Abstract

The photovoltaic properties of heterojunctions of titanium dioxide (TiO2) nanoparticle films with single crystal silicon (c-Si) substrates with different Fermi level (E f) positions were studied. The TiO2 nanoparticles of rutile and anatase structures were studied without any sintering process. To clarify the photovoltaic properties, the characteristics of the heterojunction solar cells of TiO2 nanoparticle films with p-Si and n-Si substrates were investigated, where several Si substrates with different resistivities were used. The I–V characteristics of p-Si/TiO2 heterojunction showed the rectifying behavior and photovoltaic effect. The n-Si/TiO2 heterojunction also showed good rectifying characteristics; however, the conversion efficiency was extremely lower than that of p-Si/TiO2 heterojunction. The conversion efficiencies of various Si/TiO2 (rutile) heterojunction solar cells against the Fermi level E f of c-Si showed the maximum in the p-doped region. The photovoltaic properties of the Si/TiO2 heterojunction also depended on the crystal structure of TiO2, and the conversion efficiency of anatase is higher than that of rutile, which was attributed to the higher carrier mobility of anatase.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Recently, the solution processes in solar cell manufacturing have been attempted to save the cost and energy. Semiconducting films based on nanoparticles are increasing research efforts due to the advantage of low cost and simple preparation. Especially, the metal oxide film like titanium dioxide (TiO2) has been studied widely as a photovoltaic material. The heterojunction solar cells consisting of n-type TiO2 and various semiconducting materials have been reported [1–14]. Much attention is focused on the research to develop flexible solar cells, where a plastic substrate and a transparent conducting film such as an indium-tin-oxide (ITO)-coating film are mostly used. In the fabrication of such a solar cell, high-temperature processes such as sintering and annealing are limited by the low heat resistance of polymeric materials. In this paper, the photovoltaic properties of rutile and anatase TiO2 nanoparticle films were studied without any sintering process. To clarify the photovoltaic properties of TiO2 nanoparticle films, the characteristics of the heterojunction solar cells of TiO2 nanoparticle films with p-Si and n-Si substrates whose structure and properties were well characterized were studied. In the previous studies of TiO2 heterojunction solar cells, the efficiency of n-Si/TiO2 cell higher than 10 % has been reported [13, 14], where the TiO2 films were prepared on a Si substrate by spray pyrolysis method. The energy diagrams of n-Si/TiO2 and p-Si/TiO2 heterojunctions are illustrated schematically in Fig. 1. Because the Fermi level of TiO2 is located between the valence and conduction band edges of c-Si [15–18] as illustrated by red lines in Fig. 2, the built-in potential caused by the difference of the Fermi level position between TiO2 and c-Si can be considered for both heterojunctions of n-Si/TiO2 and p-Si/TiO2. Judging from the energy diagram as shown in Fig. 1, p-Si/TiO2 heterojunction is advantageous compared to n-Si/TiO2 heterojunctions in photovoltaic efficiency because the n-Si/TiO2 heterojunction has a high energy gap for hole diffusion due to the large band gap of TiO2. Further studies are necessary in order to elucidate the details of photovoltaic properties of Si/TiO2 heterojunction solar cells. In this work, we investigated the photovoltaic properties of heterojunctions of TiO2 nanoparticle films and c-Si substrates changing the position of Fermi level E f. The difficulties in the assignment of the photovoltaic properties of Si/TiO2 heterojunction are caused by the change of the surface state of Si substrate if an acidic TiO2 nanoparticle dispersion is applied directly on the Si substrate. The heat treatment process of the TiO2 nanoparticle-coated Si substrate seriously influences the photovoltaic properties due to the change of the surface state of Si substrate by oxidation and contamination. This may be one of the reasons for the inconsistency in the photovoltaic properties of Si/TiO2 heterojunction solar cells. In this study, a Si/TiO2 heterojunction was formed by contacting a freshly HF-treated Si substrate with TiO2 nanoparticle-coated ITO-coated polyethylene terephthalate (ITO-PET) flexible film to minimize the change of Si surface state.

