectric-hysteresis experiments with the aim of gaining a more detailed understanding of the above-mentioned processes.

2 Materials and methods

2.1 Dielectric non-linearity

Landau theory provides a phenomenological description of ferroelectric materials [13], according to which the ferroelectric contribution to free energy F can be expressed in terms of even powers of the dielectric displacement D for electric field \(E=0\) as follows [14]:

where \(\alpha\), \(\gamma\), and \(\delta\) are known as Landau parameters. The Landau parameters depend in general on temperature T. In simple cases, the ferroelectric transitions can be described by the Devonshire theory in which \(\alpha\) is assumed to be proportional to temperature \(\alpha = \beta (T-T_0)\), while \(\beta\), \(\gamma\) and \(\delta\) are constant. With an electric field applied the free energy becomes [15]

As the Landau parameters depend on temperature, the free energy is a function of both electric displacement D and temperature T. The electric field E as a function of the electric displacement D is then obtained from the partial derivative of F with respect to D:

D can be expressed by a power series representation of the electric displacement in terms of E with \(D = P_\text {s}\) (spontaneous polarization) at \(E = 0\);

Thus, the odd- and even-order permittivities, and in particular \(\varepsilon _\mathrm {1}\), \(\varepsilon _\mathrm {2}\) and \(\varepsilon _\mathrm {3}\), can be calculated from the coefficients of the series expansion of the dielectric displacement D as a function of the applied electric field E in Eq. 4 [16]. As seen in the equation, \(\varepsilon _\mathrm {2}\) and \(\varepsilon _\mathrm {3}\) describe non-linear contributions of the electric field E to the displacement D. They are referred to as first- and second-order non-linear permittivities, respectively.

In the paraelectric phase, the spontaneous polarization disappears (\(P_\text {s}\) = 0), and the nonlinear permittivities \(\varepsilon _\mathrm {1}\), \(\varepsilon _\mathrm {2}\) and \(\varepsilon _\mathrm {3}\) may be calculated from the Landau parameters [14] as follows:

2.2 Order of phase transition

It is known that ferroelectric and relaxor-ferroelectric materials undergo a transition from the polar ferroelectric state to a non-polar paraelectric state above a characteristic transition temperature (\(T_\text {C}\)) [17, 18] where the phase transition can be of first or second order [13, 17].

The signs of the Landau parameters in the paraelectric phase can be used to determine the type of phase transition in ferroelectric and relaxor-ferroelectric materials [19, 20]. While the sign of \(\beta\) and \(\delta\) always remains positive, \(\gamma\) is positive in the case of a second-order transition and negative if the transition is of first order. Thus, it is possible to infer the order of the phase change also from the sign of \(\varepsilon _{\mathrm {3}}\) [14, 19]. For a second-order transition, the sign of \(\varepsilon _{\mathrm {3}}\) changes from positive to negative at \(T_\text {C}\), and for a first-order transition, the sign remains unchanged, i.e. the same below and above \(T_\text {C}\). On the other hand, the sign of \(\varepsilon _{\mathrm {2}}\) is always opposite to that of \(P_r\) below \(T_\text {C}\), and at \(T=T_\text {C}\), the value disappears for both the second- and the first-order transitions.

2.3 Remanent polarization

When the material is in its ferroelectric state, \(\varepsilon _{\mathrm {2}}\) depends on the spontaneous polarization \(P_\text {s}\) and the remanent polarization (\(P_\text {r}\)) [19, 21] according to

Because of the temperature dependence of 1/\(\varepsilon _\mathrm {1}\), we have 10\(\delta \,P_\text {s}^2 \ll 3\gamma\). In this case, the ratio \(\varepsilon _\mathrm {2}/\varepsilon _\mathrm {1}^3\) is approximately proportional to \(P_\text {r}\) [14] according to

Hence, by measuring non-linear dielectric permittivities, we can estimate the remanent polarization without subjecting the sample to very high electric fields.

