Abstract

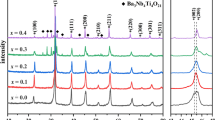

Ba0.85Ca0.15Zr0.1Ti0.9O3 (BCZT) ceramics with excellent piezoelectric properties and environment friendliness are very potential alternatives for PbZrxTi1−xO3 (PZT) ceramics. The stability and reliability of ferroelectricity and piezoelectricity in BCZT ceramics under cyclic electric field are crucial to its long-term application. Herein, BCZT ceramics were synthesized by sol–gel method and different sintering atmospheres and the influences of sintering atmosphere on the fatigue behaviors of ferroelectric and piezoelectric properties have been investigated. XPS results confirm that the oxygen vacancy concentration of BCZT ceramics sintered in oxygen, air, and nitrogen atmosphere gradually increases. After 106 cycles, the polarization of all BCZT ceramics decreases to some extent and the fatigue resistance of polarization of BCZT ceramics sintered in the air is superior to BCZT ceramics sintered in oxygen and nitrogen atmospheres, which may result from the additional contribution of higher leakage current caused by relatively poor densification of BCZT ceramics sintered in air to polarization. The internal bias field of BCZT ceramics sintered in air, O2 and N2 atmospheres after fatigue decreases, and the reduced amplitude of internal bias field in BCZT ceramics with less oxygen vacancies sintered in air and oxygen atmospheres is obviously higher than that in BCZT ceramics with more oxygen vacancies sintered in nitrogen atmosphere, which is due to the redistribution of oxygen vacancy under the repetition of external electric field. After 106 cycles, the maximum electric field-induced strain and d33* of BCZT ceramics sintered in the air and oxygen atmospheres decrease and that of BCZT ceramics sintered in nitrogen atmosphere increases. The enhanced fatigue resistance of piezoelectric response of BCZT ceramics sintered in nitrogen atmosphere results from the interaction of (100) orientation, grain refinement, and “wake up” effect caused by the repetition of enough external electric field.

Similar content being viewed by others

References

S. Trolier-McKinstry, S. Zhang, A.J. Bell, X. Tan, Annu. Rev. Mater. Res. 48, 191 (2018)

K. Shibata, R. Wang, T. Tou, J. Koruza, MRS Bull. 43, 612 (2018)

Z. Du, C. Zhao, H.C. Thong, Z. Zhou, J. Zhou, K. Wang, C. Guan, H. Liu, J. Fang, J. Alloy Compd. 801, 27 (2019)

X. Fu, W. Cai, G. Chen, R. Gao, J. Mater. Sci. Mater. Electron. 28, 8177 (2017)

Z. Fan, J. Koruza, J. Rödel, X. Tan, Acta Mater. 151, 253 (2018)

F. Han, J. Deng, X. Liu, T. Yan, S. Ren, X. Ma, S. Liu, B. Peng, L. Liu, Ceram. Int. 43, 5564 (2017)

S. Pang, L. Yang, J. Qin, H. Qin, H. Xie, H. Wang, C. Zhou, J. Xu, Appl. Phys. A 125, 119 (2019)

K. Shalini, D. Prabhu, N. Giridharan, Appl. Phys. A 124, 866 (2018)

P. Li, J. Zhai, B. Shen, S. Zhang, X. Li, F. Zhu, X. Zhang, Adv. Mater. 30, 1705171 (2018)

V. Bijalwan, H. Hughes, H. Pooladvand, P. Tofel, B. Nan, V. Holcman, Y. Bai, T.W. Button, Mater. Res. Bull. 114, 121 (2019)

L. Wang, W. Bai, X. Zhao, F. Wen, L. Li, W. Wu, P. Zheng, J. Zhai, J. Mater. Sci. Mater. Electron. 30, 9219 (2019)

W. Liu, X. Ren, Phys. Rev. Lett. 103, 257602 (2009)

I. Coondoo, N. Panwar, D. Alikin, I. Bdikin, S.S. Islam, A. Turygin, V.Y. Shur, A.L. Kholkin, Acta Mater. 155, 331 (2018)

S. Li, C. Wang, L. Li, Q. Shen, L. Zhang, J. Alloy Compd. 730, 182 (2018)

M.B. Abdessalem, S. Aydi, A. Aydi, N. Abdelmoula, Z. Sassi, H. Khemakhem, Appl. Phys. A 123, 583 (2017)

L. Jin, R. Huo, R. Guo, F. Li, D. Wang, Y. Tian, Q. Hu, X. Wei, Z. He, Y. Yan, ACS Appl. Mater. Interface 8, 31109 (2016)

Y. Zhang, H. Sun, W. Chen, J. Phys. Chem. Solids 114, 207 (2018)

Z. Liu, R. Yuan, D. Xue, W. Cao, T. Lookman, Acta Mater. 157, 155 (2018)

Y. Liu, Y. Chang, F. Li, B. Yang, Y. Sun, J. Wu, S. Zhang, R. Wang, W. Cao, ACS Appl. Mater. Interface 9, 29863 (2017)

W. Bai, D. Chen, P. Li, B. Shen, J. Zhai, Z. Ji, Ceram. Int. 42, 3429 (2016)

Q. Zhang, W. Cai, Q. Li, R. Gao, G. Chen, X. Deng, Z. Wang, X. Cao, C. Fu, J. Alloy Compd. 794, 542 (2019)

N. Chaiyo, D.P. Cann, N. Vittayakorn, Mater. Design. 133, 109 (2017)

Y. Zhang, J. Glaum, M.C. Ehmke, K.J. Bowman, J.E. Blendell, M.J. Hoffman, J. Am. Ceram. Soc. 99, 1287 (2016)

V. Rojas, J. Koruza, E.A. Patterson, M. Acosta, X. Jiang, N. Liu, C. Dietz, J. Rödel, J. Am. Ceram. Soc. 100, 4699 (2017)

