Abstract

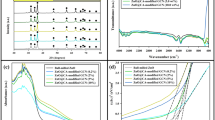

Metal ion-doped titanium dioxide (TiO2) nanoparticles have been proved to be one of the most efficient decontaminating catalysts towards chemical warfare agents (CWAs). Nowadays, most of the researchers are paying their attention to the study of single metal ion-doped TiO2 nanoparticles, while a few reports are focused on the photocatalytic degradation performance of two or more kinds of metal ions codoped TiO2 nanoparticles. In this work, Fe–Cu codoped TiO2 nanoparticles have been prepared by the homogeneous precipitation method. 2-Chloroethyl ethyl sulfide (2-CEES), as a model, has been used to investigate its photocatalytic degradation efficiency on the prepared catalysts. The results showed that 10 wt% Fe2–Cu1 codoped TiO2 nanoparticles have an obvious improved photocatalytic activity compared with the single Fe/Cu-doped TiO2 nanoparticles, which are majorly attributed to its physical structure properties through HRTEM, XRD, UV–Vis, BET and BJH characteristics. An appropriate amount of Fe–Cu dopant does not change the crystal structure of TiO2 nanoparticles, but improves the dispersion, reduces the grain size, increases the surface area and improves the light utilization. 10% Fe2–Cu1 codoped TiO2 nanoparticles were dispersed into HFE-458 (HCF2CF2CH2OCF2CF2H), and the disinfection efficiency of 2-chloroethyl ethyl sulfide (HD simulation, 2-CEES), dimethyl methanephosphonate (GD simulation, DMMP) and malathion (VX simulation) were studied under the simulated sunlight irradiation. After reacting for 60 min, the degradation efficiency of 2-CEES, DMMP and malathion is 99.73%, 99.20% and 94.27%, respectively.

Similar content being viewed by others

References

S. Chauhan, S. Chauhan, R. D’Cruz, S. Faruqi, K.K. Singh, S. Varma, M. Singh, V. Karthik, Environ. Toxicol. Pharmacol. 26, 113–122 (2008)

C. Solazzo, D. Erhardt, F. Marte, D. Von Endt, C. Tumosa, Appl. Phys. A 79, 247–252 (2004)

K. Kim, O.G. Tsay, D.A. Atwood, D.G. Churchill, Chem. Rev. 111, 5345–5403 (2011)

S.-W. Zhang, T.M. Swager, J. Am. Chem. Soc. 125, 3420–3421 (2003)

Y.-C. Yang, J.A. Baker, J.R. Ward, Chem. Rev. 92, 1729–1743 (1992)

A.B. Kanu, P.E. Haigh, H.H. Hill, Anal. Chim. Acta 553, 148–159 (2005)

F. Wang, H.W. Gu, T.M. Swager, J. Am. Chem. Soc. 130, 5392–5393 (2008)

B.-S. Joo, J.-S. Huh, D.-D. Lee, Sens. Actuator. B 121, 47–53 (2007)

B.M. Smith, Chem. Soc. Rev. 37, 470–478 (2008)

B. Singh, G.K. Prasad, K.S. Pandey, R.K. Danikhel, R. Vijayaraghavan, Def. Sci. J. 60, 428–441 (2010)

D.A. Panayotov, J.R. Morris, Langmuir 25, 3652–3658 (2009)

L.Y. Xiang, J. Ya, F.J. Hu, L.X. Li, Z.F. Liu, Appl. Phys. A 123, 160 (2017)

M. Radecka, M. Rekas, A. Trenczek-Zajac, K. Zakrzewska, J. Power Sources 181, 46–55 (2008)

L. Gu, J.Y. Wang, R. Qi, X.Y. Wang, P. Xu, X.J. Han, J. Mol. Catal. A: Chem. 357, 19–25 (2012)

V. Stengl, S. Bakardjieva, J. Phys. Chem. C 114, 19308–19317 (2010)

V. Stengl, T.M. Grygar, F. Oplustil, T. Nemec, J. Hazard. Mater. 192, 1491–1504 (2011)

V. Stengl, J. Bludska, F. Oplustil, T. Nemec, Mater. Res. Bull. 46, 2050–2056 (2011)

V. Stengl, F. Oplustil, T. Nemec, Photochem. Photobiol. 88, 265–276 (2012)

Z. Shen, J.Y. Zhong, L.K. Chen, H. Zhen, Q. Min, Y. Cui, Y.Z. Zhao, J. Inorg. Mater. 31, 427–433 (2016)

Z. Shen, J.Y. Zhong, H. Zheng, Enciron. Sci. Technol. 38, 14–20 (2015)

S. Zhong, J.-Y. Zhong, X.-Y. Han, L.-Y. Wang, Y. Cui, L.-K. Chen, Y.-C. Zheng, Chem. Eng. J. 302, 111–119 (2016)

Z. Shen, J.-Y. Zhong, N.-N. Chai, X. He, H. Zang, X.-Y. Xu, P. Han, J.-Z. Zhang, Chem. Phys. Lett. 678, 146–152 (2017)

H.F. Fei, Y.L. An, J.K. Feng, L.J. Ci, S.L. Xiong, RSC Adv. 6, 53560–53565 (2016)

K. Thamaphat, P. Limsuwan, B. Ngotawornchai, Nat. Sci. 42, 357–361 (2008)

J.G. Yu, J.X. Low, W. Xiao, P. Zhou, M. Jaroniec, J. Am. Chem. Soc. 136, 8839–8842 (2014)

M. Ksibi, S. Rossignol, J.-M. Tatibouët, C. Trapalis, Mater. Lett. 62, 4204–4206 (2008)

W.J. Foo, C. Zhang, G.W. Ho, Nanoscale 5, 759–764 (2013)

G. Schimanke, M. Martin, Solid State Ionics 136–137, 1235–1240 (2000)

R. López, R. Gómez, M.E. Llanos, Cata. Today 148, 103–108 (2009)

D. Li, H.S. Zhou, I. Honma, Nature 3, 65–72 (2004)

A.L. Linsebigler, G.Q. Lu, J.T. Yates, J. Chem. Rev. 95, 735–758 (1995)

R.M. Rioux, H. Song, J.D. Hoefelmeyer, P. Yang, G.A. Somorjai, J. Phys. Chem. B 109, 2192–2202 (2005)

R. Kaiser, A. Kulczyk, D. Rich, R.J. Willey, J. Minicucci, B. MacIver, Ind. Eng. Chem. Res. 46, 6126–6132 (2007)

J.S. Lee, K.H. You, C.B. Park, H. Photoactive, Adv. Mater. 24, 1084–1088 (2012)

Acknowledgements

This work was supported by the Scientific Rearch Fund of the Chinese Academy of Inspection and Quarantine (2017JK007).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ci, Y., Wang, S., Zhang, X. et al. Chemical warfare agents’ degradation on Fe–Cu codoped TiO2 nanoparticles. Appl. Phys. A 124, 786 (2018). https://doi.org/10.1007/s00339-018-2209-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-018-2209-x