Abstract

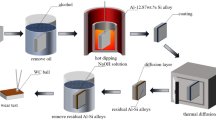

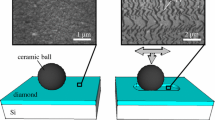

In this work, a modified reaction device was used to deposit metallised Ti films on Al2O3 substrate through the chemical vapour deposition method under different temperatures. Then, the mechanical characteristics of the films were investigated through scratch to determine the plastic behaviours and wear tests to determine the wear mechanism of the thin films. The scratch morphology, wear tracks and wear debris of the films were subjected to microstructural characterisation using a scanning electron microscope equipped with an energy-dispersive spectrometer. Results showed that the scratch and wear resistance of the films are systematically correlated with the plasticity and toughness of the films. The combined film mechanical parameters, such as H3/E2 and 1/HE2, obtained through the nanoindentation test correspond well with the highly loaded sliding contact behaviours of the films and can be used to describe the deformation mechanisms of the films. Furthermore, the film deposited at 1050 °C has potential applications in ceramic pre-treatments given its combined properties of plasticity and toughness. This combination confers durability to the film by providing an effective energy dissipation mechanism.

Similar content being viewed by others

References

D.P. Yadav, R. Kaul, P. Ganesh, R. Shiroman, R. Sridhar, L.M. Kukreja, Study on vacuum brazing of high purity alumina for application in proton synchrotron. Mater. Des. 64, 415–422 (2014)

S. Bose, S.F. Robertson, A. Bandyopadhyay, Surface modification of biomaterials and biomedical devices using additive manufacturing. Acta Biomater. 66, 6–22 (2017)

W. Zhang, M. Wei, W.S.P. Carvalho, M.J. Serpe, Enzyme-assisted polymer film degradation-enabled biomolecule sensing with poly (N-isopropylacrylamide)-based optical devices. Anal. Chim. Acta 999, 139–143 (2017)

V. Jinga, A.O. Mateescu, D. Cristea, G. Mateescu, I. Burducea, C. Ionescu, L.S. Crăciun, I. Ghiuţă, C. Samoilă, D. Ursuţiu, D. Munteanu, Compositional, morphological and mechanical investigations of monolayer type coatings obtained by standard and reactive magnetron sputtering from Ti, TiB2 and WC. Appl. Surf. Sci. 358, 579–585 (2015)

X. Quan, S. Zhang, M. Hu, X. Gao, D. Jiang, J. Sun, Tribological properties of WS2/MoS2–Ag composite films lubricated with ionic liquids under vacuum conditions. Tribol. Int. 115, 389–396 (2017)

P. Zhang, R. Fu, Y. Tang, B. Cao, M. Fei, Y. Yang, Morphology of thick film metallization on aluminum nitride ceramics and composition of interface layer. Ceram. Int. 41, 13381–13388 (2015)

T. Konishi, K. Yamaguchi, Surface control of a photoresponsive self-assembled monolayer and selective deposition of Ag nanoparticulate ink. Bull. Chem. Soc. Jpn 89, 424–429 (2016)

S.V. Komarov, S.E. Romankov, Mechanical metallization of alumina substrate through shot impact treatment. J. Eur. Ceram. Soc. 34, 391–399 (2014)

K. Ariga, Y. Yamauchi, T. Mori, J.P. Hill, 25th anniversary article: what can be done with the Langmuir–Blodgett method? Recent developments and its critical role in materials science. Adv. Mater. 25, 6477–6512 (2013)

G. Rydzek, Q. Ji, M. Li, P. Schaaf, J.P. Hill, F. Boulmedais, K. Ariga, Electrochemical nanoarchitectonics and layer-by-layer assembly: from basics to future. Nano Today 10, 138–167 (2015)

J. Li, W. Pan, Z. Yuan, Y. Chen, Titanium metallization of alumina ceramics by molten salt reaction. Appl. Surf. Sci. 254, 4584–4590 (2008)

C. Xin, W. Liu, N. Li, J. Yan, S. Shi, Metallization of Al2O3 ceramic by magnetron sputtering Ti/Mo bilayer thin films for robust brazing to Kovar alloy. Ceram. Int. 42, 9599–9604 (2016)

