Abstract

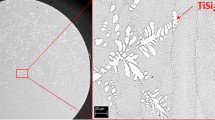

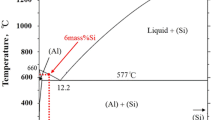

The interactions of Ti and Cr in a Sn0.3Ag0.7Cu melt with graphite were studied by continuous-heating and isothermal wetting experiments. Active Ti and Cr both had positive influences on the wettability of Sn0.3Ag0.7Cu on graphite. The Sn0.3Ag0.7Cu-Ti melt began to spread on graphite at 650 °C, while the Sn0.3Ag0.7Cu-Cr melt needed a temperature higher than 750 °C. Under the same processes, the spreading of the Sn0.3Ag0.7Cu-Cr melt was faster than that of the Sn0.3Ag0.7Cu-Ti melt. For the Sn0.3Ag0.7Cu-Ti/graphite system, the final contact angle was dependent on the isothermal temperature rather than the content of Ti, and the opposite was observed for the Sn0.3Ag0.7Cu-Cr/graphite system. Microanalyses revealed that nonstoichiometric TiCx and Cr-C compounds (Cr3C2 and Cr7C3) formed at the droplet/graphite interface. A smaller stoichiometry x of TiCx or more Cr7C3 in the Cr-C mixture indicated a better wetting. The thermodynamics of the interfacial reaction was calculated, and it was favorable. The faster spreading of the Sn0.3Ag0.7Cu-Cr melt and the more violent interfacial reaction were due to the higher activity of Cr than Ti in the melt.

Similar content being viewed by others

References

B. Venkataraman and G. Sundararajan: Acta Mater., 2002, vol. 50, pp. 1153-1163

S. Makimura, H. Ozaki, H. Okamura, M. Futakawa, T. Naoe, Y. Miyake, N. Kawamura, K. Nishiyama and M. Kawai: J. Nucl. Mater., 2008, vol. 377, pp. 28-33

N. V. Apollo, D. Lau, A. Ahnood, A. Stacey, K. Ganesan, S. G. Lichter, K. Fox, J. Foroughi, H. Meffin and G. G. Wallace: Carbon, 2016, vol. 107, pp. 180-189

H. Wang, J. Cao and J. Feng: Scripta Mater., 2010, vol. 63, pp. 859-862

N. Moutis, C. Jimenez, X. Azpiroz, T. Speliotis, C. Wilhelmi, S. Messoloras and K. Mergia: J. Mater. Sci., 2010, vol. 45, pp. 74-81

A. K. Ray, A. Kar, S. Kori, L. Pathak and A. Sonnad: J. Mater. Eng. Perform., 2013, vol. 22, pp. 258-266

K. Landry, S. Kalogeropoulou and N. Eustathopoulos: Mater. Sci. Eng., A, 1998, vol. 254, pp. 99-111

W. Fu, S. Hu, X. Song, J. Li, J. Cao, J. Feng and G. Wang: Carbon, 2017, vol. 121, pp. 536-543

X. G. Song, J. H. Chai, S. P. Hu, J. Cao, J. C. Feng and D. Y. Tang: J. Alloy. Compd., 2017, vol. 696, pp. 1199-1204

W. Fu, S. Hu, X. Song, C. Jin, J. Li, Y. Zhao, J. Cao and G. Wang: Ceram. Int., 2017, vol. 43, pp. 13206-13213

L. Yang, P. Shen, Q. Lin, F. Qiu and Q. Jiang: Mater. Chem. Phys., 2010, vol. 124, pp. 499-503

L. Yang, P. Shen, Q. Lin, F. Qiu and Q. Jiang: Appl. Surf. Sci., 2011, vol. 257, pp. 6276-6281

N. Sobczak, J. Sobczak, P. Rohatgi, M. Ksiazek, W. Radziwill and J. Morgiel: Interaction between Ti or Cr containing copper alloys and porous graphite substrate. In Proceedings of 2nd International Conference on High Temperature Capillarity; Cracow, 1997, pp. 145–52.

