Abstract

Charge-trapping characteristics of stacked LaTiON/LaON film were investigated based on Al/Al2O3/LaTiON-LaON/SiO2/Si (band-engineered MONOS) capacitors. The physical properties of the high-k films were analyzed by X-ray diffraction, transmission electron microscopy and X-ray photoelectron spectroscopy. The band profile of this band-engineered MONOS device was characterized by investigating the current-conduction mechanism. By adopting stacked LaTiON/LaON film instead of LaON film as charge-trapping layer, improved electrical properties can be achieved in terms of larger memory window (5.4 V at ±10-V sweeping voltage), higher program speed with lower operating gate voltage (2.1 V at 100-μs +6 V), and smaller charge loss rate at 125 °C, mainly due to the variable tunneling path of charge carriers under program/erase and retention modes (realized by the band-engineered charge-trapping layer), high trap density of LaTiON, and large barrier height at LaTiON/SiO2 (2.3 eV).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

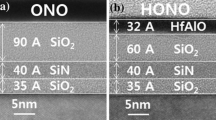

Floating-gate nonvolatile memory devices are rapidly approaching the scaling limit mainly due to their difficulty in maintaining high gate coupling ratio and suppressing cross talk between neighboring cells. As a promising candidate, metal-oxide-nitride-oxide-silicon (MONOS)-type flash memories with discrete traps in the dielectrics for charge storage have attracted increasing interest because of their localized charge-storage and coupling-free properties. Si3N4 (k∼7) was the first dielectric used as the charge-trapping layer (CTL). Recently, extensive researches have been carried out to study high-k dielectrics instead of Si3N4 for further scaling down the device dimensions and improving its charge-trapping efficiency. Among various high-k dielectrics, rare-earth metal oxides, such as La2O3 (k∼25) [1], Gd2O3 (k∼14) [2, 3], Pr2O3 (k∼15) [4], Nd2O3 (k∼16) [4], Er2O3 (k∼13) [4], have received much interest as charge-trapping layer, mainly due to their relatively high dielectric constants, appropriate conduction-band offsets with respect to Si and good electrical properties [4, 5]. Moreover, nitrogen incorporated into the charge-trapping dielectrics has also been widely investigated to induce deep-level traps and enhance the reliability of the memory devices [6–8]. For a conventional MONOS memory device, it tends to have thinner tunneling oxide for higher program/erase (P/E) speeds and lower operating voltages, whereas a thinner tunneling oxide may deteriorate its retention property. Therefore, there is a trade-off between high P/E speeds and good retention property. A novel MONOS structure with band-engineered CTL (BE-MONOS) has been demonstrated to be an effective solution, which can enhance the tunneling of carriers during P/E operation, and suppress the charge loss under retention mode by modulating the tunneling path of carriers [9, 10]. In this work, we propose a novel BE-MONOS structure with stacked LaTiON/LaON film as CTL as shown in Fig. 1(a). It is worth mentioning that the Ti incorporation into the LaON film plays a key role in the formation of this kind of band-engineered charge-trapping layer, which not only can increase the dielectric constant, but also shrink the band gap of the LaON film, thus resulting in a large band offset at the LaTiON/LaON interface [11, 12]. Compared with the BE-MONOS structure with Si3N4/HfON [9], this proposed structure with LaTiON/LaON has a higher dielectric constant, leading to higher P/E speeds. Furthermore, the stacked film can be formed by in-situ co-sputtering method, which simplifies the fabrication process [10].

2 Experiment

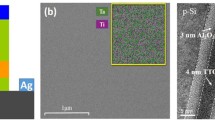

MONOS capacitor with an Al/Al2O3/LaTiON-LaON/SiO2/Si structure was fabricated on p-type silicon substrate. After a standard RCA (Radio Corporation of America) cleaning [13], 2-nm SiO2 was grown on the wafer by thermal dry oxidation. Then 2-nm LaON was deposited on the SiO2 by reactive sputtering using a La2O3 target in a mixed Ar and N2 ambient. Following that, 3-nm LaTiON was deposited in-situ by co-sputtering La2O3 and Ti targets in a mixed Ar and N2 ambient, and the atomic ratio of Ti and La in the LaTiON film was determined to be 1.7 by XPS analysis. This chosen Ti/La ratio was to suppress the diffusion of Ti into the SiO2 tunneling layer (which could deteriorate the data retention property), while maintaining the high dielectric constant and small band gap of the LaTiON film [14]. In addition, the nitrogen content in the LaTiON and LaON films was determined to be 3.3 % and 2.7 %, respectively, by XPS analysis. Then 14-nm Al2O3 as blocking layer was deposited by means of atomic layer deposition using trimethyl-aluminum (Al(CH3)3) and H2O as precursors at 300 °C. Next, the samples went through a post-deposition annealing (PDA) in N2 ambient at 850 °C for 30 s. Finally, Al was evaporated and patterned as gate electrode, followed by a forming-gas annealing at 300 °C for 20 min. A conventional MONOS capacitor with Al/Al2O3/LaON/SiO2/Si was also fabricated for comparison. To investigate the physical and electrical characteristics of the high-k films, Al/(LaON, or LaTiON, or LaTiON/LaON)/SiO2/Si(MNOS)-type capacitors were also fabricated by the same process mentioned above. The physical characteristics of the high-k dielectric films were characterized by X-ray diffraction (XRD), transmission electron microscopy (TEM) and X-ray photoelectron spectroscopy (XPS). The electrical characteristics of the memory capacitors were measured by HP4284A LCR meter and HP4156A semiconductor parameter analyzer.