2.4 Sample preparation and measurement techniques

A P(VDF-TrFE-CFE) terpolymer resin from Piezotech-Arkema with a VDF/TrFE/CFE ratio of 62.2/29.4/8.4 mol% was used. For the NLDS experiments, P(VDF-TrFE-CFE) films with thicknesses between 1.7 and 3.6 \(\upmu\)m were prepared by means of spin-coating. Accordingly, a 10 wt% terpolymer solution in acetone was spin-coated onto glass slides previously evaporated with 10 nm of chromium plus 60 nm of aluminium. Top Al electrodes (60 nm) were vacuum-deposited after spin-coating in order to provide electrical contacts for the NLDS measurements. The samples were annealed at a temperature of \(120\,^\circ\)C either immediately after spin-coating or before the NLDS runs for 4 or 1 hour(s), respectively. Spin-coated P(VDF-TrFE) films were prepared in a similar manner: P(VDF-TrFE) powder from Piezotech S.A. with a VDF/TrFE ratio of 75/25 mol% was dissolved in acetonitrile for a 10 wt% solution that was spin-coated onto a glass substrate, resulting in a 3.2 \(\upmu\)m thick film. The samples were annealed at 120\(\,^\circ\)C for one hour before the NLDS measurements.

In order to measure the non-linear permittivities, a sinusoidal electric field with an amplitude \({E_{\sim }}\) = 5 V/\(\upmu\)m below the coercive field \(E_\text {c}\) was applied at a frequency \(f_\mathrm {0}\) of 1 kHz to the capacitor-film sample from a lock-in amplifier (type SR830). The current response from the sample was recorded over a reference resistor connected in series with the sample. A Fourier transform of the current density j(t) was performed to obtain the spectral components:

The linear and non-linear permittivities \(\varepsilon _{\text {n}}\) were then calculated from a sum of the Fourier coefficients \(j^{''}_\text {i}\) [16]. If the excitation amplitude is chosen sufficiently small for the coefficients \(j^{''}_\text {n}\) to decrease strongly with increasing order n, the \(\varepsilon _\text {n}\) values can be calculated according to the approximate equation [22]:

The permittivities \(\varepsilon _\text {n}\) defined in Eqs. 4 and 9 refer to the real parts \(\varepsilon _\text {n}^{'}\) of the respective complex non-linear permittivities. Their imaginary parts \(\varepsilon _\text {n}^{''}\) can be calculated by replacing the non-vanishing component \(j^{''}_\text {n}\) with \(j^{'}_\text {n}\) in Eq. 9.

For short-circuit TSD measurements, free-standing ter- and copolymer films coated on both sides with aluminium electrodes of 60 nm thickness were used. The films were prepared by drop casting polymer solutions with the same concentrations as used for spin-coating. The thicknesses of the free-standing ter- and copolymer films were 137 and 20 \(\upmu\)m, respectively. For the TSD measurements, a Keithley 6578 electrometer was used to pole the samples at a temperature \(T_\text {p}\) = 40\(\,^\circ\)C with a DC field \(E_\text {p}\) of 10 MV/m for a time period \(t_\text {p}\) = 10 min before cooling them down to \(-60\,^\circ\)C, which is lower than the glass-transition temperature of both the terpolymer and the copolymer [9]. The depolarization currents were measured while heating the sample at a rate of 4K/min. Conventional dielectric measurements were also made on free-standing terpolymer films in vacuum by means of a Novocontrol Alpha dielectric analyzer. For both TSD and dielectric measurements, dry nitrogen gas was used for temperature control in a Novocontrol Quatro cryosystem. Dielectric-hysteresis measurements were performed by use of a Sawyer-Tower circuit. The dielectric displacement D was recorded as a function of the electric field E applied in the form of triangular voltage signals with a frequency of 10 Hz.

3 Results and discussion

3.1 Phase transition in P(VDF-TrFE-CFE) terpolymer

Figure 1 shows the real and imaginary parts of \(\varepsilon _\mathrm {1}\) (\(0\text {th}\)-order non-linear permittivity) of an annealed P(VDF-TrFE-CFE) terpolymer film, plotted as a function of temperature during heating and subsequent cooling. Let us consider the heating curve where we can see that the real part of the permittivity (\(\varepsilon ^{'}_\mathrm {1}\)) shows a maximum at the F-P transition temperature (around 27\(\,^\circ\)C) with a peak value of 63. The corresponding loss peak \(\varepsilon ^{''}\) (imaginary part of the permittivity) with a peak value above 5 is found around 15\(\,^\circ\)C. Such high permittivity values along with a low Curie-transition temperature are typical characteristics of relaxor-ferroelectric (R-F) materials [18]. R-F materials also show a shift in \(\varepsilon ^{'}_\mathrm {1}\) with increasing frequency [9, 11]. A closer look at the loss spectrum in Fig. 1 reveals an additional shoulder around − 3 \(\,^\circ\)C, corresponding to the un-freezing of the amorphous chains, as the sample passes through the glass-transition temperature (\(T_\text {g}\)) at a frequency of 1 kHz. With increasing frequency, the glass-transition loss peak also shows a shift in frequency and eventually merges with the Curie-transition peak (F-P transition) to give rise to a combined peak [9].

