Abstract

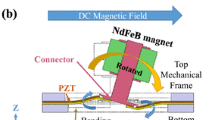

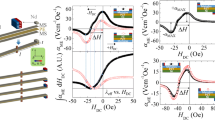

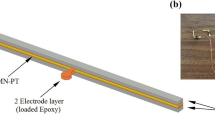

This paper presents a magnetic–piezoelectric smart material-structure using a novel magnetic-force-interaction approach to optimize the sensitivity of conventional piezoelectric current sensing technologies. The smart material-structure comprises a CuBe-alloy cantilever beam, a piezoelectric PZT sheet clamped to the fixed end of the beam, and an NdFeB permanent magnet mounted on the free end of the beam. When the smart material-structure is placed close to an AC conductor, the magnet on the beam of the smart structure experiences an alternating magnetic attractive and repulsive force produced by the conductor. Thus, the beam vibrates and subsequently generates a strain in the PZT sheet. The strain produces a voltage output because of the piezoelectric effect. The magnetic force interaction is specifically enhanced through the optimization approach (i.e., achieved by using SQUID and machining method to reorient the magnetization to different directions to maximize the magnetic force interaction). After optimizing, the beam’s vibration amplitude is significantly enlarged and, consequently, the voltage output is substantially increased. The experimental results indicated that the smart material-structure optimized by the proposed approach produced a voltage output of 4.01 Vrms with a sensitivity of 501 m Vrms/A when it was placed close to a conductor with a current of 8 A at 60 Hz. The optimized voltage output and sensitivity of the proposed smart structure were approximately 316 % higher than those (1.27 Vrms with 159 m Vrms/A) of representative piezoelectric-based current sensing technologies presented in other studies. These improvements can significantly enable the development of more self-powered wireless current sensing applications in the future.

Similar content being viewed by others

References

H. Farhangi, The path of smart grid. IEEE Power Energy Mag. 8, 18–28 (2010)

P. Ripka, Magnetic sensors and magnetometers. Meas. Sci. Technol. 13, 645 (2002)

Y.M. Jia, D. Zhou, L.H. Luo, X.Y. Zhao, H.S. Luo, S.W. Or, H.L.W. Chan, Magnetoelectric effect from the direct coupling of the Lorentz force from a brass ring with transverse piezoelectricity in a lead zirconate titanate (PZT) disk. Appl. Phys. A Mater. Sci. 89, 1025–1027 (2007)

C. Lu, P. Li, Y. Wen, A. Yang, W. He, J. Zhang, J. Yang, J. Wen, Y. Zhu, M. Yu, Investigation of magnetostrictive/piezoelectric multilayer composite with a giant zero-biased magnetoelectric effect. Appl. Phys. A Mater. Sci. 113, 413–421 (2013)

B. Guiffard, R. Seveno, Piezoelectric response of a PZT thin film to magnetic fields from permanent magnet and coil combination. Appl. Phys. A Mater. Sci. 118, 225–230 (2015)

M.H. Korayem, S. Razazzadeh, A.H. Korayem, R. Ghaderi, Effect of geometrical and environmental parameters on vibration of multi-layered piezoelectric microcantilever in amplitude mode. Appl. Phys. A Mater. Sci. 121, 203–215 (2015)

D.A. Pan, S.G. Zhang, J.J. Tian, J.S. Sun, A.A. Volinsky, L.J. Qiao, Resonant modes and magnetoelectric performance of PZT/Ni cylindrical layered composites. Appl. Phys. A Mater. Sci. 98, 449–454 (2010)

L. Li, X.M. Chen, Terfenol-D/Pb(Zr, Ti)O3 disk-ring multiferroic heterostructures coupled through normal stresses. Appl. Phys. A Mater. Sci. 98, 761–764 (2010)

J.P. Zhou, X.Z. Chen, L. Lv, C. Liu, Magnetoelectric coupling in antiferroelectric and magnetic laminate composites. Appl. Phys. A Mater. Sci. 104, 461–464 (2011)

L. Lin, L. Li, Z.B. Yan, Y.M. Tao, S. Dong, J.M. Liu, Ferroelectricity of polycrystalline GdMnO3 and multifold magnetoelectric responses. Appl. Phys. A Mater. Sci. 112, 947–954 (2013)

D.A. Filippov, T.A. Galichyan, V.M. Laletin, Magnetoelectric effect in bilayer magnetostrictive-piezoelectric structure. Theory and experiment. Appl. Phys. A Mater. Sci. 115, 1087–1094 (2014)

D. Hung, C. Lu, H. Bing, Self-biased magnetoelectric coupling characteristics of three-phase composite transducers with nanocrystallin soft magnetic alloy. Appl. Phys. A Mater. Sci. 120, 115–120 (2015)

T.K. Chung, D.G. Lee, M. Ujihara, G.P. Carman, Design, simulation, and fabrication of a novel vibration-based magnetic energy harvesting device. in Proceedings of 14th International Conference on Solid State Sensors, Actuators and Microsystems, Lyon, FR, June 2007, pp. 867