3 Results and discussion

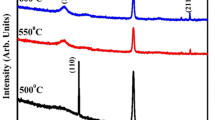

Figure 2 shows the XRD patterns of the LaON and LaTiON/LaON films. For the stacked LaTiON/LaON film, no diffraction peaks are observed from the XRD spectrum, indicating the amorphous state of the stacked film. On the contrary, there is a peak located at 2θ=33.1° for the LaON film, suggesting its crystalline structure. This peak is in accordance with the (411) reflection of the cubic La2O3 phase (2θ=33.3°). Ti incorporated into the LaON film can act as a network modifier and stabilize the amorphous state of the LaTiON film [15]. In addition, the thinner LaON film in the LaTiON/LaON stack (2 nm versus 4 nm for the sample with single LaON layer) usually needs a higher crystallization temperature for grain growth along the thickness dimension [8]. Both of the reasons lead to the amorphous state of the stacked LaTiON/LaON film. It should be noted that a charge-trapping dielectric with an amorphous structure is favorable for achieving excellent retention property, because charge loss via grain boundaries can be avoided.

Figure 3 shows the TEM cross-sectional images of the conventional MONOS and BE-MONOS capacitors. The thickness of each layer for the MONOS and BE-MONOS capacitors is determined to be 2.0 nm/4.3 nm/14.1 nm (SiO2/LaON/Al2O3) and 2.0 nm/5.0 nm/14.5 nm (SiO2/LaON-LaTiON/Al2O3), respectively. Also, an abrupt interface at SiO2/LaON is observed from Fig. 3(c). To gain deeper insight into the physical structure of the stacked film, the depth profiling of the stacked LaTiON/LaON film with sputtering time is also performed by XPS as shown in Fig. 4, where each layer can be easily distinguished based on the distribution of the elements. Moreover, the Ti content decreases linearly with sputtering time, suggesting its homogeneous distribution in the LaTiON film.

Figure 5 shows the J–V (gate current density versus gate voltage) characteristics of the MNOS capacitors with different high-k dielectric film under negative gate voltage corresponding to gate injection. The gate leakage at V G−V FB=−2 V (V G is defined as gate voltage and V FB represents flat-band voltage) is 3.6×10−3 A/cm2, 1.2×10−4 A/cm2, and 1.1×10−7 A/cm2 for the MNOS capacitors with LaTiON, LaTiON/LaON and LaON, respectively. It is obvious that the MNOS capacitor with LaTiON displays much larger leakage than the one with LaON, which should be due to its lower barrier height (see below) between Al and LaTiON because the leakage normally changes inverse-exponentially with the barrier height. Moreover, the barrier height can be extracted by studying the current-conduction mechanism. It is found that the leakage current (J) of the MNOS capacitor with LaON is well consistent with the Fowler–Nordheim (F-N) tunneling under high electric field (E) as shown in Fig. 6, where ln(J/E 2) varies linearly with E −1. For the F-N tunneling, the current density can be expressed as [16]

where q is the electron charge; h is Planck’s constant; m ∗ is the effective electron mass; and ϕ FN is the Al/LaON barrier height, which can be extracted from the slope of the fitted line shown in Fig. 6(a). The extracted ϕ FN is 2.38 eV, and is very close to the reported value (2.40 eV) [5], given that the electron affinity of Si is 4.05 eV and the work function of Al is 4.15 eV [5, 17]. On the other hand, the leakage current of the MNOS capacitor with LaTiON is found to obey Schottky emission, where ln(J/T 2) varies linearly with E 1/2 as shown in Fig. 7. For Schottky emission, the current density can be expressed as [16]

