Abstract

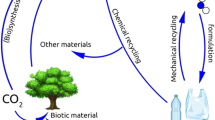

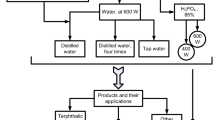

Chemical recycling of Polyethylene Terephthalate (PET) has gotten great attention today. Aminolysis, one of the chemical recycling methods, is the degradation of polyesters using primary amines that attack its functional group. It is not much explored as a commercial recycling technique among the chemical recycling methods. This review aims to explain the aminolysis method of PET degradation in terms of reaction operating conditions such as PET to solvent ratio, temperature, degradation time, and catalyst dosage. The primary product of aminolysis of PET is also discussed and their most common application in the preparation of secondary products is presented. Thus, PET-derived primary products can be used to synthesize polymers such as polyurethane and develop enhanced products like paints and coatings. Additionally, nonconventional procedures of PET aminolysis techniques: such as microwave radiation, ultrasound, UV radiation, and sunlight were assessed by comparison.

Similar content being viewed by others

Data availability

data sharing does not apply to this article since no new data is created or analyzed

References

Nisticò R (2020) Polyethylene terephthalate (PET) in the packaging industry. Polym Test 90:106707

Ge-Zhang S, Liu H, Song M, Wang Y, Yang H, Fan H, Mu L (2022) Advances in Polyethylene Terephthalate Beverage Bottle optimization: a Mini Review. Polymers 14(16):3364

Majumdar A, Shukla S, Singh AA, Arora S (2020) Circular fashion: Properties of fabrics made from mechanically recycled poly-ethylene terephthalate (PET) bottles. Resour Conserv Recycl 161:104915

Karthik G, Balaji KV, Venkateshwara R, Rahul B (2015) Eco- Friendly Recycled PET (Polyethylene Terephthalate) Material for Automotive Canopy Strip Application. In SAE Technical Paper Series

Damayanti, Wu HS (2021) Strategic possibility routes of recycled pet, Polymers, vol. 13, no. 9. pp. 1–37, https://doi.org/10.3390/polym13091475

Mohammed AA (2017) Flexural behavior and analysis of reinforced concrete beams made of recycled PET waste concrete. Constr Build Mater 155:593–604

Taheri Z (2004) Management and processes of PET recycling. Pros. Of the First National Seminar on Recycling and Waste Management on Process Industries, 20–21 September, Tehran, Iran, p. 32

Hoffer A, Jancsek-Turóczi B, Tóth Á, Kiss G, Naghiu A, Andrea Levei E, Marmureanu L, MacHon A, Gelencsér A (2020) Emission factors for PM10 and polycyclic aromatic hydrocarbons (PAHs) from illegal burning of different types of municipal waste in households. Atmos Chem Phys 20(24):16135–16144. https://doi.org/10.5194/acp-20-16135-2020

Bolanle A, Zainon Z, Hassan A, Kamaruddin M, Hamid A, Amril S, Hussein A (2019) Current developments in chemical recycling of post-consumer polyethylene terephthalate wastes for new materials production: a review. J Clean Prod 225:1052–1064. https://doi.org/10.1016/j.jclepro.2019.04.019

Mora-cortes LF et al (2022) Biocompatible enhancement of poly (ethylene terephthalate) (PET) waste films by cold plasma aminolysis. J Chem Technol Biotechnol no May. https://doi.org/10.1002/jctb.7106

Hidayah N, Syafrudin (2018) A review on Landfill Management in the utilization of Plastic Waste as an alternative fuel. E3S Web Conf 31:1–6. https://doi.org/10.1051/e3sconf/20183105013

Chirayil CJ, Mishra RK, Thomas S (2019) Materials recovery, direct reuse and incineration of PET bottles. Elsevier Inc.

