Abstract

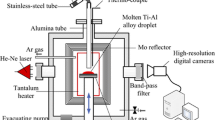

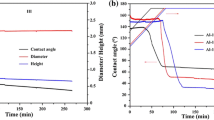

Scandia is a thermodynamically stable oxide and could be used as a structural material for a crucible in order to avoid a melt contamination. In the present study wetting experiments of Cu–Al and Cu–Ti melts on Scandia substrate were preformed at 1423 K by a sessile drop method. It was established that Al and Ti additions lead to the improved wetting and that the final contact angle decreases with increasing the additives concentration. For Al containing melts, the contact angle changes gradually with time, and a relatively thick interaction layer, which consists of Al2O3, Sc2O3, and metallic channels, was formed at the Sc2O3/Cu–Al interface. For Ti containing melts, the final contact angle is achieved already during heating, and an extremely thin layer based on a Ti–Sc–O compound was detected by AES at the Sc2O3/Cu–Ti interface.

The results of a thermodynamic analysis, which takes into account the formation free energy of the oxides, involved in the systems, and the thermodynamic properties of the liquid solutions are in a good agreement with the experimental observations.

Similar content being viewed by others

References

M.W. Chase, NIST-JANAF Thermochemical Tables, 4th edn. (American Institute of Physics for the National Institute of Standards and Technology, Woodbury, 1998)

C. Tournier, F.L. Guyadec, B. Lorrain, N. Eustathopoulos, in Proceedings of High Temperature Capillarity, Slovenia (1994), p. 160

C. Tournier, B. Lorrain, F.L. Guyadec, N. Eustathopoulos, J. Mater. Sci. Lett. 15, 485 (1996)

C. Tournier, B. Lorrain, F.L. Guyadec, L. Coudurier, N. Eustathopoulos, J. Nucl. Mater. 254, 215 (1998)

E.L. Dubinin, S.G. Gushchin, A.I. Timofeev, L.V. Uzberg, Izv. Vyssh. Uch. Zaved. Tsvetn. Metall. 5, 151 (1976)

T. Yoneoka, T. Mituyama, T. Terai, S. Tanaka, Tokyo Daigaku Genshiryoku Kenkyu Sogo Senta Shinpojumu, 4th edn. (1995), p. 162

J.E. Indacochea, W. Billings, G. McDeavitt, Ceram. Trans. 146, 103 (2005)

A.T. Pint, P.F. Torterelli, A. Jankowski, J. Hayes, T. Muroga, A. Suzuki, O.I. Yeliseyeva, V.M. Cheranov, J. Nucl. Mater. 329, 119 (2004)

A. Sawada, A. Suzuki, T. Terai, Fusion Eng. Des. 81, 579 (2006)

S. Barzilai, M. Aizenshtein, N. Froumin, N. Frage, Mater. Sci. Eng. A 420, 291 (2006)

M. Aizenshtein, S. Barzilai, N. Froumin, N. Frage, J. Mater. Sci. 43, 1259 (2008)

S. Barzilai, M. Aizenshtein, N. Froumin, N. Frage, J. Mater. Sci. 41, 5108 (2006)

Thermodynamic Data-Base SSUB3, version 3.1 (2001). Produced by Scientific Group Thermo-data Europe

M. Hilert, Phase Equilibria, Phase Diagram and Phase Transformation—their Thermodynamic Basis, 1st edn. (Cambridge University Press, Cambridge, 1998)

J.L. Murray, J. Phase Equilib. 19(4), 380 (1998)

V.M. Danilenko, N.Yu. Rusetskaya, O.L. Semenova, V.V. Yagodkin, Powder Metall. Metal Ceram. 38(7), 376 (1999)

M.A. Turchanin, Powder Metall. Metal Ceram. 45(3), 143 (2006)

I. Ansara, A.T. Dinsdale, M.H. Rand, Cost 507—Thermochemical Database for Light Metal Alloys, vol. 2 (European Communities, Belgium, 1998)

P. Wei, L. Jie, Mat. Sci. Eng. A Struct. 269, 104 (1999)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Barzilai, S., Nagar, H., Aizenshtein, M. et al. Interface interaction and wetting of Sc2O3 exposed to Cu–Al and Cu–Ti melts. Appl. Phys. A 95, 507–512 (2009). https://doi.org/10.1007/s00339-008-4930-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-008-4930-3