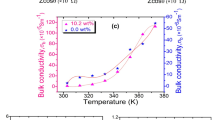

In order to compare the dielectric behavior of the R-F terpolymer with that of a typical ferroelectric material, the dielectric spectra of a P(VDF-TrFE) ferroelectric copolymer with a VDF/TrFE ratio of 75/25 (similar to the VFE/TrFE ratio in the terpolymer) are plotted as functions of temperature in Fig. 2. We can see that during the heating scan, the copolymer shows a maximum permittivity (\(\varepsilon _\mathrm {1}^{'}\)) of 35, which is lower than the value in the terpolymer investigated here. We also observe that the copolymer shows a very high \(T_\text {C}\) of approximately 128\(\,^\circ\)C. It should be noted that the \(T_\text {C}\) value of a P(VDF-TrFE) copolymer depends on the VDF/TrFE ratio and can vary between 60 and 135\(\,^\circ\)C [23], values that are higher than the transition temperature of the terpolymer studied here.

As mentioned in Sect. 2.2 above, it is possible to determine the order of the F-P phase transition from the sign of \(\varepsilon _\mathrm {3}\) (real part) in the paraelectric phase. In Fig. 3, we observe a change in the sign of \(\varepsilon ^{'}_3\) from positive to negative when the terpolymer passes through the temperature region of the F-P transition, which implies that the R-F terpolymer undergoes a second-order transition. The 2\(^\text {nd}\) order of the F-P transition is also confirmed by the results shown in Fig. 1 above where \(\varepsilon ^{'}_1\) does not exhibit any significant thermal hysteresis during cooling. On the other hand, we observe that our ferroelectric P(VDF-TrFE) copolymer with a VDF/TrFE ratio of 75/25 mol% shows a first-order transition as evident from the positive sign of \(\varepsilon ^{'}_3\) in the paraeletric phase (cf. Fig. 4) and from the presence of a thermal hysteresis in Figure 2 above.

3.2 Other transitions and relaxations in P(VDF-TrFE-CFE) terpolymer

One major advantage of NLDS is that the state of polarization of the material under investigation can be directly revealed from the sign of \(\varepsilon ^{'}_2\) (Sect. 2.2). From Eq. 5, we expect that for the terpolymer \(\varepsilon ^{'}_2\) (real part) should be zero (even-order permittivity) in the paraelectric phase, as a dielectric material in its non-polarized paraelectric state must behave as an ideal capacitor. In Fig. 5, though \(\varepsilon _2^{'}\) becomes 0 at 11\(\,^\circ\)C (\(T_\text {C}\)), which is lower than the corresponding value obtained from \(\varepsilon _1^{'}\) measurement (Fig. 1), we clearly see that the terpolymer’s \(\varepsilon _{2}^{'}\) adopts negative or non-zero values even in the paraelectric phase. In particular, new peaks are observed around 30 and 80\(\,^\circ\)C during heating as well as cooling.

In short-circuit TSD experiments, the depolarization current is measured, while the voltage decay is often recorded in open-circuit measurements that are better suited for detecting charge motion during discharge processes. Therefore, the various transitions and relaxations occurring in a polar sample can be precisely seen in short-circuit TSD experiments during heating at a constant heating rate. On the TSD curve of the terpolymer shown in Fig. 6, we can clearly observe a shoulder around 40\(\,^\circ\)C and a peak around 85\(\,^\circ\)C. The two features can be associated with the \(\varepsilon ^{'}_2\) peaks found at the same temperature ranges in Fig. 5.