Pathak G et al (January, 2023) Plastic pollution and the open burning of plastic wastes. Glob Environ Chang 80. https://doi.org/10.1016/j.gloenvcha.2023.102648

Webb HK, Arnott J, Crawford RJ, Ivanova EP (2012) Plastic degradation and its environmental implications with special reference to poly (ethylene terephthalate). Polymers 5:1–18

Beghetto V, Sole R, Buranello C, Al-Abkal M, Facchin M (2021) Recent advancements in plastic packaging recycling: a mini-review. Mater (Basel) 14(17):1–24. https://doi.org/10.3390/ma14174782

Francis R (ed) (2016) Recycling of polymers: methods, characterization and applications. Wiley

Maurya A, Bhattacharya A, Khare SK (2020) Enzymatic remediation of polyethylene terephthalate (PET)–based polymers for effective management of plastic wastes: an overview. Front Bioeng Biotechnol 8:602325

Shojaei B, Abtahi M, Najafi M (2020) Chemical recycling of PET: a stepping-stone toward sustainability. Polym Adv Technol 31(12):2912–2938. https://doi.org/10.1002/pat.5023

Tawfik ME, Ahmed NM, Eskander SB (2011) Aminolysis of poly (ethylene terephthalate) wastes based on sunlight and utilization of the end product [bis (2-hydroxyethylene) terephthalamide] as an ingredient in the anticorrosive paints for the protection of steel structures. J Appl Polym Sci 120:2842–2855

Mittal A, Soni RK, Dutt K, Singh S (2010) Scanning electron microscopic study of hazardous waste flakes of polyethylene terephthalate (PET) by aminolysis and ammonolysis. J Hazard Mater 178 (1?3) 390–396

Lopes R, Duque-Ingunza I, De Rivas B, Arnaiz S, Gutie´rrez-Ortiz JI (2010) Chemical recycling of post-consumer PET wastes by glycolysis in the presence of metal salts. Polym Degrad Stab 95:1022–1028

Pham DD, Cho J (2021) Low-energy catalytic methanolysis of poly (ethyleneterephthalate). Green Chem 23(1):511–525. https://doi.org/10.1039/D0GC03536J

Acar I, Bal A, Güçlü G (2013) The use of intermediates obtained from aminoglycolysis of waste poly (ethylene terephthalate) (PET) for the synthesis of water-reducible alkyd resin. Can J Chem 91(5):357–363. https://doi.org/10.1139/cjc-2012-0370

Zanela TMP, Muniz EC, Almeida CAP (2018) Chemical recycling of poly(ethylene terephthalate) (PET) by alkaline hydrolysis and cata- lyzed glycolysis. Orbital 10(3):226–233. https://doi.org/10.17807/orbital.v10i3.1104

Parab YS, Pingale ND, Shukla SR (2011) Aminolytic Depolymerization of Poly (ethylene terephthalate) Bottle Waste by Conventional and Microwave Irradiation Heating. https://doi.org/10.1002/app

Zhang LN, Liu LZ, Yue QF, Zhu CC (2014) From aminolysis producer of PET waste to value-added products of polymer and assistants. Polym Polym Compos 22(1):13–16. https://doi.org/10.1177/096739111402200102

More AP, Kolkata SR, Rane PC, Mhaske ST (2017) Studies of different techniques of aminolysis of poly (ethylene terephthalate) with ethylenediamine. Polym Bull 74(8):3269–3282. https://doi.org/10.1007/s00289-016-1888-8

Mersha DA, Sendekie ZB (2022) High-Temperature Performance Enhancement of Bitumen by Waste PET-Derived Polyurethane, Adv. Mater. Sci. Eng, vol. 2022, https://doi.org/10.1155/2022/9567197

Vinitha V, Preeyanghaa M, Anbarasu M, Jeya G, Neppolian B (2022) Aminolytic depolymerization of polyethylene terephthalate wastes using sn – doped ZnO nanoparticles. J Polym Environ 30(9):3566–3581. https://doi.org/10.1007/s10924-022-02455-9

Rabiei N (2022) Aminolysis of polyesters for cracking and structure clarifying: a review. 3903–3919. https://doi.org/10.1002/pat.5837. August

