Abstract

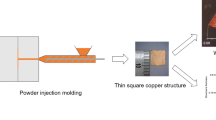

Micro powder injection molding (μPIM) is one of the potential processes for the mass production of metallic microstructures and micro components. Here, μPIM is the miniaturization of conventional PIM, which involves four processing steps: mixing, injection molding, debinding and sintering. This paper looks into the feasibility and effectiveness of μPIM as a key mass production process for the fabrication of metallic micro components. For it to be an effective re-production process, it is imperative to examine how well parts can be duplicated/fabricated from a master mold. In this work, the dimensional variation of high-aspect-ratio micro-pillars arrays, in particular the dimensional shrinkage, global warpage, and surface roughness at each stage of the μPIM process for a range of molding pressures, are quantified and compared in detail. The sensitivity of the dimensional variation of the microstructures to the packing pressure is reported. The mechanism behind the dimensional variation is analyzed.

Similar content being viewed by others

References

G. Baumeister, K. Mueller, R. Ruprecht, J. Hausselt, Microsyst. Technol. 8, 105 (2002)

V. Piotter, T. Haneman, R. Ruprecht, J. Hausselt, Microsyst. Technol. 3, 129 (1997)

R. Ruprecht, H. Kailb, B. Kowanz, W. Bacher, Microsyst. Technol. 2, 182 (1996)

R.A. Lawes, A.S. Homles, F.N. Goodall, Microsyst. Technol. 3, 17 (1996)

R. Ruprecht, T. Benzler, T. Hanemann, K. Müller, J. Konys, V. Piotter, G. Schanz, L. Schmidt, A. Thies, H. Wöllmer, J. Haußelt, Microsyst. Technol. 4, 28 (1997)

H. Lorenz, M. Despont, P. Vettiger, P. Renaud, Microsyst. Technol. 4, 143 (1998)

G.J. Schmitz, C. Brücker, P. Jacobs, J. Micromech. Microeng. 15, 1904 (2005)

K. Yoshikawa, H. Ohmori, RIKEN Review No.34 – Focus on Advances on Micro-mechanical Fabrication Techniques, April (2001)

B.Y. Tay, L. Liu, N.H. Loh, S.B. Tor, Y. Murakoshi, R. Maeda, Microsyst. Technol. 11, 210 (2005)

Z.Y. Liu, J. Mater. Sci. Lett. 20, 307 (2001)

Z.Y. Liu, N.H. Loh, S.B. Tor, Y. Murakoshi, R. Maeda, K.A. Khor, T. Shimidzu, Microsyst. Technol. 9, 507 (2003)

Z.Y. Liu, N.H. Loh, S.B. Tor, K.A. Khor, Y. Murakoshi, R. Maeda, T. Shimizu, J. Mater. Process. Technol. 127, 165 (2002)

G. Fu, N.H. Loh, S.B. Tor, B.Y. Tay, Y. Murakoshi, R. Maeda, Appl. Phys. A: Mater. 81, 495 (2005)

G. Fu, I. Reading, P. Chaturvedi, S.G. Li, S.B. Tor, S.F. Yoon, K. Youcef-Toumi, 4th Int. Symp. on Nanomanuf., Massachusetts Inst. Technol., USA (2006), p. 215

A. Rota, T.-V. Duong, T. Hartwig, Microsyst. Technol. 7, 225 (2002)

P. Dario, M.C. Carrozza, A. Benvenuto, A. Menciassi, J. Micromech. Microeng. 10, 235 (2000)

C.H. Lin, G.B. Lee, B.W. Chang, G.L. Chang, J. Micromech. Microeng. 12, 590 (2002)

G. Fu, N.H. Loh, S.B. Tor, B.Y. Tay, Y. Murakoshi, R. Maeda, Microsyst. Technol. 11, 1267 (2005)

S.B. Tor, N.H. Loh, G. Fu, B.Y. Tay, 4th Int. Symp. on Nanomanuf., Massachusetts Inst. Technol., USA (2006), p. 228

Author information

Authors and Affiliations

Corresponding author

Additional information

PACS

81.20.Ev; 81.20.Hy; 81.70.Fy; 07.60.Ly; 81.05.-t

Rights and permissions

About this article

Cite this article

Li, S., Fu, G., Reading, I. et al. Dimensional variation in production of high-aspect-ratio micro-pillars array by micro powder injection molding. Appl. Phys. A 89, 721–728 (2007). https://doi.org/10.1007/s00339-007-4150-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-007-4150-2