Similar TSD and NLDS measurements were also carried out on the reference P(VDF-TrFE) copolymer—as shown in Figs. 6 and 7, respectively. In Fig. 6, the copolymer TSD curve shows a peak around 40\(\,^\circ\)C, but no peak can be identified around 80\(\,^\circ\)C. In Figure 7, we do not observe the peak around 40\(\,^\circ\)C that had been revealed in the TSD measurement of the copolymer, and the \(\varepsilon _2^{'}\) value is essentially zero in the ferroelectric phase—as expected for a non-poled sample. However, when heating the copolymer above 110\(\,^\circ\)C, \(\varepsilon _2^{'}\) becomes positive, just below the Curie-transition temperature \(T_\text {C}\), and during cooling, the curve is shifted to lower temperatures. In the paraelectric phase, the copolymer sample shows non-zero \(\varepsilon _2^{'}\) values in a similar manner as the terpolymer sample.

The peak around 30–40\(\,^\circ\)C, found in NLDS (\(\varepsilon ^{'}_2\)) and TSD measurements on the ter- and the copolymer, can be assigned to the mid-temperature (\(T_\text {mid}\)) transition that—as discussed recently [12, 24]—has multiple origins. \(T_\text {mid}\) processes take place in the vicinity of amorphous–crystalline (a–c) interfaces and therefore depend on the structure of the respective polymer and on its processing conditions. In case of the terpolymer, the nano-crystalline regions lead to a much larger a–c interface area than in the copolymer [1] with its larger crystallites. The different nanostructures result in a much stronger \(T_\text {mid}\) process in the terpolymer [12] that is readily seen in \(\varepsilon {^{'}_2}\) measurements. Due to the proximity of the F-P transition to the \(T_\text {mid}\) process in the terpolymer, the \(T_\text {mid}\) transition can usually not be seen as a distinct phenomenon in conventional dielectric experiments. As NLDS measurements are more sensitive, they allow us to resolve the process much better.

We know that the value of \(\varepsilon _\mathrm {2}\) depends on the spontaneous polarization of the sample [19]. Since Maxwell–Wagner (MW) interface polarization (which occurs at the a–c interface [11, 25] and plays a role in the mid-temperature transition) can contribute to spontaneous polarization, we observe non-zero \(\varepsilon _\mathrm {2}\) values in the paraelectric phase of the terpolymer (cf. Fig. 5 above). Though the \(T_\text {mid}\) transition is not discernible in Fig. 7, earlier remanent-polarization measurements on thin P(VDF-TrFE) copolymer films with the same composition revealed a clear non-zero polarization peak in the \(T_\text {mid}\) range during cooling—even after the initial polarization had been lost [15, 24], probably as a result of surface and interface effects that are predominant in ultra-thin films. From the TSD results shown in Fig. 6 and from other experiments [9, 24], the presence of a \(T_\text {mid}\) process in P(VDF-TrFE) samples is obvious.

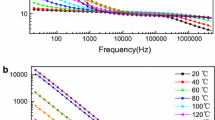

Looking again at the dielectric-loss curves shown in Fig. 1 above, we can observe a high-temperature peak around 110\(\,^\circ\)C in the terpolymer, both during heating and during cooling. It is also seen in the real part of the permittivity as a shoulder. In order to study the frequency dependence of the peak, the dielectric loss during heating has been measured at multiple frequencies. In Fig. 8, we can see that the position of the high-temperature peak shows no frequency dependence—just like a structural transition such as the Curie or the melting transition. Since the melting point of the terpolymer is about 128.5\(\,^\circ\)C, as determined previously in DSC experiments [9], the attribution of the peak to melting can be ruled out, and it is clear that the F-P transition occurs at a much lower temperature. Though the peak position does not depend on frequency, the peak amplitude shows a strong frequency dependence. In the temperature range from 50 to 120\(\,^\circ\)C, the dielectric loss is roughly proportional to the reciprocal frequency. Such a frequency dependence is expected when the dielectric loss is essentially caused by charge transport phenomena. In addition, the temperature at which the transition is seen changes from sample to sample. For a similar annealed terpolymer film, the transition is seen as a shoulder in the permittivity around 90\(\,^\circ\)C [26], about 20\(\,^\circ\)C lower than observed in the \(\varepsilon _1^{'}\) plot in Figure 1. This further supports the explanation of electrode polarization, and thus, the peak found at 80\(\,^\circ\)C in the \(\varepsilon _2^{'}\) measurement (Fig. 5) should be associated with this phenomenon. The peak is not only observed on the terpolymer, but also in the loss plot of the P(VDF-TrFE) copolymer during cooling (cf. Fig. 2 above), but at a slightly higher temperature.

