Abstract

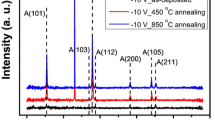

In this paper, we report the structural and electronic properties of TiC x N y films prepared by laser treatment under controlled gas atmosphere. X-ray diffraction shows the formation of TiC x N y along with the solid solutions of Ti(CN). The TiC x N y phases have been formed and are stable up to 650 °C. Subsequent laser irradiation at different laser energy densities in Ar-atmosphere modifies the microstructure and becomes oxidation resistant. Due to the formation of nano-crystalline TiC x N y , the affinity of Ti toward oxygen has been reduced remarkably after the Ar-treatments. Surface structure analysis by valence band spectroscopy reveals that the hybridization between Ti 3d and C 2p is increasing after the subsequent Ar-treatment at the cost of Ti 3d and N 2p hybridization.

Similar content being viewed by others

References

H. Holleck, J. Vac. Sci. Technol. A 4, 2661 (1986)

S.H. Jhi, J. Ihm, Phys. Rev. B 56, 13826 (1997)

V. Richter, A. Berger, J. Drobniewski, I. Endler, E. Wolf, Mater. Sci. Eng. A 209, 353 (1996)

S.J. Bull, D.G. Bhat, M.H. Staia, Surf. Coat. Technol. 163–164, 499 (2003)

R. Chen, J.P. Tu, D.G. Liu, Y.J. Mai, C.D. Gu, Surf. Coat. Technol. 205, 5228 (2011)

J.M. Lackner, W. Waldhauser, R. Ebner, Surf. Coat. Technol. 188, 519 (2004)

S. Restello, D. Boscarino, V. Rigato, Surf. Coat. Technol. 200, 6230 (2006)

R. Gupta, A. Khandelwal, A. Gupta, P. Schaaf, J. Phys D Appl. Phys. 42, 185305 (2009)

Y. Yang, D. Zhang, W. Yan, Y. Zheng, Opt. Lasers Eng. 48, 119 (2010)

M. Labudovic, R. Kovacevic, I. Kmecko, T.I. Khan, D. Blecic, Z. Blecic, Metall Mater Trans A 30A, 1597 (1999)

M. Guemmaz, G. Moraitis, A. Mosser, M.A. Khanand, J.C. Parlebas, J. Phys. Condens. Matter 9, 8453 (1997)

W. Pies, A. Weiss, H. Boehm, H.J. Meyer, Numerical Data and Functional Relationships in Science and Technology, vol. 7 (Springer, Berlin, 1979), p. 59

S. Tougaard, C. Jansson, Surf. Interface Anal. 19, 171 (1992)

A.J. Perry, M. Georgson, W. Sproul, Thin Solid Films 157, 255 (1988)

G.G. Fuentes, P. Prieto, C. Morant, C. Quiros, R. Nunez, L. Soriano, E. Elizalde, J.M. Sanz, Phys. Rev. B 63, 0754031 (2001)

U. Fano, Phys. Rev. 124, 1866 (1961)

G.G. Fuentes, E. Elizalde, J.M. Sanz, J. Appl. Phys. 90, 2737 (2001)

M. Guemmaz, G. Moraitis, A. Mosser, M.A. Khan, J.C. Parlebas, J. Alloys Compd. 262–263, 397 (1997)

J.J. Yeh, I. Lindau, At. Data Nucl. Tables 32, 1 (1985)

Acknowledgments

Mr. A. Wadikar for the RPES measurements at Indus-1. This work has been funded by UGC-DAE CSR, Indore Centre, India.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gupta, R., Soni, S. & Phase, D.M. Improvement of oxidation resistance of TiCN films prepared by laser alloying. Appl. Phys. A 118, 191–196 (2015). https://doi.org/10.1007/s00339-014-8896-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-014-8896-z