Abstract

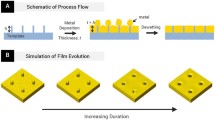

This paper addresses novel applications of an excimer laser (308 nm wavelength, 20 ns pulse duration) in nanofabrication. Specifically, laser assisted nanoimprint lithography (LAN), self-perfection by liquefaction (SPEL), fabrication of metal nanoparticle arrays, and the fabrication of sub-10-nm nanofluidic channels are covered. In LAN, a polymeric resist is melted by the laser pulse, and then imprinted with a fused silica mold within 200 ns. LAN has been demonstrated in patterning various polymer nanostructures on different substrates with high fidelity and uniformity, and negligible heat effect on both the mold and the substrate. SPEL is a novel technology that uses selective melting to remove fabrication defects in nanostructures post fabrication. Depending on the boundary conditions, SPEL is categorized into three basic types: Open-SPEL that takes place with surface open, Capped-SPEL where a cap plate holds the top surface of the nanostructures and Guided-SPEL where a plate held a distance above the structure guides the molten materials to rise and form a new structure with better profile. Using SPEL (in less than 200 ns), we have achieved a reduction of line edge roughness (LER) of Cr lines to 1.5 nm (3σ) (560% improvement from the original), which is well below what the previous technologies permit, and a dramatic increase of the aspect ratio of a nanostructure. We have used SPEL to make sub-25-nm smooth cylindrical NIL pillar molds and smoothing Si waveguides. Excimer laser is also used to make metal nanoparticles. Monolayers of particles are fabricated on various substrates (silicon, fused silica and plastics) by exposing thin metal films to a single laser pulse. Periodic nanoparticle arrays have been fabricated by fragmentation of metal grating lines. The periodicity of these nanoparticles can be regulated by surface topography such as shallow trenches. Finally, an excimer laser pulse has been used to melt the top portion of 1D and 2D Si gratings to seal off the top surface, forming enclosed nanofluidic channel arrays. The channel width has been further reduced to 9 nm using self-limited thermal oxidation. DNA stretching using 20 nm wide self-sealed channels is also demonstrated.

Similar content being viewed by others

References

T.H. Maiman, Stimulated optical radiation in ruby. Nature 187, 493–494 (1960)

A.L. Schawlow, C.H. Townes, Infrared and optical masers. Phys. Rev. 112, 1940–1949 (1958)

J.J. Ewing, Rare-gas halide lasers. Phys. Today 31, 32–39 (1978)

Q.F. Xia, Nanostructure Engineering Using Pulsed Laser and Nanoimprint Lithography (Princeton University, Princeton, 2007)

J. Boneberg, J. Bischof, P. Leiderer, Nanosecond time-resolved reflectivity determination of the melting of metals upon pulsed laser annealing. Opt. Commun. 174, 145–149 (2000)

J. Liu, H. Kurz, N. Bloembergen, Picosecond time-resolved plasma and temperature-induced changes of reflectivity and transmission in silicon. Appl. Phys. Lett. 41, 643–646 (1982)

P.G. Carey, B.J. Woratschek, F. Bachmann, Progress toward excimerlaser metal planarization and via hole filling using in situ monitoring. Microelectron. Eng. 20, 89–106 (1993)

S.Y. Chou, P.R. Krauss, P.J. Renstrom, Imprint of sub-25 nm vias and trenches in polymers. Appl. Phys. Lett. 67, 3114–3116 (1995)

S.Y. Chou, P.R. Krauss, P.J. Renstrom, Imprint lithography with 25-nanometer resolution. Science 272, 85–87 (1996)

S.Y. Chou, P.R. Krauss, W. Zhang, L.J. Guo, L. Zhuang, Sub-10 nm imprint lithography and applications. J. Vac. Sci. Technol. B 15(6), 2897–2904 (1997)

D.R. Lide, CRC Handbook of Chemistry and Physics, 79th edn. (CRC Press, Boca Raton, 1998)

W. Zhang, S.Y. Chou, Multilevel nanoimprint lithography with submicron alignment over 4 in. Si wafers. Appl. Phys. Lett. 79, 845–847 (2001)

S.Y. Chou, C. Keimel, J. Gu, Ultrafast and direct imprint of nanostructures in silicon. Nature 417(6891), 835–837 (2002)

Z.N. Yu, H. Gao, S.Y. Chou, In situ real time process characterization in nanoimprint lithography using time-resolved diffractive scatterometry. Appl. Phys. Lett. 85, 4166–4168 (2004)

