Abstract

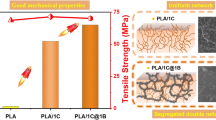

An updated organic solvation-assisted intercalation and collection (OAIC) strategy was developed to prepare high-quality 2D transition metal carbon/nitride (MXene) and evaluate its effects on the structure and properties of polylactide (PLA). Then, PLA composites with different MXene contents were prepared by solution casting method. Transmission electron microscopy, scanning electron microscopy, Fourier transform infrared spectroscopy, UV–visible spectrometry, x-ray diffraction, differential scanning calorimetry, polarized optical microscopy and mechanical tests were used to characterize the MXene/PLA composites. Also, physical models were established to describe the modification mechanism of MXene on PLA. The results show that our updated OAIC strategy successfully prepared single-layered, large-sized MXene nanosheets, which can disperse in both aqueous phase and organic solvent uniformly and stably. MXene and PLA are physically blended in the resultant composites, since PLA shows the typical spherulite morphology. Crystallite size of PLA was refined by the as-synthesized MXene nanosheets. The MXene/PLA composites illustrated prominent UV shielding effect: its UV shielding performance is very close to 100% when the MXene reaches up to 4.0 parts per hundreds of resins (phr). Elongation at break increases to 95.85% with 3.5 phr of MXene, which is 4.32 times that of pure PLA. Thermal conduction of the resultant PLA composites was greatly improved with small amount of MXene: its thermal conductivity was increased up to 0.59 W·m−1·K−1 with 1.0 phr of MXene, which is 2.2 times that of pure PLA.

Graphical abstract

Similar content being viewed by others

Data availability

No datasets were generated or analysed during the current study.

References

Geyer R, Jambeck JR, Law KL (2017) Production, use, and fate of all plastics ever made. Sci Adv. https://doi.org/10.1126/sciadv.1700782

Kwon G, Cho D, Park J, Bhatnagar A, Song H (2023) A review of plastic pollution and their treatment technology: a circular economy platform by thermochemical pathway. Chem Eng J 2023:464. https://doi.org/10.1016/j.cej.2023.142771

Van Geem KM (2023) (2023) Plastic waste recycling is gaining momentum. Science 381(6658):607–608. https://doi.org/10.1126/science.adj2807

Hinton ZR, Talley MR, Kots PA, Le AV, Zhang T, Mackay ME et al (2022) Innovations toward the valorization of plastics waste. Annu Rev Mater Res 52:249–280. https://doi.org/10.1146/annurev-matsci-081320-032344

Chawla S, Varghese BS, Chithra A, Hussain CG, Kecili R, Hussain CM (2022) Environmental impacts of post-consumer plastic wastes: treatment technologies towards eco-sustainability and circular economy. Chemosphere 2022:308. https://doi.org/10.1016/j.chemosphere.2022.135867

Daehn K, Basuhi R, Gregory J, Berlinger M, Somjit V (2022) Olivetti EA (2022) Innovations to decarbonize materials industries. Nat Rev Mater 7(4):275–294. https://doi.org/10.1038/s41578-021-00376-y

Michell RM, Ladelta V, Da Silva E, Müller AJ (2023) Hadjichristidis N (2023) Poly(lactic acid) stereocomplexes based molecular architectures: Synthesis and crystallization. Prog Polym Sci 146:101742. https://doi.org/10.1016/j.progpolymsci.2023.101742

Guseva DV, Glagolev MK, Lazutin AA, Vasilevskaya VV (2023) Revealing structural and physical properties of polylactide: What simulation can do beyond the experimental methods. Polym Rev. https://doi.org/10.1080/15583724.2023.2174136

Kost B, Basko M, Bednarek M, Socka M, Kopka B, Lapienis G et al (2022) The influence of the functional end groups on the properties of polylactide-based materials. Prog Polym Sci 2022:130. https://doi.org/10.1016/j.progpolymsci.2022.101556

Banerjee R (2021) Ray SS (2021) An overview of the recent advances in polylactide-based sustainable nanocomposites. Polym Eng Sci 61(3):617–649. https://doi.org/10.1002/pen.25623

Brzezinski M, Socka M (2019) Kost B (2019) Microfluidics for producing polylactide nanoparticles and microparticles and their drug delivery application. Polym Int 68(6):997–1014. https://doi.org/10.1002/pi.5753

