Abstract

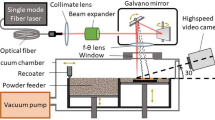

As an additive manufacturing technology, the selective laser melting (SLM) process is useful to directly form complicated shapes. The SLM process in a vacuum has been used to fabricate three-dimensional Ti6Al4V (Ti64) plates because this method can control the phase transformation. To investigate the laser melting and solidification dynamics, the formation of a Ti64 plate by SLM in a vacuum was captured by a high-speed video camera. Due to the effects of temperature and scanning speed on the phase transformation, the crystal orientation was evaluated with X-ray diffraction. A phase transformation of the crystal orientation occurred as the baseplate temperature was heated up from 50 to 150 °C.

Similar content being viewed by others

References

E.C. Santos, M. Shiomi, K. Osakada, T. Laoui, Rapid manufacturing of metal components by laser forming. Int. J. Mach. Tools Manuf 46, 1459–1468 (2006)

B. Zhang, N.E. Feinech, H.L. Liao, C. Coddet, Microstructure and magnetic properties of Fe-Ni alloy fabricated by selective laser melting Fe/Ni miced powders. J. Mater. Sci. Technol. 29(8), p757–p760 (2013)

D. Gu, Y. Shen, Z. Lu, Preparation of TiN-Ti5Si3 in situ composites by selective laser melting. Mater. Lett. 63, 1577–1579 (2009)

Z. Wang, K. Guan, M. Gao, X. Li, X. Chen, X. Zeng, The microstructure and mechanical properties of deposited—IN718 by selective laser melting. J. Alloy. Compd. 513, 518–523 (2012)

Q. Jia, G. Dongdong, Selective laser melting additive manufacturing of inconel718 super alloy parts: densification, microstructure and properties. J. Alloy. Compd. 585, 713–721 (2014)

I. Yadroitsev, P. Krakhmalev, I. Yadroitsava, S. Johansson, I. Smurov, Energy input effect on morphology and microstructure of selective laser melting single track from metallic powder. J. Mater. Process. Technol. 213, 606–613 (2013)

Y. Nakamura, N. Yoshida, Precise mold fabrication by metal laser sintering combined with high speed milling. J. Jpn. Soc. Precis. Eng. 69(9), 1242–1245 (2003). (in Japanese)

D. Buchbinder, H. Schleifenbaum, S. Heidrich, W. Meiners, J. Bultmann, Phys. Procedia 12, 271–278 (2011)

S. Bremen, W. Meiners, A. Diatlov, Selective laser melting. A manufacturing technology for the future? Laser Tech. J. 9(2), 33–38 (2012)

X. Liu, P.K. Chu, C. Ding, Surface modification of titanium alloys, and related materials for medical applications. Mater. Sci. Eng., R 47, 49–121 (2004)

H.K. Rafi, N.V. Karthik, H. Gong, T.L. Starr, B.E. Stucker, Microstructures and mechanical properties of Ti6Al4V. J. Mater. Eng. Perform. 22(12), 3872–3883 (2013)

Y. Sato, M. Tsukamoto, Y. Yamashita, Surface morphology of Ti-6Al-4V plate fabricated by vacuum selective laser melting. Appl. Phys. B 119, 545–549 (2015)

C. Qiu, N.J.E. Adkins, M.M. Attallah, Microstructure and tensile properties of selectively laser-melted and of HIPed laser-melted Ti-6Al-4V. Mater. Sci. Eng., A 578, 230–239 (2013)

E. Sallica-Leva, A.L. Jardini, J.B. Fogagnolo, Microstructure and mechanical behavior of porous Ti–6Al–4V parts obtained by selective laser melting. J. Mech. Behav. Biomed. Mater. 26, 98–108 (2013)

Baigheng. Zhang, Hanlin. Liao, Christian. Coddet, Selective laser melting commercially pure Ti under vacuum. Vacuum 95, 25–29 (2013)

Acknowledgments

This work is partly supported by the New Energy and Industrial Technology Development Organization (NEDO) of Japan.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sato, Y., Tsukamoto, M., Masuno, S. et al. Investigation of the microstructure and surface morphology of a Ti6Al4V plate fabricated by vacuum selective laser melting. Appl. Phys. A 122, 439 (2016). https://doi.org/10.1007/s00339-016-9996-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-016-9996-8