Z.N. Yu, Subwavelength Gratings and Applications (Princeton University, Princeton, 2003)

Q.F. Xia, C. Keimel, H.X. Ge, Z.N. Yu, W. Wu, S.Y. Chou, Ultrafast patterning of nanostructures in polymers using laser assisted nanoimprint lithography. Appl. Phys. Lett. 83, 4417–4419 (2003)

A. Yariv, Optical Electronics, 4th edn. (Saunders College Publishing, Philadelphia, 1991)

GSolver, http://www.gsolver.com/

E.D. Palik, Handbook of Optical Constants of Solids (Academic Press, New York, 1985)

S.A. Campbell, The Science and Engineering of Microelectronic Fabrication, 2nd edn. (Oxford University Press, Oxford, 2001)

ABAQUS, http://www.abaqus.com/

H. Du, R.C.A. Fuh, J.Z. Li, L.A. Corkan, J.S. Lindsey, PhotochemCAD: A computer-aided design and research tool in photochemistry. Photochem. Photobiol. 68, 141–142 (1998)

Z.N. Yu, H. Gao, S.Y. Chou, New developments in real-time imprint monitoring by scattering-of-light (RIMS), in The Third International Conference on Nanoimprint and Nanoprint Technology (NNT04). Vienna, Austria, 2004

R.L. Morrison, Symmetries that simplify the design of spot array phase gratings. J. Opt. Soc. Am. A 9, 464–471 (1992)

H. Gao, Nanoimprint Methods, Monitoring and Processes (Princeton University, Princeton, 2007)

Q.F. Xia, Z.N. Yu, H. Gao, S.Y. Chou, In situ real time monitoring of nanosecond imprint process. Appl. Phys. Lett. 89, 073107 (2006)

Q. Xia, TRR measurement for polymers. Unpublished, 2003

D.W. van Krevelen, Properties of Polymers, 3rd edn. (Elsevier Science, Amsterdam, 1990)

H.C. Scheer, H. Schulz, A contribution to the flow behaviour of thin polymer films during hot embossing lithography. Microelectron. Eng. 56, 311–332 (2001)

H.D. Rowland, A.C. Sun, P.R. Schunk, W.P. King, Impact of polymer film thickness and cavity size on polymer flow during embossing: toward process design rules for nanoimprint lithography. J. Micromech. Microeng. 15, 2414–2425 (2005)

Newport high-speed detector, http://www.newport.com

Tektronix digital storage oscilloscope, http://www.tektronix.com

S.Y. Chou, Q.F. Xia, Improved nanofabrication through guided transient-liquefaction. Nat. Nanotechnol. 3, 295–300 (2008)

S.Y. Chou, Q.F. Xia, Self-repair and enhancement of nanostructures by liquificaiton under guiding conditions. US Patent 7282456, 2007

International Technology Roadmap for Semiconductors, 2006 Update. http://www.itrs.net/Links/2006Update/FinalToPost/08_Lithography2006Update.pdf, 2006: p. Table 77b

C. Herring, Some theorems on the free energies of crystal surfaces. Phys. Rev. 82, 87–93 (1951)

Z.N. Yu, L. Chen, W. Wu, H.X. Ge, S.Y. Chou, Fabrication of nanoscale gratings with reduced line edge roughness using nanoimprint lithography. J. Vac. Sci. Technol. B 21(5), 2089–2092 (2003)

P.L. Silvestrelli, A. Alavi, M. Parrinello, D. Frenkel, Ab initio molecular dynamics simulation of laser melting of silicon. Phys. Rev. Lett. 77, 3149–3152 (1996)

M. Delfino, T.A. Reifsteck, Laser activated flow of phosphosilicate glass in integrated circuit devices. Electron Device Lett. 3(5), 116–118 (1982)

D.K. Armani, T.J. Kippenberg, S.M. Spillane, K.J. Vahala, Ultra-high-Q toroid microcavity on a chip. Nature 421(6926), 925–928 (2003)

D.B. Tuckerman, A.H. Weisberg, Planarization of gold and aluminum thin-films using a pulsed laser. IEEE Electron. Device Lett. 7(1), 1–4 (1986)

T. Sameshima, Self organized grain growth larger than 1 μm through pulsed-laser-induced melting of silicon films. Jpn. J. Appl. Phys. 2 32(10B), L1485–L1488 (1993)

V. Constantoudis, G.P. Patsis, A. Tserepi, E. Gogolides, Quantification of line-edge roughness of photoresists. II. Scaling and fractal analysis and the best roughness descriptors. J. Vac. Sci. Technol. B 21(3), 1019–1026 (2003)