Lule Z (2019) Kim J (2019) Thermally conductive and highly rigid polylactic acid (PLA) hybrid composite filled with surface treated alumina/nano-sized aluminum nitride. Compos A 124:105506. https://doi.org/10.1016/j.compositesa.2019.105506

Raquez J, Habibi Y, Murariu M (2013) Dubois P (2013) Polylactide (PLA)-based nanocomposites. Prog Polym Sci 38(10–11):1504–1542. https://doi.org/10.1016/j.progpolymsci.2013.05.014

Nofar M, Sacligil D, Carreau PJ, Kamal MR (2019) Poly (lactic acid) blends: Processing, properties and applications. Int J Biol Macromol 125:307–360. https://doi.org/10.1016/j.ijbiomac.2018.12.002

Rezvani Ghomi E, Khosravi F, Saedi Ardahaei A, Dai Y, Neisiany RE, Foroughi F et al (2021) The life cycle assessment for polylactic acid (PLA) to make it a low-carbon material. Polymers. https://doi.org/10.3390/polym13111854

Döhler N, Wellenreuther C (2022) Wolf A (2022) Market dynamics of biodegradable bio-based plastics: projections and linkages to European policies. EFB Bioeconomy J 2:100028. https://doi.org/10.1016/j.bioeco.2022.100028

Naguib M, Kurtoglu M, Presser V, Lu J, Niu J, Heon M et al (2011) Two-dimensional nanocrystals produced by exfoliation of Ti3AlC2. Adv Mater 23(37):4248–4253. https://doi.org/10.1002/adma.201102306

Anasori B, Lukatskaya MR (2017) 2D metal carbides and nitrides (MXenes) for energy storage. Nat Rev Mater 2(2):16098. https://doi.org/10.1038/natrevmats.2016.98

Natu V (2023) MXene surface terminations: a perspective. J Phys Chem C 127(41):20197–20206. https://doi.org/10.1021/acs.jpcc.3c04324

Shahzad F, Alhabeb M, Hatter CB, Anasori B, Man Hong S, Koo CM et al (2016) Electromagnetic interference shielding with 2D transition metal carbides MXenes. Science 353(6304):1137–1140. https://doi.org/10.1126/science.aag2421

Li X, Liu F, Huang D, Xue N, Dang Y, Zhang M et al (2020) Nonoxidized MXene quantum dots prepared by microexplosion method for cancer catalytic therapy. Adv Funct Mater 30(24):2000308. https://doi.org/10.1002/adfm.202000308

Sun W, Shah SA, Chen Y, Tan Z, Gao H, Habib T et al (2017) Electrochemical etching of Ti2AlC to Ti2CTx (MXene) in low-concentration hydrochloric acid solution. J Mater Chem A Mater 5(41):21663–21668. https://doi.org/10.1039/C7TA05574A

Li T, Yao L, Liu Q, Gu J, Luo R, Li J et al (2018) Fluorine-free synthesis of high-purity Ti3C2Tx (T=OH, O) via alkali treatment. Angew Chem Int Edit 57(21):6115–6119. https://doi.org/10.1002/anie.201800887

Li Y, Shao H, Lin Z, Lu J, Liu L, Duployer B et al (2020) A general Lewis acidic etching route for preparing MXenes with enhanced electrochemical performance in non-aqueous electrolyte. Nat Mater 19(8):894–899. https://doi.org/10.1038/s41563-020-0657-0

Li M, Lu J, Luo K, Li Y, Chang K, Chen K et al (2019) Element replacement approach by reaction with Lewis acidic molten salts to synthesize nanolaminated MAX phases and MXenes. J Am Chem Soc 141(11):4730–4737. https://doi.org/10.1021/jacs.9b00574

Ghazaly AE, Ahmed H, Rezk AR, Halim J, Persson POÅ, Yeo LY et al (2021) Ultrafast, one-step, salt-solution-based acoustic synthesis of Ti3C2 MXene. ACS Nano 15(3):4287–4293. https://doi.org/10.1021/acsnano.0c07242

Huang X (2020) A Facile, High-yield, and freeze-and-thaw-assisted approach to fabricate MXene with plentiful wrinkles and its application in on-chip micro-supercapacitors. Adv Funct Mater 30(12):1910048. https://doi.org/10.1002/adfm.201910048

Zhang Q, Fan R, Cheng W, Ji P, Sheng J, Liao Q et al (2022) Synthesis of large-area MXenes with high yields through power-focused delamination utilizing vortex kinetic energy. Adv Sci 9(28):2202748. https://doi.org/10.1002/advs.202202748