2 Experimental details

TiO2 nanoparticle sols of rutile (TK-535, 24.6 wt% TiO2 in water without organic dispersing agents, 0.7 wt% HNO3, pH 1.26) and anatase (TKS-201, 33.2 wt% TiO2 in water without organic dispersing agents, pH 1.0) were provided from TAYCA. The p-Si (0.02, 3, and 23 Ωcm) and n-Si (0.15, 2, and 10 Ωcm) substrates with (100) faces were purchased from SINYO Co., Ltd. The E f was estimated from the resistivity of c-Si. An ITO-PET film (surface resistivity 60 Ω/sq, thickness 127 μm) was purchased from Sigma-Aldrich Co. LLC. The TiO2 nanoparticle sol was spin coated on the ITO-PET film and the thickness was determined to be ca. 1 μm by a laser microscope (KEYENCE VK-9700). The surface of a Si substrate was treated by 5 % HF solution before cell fabrication. Ohmic contact was formed on a Si substrate using In-Ga alloy. The cell structure is similar to the previously reported one [19]. The cell is composed of a Si substrate, a polyimide film separator (35 μm thickness) with a circular hole of diameter 2 mm, TiO2 nanoparticle-coated ITO-PET flexible film, silicone elastomer film of 2 mm thickness, and a circular quartz window of 3 mm thickness. The contact between Si and TiO2 nanoparticle was made by pressing the TiO2 nanoparticle-coated ITO-PET film on the Si substrate through the hole of the polyimide film separator. The TiO2 nanoparticle-coated ITO-PET film was baked at 120 °C for 10 min on a hot plate before the cell fabrication. The heat treatment temperature of the ITO-PET flexible film at 120 °C is almost maximum temperature to use because of the low heat resistance of the PET film. Although an ITO-coated glass substrate can be applied to the baking around 450 °C, the formation of the junction with a Si substrate is difficult due to the rigidity and the photovoltaic properties were seriously low. The I–V curves were observed by a DC voltage/current generator (6241A, ADCMT) connected to a computer. The photovoltaic characteristics were measured under 1 sun AM1.5G illumination (100 mW/cm2) using a solar simulator (ABET Tech. Inc.). For adjusting solar simulator intensity, a reference PV cell (BS-500, BUNKOUKEIKI Co. Ltd.) was used.

3 Results and discussion

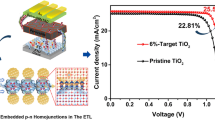

The SEM images of TiO2 nanoparticles are shown in Fig. 3. The rutile TiO2 is in rod-like form having a length of 80 nm and a width of about 30 nm; on the other hand, the anatase TiO2 is cubic with the length of one side about 40 nm. These TiO2 nanoparticles were used without any sintering. The I–V and the photovoltaic characteristics of p-Si (E f = 4.97 eV)/TiO2 (rutile) heterojunction solar cell are shown in Fig. 4. The rectifying behavior of the p-Si/TiO2 heterojunction was observed even for the simple cell structure as described above. From the I–V curve under 1 sun AM1.5G illumination, the short circuit current I sc, open circuit voltage V oc, fill factor FF, and conversion efficiency η were determined to be 5.34 mA/cm2, 0.38 V, 0.42, and 0.85 %, respectively. Such photovoltaic behavior is attributed to the p–n heterojunction between p-Si and n-type TiO2 nanoparticle films.

As shown by the energy band diagrams in Fig. 1, two kinds of heterojunction structures are possible between Si and TiO2, that is, p-Si/n-TiO2 and n-Si/n-TiO2 heterojunctions. Some papers have reported a high conversion efficiency of n-Si/n-TiO2 heterojunction solar cell lager than 10 %, although the solar cell was not composed of a TiO2 nanoparticle film but a TiO2 film prepared by spray pyrolysis [14, 15]. Figure 5 shows the I–V and the photovoltaic characteristics of n-Si (E f = 4.30 eV)/TiO2 (rutile) heterojunction solar cell. The rectifying behavior of n-Si/n-TiO2 heterojunction was also observed clearly but the direction of the electric current is opposite compared to the p-Si/TiO2 cell. It is reasonable considering the built-in potential as illustrated in Fig. 1. The photocurrent under 1 sun illumination also showed opposite direction compared to the p-Si/TiO2 cell. The solar cell parameters, I sc, V oc, FF, and conversion efficiency η were 3.0 mA/cm2, 0.04 V, 0.25, and 0.0034 %, respectively, which are much lower than those of p-Si/n-TiO2 heterojunction solar cell. It is reasonable judging from the energy band diagrams as shown in Fig. 1. A high energy barrier caused by the heterojunction between n-Si and TiO2 with a wide band gap blocks the hole transport from n-Si to TiO2 as illustrated in Fig. 1 [1]. On the other hand, the enhancement of the hole transport is expected by the large built-in potential in the case of p-Si/n-TiO2 heterojunction.

The photovoltaic properties of the Si/TiO2 heterojunction also depended on the crystal form of TiO2. The characteristics of the heterojunction solar cells of p-Si with rutile and anatase TiO2 nanoparticle films are summarized in Table 1. The efficiency of p-Si/anatase solar cell was higher than that of p-Si/rutile. It can be attributed to the higher carrier mobility of anatase than rutile [20]. However, the anatase TiO2 nanoparticle film showed cracking after spin coating. The low fill factor FF of the anatase cell is attributable to the poor film quality. The optical micrograph of rutile and anatase TiO2 nanoparticle films is shown in Fig. 6. The anatase TiO2 film showed cracking during solvent evaporation whereas the rutile TiO2 nanoparticle film did not show any cracking behavior as shown in Fig. 6. Such difference of the quality of the spin-coating film between anatase and rutile TiO2 nanoparticles may be caused by the difference of nanoparticle shape as shown in Fig. 3. The rod-like shape of rutile nanoparticle must be advantageous to form a homogenous film due to the aggregation of rod-like nanoparticles [21]. In the following experiments, rutile TiO2 nanoparticle films were used because of the film homogeneity.

