Abstract

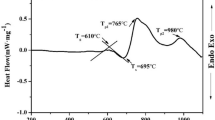

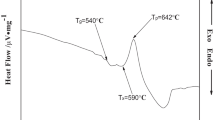

The high crystallinity transparent glass ceramics based on Nd3+-doped 70TeO2–15Bi2O3–15ZnO (TBZ) compositions were successfully prepared by two-step heat treatment process. The effects of Nd2O3 content on the thermal, structural, mechanical, and optical properties of TBZ glass ceramics were studied. The incorporation of Nd2O3 enhanced the crystallization tendency in the matrix glass composition. The crystal phase and morphology of Bi2Te4O11 in the glass ceramics were confirmed by X-ray diffraction and field emission scanning electron microscopy. Due to precipitate more crystal phase, the hardness values increased from 3.21 to 3.66 GPa. Eight absorption peaks were observed from 400 to 900 nm and three emission bands appeared in the range of 850–1400 nm. With the increasing of Nd2O3 content from 0.5 to 2.5 wt%, the intensity of absorption peaks enhanced and the emission intensity increased up to 1.0 wt% and then fell down for further dopant concentration. The fluorescence decay lifetime decreased rapidly starting from 1.5 wt% Nd2O3 content due to the obvious energy migration among Nd3+. According to the extreme strong emission band around 1062 nm and the optimum Nd2O3 content (1.0 wt%), N10 glass ceramic was considered as a potential material for 1.06 μm laser applications.

Similar content being viewed by others

References

R. Molla, A. Tarafder, B. Karmakar, J. Alloy. Compd. 680, 237 (2016)

D.F.D. Sousa, L.A.O. Nunes, J.H. Rohling et al., Appl. Phys B 77, 59 (2003)

K.F. Li, S.J. Fan, L. Zhang et al., J. Non Cryst. Solids 357, 2417 (2011)

A.N. Moiseev, V.V. Dorofeev, A.V. Chilyasov et al., Opt. Mater 33, 1858 (2011)

A. Chagraoui, A. Chakib, A. Mandil, et al., Scripta. Mater. 56, 93 (2007)

S.B. Lin, P.F. Wang, J.B. She et al., J. Lumin. 153, 29 (2014)

S.K. Singh, N.K. Giri, D.K. Rai, et al., Solid State Sci., 12, 1480 (2010)

X. Hu, G. Guery, J. Boerstler et al., J. Non Cryst. Solids 358, 952 (2012)

H.P. Ma, P. Liu, Q.H. Yang et al., Mater. Lett. 116, 13 (2014)

Q. Yang, W.H.Zhang Wang, et al., J. Lumin. 158, 390 (2015)

Z.X. Hou, Z.L. Xue, S.H. Wang, J. Alloy. Compd. 514, 109 (2012)

Z.J. Xing, S. Gao, X.Q. Liu et al., J. Alloy. Compd. 660, 375 (2016)

X. Hu, G. Guery, J.D. Musgraves et al., J. Non Cryst. Solids 357, 3648 (2011)

M.A.P. Silva, Y. Messaddeq, V. Briois et al., J. Phys. Chem. Solids 63, 605 (2002)

A. Miguel, R. Morea, M.A. Arriandiaga et al., J. Eur. Ceram. Soc 34, 3959 (2014)

K. Hirano, Y. Benino, T. Komatsu, J. Phys. Chem. Solids 62, 2075 (2001)

Y.L. Yu, D.Q. Chen, Y. Cheng et al., J. Eur. Ceram. Soc. 26, 2761 (2006)

M.R. Dousti, R.J. Amjad, M.R. Sahar et al., J. Non Cryst. Solids 429, 70 (2015)

P. Chimalawong, J. Kaewkhao, T. Kittiauchawal et al., Am. J. Appl. Sci. 7, 584 (2010)

J. Ozdanova, H. Ticha, L. Tichy, J. Non Cryst. Solids 353, 2799 (2007)

N. Jaba, A. Mermet, E. Duval et al., J. Non Cryst. Solids 351, 833 (2005)

G.N. Wang, J.J. Zhang, S.X. Dai et al., J. Mol. Struct. 750, 1 (2005)

I. Jlassi, H. Elhouichet, S. Hraiech et al., J. Lumin. 132, 832 (2012)

A.X. Lin, A. Ryasnyanskiy, J. Toulouse, Opt. Lett. 65, 664 (2011)

M. Udovic, P. Thomas, A. Mirgorodsky et al., J. Solid State Chem. 179, 3252 (2006)

W.T. Carnall, P.R. Fields, K. Rajnak, J. Chem. Phys. 49, 4424 (1968)

G.H. Beall, D.A. Duke, J. Mater. Sci. 4, 340 (1969)

G.D. Hu, S.H. Fan, X. Cheng, J. Appl. Phys. 101, 054111 (2007)

A.R. Molla, A. Tarafder, S. Mukherjee, et al, Opt. Mater. Express. 4, 843 (2014)

A. Tarafder, K. Annapurna, R.S. Chaliha et al., J. Alloy Compd. 489, 281 (2010)

A.D. Sontakke, K. Annapurna, Mater. Chem. Phys. 137, 916 (2013)

A.D. Sontakke, K. Biswas, A.K. Mandal, K. Annapurna, Appl. Phys. B 101, 235 (2011)

H. Ebendorff-Heidepriem, W. Seeber, D. Ehrt, J. Non Cryst. Solids 183, 191 (1995)

Acknowledgements

The research has been partially supported by the National Natural Science Foundation of China (No. 51172286).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hu, X., Luo, Z., Liu, T. et al. Nd3+-doped TeO2–Bi2O3–ZnO transparent glass ceramics for laser application at 1.06 μm. Appl. Phys. A 123, 258 (2017). https://doi.org/10.1007/s00339-017-0861-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-017-0861-1