Qu D, Jian Y, Guo L, Su C, Tang N, Zhang X et al (2021) An organic solvent-assisted intercalation and collection (OAIC) for Ti3C2Tx MXene with controllable sizes and improved yield. Nanomicro Lett 13(1):188. https://doi.org/10.1007/s40820-021-00705-4

Liu Y, Cao L, Yuan D (2018) Design of super-tough co-continuous PLA/NR/SiO2 TPVs with balanced stiffness-toughness based on reinforced rubber and interfacial compatibilization. Compos Sci Technol 165:231–239. https://doi.org/10.1016/j.compscitech.2018.07.005

Zha X, Li T, Bao R, Bai L, Liu Z, Yang W et al (2017) Constructing a special “sosatie” structure to finely dispersing MWCNT for enhanced electrical conductivity, ultra-high dielectric performance and toughness of iPP/OBC/MWCNT nanocomposites. Compos Sci Technol 139:17–25. https://doi.org/10.1016/j.compscitech.2016.12.011

Xue Y, Feng J, Huo S, Song P, Yu B, Liu L et al (2020) Polyphosphoramide-intercalated MXene for simultaneously enhancing thermal stability, flame retardancy and mechanical properties of polylactide. Chem Eng J 397:125336. https://doi.org/10.1016/j.cej.2020.125336

Chen J, Liu Z, Qiu S, Li Y, Sun J, Li H et al (2023) A new strategy for the preparation of polylactic acid composites with flame retardancy, UV resistance, degradation, and recycling performance. Chem Eng J 472:145000. https://doi.org/10.1016/j.cej.2023.145000

Xue Y, Zhang T, Tian L, Feng J, Song F, Pan Z et al (2023) A molecularly engineered bioderived polyphosphonate containing Schiff base towards fire-retardant PLA with enhanced crystallinity and mechanical properties. Chem Eng J 472:144986. https://doi.org/10.1016/j.cej.2023.144986

Zhao Q, Wang B, Qin C, Li Q (2021) Nonisothermal melt and cold crystallization behaviors of biodegradable poly(lactic acid)/Ti3C2Tx MXene nanocomposites. J Therm Anal Calorim 147:2239–2251. https://doi.org/10.1007/s10973-020-10502-7

Krishnan S, Pandey P, Mohanty S (2016) Toughening of polylactic acid: An overview of research progress. Polym-Plast Technol Eng 55(15):1623–1652. https://doi.org/10.1080/03602559.2015.1098698

Wang Y, Liang L, Du Z, Wang Y, Liu C (2021) Biodegradable PLA/CNTs/Ti3C2Tx MXene nanocomposites for efficient electromagnetic interference shielding. J Mater Sci-Mater El 32(21):25952–25962. https://doi.org/10.1007/s10854-021-05377-9

Liu J, Liu Z, Zhang H, Chen W, Zhao Z, Wang Q et al (2020) Ultrastrong and highly conductive MXene-based films for high-performance electromagnetic interference shielding. Adv Electron Mater 6(1):1901094. https://doi.org/10.1002/aelm.201901094

Lu X, Sheng M, Deng Y, Lu J, Wu H, Li Y et al (2022) Dynamically vulcanized poly (lactic acid)/polyurethane/MXene nanocomposites with balanced stiffness and toughness. Polymer 255:125165. https://doi.org/10.1016/j.polymer.2022.125165

Cao W, Chen F, Zhu Y, Zhang Y, Jiang Y, Ma M et al (2018) Binary strengthening and toughening of MXene/cellulose nanofiber composite paper with nacre-inspired structure and superior electromagnetic interference shielding properties. ACS Nano 12(5):4583–4593. https://doi.org/10.1021/acsnano.8b00997

Huang H, Dong D, Li W, Zhang X, Zhang L, Chen Y et al (2020) Synergistic effect of MXene on the flame retardancy and thermal degradation of intumescent flame retardant biodegradable poly (lactic acid) composites. Chin J Chem Eng 28(7):1981–1993. https://doi.org/10.1016/j.cjche.2020.04.014

Du Z, Zhang G, Chen K, Zhou C, Zhu X, Zhang Y et al (2022) MXene/polylactic acid fabric-based resonant cavity for realizing simultaneous high-performance electromagnetic interference (EMI) shielding and efficient energy harvesting. ACS Appl Mater Interfaces 14(12):14607–14617. https://doi.org/10.1021/acsami.2c01160

