Abstract

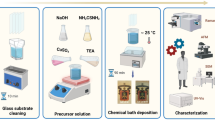

In this present work, we have studied the effect of organic solvents and acetylacetone (Acac) molar ratio on several properties of TiO2 thin films prepared by pneumatic spray pyrolysis (SP). The TiO2 thin films were characterized by the following techniques including the following: X-ray diffraction (XRD), Raman spectroscopy, Scanning Electron Microscopy (SEM) and UV–visible spectrophotometer. The XRD results showed pure anatase TiO2 thin films with preferential orientation (101) plan, the crystallite size varying between 14.72 and 35.12 nm. The Raman spectroscopy confirmed the formation of the only phase of TiO2 (anatase). The morphological properties were investigated by SEM. The UV–Visible spectrophotometer showed the semiconducting properties of anatase TiO2, and the optical band gap was ranged between 3.17–3.34 eV. The refraction index, the extinction coefficient and the porosity were estimated using transmittance values. The TiO2 thin films have had good properties. They were prepared by low-cost technique, spray pyrolysis, by saving energy and time because the samples were synthesized using air pulverization without using any oxygen sources and without any annealing requires the following: CVD room, low pressure and more time for annealing (Sahoo et al. 2019 in Phys Chem Chem Phys 21: 6198–6206).

Similar content being viewed by others

References

M. Sahoo, A.K. Yadav, S. Ghosh, S.N. Jha, D. Bhattacharyya, T. Mathews, Phys. Chem. Chem. Phys. 21, 6198–6206 (2019). https://doi.org/10.1039/C8CP06811A

S. Kirchner, J.F. Arenes, C. Cochet, M. Derbez, C. Duboudin, P. Elias, A. Gregoire, B. Jedor, J.P. Lucas, N. Pasquier, M. Pigneret, O. Ramalho, Campagne Nationale Logements: Etat de la Qualite de l’air dans les Logements Français rapport final (Observatory on indoor air quality national survey: indoor air quality in French dwellings, 2007). http://oqai.fr. Accessed 26 May 2007

P. Yoboué, P. Kouakou, A. Kamagaté, P. Menini, F. Mesnilgrente, V. Conédéra, N. Fabre, Int. J. Mater. Eng. Technol. 55–66 (2019) (Pushpa Publishing House)

R. Godbole, V.P. Godbole, P.S. Alegaonkar, S. Bhagwat, New J. Chem. 41(20), 11807–11816 (2017). https://doi.org/10.1039/C7NJ00963A

M.A. Han, H.J. Kim, H.C. Lee, J.-S. Park, H.-N. Lee, Appl. Surf. 481, 133–137 (2019). https://doi.org/10.1016/j.apsusc.2019.03.043

Y.N. Colmenares, W. Correr, B.S. Lima, V.R. Mastelaro, Thin solid film 703, 137975 (2020). https://doi.org/10.1016/j.tsf.2020.137975

J.H. Kim, S. Lee, H.S. Im, Appl. Surf. Sci. 151, 6–16 (1999)

Y.M. Sung, H.J. Kim, Thin Solid Films 515(12), 4996–4999 (2007)

M. Addamo, V. Augugliaro, A.D. Paola, E. Garcia Lopez, V. Loddo, G. Marci, L. Palmisano, Thin Solid Films 516(12), 3802–3807 (2008). https://doi.org/10.1016/j.tsf.2007.06.139

H.O. Seo, T.G. Woo, E.J. Park, B.J. Cha, I.H. Kim, S.W. Han, Y.D. Kim, Appl. Surf. Sci 420, 808–816 (2017)

R. Kumar, R. Kumar, N. Kushwaha, J. Mittal, IEEE Sens J 16(12), 4691–4695 (2016). https://doi.org/10.1109/JSEN.2016.2550079

C.-H. Chang, T.-C. Chou, W.-C. Chen, J.-S. Niu, K.-W. Lin, S.-Y. Cheng, W.-C. Liu, Sens. Actuators, B Chem. 317, 128145 (2020). https://doi.org/10.1016/j.snb.2020.128145

J. Bai, B. Zhou, Chem. Rev. 114(19), 10131–10176 (2014)

A. Paliwal, A. Sharma, M. Tomar, V. Gupta, Sens. Actuators B Chem. 250, 679–685 (2017). https://doi.org/10.1016/j.snb.2017.05.064

H. Chen, Y. Liu, C. Xie, J. Wu, D. Zeng, Y. Liao, Ceram. Int. 38(1), 503–509 (2012)

A. Fujishima, K. Honda, Nature 238, 37–38 (1972)

M. Zdorovets, A. Kozlovskiy, D. Tishkevich, T. Zubar, A. Trukhanov, J. Mater. Sci. Mater. Electron. 31, 21142–21153 (2020). https://doi.org/10.1007/s10854-020-04626-7