Suhaimi NAS, Muhamad F, Abd NA, Razak, Zeimaran E (2022) Recycling of polyethylene terephthalate wastes: a review of technologies, routes, and applications. Polym Eng Sci 62(8):2355–2375. https://doi.org/10.1002/pen.26017

Magda E, Tawfik NM, Ahmed SBE (2010) Aminolysis of Poly (ethylene terephthalate) wastes based on sunlight and utilization of the end product [Bis (2-hydroxyethylene) Terephthalamide] as an ingredient in the anti corrosive paints for the Protection of Steel Structures. J Appl Polym Sci 116(5):2658–2667. https://doi.org/10.1002/app

Bäckström E, Odelius K, Hakkarainen M (2021) Ultrafast microwave assisted recycling of pet to a family of functional precursors and materials. Eur Polym J 151:110441

Ghosal K, Nayak C (2022) Recent advances in chemical recycling of polyethylene terephthalate waste into value added products for sustainable coating solutions-hope vs. hype. Mater Adv 3(4):1974–1992. https://doi.org/10.1039/d1ma01112j

Padhan RK, Gupta AA (2018) Preparation and evaluation of waste PET derived polyurethane polymer modified bitumen through in situ polymerization reaction. Constr Build Mater 158:337–345. https://doi.org/10.1016/j.conbuildmat.2017.09.147

Parab YS, Wasekar PA (2014) Novel synthesis, characterization and application of dibutyrate bis (2-hydroxyethyl) terephthalamide as a plasticizer in PVC compounding. Polym Bull 2695–2707. https://doi.org/10.1007/s00289-014-1218-y

Mhaske PCR, A. PMST (2017) Synthesis of tetra (2,2-hydroxyethylene) terephthalamide from PET waste and its application in synthesis of polyester amide coating. Pigm Resin Technol 46(1):40–47. https://doi.org/10.1108/PRT-09-2015-0087

George N, Kurian T (2015) Sodium Carbonate Catalyzed Aminolytic degradation of PET. Progress Rubber Plast Recycling Technol 32(3):153–168

More AP, Cute RA, Mhaske ST (2014) Chemical conversion of PET waste using ethanolamine to bias (2-hydroxyethyl) terephthalamide (BHETA) through aminolysis and a novel plasticizer for PVC. Iran Polym J (English Edition) 23(1):59–67. https://doi.org/10.1007/s13726-013-0200-0

Musale RM, Shukla SR (2016) Deep eutectic solvent as effective catalyst for aminolysis of polyethylene terephthalate (PET) waste. Int J Plast Technol 20(1):106–120. https://doi.org/10.1007/s12588-016-9134-7

Ghorbantabar S, Ghiass M, Yaghobi N, Bouhendi H (2021) Investigation of conventional analytical methods for determining conversion of polyethylene terephthalate waste degradation via aminolysis process. J Mater Cycles Waste Manage 23(2):526–536. https://doi.org/10.1007/s10163-020-01149-5

Kárpáti L, Fejér M, Kalocsai D, Molnár J, Vargha V (2019) Synthesis and characterization of isophorondiamine based epoxy hardeners from aminolysis of PET. Express Polym Lett 13(7):618–631. https://doi.org/10.3144/expresspolymlett.2019.52

Achilias DS, Tsintzou GP, Nikolaidis AK, Bikers DN, Karayannidis GP (2011) Aminolytic depolymerization of poly (ethylene terephthalate) waste in a microwave reactor. Polym Int 60(3):500–506. https://doi.org/10.1002/pi.2976

Tawfik ME, Eskander SB (2010) Chemical recycling of poly (ethylene terephthalate) waste using ethanolamine sorting of the end products. Polym Degrad Stab 95:187–194. https://doi.org/10.1016/j.polymdegradstab.2009.11.026

