Abstract

CaCu3Ti4O12 (CCTO)–silicone resin composites with various CCTO volume fractions were prepared. Relatively high dielectric constant (ε=119) and low loss (tanδ=0.35) of the composites with CCTO volume fraction of 0.9 were observed. Two theoretical models were employed to predict the dielectric constant of these composites; the dielectric constant obtained via the Maxwell–Garnett model was in close agreement with the experimental data. The dielectric constant of CCTO–silicone resin composites showed a weak frequency dependence at the measuring frequency range and the loss tangent apparently decreases with increase in frequency.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In recent years, there has been an increasing interest in high dielectric constant flexible composites made up of a ferroelectric ceramic and a polymer for high-density energy storage and capacitor applications [1]. However, the dielectric constant of such polymer-based composites is rather low (about 50) because of the lower dielectric constant of the matrix [2, 3]. For instance, in BaTiO3/epoxy composites, though BaTiO3 has relatively high dielectric constant (>1000), the effective dielectric constant of the composite was as low as 50, even when the highest possible volume fraction of ceramics was incorporated [4]. As the volume fraction of ceramics increased, the composite, unfortunately, lost its flexibility. A new generation of ultra-high-dielectric constant materials such as CaCu3Ti4O12 (CCTO) can be used in order to obtain composites with better performance [5]. The CaCu3Ti4O12 (CCTO) ceramic which has centrosymmetric bcc structure (space group Im3, lattice parameter a≈7.391 Å and Z=2) has gained considerable attention due to its large dielectric constant (ε=104−5), which is nearly independent of frequency (up to 10 MHz), and low thermal coefficient of permittivity over the 100–600 K temperature range [6]. A number of theoretical studies and experimental observations have attempted to elucidate the remarkable dielectric properties of CCTO perovskite-like material. In this work, an attempt has been made to study dielectric properties of CCTO–silicone resin composites.

2 Experimental

CCTO–silicone resin composites of 0–3 connectivity were prepared by mixing pre-sintered powder of CCTO ceramic. The first set of samples were prepared in such a way that the material contains 30 percent (30 %) by volume of CCTO ceramic and 70 percent (70 %) by volume of silicone resin. A paste of the ceramic and resin is formed; one assumes that the CCTO powder has been evenly distributed into a matrix of silicone resin. To 0.5 % by weight of the prepared paste, dibenzoyl peroxide was added and the paste was again mixed so that the peroxide distributes evenly throughout the volume of the mixture. Dibenzoyl peroxide acts as a cross-linking agent between the resin molecules. The paste is now injected into a steel die (mould) and the mould loaded with the paste is then heated to 140 ∘C. The temperature was held for 30 min after which the heater was turned off and the mould was allowed to cool to room temperature, opened and the material inside the cavity is removed. We obtained a cured sample which is rubber-like, since the silicone resin now acts like an elastic solid, with CCTO ceramic powder distributed within the matrix like filler. This is now a 0:3 ceramic polymer composite sample. The resulting sample yields a thickness of not more than 1.5 mm. The procedure mentioned above was repeated for samples of compositions 50 %, 70 % and 90 % by volume of CCTO. The dielectric properties of the samples were determined using a HP 4192A LF impedance analyzer.

3 Results and discussion

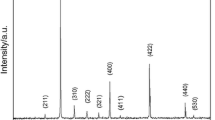

Figure 1 shows the X-ray diffraction (XRD) patterns of the CCTO–silicone resin composites with (a) 0.3, (b) 0.5 and (c) 0.7 CCTO volume fractions. The XRD analysis for the composites revealed that the intensities of the diffraction peaks were slightly increased with an increase in CCTO content in the composites. A higher percentage of silicone in the composites has a tendency to suppress the CCTO peaks. The morphology of the CCTO–silicone resin composites measured by scanning electron microscopy (SEM) is shown in Fig. 2. Figure 3 illustrates the dielectric constant (ε) and the loss tangent (tanδ) of the composites measured at 1 kHz and room temperature. It was found that both ε and tan δ increased gradually with the increase in CCTO content. For the composite with CCTO volume fraction of 0.9, the ε and tan δ values at 1 kHz were 119 and 0.35, respectively. In comparing with pure silicone resin (the experimental values of pure silicone resin are ε=3.0 and tan δ=0.03), the ε value of the composite was improved by 40 times, while the tan δ value increased by nearly 12 times. High ε and low tan δ of the CCTO–silicone resin composite made it attractive for practical applications. A number of numerical relations have been put forward by researchers to predict the dielectric constant of the composite. In the present study, the following two equations were used to calculate the effective dielectric constant of the CCTO–silicone resin composite.