where A is the Richardson constant; T is the Kelvin temperature; ε 0 is the permittivity of vacuum; ε r is the dynamic dielectric constant of the dielectric film; k is Boltzmann’s constant; and ϕ B is the Al/LaTiON barrier height, which can be determined by the y-intercept of the fitted line in Fig. 7(a). The extracted ϕ B is 0.97±0.04 eV, which is intermediate between the Al/TiO2 barrier height (0.10 eV) and Al/La2O3 barrier height (2.40 eV) [5]. For LaTiON, due to the smaller atomic radius of Ti (1.40 Å) than that of La (1.95 Å), Ti d states (instead of La d states) act as the conduction-band edge of LaTiON, thus leading to a smaller barrier height at Al/LaTiON (0.97 eV) than that at Al/LaON (2.38 eV) [11, 12]. According to the above analysis, the energy band diagram for the BE-MONOS capacitor under P/E and retention modes can be illustrated in Fig. 1, where the band gap of the Al2O3, LaTiON, LaON and SiO2 layers is about 8.8 eV, 3.5 eV, 6.0 eV, and 9.0 eV, respectively [5, 18]. In addition, the dielectric constant of the LaTiON and LaON is evaluated by C–V (capacitance versus gate voltage) measurements to be 33 and 15, respectively. Ti incorporated into the LaON film can induce softening of phonon modes which is responsible for the increase in dielectric constant of the LaTiON film [11, 12]. It is believed that the formation of silicate at the LaON/SiO2 interface leads to a lower dielectric constant than that of pure La2O3(25) [1, 19].

Figure 8 exhibits the 1-MHz C–V hysteresis loops of the conventional MONOS and BE-MONOS capacitors. Sweeping starts from inversion region to accumulation region, and back to inversion region again. As the sweeping voltage increases from ±8 V to ±10 V, the memory window increases from 3.5 V/2.9 V to 5.4 V/4.9 V for the BE-MONOS and MONOS devices, respectively. It is obvious that the BE-MONOS capacitor possesses a larger memory window than the MONOS one, indicating higher trap density in the stacked LaTiON/LaON film.

Figure 9 depicts the P/E transient characteristics of the conventional MONOS and BE-MONOS capacitors under various gate voltages, with the BE-MONOS sample displaying higher P/E speeds than the latter under the same operating conditions. For the BE-MONOS and MONOS capacitors, the programmed V FB shift (ΔV FB, defined as the change of V FB due to stress) at +14 V for 1 ms is 7.2 V and 4.9 V, respectively. Moreover, the BE-MONOS capacitor even shows a memory window of 4.7 V under a lower program voltage of +10 V for 1 ms, which is close to the value at +14 V for 1 ms for the conventional MONOS one, further supporting its higher program speed. For the BE-MONOS sample, a ΔV FB of 2.1 V can still be obtained even under a lower gate voltage of +6 V for 100 μs, suggesting its potential for low-voltage high-performance memory applications. As illustrated by the energy band diagram in Fig. 1(b), this higher program speed of the BE-MONOS sample should be mainly ascribed to the shortened tunneling path of electrons from the substrate into CTL. Moreover, the higher trap density and higher dielectric constant of the stacked LaTiON/LaON film can also contribute to the higher program speed. However, different from the program phenomenon shown in Fig. 9(a), only a slight improvement of the erase speed is observed for the BE-MONOS sample shown in Fig. 9(b). In the erase mode, the stored electrons in CTL will tunnel back into the Si substrate, or recombine with holes from the substrate. The higher erase speed for the BE-MONOS sample should be ascribed to its higher hole-trapping efficiency resulting from its higher trap density. Due to the different valence of the Ti and La atoms, Ti incorporated into the LaON film can induce considerable oxygen vacancies which will give rise to large quantities of traps in the band gap of the LaTiON film [12]. On the other hand, as shown in Fig. 1(c), it is more difficult for the trapped electrons tunneling back to the substrate because of the larger barrier height (2.33 eV) between LaTiON and SiO2 as compared with that of LaON/SiO2 (0.90 eV) in the MONOS sample. Subsequently, only a slight improvement of the erase speed is observed for the BE-MONOS sample compared with the MONOS one.

Figure 10(a) shows the retention characteristics of the conventional MONOS and BE-MONOS capacitors measured at 25 °C and 125 °C. Both of the samples are operated to achieve a similar P/E memory window (5.7 V) at first for the measurement. For the BE-MONOS and MONOS capacitors, the retained P/E memory window after 104-s baking time degrades to be 3.6 V and 3.0 V, corresponding to a charge loss of 37.2 % and 47.1 %, respectively. For the BE-MONOS sample, two main reasons are responsible for the improvement of its retention characteristics, and can be illustrated by the energy band diagram shown in Fig. 1(d). One is the large barrier height between LaTiON and SiO2 which suppresses the escaping of charges from the CTL because the tunneling probability changes inverse-exponentially with the barrier height. Another reason lies in the lengthened tunneling path for the trapped charges detrapping under the retention mode. The retention property can further be investigated by the J–V curves shown in Fig. 10(b), where the BE-MONOS sample displays smaller gate leakage than the MONOS one at low gate voltage, thus smaller charge loss. The smaller gate leakage of the BE-MONOS sample suggests its lower power consumption, which should be due to its lengthened tunneling path at low gate voltage (retention mode) and higher charge-trapping efficiency at high gate voltage (program mode), thus fewer electrons passing through the CTL into the gate.