Image Pro Plus, http://www.mediacy.com

S.E. Orchard, On surface levelling in viscous liquids and gels. Appl. Sci. Res. A11, 451–464 (1962)

Y. Sato, Y. Kameda, T. Nagasawa, T. Sakamoto, S. Moriguchi, T. Yamamura, Y. Waseda, Viscosity of molten silicon and the factors affecting measurement. J. Cryst. Growth 249(3–4), 404–415 (2003)

P.H. Keck, W. Vanhorn, The surface tension of liquid silicon and germanium. Phys. Rev. 91(3), 512–513 (1953)

R.F. Brooks, A.T. Dinsdale, P.N. Quested, The measurement of viscosity of alloys—a review of methods, data and models. Meas. Sci. Technol. 16(2), 354–362 (2005)

B.J. Keene, Review of data for the surface tension of pure metals. Int. Mat. Rev. 38(4), 157–192 (1993)

J. Brandrup, E.H. Immergut, Polymer Handbook, 3rd edn. (Wiley, New York, 1989)

S.Y. Chou, Q.F. Xia, Ultrafast selective self-repair of nanostructures by liquefaction, in The 49th International Conference on Electron, Ion and Photon Beam Technology and Nanofabrication (EIPBN) (AVS, Orlando, 2005)

E. Yablonovitch, T. Gmitter, Wetting angles and surface tension in the crystallization of thin liquid films. J. Electrochem. Soc. 131, 2625–2630 (1984)

S.Y. Chou, L. Zhuang, Lithographically induced self-assembly of periodic polymer micropillar arrays. J. Vac. Sci. Technol. B 17, 3197–3202 (1999)

S.Y. Chou, L. Zhuang, L.J. Guo, Lithographically induced self-construction of polymer microstructures for resistless patterning. Appl. Phys. Lett. 75, 1004–1006 (1999)

L. Wu, S.Y. Chou, Electrohydrodynamic instability of a thin film of viscoelastic polymer underneath a lithographically manufactured mask. J. Non-Newtonian Fluid. Mech. 125, 91–99 (2005)

N. Otsu, A threshold selection method from gray level histograms. IEEE Trans. Syst. Man Cybern. 9, 62–66 (1979)

W. Zhang, Development of Large-Area and Multilevel Nanoimprint Lithography and the Applications in MOSFETs (Princeton University, Princeton, 2001)

S.Y. Chou, P. Krauss, Imprint lithography with sub-10 nm feature size and high throughput. Microelectron. Eng. 35, 237–240 (1997)

S. Park, H. Schift, H.H. Solak, J. Gobrecht, Stamps for nanoimprint lithography by extreme ultraviolet interference lithography. J. Vac. Sci. Technol. B 22(6), 3246–3250 (2004)

K. Ansari, J.A. van Kan, A.A. Bettiol, F. Watt, Fabrication of high aspect ratio 100 nm metallic stamps for nanoimprint lithography using proton beam writing. Appl. Phys. Lett. 85(3), 476–478 (2004)

K. Watanabe, T. Morita, R. Kometani, T. Hoshino, K. Kondo, K. Kanda, Y. Haruyama, T. Kaito, J. Fujita, M. Ishida, Y. Ochiai, T. Tajima, S. Matsui, Nanoimprint using three-dimensional microlens mold made by focused-ion-beam chemical vapor deposition. J. Vac. Sci. Technol. B 22(1), 22–26 (2004)

I. Junarsa, P.F. Nealey, Fabrication of masters for nanoimprint, step and flash, and soft lithography using hydrogen silsesquioxane and x-ray lithography. J. Vac. Sci. Technol. B 22(6), 2685–2690 (2004)

Q.F. Xia, S.Y. Chou, Fabrication of sub-25 nm diameter pillar nanoimprint molds with smooth sidewalls using self perfection by liquefaction (SPEL) and reactive ion etching. Nanotechnology 19, 455301 (2008)

L.C. Kimerling, L.D. Negro, S. Saini, Y. Yi, D. Ahn, S. Akiyama, D. Cannon, J. Liu, J.G. Sandland, D. Sparacin, J. Michel, K. Wada, M.R. Watts, Monolithic silicon microphotonics. Top. Appl. Phys. 94, 89–119 (2004)

K.K. Lee, D.R. Lim, L.C. Kimerling, J. Shin, F. Cerrina, Fabrication of ultralow-loss Si/SiO2 waveguides by roughness reduction. Opt. Lett. 26(23), 1888–1890 (2001)

