Abstract

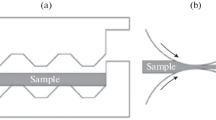

1050 commercial purity aluminum was subjected to severe plastic deformation through constrained groove pressing (CGP) at room temperature. Transmission electron microscope observations showed that after four CGP passes the majority of microstructure is composed of elongated grains/subgrains whose width/length average sizes are 506/1440 nm. This ultrafine-grained microstructure leads to a significant increase in yield strength of starting material from 93 to 182 MPa. At the same time, after four passes of CGP the material still displays a considerable ductility of 19%. Microhardness profiles reveal that average microhardness value in sample increases monotonically with increased straining during CGP. However, the degree of deformation homogeneity in samples remains almost unchanged at higher number passes. The latter was also confirmed by non-uniform distribution of imposed plastic strain in samples predicted by finite-element analysis.

Similar content being viewed by others

References

R.Z. Valiev, R.K. Islamgaliev, I.V. Alexandrov, Prog. Mater Sci. 45, 103 (2000)

Y. Saito, H. Utsunomiya, N. Tsuji, T. Sakai, Acta Mater. 47, 579 (1999)

Y.H. Ji, J.J. Park, Mater. Sci. Eng. A 499, 14 (2009)

D.H. Shin, J.J. Park, Y.S. Kim, K.T. Park, Mater. Sci. Eng. A 328, 98 (2002)

S.A.A. Akbari Mousavi, S.M. Ebrahimi, R. Madoliat, J. Mater. Process. Technol. 187–188, 725 (2007)

M.S. Ghazani, A. Vajd, Model. Simul. Mater. Sci. Eng. 4, 32 (2014)

J. Zrnik, T. Kovarik, Z. Novy, M. Cieslar, Mater. Sci. Eng. A 503, 126 (2009)

S.S. Satheesh Kumar, T. Raghu, Mater. Des. 57, 114 (2014)

S. Morattab, K. Ranjbar, M. Reihanian, Mater. Sci. Eng. A 528, 6912 (2011)

A. Krishnaiah, U. Chakkingal, P. Venugopal, Scr. Mater. 52, 1229 (2005)

A. Shirdel, A. Khajeh, M.M. Moshksar, Mater. Des. 31, 946 (2010)

E. Hosseini, M. Kazeminezhad, Mater. Sci. Eng. A 526, 219 (2009)

M. Borhani, F. Djavanroodi, Mater. Sci. Eng. A 546, 1 (2012)

A. Sajadi, M. Ebrahimi, F. Djavanroodi, Mater. Sci. Eng. A 552, 97 (2012)

J.W. Lee, J.J. Park, J. Mater. Process. Technol. 130–131, 208 (2002)

S.C. Yoon, A. Krishnaiah, U. Chakkingal, H.S. Kim, Comput. Mater. Sci. 43, 641 (2008)

S.S. Satheesh Kumar, I. Balasundar, T. Raghu, Int. J. Comput. Mater. Sci. Eng. 2, 1 (2013)

Y.T. Zhu, J.Y. Huang, J. Gubicza, T. Ungar, Y.M. Wang, E. Ma, R.Z. Valiev, J. Mater. Res. 18, 1908 (2003)

B. Bay, N. Hansen, D.A. Hughes, D. Kuhlmann-Wilsdorf, Acta Metall. Mater. 40, 205 (1992)

R.Z. Valiev, T.G. Langdon, Prog. Mater Sci. 51, 881 (2006)

R. Pippan, S. Scheriau, A. Taylor, M. Hafok, A. Hohenwarter, A. Bachmaier, Annu. Rev. Mater. Res. 40, 319 (2010)

X. Sauvage, G. Wilde, S.V. Divinski, Z. Horita, R.Z. Valiev, Mater. Sci. Eng. A 540, 1 (2012)

M. Kawasaki, Z. Horita, T.G. Langdon, Mater. Sci. Eng. A 524, 143 (2009)

P.L. Sun, P.W. Kao, C.P. Chang, Metall. Mater. Trans. A 35A, 1359 (2004)

K. Peng, Y. Zhang, L.L. Shaw, K.W. Qian, Acta Mater. 57, 5543 (2009)

G.E. Dieter, Mechanical Metallurgy (McGraw Hill, Singapore, 1998)

D. Jia, Y.M. Wang, T. Ramesh, E. Ma, Y.T. Zhu, R.Z. Valiev, Appl. Phys. Lett. 79, 611 (2001)

Y.M. Wang, E. Ma, Acta Mater. 52, 1699 (2004)

R.Z. Valiev, J. Mater. Sci. 42, 1483 (2007)

J. May, H.W. Hoppel, M. Goken, Scr. Mater. 53, 189 (2005)

K. Hajizadeh, B. Eghbali, K. Topolski, K.J. Kurzydlowski, Mater. Chem. Phys. 143, 1032 (2014)

R.Z. Valiev, I.V. Alexandrov, T.C. Lowe, Y.T. Zhu, J. Mater. Res. 17, 5 (2002)

X.Z. Liao, Y.H. Zhao, Y.T. Zhu, R.Z. Valiev, D.V. Gunderov, J. Appl. Phys. 96, 636 (2004)

Acknowledgements

The authors would like to thank Prof. K. J. Kurzydlowski for providing the opportunity to perform TEM observations in Warsaw University of Technology.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hajizadeh, K., Ejtemaei, S. & Eghbali, B. Microstructure, hardness homogeneity, and tensile properties of 1050 aluminum processed by constrained groove pressing. Appl. Phys. A 123, 504 (2017). https://doi.org/10.1007/s00339-017-1123-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-017-1123-y