Abstract

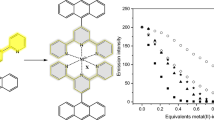

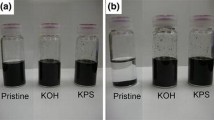

A simple and highly efficient compositing process was developed by synthesizing Pt or Pd nanoparticles embedded in polymers (Nafion™) with uniform distribution by in situ thermal decomposition of noble metal complexes. The homogenous mixtures of the metal complexes (trans-Pt(DMSO)(NH2CH2CH2OH)Cl2 or trans-Pd(DMSO)(H2NCH2CH2OH)Cl2) and Nafion™ dispersion went through a film casting process, and the metal ions in the Nafion™ were reduced to metal nanoparticles by the annealing process. The in situ compositing method avoids the use of excess metal sources and any external reducing agent/stabilizing agents, and leads to a uniform distribution of nanoparticles in the polymer matrixes. The films were characterized using optical microscopy and scanning electron microscopy. The actuation behavior in response to an AC electric field was investigated by bending displacements and blocking force measurements.

Similar content being viewed by others

References

K. Mallavarapu, D.J. Leo, Feedback control of the bending response of ionic polymer actuators. J. Intell. Mater. Syst. Struct. 12, 143–155 (2001)

M. Shahinpoor, K.J. Kim, Ionic polymer–metal composites: IV. Industrial and medical applications. Smart Mater. Struct. 14, 197–214 (2005)

C. Bonomo, L. Fortuna, P. Giannone, S. Graziani, A method to characterize the deformation of an IPMC sensing membrane. Sens. Actuators A Phys. 123–124, 146–154 (2005)

J.S. Yun, K.S. Yang, N.J. Choi, H.K. Lee, S.E. Moon, D.H. Kim, Microvalves based on ionic polymer–metal composites for microfluidic application. J. Nanosci. Nanotechnol. 11, 5975–5979 (2011)

J.Y. Jung, I.K. Oh, Novel nanocomposite actuator based on sulfonated poly(styrene-b-ethylene-co-butylene-b-styrene) polymer. J. Nanosci. Nanotechnol. 7, 3740–3743 (2007)

N.J. Choi, H.K. Lee, S. Jung, S. Lee, K.H. Park, electroactive polymer actuator with high response speed through anisotropic surface roughening by plasma etching. J. Nanosci. Nanotechnol. 8, 5385–5388 (2008)

H.K. Lee, N.J. Choi, S. Jung, K.H. Park, J. Kim, Ionic polymer–metal composites (IPMCs) containing Cu/Ni electrodes and ionic liquids for durability. Proc. SPIE 7362, 73620I (2009)

V.K. Nguyen, Y. Yoo, A novel design and fabrication of multilayered ionic polymer–metal composite actuators based on Nafion/layered silicate and Nafion/silica nanocomposites. Sens. Actuators B Chem. 123, 183–190 (2007)

J.W. Lee, Y.T. Yoo, The structure and performance of ionic polymer–metal composite actuators prepared via electroless plating process using various alcohols. Macromol. Symp. 249–250, 56–60 (2007)

K. Oguro, N. Fujiwara, K. Asaka, K. Onishi, S. Sewa, Polymer electrolyte actuator with gold electrodes. Proc. SPIE 3669, 64 (1999)

M. Shahinpoor, Y. Bar-Cohen, J.O. Simpson, J. Smith, Ionic polymer–metal composites (IPMCs) as biomimetic sensors, actuators and artificial muscles—a review. Smart Mater. Struct. 7, R15–R30 (1998)

K.J. Kim, M. Shahinpoor, Ionic polymer–metal composites: manufacturing techniques. Proc. SPIE 4695, 210 (2002)

H. Tamagawa, F. Nogata, T. Watanabe, A. Abe, K. Yagasaki, J.Y. Jin, Influence of metal plating treatment on the electric response of Nafion. J. Mater. Sci. 38, 1039–1044 (2003)

U. Johanson, U. Mäeorg, V. Sammelselg, D. Brandell, A. Punning, M. Kruusmaa, A. Aabloo, Electrode reactions in Cu–Pt coated ionic polymer actuators. Sens. Actuators B Chem. 131, 340–346 (2008)

I.S. Park, S.M. Kim, K.J. Kim, Mechanical and thermal behavior of ionic polymer–metal composites: effects of electroded metals. Smart Mater. Struct. 16, 1090–1097 (2007)

M. Shahinpoor, K.J. Kim, Ionic polymer–metal composites: I. Fundamentals. Smart Mater. Struct. 10, 819–833 (2001)

N.I. Dodoff, D. Kovala-Demertzi, M. Kubiakc, J. Kuduk-Jaworskac, A. Kochelc, G.A. Gornevaa, Dimethyl sulfoxide containing platinum(II) and palladium(II) chelate complexes of glyoxylic and pyruvic acid thiosemicarbazones. A new class of cytotoxic metal complexes. Z. Naturforsch. 61b, 1110–1122 (2006)

X.L. Wang, I.K. Oh, T.H. Cheng, Electro-active polymer actuators employing sulfonated poly(styrene-ran-ethylene) as ionic membranes. Polym. Int. 59, 305–312 (2010)

Y. Wyser, C. Pelletier, J. Lange, Predicting and determining the bending stiffness of thin films and laminates. Packag. Technol. Sci. 14, 97–108 (2001)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, K.S., Lee, HK., Choi, NJ. et al. IPMC actuators based on metal–Nafion™ composite films prepared by thermal decomposition of noble metal complexes. Appl. Phys. A 120, 785–791 (2015). https://doi.org/10.1007/s00339-015-9256-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-015-9256-3