Abstract

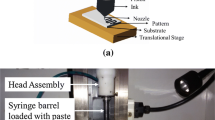

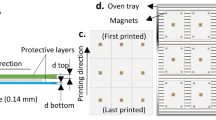

The present work is intended to fabricate low-cost flex sensor from conductive carbon paste using direct ink write (DIW) technique. DIW method is one of the additive manufacturing processes, which is capable to deposit a variety of material on a variety of substrates by a different mechanism to feature resolution at a microns level. It is widely used in the electronic industry for fabrication of PCBS and electrodes for different electronic devices. The DIW system in present study extrudes material stored in the syringe barrel through nozzle using compressed air. This mechanism will assist in creating patterns on a variety of substrates. Pneumatic controller is employed to control deposition of material, while computer-controlled X–Y stage is employed to control pattern generation. For effective and control patterning, printing parameters were optimized using Taguchi design optimization technique. The conductive carbon paste is used as ink for pattern generation on flexible PET substrate. Samples of flex sensor having different dimensions are prepared through DIW. The fabricated sensors were used as flexion sensor, and its electrical characteristic was evaluated. The obtained sensors are stable and reliable in performance.

Similar content being viewed by others

References

S. Rosset, H.R. Shea, Flexible and stretchable electrodes for dielectric elastomer actuators. Appl. Phys. A 110(2), 281–307 (2013)

S. Garner, S. Glaesemann, X. Li, Ultra-slim flexible glass for roll-to-roll electronic device fabrication. Appl. Phys. A 116(2), 403–407 (2014)

T. Sekitani, T. Yokota, U. Zschieschang, H. Klauk, S. Bauer, K. Takeuchi et al., Organic nonvolatile memory transistors for flexible sensor arrays. Science 326(5959), 1516–1519 (2009)

V. Dua, S.P. Surwade, S. Ammu, S.R. Agnihotra, S. Jain, K.E. Roberts et al., All-organic vapor sensor using inkjet-printed reduced graphene oxide. Angew. Chem. Int. Ed. 49(12), 522–531 (2010)

L. Zhou, A. Wanga, S. Wu, J. Sun, S. Park, T.N. Jackson, All-organic active matrix flexible display. Appl. Phys. Lett. 88(8), 083502 (2006). doi:10.1063/1.2178213

K. Shin, J. Hong, J. Jang, Micropatterning of graphene sheets by inkjet printing and its wideband dipole-antenna application. Adv. Mater. 23(18), 2113–2118 (2011)

M.E. Jalil, M.K.A. Rahim, N.A. Samsuri et al., Flexible printed chipless RFID tag using metamaterial–split ring resonator. Appl. Phys. A 122, 348 (2016). doi:10.1007/s00339-016-9865-5

D. Kim, N. Lu, R. Ma, Y. Kim, S. Wang et al., Epidermal electronics. Science 333(6044), 838–843 (2011)

O. Catanescu, L. Chien, Patterning a poly (3,4-ethylenedioxythiophene) thin film using a liquid crystalline network. Adv. Mater. 17(3), 305–309 (2005)

J.H. Lim, C.A. Mirkin, Electrostatically driven dip-pen nanolithography of conducting polymers. Adv. Mater. 14(20), 1474–1477 (2002)

L. Dipietro, A.M. Sabatini, P. Dario, Survey of glove-based systems and their applications. IEEE Trans. Syst. Man Cybern. C Appl. Rev. 38(4), 461–482 (2008)

S. Merilampi, T. Laine-Ma, P. Ruuskanen, The characterization of electrically conductive silver ink patterns on flexible substrates. Microelectron. Reliab. 49(7), 782–790 (2009)

M.A. Zawawi, S. O’Keeffe, E. Lewis, Intensity-modulated fiber optic sensor for health monitoring applications: a comparative review. Sens. Rev. 33(1), 57–67 (2013)