N. Tsumita, J. Melngailis, A.M. Hawryluk, H.I. Smith, Fabrication of x-ray masks using anisotropic etching of (110) Si and shadowing techniques. J. Vac. Sci. Technol. B 19, 1211–1213 (1981)

J. Arentoft, T. Sondergaard, M. Kristensen, A. Boltasseva, M. Thorhauge, L. Frandsen, Low-loss silicon-on-insulator photonic crystal waveguides. Electron. Lett. 38, 274–275 (2002)

W.H. Juan, S.W. Pang, Controlling sidewall smoothness for micromachined Si mirrors and lenses. J. Vac. Sci. Technol. B 14, 4080–4084 (1996)

Q.F. Xia, P.F. Murphy, H. Gao, S.Y. Chou, Ultrafast and selective reduction of sidewall roughness in silicon waveguides using self-perfection by liquefaction. Nanotechnology 20, 345302 (2009)

G. Schmid, Large clusters and colloids-metals in the embryonic state. Chem. Rev. 92, 1709–1727 (1992)

W.X. Zhang, Nanoscale iron particles for environmental remediation: An overview. J. Nanopart. Res. 5, 323–332 (2003)

W. Fritzsche, T.A. Taton, Metal nanoparticles as labels for heterogeneous, chip-based DNA detection. Nanotechnology 14, R63–R73 (2003)

S. Sun, C.B. Murray, D. Weller, L. Folks, A. Moser, Monodisperse FePt nanoparticles and ferromagnetic FePt nanocrystal superlattices. Science 287, 1989–1992 (2000)

H.-M. So, J. Kim, W.S. Yun, J.W. Park, J.-J. Kim, D.-J. Won, Y. Kang, C. Lee, Molecule-based single electron transistor. Physica E 18, 243–244 (2003)

Z.C. Wang, G. Chumanov, WO3 sol–gel modified Ag nanoparticle arrays for electrochemical modulation of surface plasmon resonance. Adv. Mater. 15, 1285–1289 (2003)

G. Leo, Y. Chushkin, S. Luby, E. Majkova, I. Kostic, M. Ulmeanu, A. Luches, M. Giersig, M. Hilgendorff, Ordering of free-standing co nanoparticles. Mater. Sci. Eng. C, Biomim. Supramol. Syst. 23, 949–952 (2003)

S.W. Chen, Langmuir-blodgett fabrication of two-dimensional robust crosslinked nanoparticle assemblies. Langmuir 17, 2878–2884 (2001)

J. Bosbach, D. Martin, F. Stietz, T. Wenzel, F. Trager, Laser-based method for fabricating monodisperse metallic nanoparticles. Appl. Phys. Lett. 74, 2605–2607 (1999)

T. Wenzel, J. Bosbach, A. Goldmann, F. Stietz, F. Trager, Shaping nanoparticles and their optical spectra with photons. Appl. Phys. B 69, 513–517 (1999)

M. Kawasaki, M. Hori, Laser-induced conversion of noble metal-island films to dense monolayers of spherical nanoparticles. J. Phys. Chem. B 107, 6760–6765 (2003)

D.Q. Yang, M. Meunier, E. Sacher, Excimer laser manipulation and pattering of gold nanoparticles on the SiO2/Si surface. J. Appl. Phys. 95, 5023–5026 (2004)

S. Gupta, D. Choudhary, A. Sarma, Study of carbonaceous clusters in irradiated polycarbonate with UV-VIS spectroscopy. J. Polym. Sci. Part B, Polym. Phys. 38, 1589–1594 (2000)

S. Hofmann, C. Ducati, J. Robertson, B. Kleinsorge, Low-temperature growth of carbon nanotubes by plasma-enhanced chemical vapor deposition. Appl. Phys. Lett. 83, 135–137 (2003)

S. Hofmann, C. Ducati, B. Kleinsorge, J. Robertson, Direct growth of aligned carbon nanotube field emitter arrays onto plastic substrates. Appl. Phys. Lett. 83, 4661–4663 (2003)

M.K. Min, J.H. Cho, K.W. Cho, H. Kim, Particle size and alloying effects of Pt-based alloy catalysts for fuel cell applications. Electrochim. Acta 45, 4211–4217 (2000)

J. Bischof, D. Scherer, S. Herminghaus, P. Leiderer, Dewetting modes of thin metallic films: nucleation of holes and spinodal dewetting. Phys. Rev. Lett. 77, 1536–1539 (1996)

