Abstract

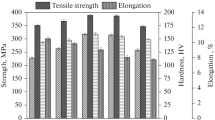

Evolutions of microstructure and mechanical property of Al-3.0 wt%Mg alloy in the cold-drawing process were investigated by 2D-XRD, SEM observation and tensile test. The relationship between microstructure and mechanical property was studied. The result indicated that the equiaxed grains of the alloys were elongated and the skeletal second phase particles were fragmented during the cold-drawing process. Meanwhile, the grain and dendrite boundaries aligned along the drawing direction with a lamellar structure. The texture changed as 〈101〉 + 〈001〉 + 〈111〉 → 〈 001〉 + 〈111〉→ 〈111〉 and S{123} 〈634〉 + Brass{001} 〈211〉→ Copper{112} 〈111〉 + Goss {011} 〈110〉 + Brass{001} 〈211〉 → Copper{112} 〈111〉. With the increase of strain, the strength of the alloys increased linearly, while the plasticity exhibited the three-stage characteristic decreasing. The strength of the cold-drawn alloy increased and the plasticity decreased as the texture intensity increasing and the grain/second phase size decreasing. When the deformation was low (below 51% in this paper), the mechanical property changing was mainly affected by the dislocation motion. When deformation was high (exceed 51% in this paper), the texture intensity, grain size and second phase size became the key factors to the variety of mechanical property.

Similar content being viewed by others

References

Z.G. Wu, M. Song, Y.H. He. Mater. Sci. Eng. A. 504, 183–187 (2009)

H.H. Chen, J.Y. Wang, J. Lee, S. Lee. J. Alloy. Compd. 460, 305–308 (2008)

J.Y. Zhang, M.Y. Ma, F.H. Shen, D.Q. Yi, B. Wang. Mater. Sci. Eng. A. 710, 27–37 (2018)

K.R. Narayanan, S.S. Subbiah, Appl. Phys. A-Mater. 107, 485–495 (2012)

J. Chen, W. Yan, B. Li, X.G. Ma, X.Z. Du, X.H. Fan. Sci. China Technol. Sci. 54, 1551–1559 (2011)

J. Chen, W. Yan, J. Miao, C.X. Liu, X.H. Fan, Metall. Mat. Trans. A. 54, 1551–1559 (2011)

H.S. Joo, Y.N. Kim, S.K. Kwang, Y.T. Im. Procedia Eng. 207, 1129–1134 (2017)

T.S. Cao, C. Vachey, P. Montmitinnet, P.O. Bouchard. J. Mater. Process. Tech. 217, 30–47 (2015)

N.A. Raji, O.O. Oluwole, Res. J. Appl. Sci. Eng. Tech. 5, 118–122 (2013)

C.S. Cetinarslan, Indian J. Eng. Mater. S. 19, 221–228 (2012)

H.J. Shin, H.T. Jeong, D.N. Lee, Mater. Sci. Eng. A. 279, 244–253 (2000)

P. Kustra, A. Milenin, D. Byrska-Wójcik, O. Grydin, M. Schaper. J. Mater. Process. Tech. 247, 234–242 (2017)

L.X. Sun, J. Bai, F. Xue, L. Tao, C.L. Chu, J. Meng. Mater. Design. 135, 267–274 (2017)

X. Zhang, Z.H. Wang, Z.H. Zhou, J.M. Xu, J. Alloy. Compd. 698, 241–249 (2017)

X. Zhang, Z.H. Wang, Z.H. Zhou, J.M. Xu, J. Mater. Eng. Perform. 25, 1122–1128 (2016)

X. Zhang, Z.H. Wang, Z.H. Zhou, J.M. Xu, Z.J. Zhong, H.L. Yuan, Rare Metals. 36, 627–634 (2017)

X. Zhang, Z.H. Wang, Z.H. Zhou, J.M. Xu, J. Wuhan Univ. Technol. 32, 611–618 (2017)

T.A. Parthasarathy, S.I. Rao, D.M. Dimiduk, M.D. Uchic, D.R. Trinkle, Scripta Mater. 56, 313–316 (2007)

J.P. Hou, Q. Wang, H.J. Yang, Mater. Sci. Eng. A. 639, 103–106 (2015)

I.J. Beyerleina, L.S. Tóth, Prog. Matet. Sci. 54, 427–510 (2009)

Q. Zeng, X. Wen, T. Zhai, Metall. Mat. Trans. A. 40, 2488–2497 (2009)

Q. Liu, Z.Y. Yao, A. Godfrey, W. Liu. J. Alloy Compd 482, 264–271 (2009)

Q. Wang, X.M. Wu, C.H. Li, J.L. Liu, F. Zhang, Y.H. Sha, Chin. J. Mater. Res. 27, 231–236 (2013)

Acknowledgements

This study was financially supported by “the Fundamental Research Funds for the Central Universities (2018B02514).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, X., Wang, Z., Zhou, Z. et al. Microstructure and mechanical property evolutions in Al-3.0 wt%Mg alloy wire drawing. Appl. Phys. A 124, 690 (2018). https://doi.org/10.1007/s00339-018-2113-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-018-2113-4