C. Xin, J. Yan, N. Li, W. Liu, J. Du, Y. Cao, H. Shi, Microstructural evolution during the brazing of Al2O3 ceramic to kovar alloy by sputtering Ti/Mo films on the ceramic surface. Ceram. Int. 42, 12586–12593 (2016)

J.-W. Park, P.F. Mendez, T.W. Eagar, Strain energy release in ceramic-to-metal joints by ductile metal interlayers. Scr. Mater. 53, 857–861 (2005)

Y. Wang, Z.W. Yang, L.X. Zhang, D.P. Wang, J.C. Feng, Low-temperature diffusion brazing of actively metallized Al2O3 ceramic tube and 5A05 aluminum alloy. Mater. Des. 86, 328–337 (2015)

Z.W. Yang, L.X. Zhang, Y.C. Chen, J.L. Qi, P. He, J.C. Feng, Interlayer design to control interfacial microstructure and improve mechanical properties of active brazed Invar/SiO2–BN joint. Mater. Sci. Eng. A. 575, 199–205 (2013)

J.J. Stephens, F.M. Hosking, T.J. Headley, P.F. Hlava, F.G. Yost, Reaction layers and mechanisms for a Ti-activated braze on sapphire. Metall. Mater. Trans. A 34, 2963–2972 (2003)

O. Kozlova, M. Braccini, R. Voytovych, N. Eustathopoulos, P. Martinetti, M.F. Devismes, Brazing copper to alumina using reactive CuAgTi alloys. Acta Mater. 58, 1252–1260 (2010)

R. Voytovych, F. Robaut, N. Eustathopoulos, The relation between wetting and interfacial chemistry in the CuAgTi/alumina system. Acta Mater. 54, 2205–2214 (2006)

J. Li, X. Li, L. Wang, Y.-H. Mei, G.-Q. Lu, A novel multiscale silver paste for die bonding on bare copper by low-temperature pressure-free sintering in air. Mater. Des. 140, 64–72 (2018)

J. Zhang, Y. Huang, Y. Liu, Z. Wang, Direct diffusion bonding of immiscible tungsten and copper at temperature close to copper’s melting point. Mater. Des. 137, 473–480 (2018)

K. Holmberg, H. Ronkainen, A. Laukkanen, K. Wallin, Friction and wear of coated surfaces—scales, modelling and simulation of tribomechanisms. Surf. Coat. Technol. 202, 1034–1049 (2007)

N. Schwarzer, Q.H. Duong, N. Bierwisch, G. Favaro, M. Fuchs, P. Kempe, B. Widrig, J. Ramm, Optimization of the Scratch Test for specific coating designs. Surf. Coat. Technol. 206, 1327–1335 (2011)

K. Sato, N. Ichimiya, A. Kondo, Y. Tanaka, Microstructure and mechanical properties of cathodic arc ion-plated (Al,Ti) N coatings. Surf. Coat. Technol. 163–164, 135–143 (2003)

B.D. Beake, V.M. Vishnyakov, A.J. Harris, Relationship between mechanical properties of thin nitride-based films and their behaviour in nano-scratch tests. Tribol. Int. 44, 468–475 (2011)

V. Jardret, B.N. Lucas, W. Oliver, A.C. Ramamurthy, Scratch durability of automotive clear coatings: a quantitative, reliable and robust methodology. J. Coat. Technol. 72, 79–88 (2000)

A. Leyland, A. Matthews, On the significance of the H/E ratio in wear control: a nanocomposite coating approach to optimised tribological behaviour. Wear 246, 1–11 (2000)

G.S. Fox-Rabinovich, S.C. Veldhuis, V.N. Scvortsov, L.S. Shuster, G.K. Dosbaeva, M.S. Migranov, Elastic and plastic work of indentation as a characteristic of wear behavior for cutting tools with nitride PVD coatings. Thin Solid Films 469–470, 505–512 (2004)

B.D. Beake, V.M. Vishnyakov, A.J. Harris, Nano-scratch testing of (Ti, Fe) Nx thin films on silicon. Surf. Coat. Technol. 309, 671–679 (2017)