In order to shed more light on the high-temperature peak, dielectric-hysteresis measurements at selected temperatures were carried out. Results for the terpolymer are depicted in Fig. 9 where, at RT, we can see that the terpolymer shows its characteristic slim hysteresis loop [1, 27]. In the paraelectric phase above 20\(\,^\circ\)C, we notice a steady drop in the electric-displacement values up to 100\(\,^\circ\)C. Between 100 and 110\(\,^\circ\)C, however, the loop collapses into a straight line in the same temperature range where we observe the high-temperature peaks in dielectric-spectroscopy measurements. A small offset of the hysteresis curve is seen both in the direction of D and E in the Figure. The offset in D direction is due to design of the Sawyer–Tower circuit which only records the change in displacement values and the shift in the E direction could be due to variations of the top and bottom surfaces of the film deposited onto the glass-substrate (defects on film surface, non-alignment of top and bottom aluminum electrode area, etc.).

Since non-linear permittivities can give information about the ferroelectric state of the sample, complementing the results obtained from dielectric hysteresis measurements, the remanent polarization ratio \(\varepsilon _\mathrm {2}/3\varepsilon _\mathrm {0}^\mathrm {2}\varepsilon _\mathrm {1}^\mathrm {3}\) is plotted as a function of temperature for a poled and annealed terpolymer sample in Fig. 10. The plot shows a minimum at approximately 30\(\,^\circ\)C due to the mid-temperature transition. Upon further heating, we observe yet another minimum in the high-temperature peak range around 100\(\,^\circ\)C, followed by a steep increase in \(P_\text {r}\) ratio. Both observations, i.e. a straight line instead of a hysteresis loop and an irregular \(P_\text {r}\) curve above 100\(\,^\circ\)C, indicate that the high-temperature peak observed in the permittivity measurements has its origin in real charges at the electrode–sample interface [28, 29]—an explanation that is supported by the shift in the polarization curve during cooling within the high-temperature range, as seen in Fig. 10. In addition, we find from \(\varepsilon ^{''}_{1}\) measurements at different frequencies (Fig. 8) that the peak is stronger at lower frequencies (< 1 kHz) and gradually disappears at higher frequencies, which is expected in the case of electrode/space-charge polarization processes, as the charges cannot follow the faster electric-field variations at higher frequencies [28]. Furthermore, previous TSD measurements on a similar terpolymer poled at different electric fields show that the position of the peak seen around 90\(\,^\circ\)C changes and that the peak does not seem to depend on poling conditions, which means that there is no distinct dipolar motion behind the process [30]. The onset of melting in the same temperature range (see the DSC thermogram in Fig. 1 of Ref. [12]) increases conductivity in the sample, facilitates motion of real charges towards the electrodes, and thus induces electrode polarization.

The results of dielectric-hysteresis and remanent-polarization measurements on the P(VDF-TrFE) copolymer are shown in Figs. 11 and 12, respectively. From Fig. 11, we see that as the temperature increases, not only the maximum displacement \(D_\text {max}\) (as also found on the terpolymer), but also its remanent value \(D_\text {r}\) (related to the remanent polarization \(P_\text {r}\)) decreases. In particular, between 100 and 110 \(^\circ\)C, the displacement decreases drastically. The decrease in \(D_\text {r}\) can be explained with the gradual decrease of the crystallinity in the copolymer at increasing temperatures [31]. At 120\(\,^\circ\)C, we see that the loop stops shrinking. At 130\(\,^\circ\)C, however, the recorded hysteresis loop is bigger than that observed at 120\(\,^\circ\)C with a higher \(D_\text {r}\), but a lower \(D_\text {max}\).