D. Mortimer and M. Nicholas: J. Mater. Sci., 1970, vol. 5, pp. 149-155

O. Dezellus, F. Hodaj, A. Mortensen and N. Eustathopoulos: Scripta Mater., 2001, vol. 44, pp. 2543-2549

L. Gremillard, E. Saiz, J. Chevalier and A. P. Tomsia: Zeitschrift Für Metallkunde, 2004, vol. 95, pp. 261-265

L. Gremillard, E. Saiz, V. R. Radmilovic and A. P. Tomsia: J. Mater. Res., 2006, vol. 21, pp. 3222-3233

E. Saiz, R. Cannon and A. Tomsia: Acta Mater., 2000, vol. 48, pp. 4449-4462

S. Hu, Y. Lei, X. Song, J. Kang, Y. Zhao, J. Cao and D. Tang: J. Mater. Sci., 2018, vol. 53, pp. 6864-6871

R. Koleňák, P. Šebo, M. Provazník, M. Koleňáková and K. Ulrich: Mater. Des., 2011, vol. 32, pp. 3997-4003

W. Fu, X. Song, S. Hu, J. Chai, J. Feng and G. Wang: Mater. Des., 2015, vol. 87, pp. 579-585

R. Standing and M. Nicholas: J. Mater. Sci., 1978, vol. 13, pp. 1509-1514

H. Okamoto: J. Phase Equilib. Diff., 2010, vol. 31, pp. 202-203

M. Venkatraman and J. Neumann: Bulletin of Alloy Phase Diagrams, 1990, vol. 11, pp. 152-159

[25] M. Venkatraman and J. Neumann: J. Phase Equilib., 1988, vol. 9, pp. 159-162

N. Zarrinfar, P. Shipway, A. Kennedy and A. Saidi: Scripta Mater., 2002, vol. 46, pp. 121-126

N. Frage, N. Froumin and M. Dariel: Acta Mater., 2002, vol. 50, pp. 237-245

L. Lu, J. Y. H. Fuh, Z. D. Chen, C. C. Leong and Y. S. Wong: Mater. Res. Bull., 2000, vol. 35, pp. 1555-1561

H. Kleykamp: J. Alloy. Compd., 2001, vol. 321, pp. 138-145

G. Vassilev: Journal of Mining and Metallurgy, Section B: Metallurgy, 2005, vol. 41, pp. 79-93

W. Fu, X. G. Song, Y. X. Zhao, J. Cao, J. C. Feng, C. Jin and G. D. Wang: Mater. Des., 2017, vol. 115, pp. 1-7

R. Voytovych, F. Robaut and N. Eustathopoulos: Acta Mater., 2006, vol. 54, pp. 2205-2214

N. Eustathopoulos and R. Voytovych: J. Mater. Sci., 2016, vol. 51, pp. 425-437

G. Kumar and K. N. Prabhu: Adv. Colloid. Interfac., 2007, vol. 133, pp. 61-89

Z. Moser, W. Gasior and J. Pstruś: J. Phase Equilib., 2001, vol. 22, pp. 254-258

A. Miriyev, M. Sinder and N. Frage: Acta Mater., 2014, vol. 75, pp. 348-355

F. Hodaj, O. Dezellus, J. Barbier, A. Mortensen and N. Eustathopoulos: J. Mater. Sci., 2007, vol. 42, pp. 8071-8082

R. Voitovitch, A. Mortensen, F. Hodaj and N. Eustathopoulos: Acta Mater., 1999, vol. 47, pp. 1117-1128

Acknowledgments

We are grateful to the helpful discussion and suggestions of Dr. V. Fabrizio and Dr. A. Passerone of Inst. of Condensed Matter Chemistry and Technologies for Energy-ICMATE-CNR. This project is supported by National Natural Science Foundation of China (Grant Nos. 51775138 and U1537206) and the Key Research & Development Program of Shandong Province (No. 2017GGX40103).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted May 14, 2018.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Fu, W., Hu, S., Song, X. et al. Wetting Behaviors and Interfacial Characteristics of Sn0.3Ag0.7Cu Alloys Containing Ti or Cr on Graphite. Metall Mater Trans A 49, 5823–5832 (2018). https://doi.org/10.1007/s11661-018-4895-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-018-4895-6