Abstract

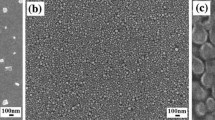

p-type and n-type thermoelectric micropatterns were selectively fabricated via the reduction and reoxidation of CuO/NiO mixed nanoparticles using femtosecond laser pulses. The micropatterns were formed by raster scanning focused femtosecond laser pulses on a solution film containing CuO and NiO nanoparticles, ethylene glycol, and polyvinylpyrrolidone, followed by the removal of the non-irradiated nanoparticles. Cu–Ni was generated by reductive sintering of the CuO/NiO mixed nanoparticles at laser scanning speeds ranging from 5 to 20 mm/s and a laser fluence of 0.055 J/cm2. In contrast, intense peaks corresponding to Cu2O and NiO were observed in the X-ray diffraction spectrum of the micropattern formed at a scanning speed of 1 mm/s, indicating that Cu2O and NiO were generated via the reoxidation of the reduced metals. The Seebeck coefficients of the micropatterns formed at a fluence of 0.055 J/cm2 and scanning speeds of 5–20 mm/s were between − 32 and − 16 µV/K, whereas that of the micropattern formed at a fluence of 0.055 J/cm2 and scanning speed of 1 mm/s was ~ 250 µV/K. These results suggest that the Seebeck coefficient depends on the generated n-type Cu–Ni and p-type Cu2O and NiO phases. A thermoelectric couple was fabricated by selectively fabricating p-type and n-type thermoelectric elements. The thermoelectric couple exhibited a thermoelectric voltage of 0.25 mV/K when a temperature gradient was applied between its hot and cold sides. The generated voltage was nearly consistent with the estimated voltage based on the Seebeck coefficient. The developed process for selective fabrication is expected to be useful for the direct writing of thermoelectric-type sensors.

Similar content being viewed by others

References

S.H. Ko, H. Pan, C.P. Grigoropoulos, C.K. Luscombe, J.M.J. Frechet, D. Poulikakos, Nanotechnology 18, 345202 (2007)

W. Cui, W. Lu, Y. Zhang, G. Lin, T. Wei, L. Jang, Colloids Surf A Physicochem. Eng. Aspects 358, 35 (2010)

C.-L. Lee, K.-C. Chang, C.-M. Syu, Colloids Surfaces A Physicochem. Eng. Aspects 381, 85 (2011)

K.-S. Moon, H. Dong, R. Maric, S. Pothukuchi, A. Hunt, Y. Li, C.P. Wong, J. Electron. Mater. 34, 168 (2005)

S. Sivaramakrishnan, P.-J. Chia, Y.-C. Yeo, L.-L. Chua, P.K.-H. Ho, Nat. Mater. 6, 149 (2007)

Y. Lee, J.-R. Choi, K.J. Lee, N.E. Stott, D. Kim, Nanotechnology 19, 415604 (2008)

H.-S. Kim, S.R. Dhage, D.-E. Shim, H.T. Hahn, Appl. Phys. A 97, 791 (2009)

J. Ryu, H.-S. Kim, H.T. Hahn, J. Electron. Mater. 40, 42 (2011)

B. Kang, S. Han, J. Kim, S. Ko, M. Yang, J. Phys. Chem. C 115, 23664 (2011)

D. Lee, D. Paeng, H.K. Park, C.P. Grigoropoulos, ACS Nano 8, 9807 (2014)

D. Paeng, D. Lee, J. Yeo, J.-H. Yoo, F.I. Allen, E. Kim, H. So, H.K. Park, A.M. Minor, C.P. Grigoropoulos, J. Phys. Chem. C 119, 6363 (2015)

M. Mizoshiri, S. Arakane, J. Sakurai, S. Hata, Appl. Phys. Express 9, 036701 (2016)

M. Mizoshiri, Y. Ito, S. Arakane, J. Sakurai, S. Hata, Jpn. J. Appl. Phys. 55, 06GP05 (2016)

K. Tamura, M. Mizoshiri, J. Sakurai, S. Hata, Jpn. J. Appl. Phys. 56, 06GN08 (2017)

D. Moser, H. Baltes, Sens. Actuators A 37, 33 (1993)

F. Zhang, Y. Zang, D. Huang, C.-an. Di, D. Zhu, Nat. Commun. 6, 8356 (2015)

L. Yang, Y. Zhao, C. Feng, H. Zhou, Phys. Proc 22, 95 (2011)

S. Nandy, A.N. Banerjee, E. Fortunato, R. Martins, Rev. Adv. Sci. Eng. 2, 273 (2013)

X. Chen, D. Parker, M.-H. Du, D.J. Singh, New. J. Phys. 15, 043029 (2013)

C.M. McShane, K.-S. Choi, J. Am. Chem. Soc. 131, 2561 (2009)

W. Shin, N. Murayama, K. Ikeda, S. Sago, Jpn. J. Appl. Phys. 39, 1254 (2000)

M. Tyagi, M. Tomar, V. Gupta, J. Mater. Res. 28, 723 (2013)

Acknowledgements

This study was partially supported by the Nanotechnology Platform Program (Micro-Nano Fabrication) of the Ministry of Education, Culture, Sports, Science and Technology, Japan (MEXT), the 10th “Shiseido Female Researcher Science Grant”, and JSPS KAKENHI Grant number JP16H06064.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mizoshiri, M., Hata, S. Selective fabrication of p-type and n-type thermoelectric micropatterns by the reduction of CuO/NiO mixed nanoparticles using femtosecond laser pulses. Appl. Phys. A 124, 64 (2018). https://doi.org/10.1007/s00339-017-1489-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-017-1489-x