J. Lee, W. Shimoda, T. Tanaka, Temperature dependence of surface tension of liquid Sn–Ag, In–Ag and In–Cu alloys. Meas. Sci. Technol. 16, 438–442 (2005)

W.J. Yao, X.J. Han, M. Chen, B. Wei, Z.Y. Guo, Surface tension of undercooled liquid cobalt. J. Phys., Condens. Matter 14, 7479–7485 (2002)

Q.F. Xia, S.Y. Chou, The fabrication of periodic metal nanodot arrays through pulsed laser melting induced fragmentation of metal nanogratings. Nanotechnology 20, 285310 (2009)

L. Rayleigh, On the instability of jets. Proc. Lond. Math. Soc. 10, 4–13 (1878)

F.A. Nichols, W.W. Mullins, Surface- (interface-) and volume-diffusion contributions to morphological changes driven by capilliarity. Trans. Metall. Soc. AIME 233, 1840–1848 (1965)

R.H. Austin, J.P. Brody, E.C. Cox, T. Duke, W. Volkmuth, Stretch genes. Phys. Today 50(2), 32–38 (1997)

H. Asoh, K. Nishio, M. Nakao, A. Yokoo, T. Tamamura, H. Masuda, Fabrication of ideally ordered anodic porous alumina with 63 nm hole periodicity using sulfuric acid. J. Vac. Sci. Technol. B 19(2), 569–572 (2001)

C.K. Harnett, G.W. Coates, H.G. Craighead, Heat-depolymerizable polycarbonates as electron beam patternable sacrificial layers for nanofluidics. J. Vac. Sci. Technol. B 19(6), 2842–2845 (2001)

D.M. Cannon, B.R. Flachsbart, M.A. Shannon, J.V. Sweedler, P.W. Bohn, Fabrication of single nanofluidic channels in poly(methylmethacrylate) films via focused-ion beam milling for use as molecular gates. Appl. Phys. Lett. 85(7), 1241–1243 (2004)

H. Cao, Z.N. Yu, J. Wang, J.O. Tegenfeldt, R.H. Austin, E. Chen, W. Wu, S.Y. Chou, Fabrication of 10 nm enclosed nanofluidic channels. Appl. Phys. Lett. 81(1), 174–176 (2002)

W. Reisner, K.J. Morton, R. Riehn, Y.M. Wang, Z.N. Yu, M. Rosen, J.C. Sturm, S.Y. Chou, E. Frey, R.H. Austin, Statics and dynamics of single DNA molecules confined in nanochannels. Phys. Rev. Lett. 94(19) (2005)

L.J. Guo, X. Cheng, C.F. Chou, Fabrication of size-controllable nanofluidic channels by nanoimprinting and its application for DNA stretching. Nano Lett. 4(1), 69–73 (2004)

H.P. Chou, C. Spence, A. Scherer, S. Quake, A microfabricated device for sizing and sorting DNA molecules. Proc. Natl. Acad. Sci. USA 96(1), 11–13 (1999)

M. Stjernstrom, J. Roeraade, Method for fabrication of microfluidic systems in glass. J. Micromech. Microeng. 8(1), 33–38 (1998)

S.W. Turner, A.M. Perez, A. Lopez, H.G. Craighead, Monolithic nanofluid sieving structures for DNA manipulation. J. Vac. Sci. Technol. B 16(6), 3835–3840 (1998)

W.L. Li, J.O. Tegenfeldt, L. Chen, R.H. Austin, S.Y. Chou, P.A. Kohl, J. Krotine, J.C. Sturm, Sacrificial polymers for nanofluidic channels in biological applications. Nanotechnology 14(6), 578–583 (2003)

Q.F. Xia, K.J. Morton, R.H. Austin, S.Y. Chou, Sub-10 nm self-enclosed self-limited nanofluidic channel arrays. Nano Lett. 8, 3830–3833 (2008)

D.H. Auston, J.A. Golovchenko, A.L. Simons, C.M. Surko, T.N.C. Venkatesan, Dynamics of Q-switched laser annealing. Appl. Phys. Lett. 34(11), 777–779 (1979)

A.D. McLachlan, F.P. Meyer, Temperature-dependence of the extinction coefficient of fused-silica for Co2-laser wavelengths. Appl. Opt. 26(9), 1728–1731 (1987)

Author information

Authors and Affiliations

Corresponding author

Additional information

Q. Xia current address: Information and Quantum Systems Lab, Hewlett-Packard Laboratories, 1501 Page Mill Road, Palo Alto, CA 94304, USA.