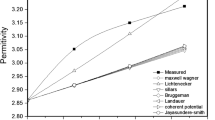

Equations (1) and (2) are the expressions of logarithmic and Maxwell–Garnett models, respectively, where ε,ε 1 and ε 2 are the dielectric constants of the composites, CCTO ceramic powder and silicone resin respectively and f is the volume fraction of the CCTO ceramic. The dielectric constants of silicone resin and CCTO ceramic measured at 1 kHz are 3.0 and 139, respectively. Figure 4 depicts the comparisons of dielectric constants of the CCTO–silicone resin composites with the values predicted by the above equations at 1 kHz. From this figure, it is clear that the Maxwell–Garnett model is the best fit of the experimental values for the CCTO–silicone resin composites. The Maxwell–Garnett model predicts that the dielectric constant of the composites is nearly equal to the experimental values up to 0.6 CCTO volume fraction. However, as the volume fraction of CCTO increases beyond 0.6, a deviation from the predicted value of the dielectric constant is observed in CCTO–silicone resin composites.

The frequency dependence of dielectric properties for the CCTO–silicone resin composites is shown in Fig. 5. As seen from Fig. 5a, for the composites with CCTO volume fractions of 0.3, 0.5 and 0.7, the dielectric constants are nearly independent of frequency but, for the composite with CCTO volume fraction of 0.9, the dielectric constant slightly decreases as the measuring frequency increases. The loss tangents of CCTO–silicone resin composites measured in the frequency range from 100 Hz to 1 MHz at room temperature are also shown in Fig. 5b; it can be seen that the loss tangents apparently decrease with the increase in measuring frequency from 100 Hz to 50 kHz. When the measuring frequency is higher than 50 kHz, the loss tangents of CCTO–silicone resin composites are almost unchanged. The CCTO–silicone resin composites revealing larger dielectric constants and loss tangents at lower frequencies toward 100 Hz indicate the existence of interfacial polarization. The decrease in the dielectric constant and loss tangent with increase in frequency is explained by the fact that as the frequency is raised, the interfacial dipoles have less time to orient themselves in the direction of the alternating field. The CCTO–silicone resin composites formatted in this study have good dielectric characteristics and most loss tangents of the CCTO–silicone resin composites are less than 0.7.

4 Conclusions

A two-phase composite containing CCTO particles dispersed in silicone resin was fabricated for different volume fractions of CCTO. The dielectric constant of the composite was simulated based on two different models. The values obtained by the Maxwell–Garnett model are in close agreement with the experimental values up to 0.6 CCTO volume fraction. For the composites with CCTO volume fractions of 0.3, 0.5 and 0.7, the dielectric constants are nearly independent of frequency but, for the composite with CCTO volume fraction of 0.9, the dielectric constant slightly decreases as the measuring frequency increases. The loss tangents of CCTO–silicone resin composites apparently decrease with the increase in measuring frequency from 100 Hz to 50 kHz. When the measuring frequency is higher than 50 kHz, the loss tangents of CCTO–silicone resin composites are almost unchanged. The CCTO–silicone resin composites revealing larger dielectric constants and loss tangents at lower frequencies toward 100 Hz indicate the existence of interfacial polarization.

References

L.A. Ramajo, M.A. Ramírez, P.R. Bueno, M.M. Reboredo, M.S. Castro, Mater. Res. 11(1), 85 (2008)

C.J. Dias, D.K. Das-Gupta, IEEE Trans. Dielectr. Electr. Insul. 5(3), 706 (1996)

Y. Bai, Z.-Y. Cheng, V. Bharti, H.S. Xu, Q.M. Zhang, Appl. Phys. Lett. 25(76), 3804 (2000)

D.-H. Kuo, C.-C. Chang, T.-Y. Su, W.-K. Wang, B.-Y. Lin, J. Eur. Ceram. Soc. 21(9), 1171 (2001)

P.R. Bueno, M.A. Ramírez, J.A. Varela, E. Longo, Appl. Phys. Lett. 89(19), 191117 (2006)

P. Thomas, K.T. Varughese, K. Dwarakanath, K.B.R. Varma, Compos. Sci. Technol. 70, 539 (2010)

Acknowledgements

The authors are very grateful to the authorities of the National Physical Laboratory and the Inter University Accelerator Centre, New Delhi (India) for providing the necessary facilities.

Open Access

This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Babu, S., Singh, K. & Govindan, A. Dielectric properties of CaCu3Ti4O12–silicone resin composites. Appl. Phys. A 107, 697–700 (2012). https://doi.org/10.1007/s00339-012-6885-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-012-6885-7