T.K. Chung, C.M. Wang, P.C. Yeh, T.W. Liu, C.Y. Tseng, C.C. Chen, A three-axial frequency-tunable piezoelectric energy harvester using a magnetic-force configuration. IEEE Sens. J. 14, 3152–3163 (2014)

C.C. Chen, T.K. Chung, C.Y. Tseng, C.F. Hung, P.C. Yeh, C.C. Cheng, A miniature magnetic-piezoelectric thermal energy harvester. IEEE Trans. Magn. 51, 9100309 (2015)

I. Enchlescu, M.E. Toimil-molares, C. Zet, M. Daub, L. Westerberg, R. Neumann, R. Spohr, Current perpendicular to plane single-nanowire GMR sensor. Appl. Phys. A Mater. Sci. 86, 43–48 (2007)

X. Sun, J. Du, Z. Zhu, J. Wang, Q. Liu, Enhanced GMI effect in NiZn-ferrite-modified Fe-based amorphous ribbons. Appl. Phys. A Mater. Sci. 119, 1277–1281 (2015)

E.S. Leland, P.K. Wright, R.M. White, A MEMS AC current sensor for residential and commercial electricity end-use monitoring. J. Micromech. Microeng. 19, 094018 (2009)

Q.R. Xu, I. Paprotny, M. Seidel, R.M. White, P.K. Wright, Stick-on piezoelectromagnetic AC current monitoring of circuit breaker panels. IEEE Sens. J. 13, 1055–1064 (2013)

I. Paprotny, Q. Xu, W.W. Chan, R.M. White, P.K. Wright, Electromechanical energy scavenging from current-carrying conductors. IEEE Sens. J. 13, 190–201 (2013)

D.F. Wang, K. Isagawa, T. Kobayashi, T. Itoh, R. Maeda, Passive piezoelectric DC sensor applicable to one-wire or two-wire DC electric appliances for end-use monitoring of DC power supply. Microsyst. Technol. 18, 1897–1902 (2012)

D.F. Wang, K. Isagawa, T. Kobayashi, T. Itoh, R. Maeda, Developing passive piezoelectric MEMS sensor applicable to two-wire DC appliances with current switching. Micro Nano Lett. 7, 68–71 (2012)

D.F. Wang, Y. Suzuki, Y. Suwa, T. Kobayashi, T. Itoh, R. Maeda, Integrated piezoelectric direct current sensor with actuating and sensing elements applicable to two-wire DC appliances. Meas. Sci. Technol. 24, 125109 (2013)

W. He, P. Li, Y. Wen, J. Zhang, A. Yang, C. Lu, A high-sensitivity current sensor based on piezoelectric ceramic Pb(Zr, Ti)O3 and ferromagnetic materials. Rev. Sci. Instrum. 85, 026110 (2014)

F. Koga, T. Tadatsu, J. Inoue, I. Sasada, A new type of current based on inverse magnetostriction for large current detection. IEEE Trans. Magn. 45, 4506–4509 (2009)

T. Ueno, T. Higuchi, High sensitive and heat-resistant magnetic sensor using magnetostrictive/piezoelectric laminate composite. IEEE Trans. Magn. 41, 3670–3672 (2005)

P. Ripka, Current sensors using magnetic materials. J. Optoelectron. Adv. Mater. 6, 587–592 (2004)

T.K. Chung, P.C. Yeh, C.M. Wang, A magnetic/mechanical approach for optimizing a miniature self-powered current sensor. in Proceedings of ASME Conference on SMASIS, Snowbird, USA, 2013, pp. V001T04A010

S.B. Lao, S.S. Chauhan, T.E. Pollock, T. Schröder, I.S. Cho, A. Salehian, Design, fabrication and temperature sensitivity testing of a miniature piezoelectric-based sensor for current measurements. Actuators 3, 162–181 (2014)

J.W. Yi, W.Y. Shih, W.-H. Shih, Effect of length, width, and mode on the mass detection sensitivity of piezoelectric unimorph cantilevers. J. Appl. Phys. 91, 1680 (2002)

Quantum Design, Inc. MPMS-XL. http://www.qdusa.com/sitedocs/productBrochures/1014-003.pdf

Taiwan Leader Magnet Co. Ltd. http://www.all-magnet.com/db/upload/webdata3/1405TMPRForSintered%20Ndfeb.pdf

Acknowledgments

Support for this work was obtained from the Taiwan Ministry of Science and Technology (Grant Nos. 103-2221-E-009-025 and 104-2221-E-009-017).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yeh, PC., Chung, TK., Lai, CH. et al. A magnetic–piezoelectric smart material-structure utilizing magnetic force interaction to optimize the sensitivity of current sensing. Appl. Phys. A 122, 29 (2016). https://doi.org/10.1007/s00339-015-9552-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-015-9552-y