Pingale ND, Shukla SR (2010) Microwave-assisted aminolytic depolymerization of PET waste. Eur Polymer J 45(9):2695–2700. https://doi.org/10.1016/j.eurpolymj.2009.05.028

Shah RV, Borude VS, Shukla SR (2013) Recycling of PET waste using 3-amino-1-propanol by conventional or microwave irradiation and synthesis of bis-oxazin therefrom. J Appl Polym Sci 127(1):323–328. https://doi.org/10.1002/app.37900

Gopal J, Elumalai G, Tajuddin AAH, Ito Y, Vajiravelu S, Ravikumar D (2022) Recyclable clay-supported Heteropolyacid catalysts for complete glycolysis and Aminolysis of Post-consumer PET Beverage bottles. J Polym Environ 30(6):2614–2630. https://doi.org/10.1007/s10924-022-02386-5

Chan K, Kawai M, Yamake M, Zinchenko A (2023) Copper ion removal using a Waste-Plastic-Derived Hydrogel Adsorbent prepared via microwave-assisted PET aminolysis. Gels 9(11):1–11. https://doi.org/10.3390/gels9110874

Dolores M, Caputto DD (2022) Chemical upcycling of poly (ethylene terephthalate) waste: moving to a circular model. March 3269–3283. https://doi.org/10.1002/pol.20220137

Leng Z, Padhan RK, Sreeram A (2018) Production of a sustainable paving material through chemical recycling of waste PET into crumb rubber modified asphalt. J Clean Prod 180:682–688. https://doi.org/10.1016/j. Jclepro. 2018.01.171

Hoang C.N., Dang Y.H. (2013) Aminolysis of poly (ethylene terephthalate) waste with ethylenediamine and characterization of α, ω-diamond products. Polym Degrad Stab 98(3):697–708. https://doi.org/10.1016/j. Polymdegradstab. 2012.12.026

Mittal A, Soni RK, Dutt K, Singh S (2010) Scanning electron microscopic study of hazardous waste flakes of polyethylene terephthalate (PET) by aminolysis and ammonolysis. J Hazard Mater 178:390–396. https://doi.org/10.1016/j. Jhazmat. 2010.01.092

Aslzadeh MM, Sadeghi GMM, Abdouss M (2010) Synthesis and characterization of BHETA based new polyurethanes. Materialwiss Werkstofftech 41(8):682–688. https://doi.org/10.1002/mawe.201000584

Vandana J, Mukesh K, Anagha S (2018) Depolymerization Study of PET Waste Using Aminoethylethanolamine and recycled product application as Polyester Amide Synthesis. J Polym Environ 26:2601–2618. https://doi.org/10.1007/s10924-017-1149-4

More AP, cute Mhaske Shashank RA T (2014) Polyesteramide resin from PET waste and fatty amide. Pigment Resin Technol 43(5):285–292

Ell-Sherbiny SI, Morsy FA, Atta AM (2010) Synthesis of new cationic surfactants based on recycled poly (ethylene terephthalate) for drinking of solvent-based ink from low-density polyethylene surface. J Appl Polym Sci 118:1160–1172

Chan K, Zinchenko A (2021) Conversion of waste bottles ’ PET to a hydrogel adsorbent via PET aminolysis. J Environ Chem Eng 9(5):106129. https://doi.org/10.1016/j.jece.2021.106129

Ferreira MM, da Silva EA, Cotting F, Lins VDF (2021) UV weathering and performance of a novel corrosion protective coating on steel made from recycled polyethylene terephthalate (PET). Corros Eng Sci Technol 56(3):199–209

Gabriel VA (2022) Sustainable Polymer Reaction Engineering: Towards Fully Renewable Pressure-Sensitive Adhesives (Doctoral dissertation, Université d’Ottawa/University of Ottawa)

Gupta P, Bhandari S (2019) Chemical depolymerization of PET bottles via Ammonolysis and Aminolysis. Recycling of polyethylene terephthalate. Elsevier Inc, pp 109–134. https://doi.org/10.1016/b978-0-12-811361-5.00006-7