Du Z, Chen K, Zhang Y, Wang Y, He P, Mi H et al (2021) Engineering multilayered MXene/electrospun poly(lactic acid) membrane with increscent electromagnetic interference (EMI) shielding for integrated Joule heating and energy generating. Compos Commun 26:100770. https://doi.org/10.1016/j.coco.2021.100770

Zhang P, Tong W, Liang C, Chen Y, Liu Y, Wang Z et al (2022) Enhancing the endogenous triboelectricity of a polylactic acid nanofiber film by controlling the MXene content and distribution. J Mater Chem A Mater 10:24310–24319. https://doi.org/10.1039/D2TA05905C

Kyrylenko S, Kornienko V, Gogotsi O, Oleshko O, Kolesnyk M, Mishchenko O, et al., 2020 Bio-functionalization of electrospun polymeric nanofibers by Ti3C2Tx MXene. https://doi.org/10.1109/NAP51477.2020.9309612

Zhang Q, Lai H, Fan R, Ji P, Fu X (2021) High concentration of Ti3C2Tx MXene in organic solvent. ACS Nano 15(3):5249–5262. https://doi.org/10.1021/acsnano.0c10671

Suter JL, Sinclair RC (2020) Principles governing control of aggregation and dispersion of graphene and graphene oxide in polymer melts. Adv Mater 32(36):2003213. https://doi.org/10.1002/adma.202003213

Chen H, Wen Y, Qi Y, Zhao Q, Qu L (2020) Pristine titanium carbide MXene films with environmentally stable conductivity and superior mechanical strength. Adv Funct Mater 30(5):1906996. https://doi.org/10.1002/adfm.201906996

He M, Lu T, Jia Z, Tian H, Feng M, Zhang X et al (2022) Fabrication and properties of novel chitosan/ZnO composite bioplastic. Cellulose 29(1):233–243. https://doi.org/10.1007/s10570-021-04315-6

Eklund P, Beckers M, Jansson U, Högberg H (2010) The Mn+1AXn phases: materials science and thin-film processing. Thin Solid Films 518(8):1851–1878. https://doi.org/10.1016/j.tsf.2009.07.184

Ding H, Li Y, Li M, Chen K, Liang K, Chen G et al (2023) Chemical scissor-mediated structural editing of layered transition metal carbides. Science 379(6637):1130–1135. https://doi.org/10.1126/science.add5901

VahidMohammadi A, Rosen J, Gogotsi Y (2021) The world of two-dimensional carbides and nitrides MXenes. Science 372(6547):1581. https://doi.org/10.1126/science.abf1581

Zhang J, Wu J, Langner S, Zhao B, Xie Z, Hauch JA et al (2022) Exploring the steric hindrance of alkylammonium cations in the structural reconfiguration of quasi-2D perovskite materials using a high-throughput experimental platform. Adv Funct Mater 32(43):2207101. https://doi.org/10.1002/adfm.202207101

Puglisi A, Giovannini T, Antonov L (2019) Cappelli C (2019) Interplay between conformational and solvent effects in UV-visible absorption spectra: curcumin tautomers as a case study. Phys Chem Chem Phys 21(28):15504–15514. https://doi.org/10.1039/C9CP00907H

Zhang H, Shao C, Kong W, Wang Y, Cao W, Liu C et al (2017) Memory effect on the crystallization behavior of poly(lactic acid) probed by infrared spectroscopy. Eur Polym J 91:376–385. https://doi.org/10.1016/j.eurpolymj.2017.04.016

Pope CG (1997) 1997 X-ray diffraction and the Bragg equation. J Chem Educ 74(1):129. https://doi.org/10.1021/ed074p129

Muniz FTLA, Miranda MAEL (2016) The Scherrer equation and the dynamical theory of X-ray diffraction. Acta Crystallogr A 72(3):385–390. https://doi.org/10.1107/S205327331600365X

Niteesh Kumar SJ, Keshavamurthy R, Haseebuddin MR (2017) Mechanical properties of Aluminium-graphene composite synthesized by powder metallurgy and hot extrusion. Trans Indian Inst Met 70(3):605–613. https://doi.org/10.1007/s12666-017-1070-5

Tábi T, Ageyeva T (2022) The influence of nucleating agents, plasticizers, and molding conditions on the properties of injection molded PLA products. Mater Today Commun 32:103936. https://doi.org/10.1016/j.mtcomm.2022.103936