W. Yang, H. Shen, J. Ge, B. Xu, Nanotechnology 32, 155503 (2021). https://doi.org/10.1016/j.apsusc.2021.149446

S.S. El-Deen, A.M. Hashem, A.E. Abdel Ghany, Ionics 24, 2925–2934 (2018). https://doi.org/10.1007/s11581-017-2425-y

F. Aydin Unal, S. Ok, M. Unal, S. Topal, K. Cellat, F. Şen, J. Mol. Liquids 299, 112177 (2020). https://doi.org/10.1016/j.molliq.2019.112177

M. Fitraa, I. Dauta, M. Irwantoa, N. Gomesha, Y.M. Irwan, Energy Procedia J. Mol. Liquid 36, 278–286 (2013). https://doi.org/10.1016/j.egypro.2013.07.038

I. Dundar, M. Krichevskaya, A. Katerski, I.O. Acik, R. Soc. Open Sci. 6, 181578 (2019). https://doi.org/10.1098/rsos.181578

R. Dholam, N. Patel, M. Adami, A. Miotello, Int. J. Hydrogen Energy 33, 6896–6903 (2008). https://doi.org/10.1016/j.ijhydene.2008.08.061

Y. Doubi, B. Hartiti, H. Labrim, S. Fadili, A. Batan, M. Tahri, A. Belfhaili, P. Thevenin, Mater. Today Proc. 30, 823–827 (2020). https://doi.org/10.1016/j.matpr.2020.04.186

C. Balasingh, A. Abuhasan. Diffraction peak broadening studies in Al2O3 (Whisker) composites. Powder Diffr. (1991)

Z. Matěj, L. Matějová, R. Kužel, Powder Diffr. 28, 161–183 (2013). https://doi.org/10.1017/S0885715613001061

S. Benramache, A. Rahal, B. Benhaoua, Optik 125(2), 663–666 (2014). https://doi.org/10.1016/j.ijleo.2013.07.085

A. Begum, A. Hussain, A. Rahman, Beilstein J. Nanotechnol. 2(3), 438–443 (2012)

M.R. Alfaro Cruz, D. Sanchez-Martinez, L.M. Torres-Martinez, Int. J. Hydrogen Energy 44(36), 20017–20028 (2019)

A. Kotbi, B. Hartiti, S. Fadili, A. Ridah, P. Thevenin, Opt. Quant. Electron 48, 524 (2016). https://doi.org/10.1007/s11082-016-0784-7

Z. Essalhi, B. Hartiti, A. Lfakir, B. Mari, P. Thevenin, Opt. Quant. Electron 49, 301 (2017). https://doi.org/10.1007/s11082-017-1142-0

T.I.A.N. Guang-Lei, H.E. Hong-Bo, S.H.A.O. Jian-Da, Chinese Phys. Lett. 22(7), 1787 (2005)

F. Zahedi, R.S. Dariani, S.M. Rozati, Bull. Mater. Sci. 37(3), 433–439 (2014). https://doi.org/10.1007/s12034-014-0696-8

B.E. Yoldas, P.W. Partlow, Thin Solid Films 129, 1–14 (1985). https://doi.org/10.1016/0040-6090(85)90089-6

M.H. Liao, C.H. Hsu, D.H. Chen, J. Solid State Chem. 179, 2020–2026 (2006)

R. Shakoury, A. Zarei, SILICON 11, 1247–1252 (2019). https://doi.org/10.1007/s12633-018-9897-x

I.M. El Radaf, H.Y.S. Al-Zahrani, A.S. Hassanien, J. Mater. Sci.: Mater. Electron. (2020). https://doi.org/10.1007/s10854-020-03369-9

J. Sabataityte, I. Oja, F. Lenzmann, O. Volobujeva, M. Krunks, J. Solid State Chem. 9(5–6), 708–712 (2006)

I.A. Kariper, J. Mater. Res. Technol 5(1), 77–83 (2016)

Z. Elkhalidi, B. Hartiti, S. Fadili, P. Thevenin, Int. J. Hydrogen Energy 43(27), 12574–12583 (1987). https://doi.org/10.1016/j.ijhydene.2018.04.162

K. Sangwal, W. Kucharczyk, J. Phys. D 20, 522 (1987)

Acknowledgements

The authors are very grateful to PHC Toubkal/19/85 for financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Doubi, Y., Hartiti, B., Labrim, H. et al. Experimental study of properties of TiO2 thin films deposited by spray pyrolysis for future sensory applications. Appl. Phys. A 127, 475 (2021). https://doi.org/10.1007/s00339-021-04629-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-021-04629-z