Dutt K, Soni RK (2014) Synthesis and characterization of bis-amino ethyl terephthalamide from PET waste and its applications as hardener in DGEBA. Int J Plast Technol. https://doi.org/10.1007/s12588-014-9071-2

Lorusso E, Parasothy N, Feng Y, Schneider J, Kamps L, Mayer-gall T, Gutmann JS, Ali W (2022) Investigation of aminolysis routes on PET fabrics using different amine-based materials. Nano Select 594–607. https://doi.org/10.1002/nano.202100121

Zhang Y, Tian YHW (2023) FeiChengguo Liu b, Xiaochen Liu a, Upcycling of waste PET into high-performance and multifunctional materials. J Clean Prod 434:2–5. https://doi.org/10.1016/j.jclepro.2023.140048

Rabiei N, Haghighat Kish M (2024) Modification of poly (ethylene terephthalate) fibers, fabrics, and films by amination reactions—A review. Polym Adv Technol, 35(2), e6326

Kawadkar AS, Gogate PR (2023) Intensified depolymerization using ultrasound–A review of mechanisms, reactors, operating conditions and applications. Chem Eng Processing-Process Intensif, 109446

Jamalzadeh M, Sobkowicz MJ (2022) Review of the effects of irradiation treatments on poly (ethylene terephthalate). Polym Degrad Stab, 110191

Palekar VS, Shah RV, Shukla SR (2012) Ionic liquid-catalyzed aminolysis of poly (ethylene terephthalate) Waste. J Appl Polym Sci 126:1174–1181. https://doi.org/10.1002/app.36878

Parab YS, Shah RV, Shukla SR (2012) Microwave irradiated synthesis and characterization of 1, 4-phenylene bis-oxazoline form bis-(2-hydroxyethyl) terephthalamide obtained by depolymerization of poly (ethylene terephthalate) (PET) bottle wastes. Curr Chem Lett 1(2):81–90. https://doi.org/10.5267/j.ccl.2012.3.003

Paliwal NR, Mungray AK (2013) Ultrasound assisted alkaline hydrolysis of poly (ethylene terephthalate) in presence of phase transfer catalyst. Polym Degrad Stab 98:2094–2101

Podzorova MV, Varyan IA, Kiselev NV, Tertyshnaya YV, Khramkova AV (2023) Influence of UV irradiation on the degradation of composites based on polyethylene. In E3S Web of Conferences (Vol. 413, p. 02018). EDP Sciences

Atta AM, Al-Lohedan HA, Ezzat AO, Sabeela NI (2020) New Imidazolium ionic liquids from recycled polyethylene terephthalate waste for curing epoxy resins as organic coatings of steel. Coatings 10(11):1–17. https://doi.org/10.3390/coatings10111139

Bäckström E, Odelius K, Hakkarainen M (February, 2021) Ultrafast microwave assisted recycling of PET to a family of functional precursors and materials. Eur Polym J 151. https://doi.org/10.1016/j.eurpolymj.2021.110441

Wu F et al (2023) Lactate anion catalyzes aminolysis of polyesters with anilines. Sci Adv 9(5):1–9. https://doi.org/10.1126/sciadv.ade7971

Acknowledgements

We would like to extend our appreciation to the participants who willingly contributed their time and effort to be part of this study. We want to thank the journal reviewers and editors for their constructive feedback and suggestions, which have significantly enhanced the quality of this review article.

Funding

has not received funding.

Author information

Authors and Affiliations

Contributions

D.A drafted and wrote the paper, Z.B editing the revision, T.N wrote the paper, A.T prepared tables and figures, A.J wrote the paper.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflicts of interest.

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mersha, D.A., Gesese, T.N., Sendekie, Z.B. et al. Operating conditions, products and sustainable recycling routes of aminolysis of polyethylene terephthalate (PET) – a review. Polym. Bull. (2024). https://doi.org/10.1007/s00289-024-05259-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00289-024-05259-0