Comparing \(D_\text {r}\) in Fig. 11 with the \(\varepsilon _\mathrm {2}/3\varepsilon _\mathrm {0}^\mathrm {2}\varepsilon _\mathrm {1}^\mathrm {3}\) ratio in Fig. 12, we see that the polarization remains stable up to 100\(\,^\circ\)C. Above 100\(\,^\circ\)C, we observe a sharp decrease in \(P_\text {r}\) similar to that observed for its corresponding hysteresis curves, and as the temperature increases further, \(P_\text {r}\) drops to zero at the \(T_\text {C}\). At 130\(\,^\circ\)C, we observe a steep rise in the polarization, as also observed in the high-temperature range of the terpolymer, which confirms that the growth of the hysteresis loop of the copolymer in the same temperature range (cf. Fig. 11) is due to an electrode polarization that increases the overall sample capacitance. The elliptical shape of the hysteresis loop corresponds to the same phenomenon. It should be mentioned that new crystals have been observed to be formed in the paraelectric phase of the same copolymer [31], which can also contribute to the increase in capacitance. The resulting charge migration could lead to a much stronger growth of \(P_\text {r}\) in the copolymer (as observed above 130\(\,^\circ\)C in Fig. 12) than in the terpolymer above 100\(\,^\circ\)C (Fig. 10). The other difference observed in the copolymer in Fig. 12, when compared to the corresponding plot of the terpolymer, is that \(P_\text {r}\) drops to zero upon cooling, which indicates that all the electrode polarization has been lost. Real charges which are responsible for the electrode polarization observed in both the ter- and the copolymer can exist in the sample due to impurities or defects introduced during preparation or processing. Hence, the method of preparation, the choice of solvents, etc., play important roles for the presence of the observed charges.

4 Conclusion

In this study, non-linear dielectric spectroscopy (NLDS) has been employed to study transitions and relaxations in P(VDF-TrFE-CFE) relaxor-ferroelectric (R-F) terpolymers. In particular, non-linear measurements provide insight into the mid-temperature transition and the high-temperature relaxation that cannot be observed and explained through conventional dielectric measurements. In order to complement the NLDS results, related techniques such as thermally stimulated depolarization (TSD) and dielectric hysteresis measurements have been used. For comparing and highlighting the differences between a relaxor-ferroelectric and a ferroelectric polymer, reference measurements were performed on a P(VDF-TrFE) copolymer with a comparable VDF/TrFE ratio as that found in the terpolymer.

Several noteworthy results have been obtained, and they may shed new light on the large range of possible structure-property relations in complex polymers:

-

The sign of \(\varepsilon _3^{'}\) changes from positive to negative at the ferroelectric-to-paraelectric (F-P) transition temperature, which reveals that the R-F terpolymer undergoes a second-order transition, while the ferroelectric copolymer shows a positive sign throughout, which indicates a first-order transition.

-

As the remanent polarization vanishes in the paraelectric phase irrespective of the order of the transition, the value of \(\varepsilon _2^{'}\) should be zero above the respective F-P transition temperature. However, measurements on both the ter- and the copolymer reveal non-zero values in the paraelectric state. Especially for the terpolymer, new peaks are observed in the paraelectric state at 30\(\,^\circ\)C and 80\(\,^\circ\)C.

-

The peak at 30\(\,^\circ\)C in the terpolymer is associated with the mid-temperature transition. Though the peak is absent in \(\varepsilon _2^{'}\) versus temperature measurements on the P(VDF-TrFE) copolymer, it is indeed observed in TSD experiments and other previous measurements.

-

The peak at 80\(\,^\circ\)C found in \(\varepsilon _2^{'}\) measurement is related to the high-temperature peak observed around 100\(\,^\circ\)C on the terpolymer in conventional dielectric-loss (\(\varepsilon _1^{'}\)) measurements, which shows frequency-independent nature at lower frequencies—similar to that of a structural transition. However, the amplitude of the peak is inversely proportional to frequency, indicating that the dielectric loss may originate from charge motion.

-

Evaluating the ratio \(\varepsilon _\mathrm {2}/3\varepsilon _\mathrm {0}^\mathrm {2}\varepsilon _\mathrm {1}^\mathrm {3}\) which is proportional to the remanent polarization in a given sample, we have shown that the high-temperature peak is a result of the space-charge/electrode polarization at the metal-electrode/sample interface—in close agreement with electrical-hysteresis measurements. A similar origin can be deduced for the shift in the \(\varepsilon _{\mathrm {2}}^{'}\) values of the copolymer above 110\(\,^\circ\)C.