Figure 11 shows the endurance characteristics of the BE-MONOS capacitor under a ±8-V 100-μs stress pulse. The P/E memory window before and after 105-cycle P/E stressing is 2.78 V and 2.65 V, respectively, corresponding to a slight degradation of 4.7 %. Such a good endurance property should be mainly due to its high P/E speeds at low gate voltages.

4 Conclusion

In conclusion, the charge-trapping characteristics of stacked LaTiON/LaON film are investigated by using MONOS-type memory capacitors. The band profile of the BE-MONOS structure is built by investigating its current-conduction mechanism. Compared with the conventional MONOS capacitor with LaON as CTL, the BE-MONOS one with stacked LaTiON/LaON as CTL shows better electrical characteristics in terms of larger memory window, higher P/E speeds and smaller charge loss at high temperature. Therefore, the stacked LaTiON/LaON film is promising as charge-trapping layer for high-performance nonvolatile memory applications.

References

H.J. Kim, S.Y. Cha, D.J. Choi, Mater. Sci. Semicond. Process. 13, 9 (2010)

J.C. Wang, C.T. Lin, J. Appl. Phys. 109, 064506 (2011)

J. Kwo, M. Hong, A.R. Kortan, K.L. Queeney, Y.J. Chabal, R.L. Opila, D.A. Muller, S.N.G. Chu, B.J. Sapjeta, T.S. Lay, J.P. Mannaerts, T. Boone, H.W. Krautter, J.J. Krajewski, A.M. Sergnt, J.M. Rosamilia, J. Appl. Phys. 89, 3920 (2001)

T.M. Pan, T.Y. Yu, Semicond. Sci. Technol. 24, 095022 (2009)

J. Robertson, Rep. Prog. Phys. 69, 327 (2006)

Y.H. Wu, L.L. Chen, Y.S. Lin, M.Y. Li, H.C. Wu, IEEE Electron Device Lett. 30, 1290 (2009)

H.J. Yang, C.F. Cheng, W.B. Chen, S.H. Lin, F.S. Yeh, S.P. McAlister, A. Chin, IEEE Trans. Electron Devices 55, 1417 (2008)

J.Y. Wu, Y.T. Chen, M.H. Lin, T.B. Wu, IEEE Electron Device Lett. 31, 993 (2010)

S.H. Lin, A. Chin, F.S. Yeh, S.P. McAlister, in Tech. Dig. Int. Electron Device Meet (2008), p. 843

G. Zhang, C.H. Ra, H.M. Li, T.Z. Shen, B.K. Cheong, W.J. Yoo, IEEE Trans. Electron Devices 57, 2794 (2010)

G. Dutta, K.P.S.S. Hembram, G.M. Rao, U.V. Waghmare, J. Appl. Phys. 103, 016102 (2008)

D.M. Ramo, A.L. Shluger, G. Bersuker, Phys. Rev. B 79, 035306 (2009)

F.Y. Tian, D. Yang, R.L. Opila, A.V. Teplyakov, Appl. Surf. Sci. 258, 3019 (2012)

X.D. Huang, P.T. Lai, ECS Trans. (2012) will be published

X.P. Wang, M.F. Li, A. Chin, C.X. Zhu, J. Shao, W. Lu, X.C. Shen, X.F. Yu, R. Chi, C. Shen, A.C.H. Huan, J.S. Pan, A.Y. Du, P. Lo, D.S.H. Chan, D.L. Kwong, Solid-State Electron. 50, 986 (2006)

Y. Kim, S.I. Ohmi, K. Tsutsui, H. Iwai, Jpn. J. Appl. Phys. 44, 4032 (2005)

W.J. Zhu, T.P. Ma, T. Tamagawa, J. Kim, Y. Di, IEEE Electron Device Lett. 23, 97 (2002)

A. Ziani, C. Le Paven-Thivet, L. Le Gendre, D. Fasquelle, J.C. Carru, F. Tessier, J. Pinel, Thin Solid Films 517, 544 (2008)

D. Eom, S.Y. No, C.S. Hwang, H.J. Kim, J. Electrochem. Soc. 154, G49 (2007)

Open Access

This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Huang, X.D., Lai, P.T. & Sin, J.K.O. LaTiON/LaON as band-engineered charge-trapping layer for nonvolatile memory applications. Appl. Phys. A 108, 229–234 (2012). https://doi.org/10.1007/s00339-012-6881-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-012-6881-y