The conversion efficiencies of Si/TiO2 (rutile) heterojunction solar cells are plotted against Fermi level E f of Si in Fig. 7. A clear relationship between conversion efficiency and the E f was observed for Si/TiO2 nanoparticle heterojunction solar cells. In the n-type Si region, the conversion efficiency is lower than 0.1 %. With increase in the E f, the conversion efficiency showed the increase and became maximum (1.10 %) around 4.97 eV. Further increase in the E f to 5.14 eV caused drastic decrease of the conversion efficiency to 0.024 %.

The I–V and the photovoltaic characteristics of p-Si (E f = 5.14 eV)/TiO2 (rutile) heterojunction solar cell are shown in Fig. 8. The I–V relationship is almost linear, which means the ohmic contact between p-Si (E f = 5.14 eV) and TiO2. The ohmic characteristics must be induced by narrowing of the depletion layer with increase in the dopant concentration of p-Si. The photocurrent attributable to the p-Si/TiO2 heterojunction was observed as shown in Fig. 8b although the conversion efficiency was lower than 0.1 %.

4 Conclusions

The characteristics of the heterojunction solar cells of TiO2 nanoparticle films with c-Si substrates were studied with changing the Fermi level E f position of c-Si. The photovoltaic behavior of Si/TiO2 heterojunction solar cells remarkably depended on the Fermi level. The I–V characteristics of p-Si/TiO2 heterojunction showed the rectifying behavior and photovoltaic effect. On the other hand, the n-Si/TiO2 heterojunction showed a good rectifying characteristic but the conversion efficiency was extremely lower than that of p-Si/TiO2 heterojunction. Although the photovoltaic properties of c-Si/TiO2 heterojunction solar cell without any sintering process of the nanoparticle became clear, further investigations for the TiO2 films prepared under various conditions are necessary to develop the metal oxide/Si heterojunction solar cell.

References

S. Avasthi, W.E. McClain, G. Man, A. Kahn, J. Schwartz, J.C. Sturm, Appl. Phy. Lett. 102, 203901 (2013)

Y.-H. Chang, C.-M. Liu, C. Chen, H. Cheng, Nanoscale Res. Lett. 7, 231 (2012)

A. Arena, N. Donato, G. Saitta, G. Rizzo, G. Neri, G. Pioggia, J. Sol-Gel, Sci. Technol. 43, 41 (2007)

C. Pan, J. Zhu, J. Mat. Chem. 19, 869 (2009)

Y. Zhang, X. Ma, P. Chen, D. Li, X. Pi, D. Yang, P.G. Coleman, Appl. Phys. Lett. 95, 252102 (2009)

H. Yu, X. Li, X. Quan, S. Chen, A. Zhang, Environ. Sci. Technol. 43, 7849 (2009)

Y.J. Hwang, A. Boukai, P. Yang, Nano Lett. 9, 410 (2009)

A.C. Tuan, T.C. Kaspar, T. Droubay, J.W. Rogers Jr, S.A. Chambersa, Appl. Phys. Lett. 83, 3734 (2003)

H. Yu, S. Chen, X. Quan, H. Zhao, Y. Zhang, Appl. Cat. B Environ. 90, 242 (2009)

L. Etgar, T. Moehl, S. Gabriel, S.G. Hickey, A. Eychmüller, M, Grätzel. ACS Nano 6, 3092 (2012)

L. Etgar, P. Gao, Z. Xue, Q. Peng, A.K. Chandiran, B. Liu, M.K. Nazeeruddin, M. Grätzel, J. Am. Chem. Soc. 134, 17396 (2012)

M. Wang, L. Sun, Z. Lin, J. Cai, K. Xiea, C. Lin, Energy Environ. Sci. 6, 1211 (2013)

W.A. Badawy, Sol. Energy Mater. Sol. Cells 71, 281 (2002)

W.A. Badawy, J. Mater. Sci. 32, 4979 (1997)

T.T.Y. Tan, C.K. Yip, D. Beydoun, R. Amal, Chem. Eng. J. 95, 179 (2003)

A. Imanishi, E. Tsuji, Y. Nakato, J. Phys. Chem. C 111, 2128 (2007)

O.V. Prezhdo, W.R. Duncan, V.V. Prezhdo, Prog. Surf. Sci. 84, 30 (2009)

N. Fuke, A. Fukui, A. Islam, R. Komiya, R. Yamanaka, H. Harima, L. Han, Sol. Energy Mater. Sol. Cells 93, 720 (2009)

A. Watanabe, Proc. SPIE. 8244, 82440 V-1 (2012)

H. Tang, K. Prasad, R. Sanjinès, P.E. Schmid, F. Lévy, J. Appl. Phys. 75, 2042 (1994)

G. Qin, A. Watanabe, J. Nanopart. Res. 15, 2084 (2013)

Acknowledgments

This work was supported by a Grant-in-Aid for Scientific Research on Innovative Areas “New Polymeric Materials Based on Element-Blocks (No.2401)” (24102004) of The Ministry of Education, Culture, Sports, Science, and Technology, Japan.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Watanabe, A., Qin, G. Heterojunctions of TiO2 nanoparticle film and c-Si with different Fermi level positions. Appl. Phys. A 116, 1281–1285 (2014). https://doi.org/10.1007/s00339-014-8221-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-014-8221-x