The results and insights obtained from the non-linear measurements on the terpolymer will pave the way for future studies on the present and on other similar VDF-based terpolymers from both a fundamental and an applications-related point of view. A better understanding of the underlying structure-property relations at the micro- and nano-scales will help to design and optimize advanced materials for demanding future applications.

References

F. Bauer, E. Fousson, Q.M. Zhang, L.M. Lee, Ferroelectric copolymers and terpolymers for electrostrictors: synthesis and properties. IEEE Trans. Dielectrics Electr. Insulation 11(2), 293–298 (2004)

F. Bauer, Relaxor fluorinated polymers: novel applications and recent developments. IEEE Trans. Dielectrics Electr. Insulation 17(4), 1106–1112 (2010)

X. Chen, L. Liu, S.-Z. Liu, Y.-S. Cui, X.-Z. Chen, H.-X. Ge, Q.-D. Shen, P(VDF-TrFE-CFE) terpolymer thin-film for high performance nonvolatile memory. Appl. Phys. Letts. 102(6), 063103 (2013)

J.S. Lee, A.A. Prabu, K.J. Kim, Annealing effect upon chain orientation, crystalline morphology, and polarizability of ultra-thin P(VDF-TrFE) film for nonvolatile polymer memory device. Polymer 51(26), 6319–6333 (2010)

Z. Hu, M. Tian, B. Nysten, A.M. Jonas, Regular arrays of highly ordered ferroelectric polymer nanostructures for non-volatile low-voltage memories. Nat. Mater. 8(1), 62–67 (2009)

T.C. Chung, A. Petchsuk, Synthesis and Properties of Ferroelectric Fluoroterpolymers with Curie Transition at Ambient Temperature. Macromolecules 35(20), 7678–7684 (2002)

F. Xia, High Electromechanical Responses in a Poly(vinylidene fluoride-trifluoroethylene-chlorofluoroethylene) Terpolymer. Adv. Mater. 14(21), 1570–1574 (2002)

T. Raman Venkatesan, P. Frübing, R. Gerhard, in Influence of Composition and Preparation on Crystalline Phases and Morphology in Poly(vinylidene fluoride-trifluoroethylene-chlorofluoroethylene) Relaxor-Ferroelectric Terpolymer (Budapest, Hungary, 2018), 4 p. https://doi.org/10.1109/ICD.2018.8468492

T. Raman Venkatesan, A.A. Gulyakova, P. Frubing, R. Gerhard, Relaxation processes and structural transitions in Poly(vinylidene fluoride-trifluoroethylene-chlorofluoroethylene) relaxor-ferroelectric terpolymers as seen in dielectric spectroscopy. IEEE Trans. Dielectrics Electr. Insulation 25(6), 2229–2235 (2018)

H.-M. Bao, J.-F. Song, J. Zhang, Q.-D. Shen, C.-Z. Yang, Q.M. Zhang, Phase Transitions and Ferroelectric Relaxor Behavior in P(VDF-TrFE-CFE) Terpolymers. Macromolecules 40(7), 2371–2379 (2007)

T. Raman Venkatesan, A.A. Gulyakova, P. Frübing, R. Gerhard, Electrical polarization phenomena, dielectric relaxations and structural transitions in a relaxor-ferroelectric terpolymer investigated with electrical probing techniques. Mater. Res. Express 6(12), 125301 (2019)

T. Raman Venkatesan, R. Gerhard, Origin of the mid-temperature transition in vinylidenefluoride-based ferro-, pyro- and piezoelectric homo-, co- and ter-polymers. Mater. Res. Express 7(6), 065301 (2020). (and references therein)

M.E. Lines, A.M. Glass, Principles and Applications of Ferroelectrics and Related Materials (Oxford University Press, Oxford, 2001)

B. Heiler, B. Ploss, in Dielectric nonlinearities of P(VDF-TrFE), International Symposium on Electrets (ISE)-8, (Paris, France, 1994), pp. 662–667

D. Nordheim, S. Hahne, B. Ploss, Nonlinear dielectric properties and polarization in thin ferroelectric P(VDF-TrFE) copolymer films. IEEE Trans. Dielectrics Electr. Insulation 19(4), 1175–1180 (2012)