Y. Liu, Y. Chang, E. Sun, F. Li, S. Zhang, B. Yang, Y. Sun, J. Wu, W. Cao, ACS Appl. Mater. Interface 10, 31488 (2018)

Y.A. Genenko, J. Glaum, M.J. Hoffmann, K. Albe, Mater. Sci. Eng. B Adv. 192, 52 (2015)

J. Glaum, M. Hoffman, J. Am. Ceram. Soc. 97, 665 (2014)

X. Jia, J. Zhang, L. Wang, J. Wang, H. Du, Y. Yao, L. Ren, F. Wen, P. Zheng, J. Am. Ceram. Soc. 102, 5203 (2019)

K. Tanaka, S. Takatsuka, H. Nishiyama, K. Kakimoto, AIP Adv. 9, 045102 (2019)

B. Akkopru-Akgun, W. Zhu, M.T. Lanagan, S. Trolier-McKinstry, J. Am. Ceram. Soc. 102, 5328 (2019)

Y.J. Kao, C.Y. Su, C. Pithan, D.F. Hennings, C.Y. Huang, R. Waser, J. Am. Ceram. Soc. 99, 1311 (2016)

Q. Lin, D. Wang, S. Li, J. Am. Ceram. Soc. 98, 2094 (2015)

S.W. Zhang, H. Zhang, B.P. Zhang, G. Zhao, J. Eur. Ceram. Soc. 29, 3235 (2009)

Z. Shen, X. Wang, H. Gong, L. Wu, L. Li, Ceram. Int. 40, 13833 (2014)

J.P.B. Silva, F.L. Faita, K. Kamakshi, K.C. Sekhar, J.A. Moreira, A. Almeida, M. Pereira, A.A. Pasa, M.J.M. Gomes, Sci. Rep.UK 7, 46350 (2017)

W. Bai, J. Hao, B. Shen, F. Fu, J. Zhai, J. Alloy Compd. 536, 189 (2012)

S. Ye, J. Fuh, L. Lu, Appl. Phys. Lett. 100, 252906 (2012)

C. Yang, H. Sui, H. Wu, G. Hu, J. Alloys Compd. 637, 315 (2015)

F. Zhang, L. Zhang, X. Guo, S. Yang, Q. Tian, S. Fan, Ceram. Int. 44, 13502 (2018)

D. Deng, Q. Guo, W. Hu, J. Phy. B Atomic Mol. Opt. 41, 225402 (2008)

J. Ma, X. Liu, W. Li, J. Alloy Compd. 581, 642 (2013)

A. Tkach, O. Okhay, A. Almeida, P.M. Vilarinho, Acta Mater. 130, 249 (2017)

L. Zhang, Z. Yao, M.T. Lanagan, H. Hao, J. Xie, Q. Xu, M. Yuan, M. Sarkarat, M. Cao, H. Liu, J. Eur. Ceram. Soc. 38, 2534 (2018)

H. Kaddoussi, Y. Gagou, A. Lahmar, J. Belhadi, B. Allouche, J.L. Dellis, M. Courty, H. Khemakhem, M. El Marssi, Solid State Commun. 201, 64 (2015)

Z. Zhao, X. Li, H. Ji, Y. Dai, T. Li, J. Alloy Compd. 637, 291 (2015)

Y. Zhang, J. Glaum, M.C. Ehmke, J.E. Blendell, K.J. Bowman, M.J. Hoffman, J. Am. Ceram. Soc. 99, 174 (2016)

J. Zhao, Z. Yue, W. Wang, Z. Gui, L. Li, J. Electroceram. 21, 581 (2008)

H. Simons, J. Glaum, J.E. Daniels, A.J. Studer, A. Liess, J. Rödel, M. Hoffman, J. Appl. Phys. 112, 044101 (2012)

O. Namsar, C. Uthaisar, S. Pojprapai, J. Mater. Sci. Mater. Electron. 29, 7188 (2018)

H. Guo, X. Liu, J. Rödel, X. Tan, Adv. Funct. Mater. 25, 270 (2015)

W.L. Tan, K.T. Faber, D.M. Kochmann, Acta Mater. 164, 704 (2019)

G. Arlt, H. Neumann, Ferroelectr. 87, 109 (1988)

Y. Chang, S. Poterala, D. Yener, G.L. Messing, J. Am. Ceram. Soc. 96, 1390 (2013)

Acknowledgements

This work was supported by Excellent Talent Project in University of Chongqing (Grant No. 2017-35), the Science and Technology Innovation Project of Social Undertakings and People’s Livelihood Guarantee of Chongqing (Grant No. cstc2017shmsA90015), the Program for Creative Research Groups in University of Chongqing (Grant No. CXQT19031), the Leading Talents of Scientific and Technological Innovation in Chongqing (CSTCCXLJRC201919), the Chongqing Research Program of Basic Research and Frontier Technology (Grant No. CSTC2018jcyjAX0416).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, Q., Cai, W., Zhou, C. et al. Electric fatigue of BCZT ceramics sintered in different atmospheres. Appl. Phys. A 125, 759 (2019). https://doi.org/10.1007/s00339-019-3062-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-019-3062-2