Belyakov A, Tikhonova M, Dolzhenko P, Sakai T (2019) On kinetics of grain refinement and strengthening by dynamic recrystallization. Adv Eng Mater 21(1):1800104. https://doi.org/10.1002/adem.201800104

Pinto AM, Cabral J, Tanaka DAP, Mendes AM (2013) Effect of incorporation of graphene oxide and graphene nanoplatelets on mechanical and gas permeability properties of poly(lactic acid) films. Polym Int 62(1):33–40. https://doi.org/10.1002/pi.4290

Monastyreckis G, Mishnaevsky L, Hatter CB, Aniskevich A, Gogotsi Y, Zeleniakiene D (2020) Micromechanical modeling of MXene-polymer composites. Carbon 2020(162):402–409. https://doi.org/10.1016/j.carbon.2020.02.070

McLauchlin AR (2016) Studies on the thermal and mechanical behavior of PLA-PET blends. J Appl Polym Sci 133(43):44147. https://doi.org/10.1002/app.44147

Sheng X, Zhao Y, Zhang L (2019) Properties of two-dimensional Ti3C2 MXene/thermoplastic polyurethane nanocomposites with effective reinforcement via melt blending. Compos Sci Technol 181:107710. https://doi.org/10.1016/j.compscitech.2019.107710

Eun JH, Kim DH, Jang IU, Sung SM, Kim MS, Choi BK et al (2022) A study on mechanical properties and thermal properties of UHMWPE/MWCNT composite fiber with MWCNT content and draw ratio. J Eng Fiber Fabr 17:155892502211084. https://doi.org/10.1177/15589250221108484

Wang Z, Wu Z, Weng L, Ge S, Jiang D, Huang M et al (2023) A roadmap review of thermally conductive polymer composites: critical factors, progress, and prospects. Adv Funct Mater 33(36):2301549. https://doi.org/10.1002/adfm.202301549

Meng X, Yu H, Wang L, Wu X (2021) Recent progress on fabrication and performance of polymer composites with highly thermal conductivity. Macromol Mater Eng 306(11):2100434. https://doi.org/10.1002/mame.202100434

Singh AK, Panda BP, Mohanty S, Nayak SK (2018) Recent developments on epoxy-based thermally conductive adhesives (TCA): a review. Polym-Plast Technol Eng 57(9):903–934. https://doi.org/10.1080/03602559.2017.1354253

Guo J, Tsou C, Yu Y, Wu C, Zhang X, Chen Z et al (2021) Conductivity and mechanical properties of carbon black-reinforced poly(lactic acid) (PLA/CB) composites. Iran Polym J 30(12):1251–1262. https://doi.org/10.1007/s13726-021-00973-2

Fu JF, Shi LY, Zhang DS, Zhong QD (2010) Effect of nanoparticles on the performance of thermally conductive epoxy adhesives. Polym Eng Sci 50(9):1809–1819. https://doi.org/10.1002/pen.21705

Chen L, Shi X, Yu N, Zhang X, Du X (2018) Measurement and analysis of thermal conductivity of Ti3C2Tx MXene films. Materials 11(9):1701. https://doi.org/10.3390/ma11091701

Sun L, Feng C, Cui Y (2017) Influence of temperature and moisture content on the thermal conductivity of building materials. J Civil Archit Envir Eng 39(6):123–128. https://doi.org/10.11835/j.issn.1674-4764.2017.06.017

Wang J, Hu L, Li W, Ouyang Y (2022) Development and perspectives of thermal conductive polymer composites. Nanomaterials 12(20):3574

Acknowledgements

The authors thank the financial support from the Education Department of the Shaanxi Provincial Government (Program No. 22JC038). Thanks go to Prof. Jianhui Tian at XATU for his sincere help in thermal conductivity measurement.

Author information

Authors and Affiliations

Contributions

Qiang T and Gao HH involved in design of the experiment, Analysis and interpretation of data, writing the main manuscript, editing. Qi XY and Qiang H involved in acquisition the data. Hu L and Hu N involved in critical revision of the manuscript. Wang S involved in validation of the final version. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing financial interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Qiang, T., Qi, X., Gao, H. et al. UV-shielding, flexible and enhanced thermal-conductive polylactide composites modified with single-layered, large-sized MXene nano-sheets. Polym. Bull. (2024). https://doi.org/10.1007/s00289-024-05303-z

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00289-024-05303-z