X. Xing, H. Wang, G. Xiao, S. Yang, X. Shu, Assessment of titanium metallization thin film deposited on alumina substrate: microstructure and nano-indentation. J. Mech. Behav. Biomed. Mater. 80, 235–245 (2018)

X. Chen, H. Wang, Y. Liu, M. Fang, Thermodynamic analysis of production of high purity titanium by thermal decomposition of titanium iodide. Trans. Nonferrous Metal Soc. China 19, 1348–1352 (2009)

B. Liang, W. Li, Y. Zeng, Z. Wang, Thermodynamical and kinetical analysis of crystal nucleation process and deposition rate of high-purity titanium prepared via CVD. Vacuum 48, 46–50 (2011)

D.L. Ye, J.H. Hu, Practical Handbook of Thermodynamic Data on Inorganic Substances (Metallurgical Industry Press, Beijing, 2002)

J.L. Murray, Phase Diagrams of Binary Titanium Alloys (ASM International, Ohio, 1987)

L.B. Freund, S. Suresh, Thin Film Materials: Stress, Defect Formation, and Surface Evolution, (Cambridge University Press, Cambridge, 2004)

P.A. Steinmann, Y. Tardy, H.E. Hintermann, Adhesion testing by the scratch test method: the influence of intrinsic and extrinsic parameters on the critical load. Thin Solid Films 154, 333–349 (1987)

M. Callisti, T. Polcar, The role of Ni–Ti–(Cu) interlayers on the mechanical properties and nano-scratch behaviour of solid lubricant W–S–C coatings. Surf. Coat. Technol. 254, 260–269 (2014)

J.B. Singh, J.G. Wen, P. Bellon, Nanoscale characterization of the transfer layer formed during dry sliding of Cu–15 wt% Ni–8 wt% Sn bronze alloy. Acta Mater. 56, 3053–3064 (2008)

X. Yang, C.R. Hutchinson, Corrosion-wear of beta-Ti alloy TMZF (Ti–12Mo–6Zr–2Fe) in simulated body fluid. Acta Biomater. 42, 429–439 (2016)

B. Briscoe, Tribology—friction and wear of engineering materials: I.M. Hutchings. Tribol. Int. 25, 357–357 (1992)

M.S. Kabir, P. Munroe, Z. Zhou, Z. Xie, Scratch adhesion and tribological behaviour of graded Cr/CrN/CrTiN coatings synthesized by closed-field unbalanced magnetron sputtering. Wear 380–381, 163–175 (2017)

J.C. Weaver, Q. Wang, A. Miserez, A. Tantuccio, R. Stromberg, K.N. Bozhilov, P. Maxwell, R. Nay, S.T. Heier, E. DiMasi, D. Kisailus, Analysis of an ultra hard magnetic biomineral in chiton radular teeth. Mater. Today 13, 42–52 (2010)

B.D. Beake, V.M. Vishnyakov, R. Valizadeh, J.S. Colligon, Influence of mechanical properties on the nanoscratch behaviour of hard nanocomposite TiN/Si3N4 coatings on Si. J. Phys. D Appl. Phys. 39, 1392 (2006)

T.Y. Tsui, G.M. Pharr, Substrate effects on nanoindentation mechanical property measurement of soft films on hard substrates. J. Mater. Res. 14, 292–301 (2012)

G.M. Pharr, Measurement of mechanical properties by ultra-low load indentation. Mater. Sci. Eng. A. 253, 151–159 (1998)

Acknowledgements

The authors would like to thank the National Natural Science Foundation of China (Grant nos. 11772217, 11702182), the Natural Science Foundation for Young Scientists of Shanxi Province, China (Grant no. 201601D202004), the School Foundation of Taiyuan University of Technology (no. 2016QN68).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xing, X., Wang, H., Jin, T. et al. Scratch and wear behaviours of metallised Ti thin films deposited on Al2O3 substrate. Appl. Phys. A 124, 718 (2018). https://doi.org/10.1007/s00339-018-2137-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-018-2137-9