H. Yoon, Current trends in sensors based on conducting polymer nanomaterials. Nanomaterials 3(3), 524–549 (2013)

M.S. Kim, H.J. Shin, Y.K. Park, Design concept of high-performance flexible tactile sensors with a robust structure. Int. J. Precis. Eng. Manuf. 13(11), 1941–1947 (2012)

M. Vatani, Y. Lu, E.D. Engeberg, J.W. Choi, Combined 3D printing technologies and material for fabrication of tactile sensors. Int. J. Precis. Eng. Manuf. 16(7), 1375–1383 (2015)

H.J. Bang, H.I. Kim, K.S. Lee, Measurement of strain and bending deflection of a wind turbine tower using arrayed FBG sensors. Int. J. Precis. Eng. Manuf. 13(12), 2121–2126 (2012)

M.K. Kang, D.J. Park, S.S. Lee, Strain measurements on a cantilever beam with fiber bragg grating sensors using a pair of collimators. Int. J. Precis. Eng. Manuf. 13(3), 455–458 (2012)

G. Saggio, Mechanical model of flex sensors used to sense finger movements. Sens. Actuators A 185, 53–58 (2012)

L.K. Simone, D.G. Kamper, Design considerations for a wearable monitor to measure finger posture. J. Neuro Eng. Rehabil. 2(1), 1 (2005)

C. Rendl, D. Kim, S. Fanello, P. Parzer, C. Rhemann, J. Taylor, M. Zirkl, et al., FlexSense: a transparent self-sensing deformable surface, in Proceedings of the 27th Annual ACM Symposium on User Interface Software and Technology (2014), pp. 129–138

J. Jurgens, P.E. Patterson, Development and evaluation of an inexpensive sensor system for use in measuring relative finger positions. Med. Eng. Phys. 19(1), 1–6 (1997)

G. Saggio, Electrical resistance profiling of bend sensors adopted to measure spatial arrangement of the human body, in Proceedings of the 4th International Symposium on Applied Sciences in Biomedical and Communication Technologies (2011), p. 5

S. Luo, P.T. Hoang, T. Liu, Direct laser writing for creating porous graphitic structures and their use for flexible and highly sensitive sensor and sensor arrays. Carbon 96, 522–531 (2015)

G. Saggio, A novel array of flex sensors for a goniometric glove. Sens. Actuators 205, 119–125 (2014)

S. Bakhshi, M.H. Mahoor, Development of a wearable sensor system for measuring body joint flexion, in International Conference on Body Sensor Networks (2011), pp. 35–40

K. Kure, T. Kanda, K. Suzumori, S. Wakimoto, Flexible displacement sensor using injected conductive paste. Sens. Actuators 143(2), 272–278 (2008)

K. Kure, T. Kanda, K. Suzumori, S. Wakimoto, Intelligent FMA using flexible displacement sensor with paste injection, in IEEE International Conference on Robotics and Automation, ICRA (2006), pp. 1012–1017

M. Sajid, H.W. Danga, K.H. Na, K.H. Choi, Highly stable flex sensors fabricated through mass production roll-to-roll micro-gravure printing system. Sens. Actuators, A 236, 73–81 (2015)

J.J. Gems, P.E. Pattersont, Development and evaluation of an inexpensive sensor system for use in measuring relative finger positions. Med. Eng. Phys. 19(1), 1–6 (1997)

R. Gentner, J. Classen, Development and evaluation of a low-cost sensor glove for assessment of human finger movements in neurophysiological settings. J. Neurosci. Methods 178(1), 138–147 (2009)

Z.L. Jiang, Y.Y. Liu, H.P. Chen, Y.N. Zhang, Q.X. Hu, Multi-objective optimization of process parameters for biological 3D printing composite forming based on SNR and grey correlation degree. Int. J. Adv. Manuf. Technol. 80(1), 549–554 (2015)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abas, M., Rahman, K. Fabrication of flex sensors through direct ink write technique and its electrical characterization. Appl. Phys. A 122, 972 (2016). https://doi.org/10.1007/s00339-016-0507-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-016-0507-8