B. Ploss, B. Ploss, Influence of poling and annealing on the nonlinear dielectric permittivity of P(VDF-TrFE) copolymers. IEEE Trans. Dielectrics Electr. Insulation 5(1), 91–95 (1998)

H.S. Nalwa, Ferroelectric Polymers: Chemistry, Physics, and Applications (M. Dekker Inc, New York, 1995)

L.E. Cross, Relaxorferroelectrics: an overview. Ferroelectrics 151(1), 305–320 (1994)

S. Ikeda, H. Kominami, K. Koyama, Y. Wada, Nonlinear dielectric constant and ferroelectric-to-paraelectric phase transition in copolymers of vinylidene fluoride and trifluoroethylene. J. Appl. Phys. 62, 3339–3342 (1987)

T. Furukawa, Recent advances in ferroelectric polymers. Ferroelectrics 104(1), 229–240 (1990)

S. Ikeda, H. Suzuki, K. Koyama, Y. Wada, Second-Order Dielectric Constant of a Copolymer of Vinylidene Fluoride and Trifluoroethylene (52:48 Mole Ratio). Polym. J. 19(6), 681–686 (1987)

M. Wübbenhorst, X. Zhang, T. Putzeys, Polymer Electrets and Ferroelectrets as EAPs: Characterization (Springer International Publishing, Cham, 2016), pp. 591–623. ((and references therein))

K.J. Kim, G.B. Kim, C.L. Vanlencia, J.F. Rabolt, Curie transition, ferroelectric crystal structure, and ferroelectricity of a VDF/TrFE (75/25) copolymer 1. The effect of the consecutive annealing in the ferroelectric state on curie transition and ferroelectric crystal structure. J. Polym. Sci. Part B Polym. Phys. 32(15), 2435–2444 (1994)

T. Raman Venkatesan, M. Wübbenhorst, B. Ploss, X. Qiu, T. Nakajima, T. Furukawa, R. Gerhard, The mystery behind the mid-temperature transition(s) in vinylidenefluoride-based homo-. co- and terpolymers - has the puzzle been solved? IEEE Transac. Delectrics Electr. Insulation 27(5), 1446–1464 (2020)

D. Rollik, S. Bauer, R. Gerhard(-Multhaupt). , Separate contributions to the pyroelectricity in poly(vinylidene fluoride) from the amorphous and crystalline phases, as well as from their interface. J. Appl. Phys. 85(6), 3282–3288 (1999)

T. Raman Venkatesan, M. Wübbenhorst, and R. Gerhard. Structure-property relationships in three-phase relaxor-ferroelectric terpolymers. Ferroelectrics (2021) (accepted)

F. Bauer, Review on the properties of the ferrorelaxor polymers and some new recent developments. Appl. Phys. A 107(3), 567–573 (2012)

K.C. Kao, Electric Polarization and Relaxation. In Dielectric Phenomena in Solids, Chapter, vol. 2 (Academic Press, San Diego, 2004), pp. 58–77

E. Riande and R. Diaz-Calleja. Physical fundamentals of dielectrics. In Electrical Properties of Polymers, chapter 1. New York: M. Dekker, Inc, New York, 2004

T. Raman Venkatesan. Relaxation processes and structural transitions in poly(vinylidenefluoride-trifluoroethylene-chlorofluoroethylene) relaxor-ferroelectric terpolymers. Master’s thesis, Joint Polymer-Science Program at FU, HU and TU Berlin, and U Potsdam, 2017

F. Bargain, P. Panine, F. Domingues Dos Santos, S. Tencé-Girault, From solvent-cast to annealed and poled poly(VDF- co -TrFE) films: New insights on the defective ferroelectric phase. Polymer 105, 144–156 (2016)

Acknowledgements

The paper is dedicated to the loving memory of our friend and colleague Prof. Siegfried Bauer who passed away much too early at the end of 2018 and who proposed several concepts discussed here. We are missing his brilliant ideas and the fascinating discussions with him.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Raman Venkatesan, T., Smykalla, D., Ploss, B. et al. Non-linear dielectric spectroscopy for detecting and evaluating structure-property relations in a P(VDF-TrFE-CFE) relaxor-ferroelectric terpolymer. Appl. Phys. A 127, 756 (2021). https://doi.org/10.1007/s00339-021-04876-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-021-04876-0