Abstract

Various parameters of a melt blending processing including the extruders’ type, processing conditions (barrel temperature, screw speed and screw configuration), shear rate, residence time and distribution in relation to the mechanical properties of polymer nanocomposites were qualitatively reviewed. The tensile, flexural and impact strengths and their moduli of the composites were discussed. It was found that the tensile modulus of the extruded nano-sized fillers-reinforced polymers is highly influenced by these fillers’ distribution and their planner orientation in the polymeric matrix. The use of intermeshing co-rotating twin-screw extruders can provide better exfoliated/intercalated nanocomposites' structure with superior mechanical strength when compared to the composites made by the other processing methods. However, it was noticed that the tensile strength of the composite is not substantially affected by changing the melt blending processing parameters.

Similar content being viewed by others

References

Albdiry M et al (2013) A critical review on the manufacturing processes in relation to the properties of nanoclay/polymer composites. J Compos Mater 47(9):1093–1115

Paul DR, Robeson LM (2008) Polymer nanotechnology: nanocomposites. Polymer 49(15):3187–3204

Hejazi I, Sharif F, Garmabi H (2011) Effect of material and processing parameters on mechanical properties of Polypropylene/Ethylene–Propylene–Diene–Monomer/clay nanocomposites. Mater Des 32:3803–3809

Koo JH (2006) Polymer nanocomposites processing, characterization, and applications. McGraw-Hill Professional Publishing, USA.

Abdullah AQ, Ali NA, Hussein SI, Hakamy A, Abd-Elnaiem AM (2023) Improving the dielectric, thermal, and electrical properties of poly (methyl methacrylate)/hydroxyapatite blends by incorporating graphene nanoplatelets. J Inorganic Organometallic Polymers Mater

Samakande A (2008) Use of the RAFT technique as an efficient method to synthesise well-defined polymer–clay nanocomposites with improved properties, in Polymer Science. University of Stellenbosch: Stellenbosch, South Africa, p. 190.

Al-badri M, Albdiry M (2020) Electrochemical performance of ternary s-GN/PANI/CNTs nanocomposite as supercapacitor power electrodes. Period Eng Natural Sci 8(4):2484–2489

Albdiry M, Al-Nayili A (2023) Ternary sulfonated graphene/polyaniline/carbon nanotubes nanocomposites for high performance of supercapacitor electrodes. Polymer Bull 80(8):8245–8258

Abd-Elnaiem AM et al (2023) Improvement of optical properties of functionalized polyvinyl alcohol-zinc oxide hybrid nanocomposites for wide UV optoelectronic applications. J Inorg Organomet Polym Mater 33(8):2429–2444

Mohammed Ali AN et al (2023) Nanoarchitectonics of silver/poly (methyl methacrylate) films: structure, optical characteristics, antibacterial activity, and wettability. J Inorg Organomet Polym Mater 33(3):694–706

Harold F Giles J, John J, Wagner R, Eldridge I, Mount M (eds) (2005) Extrusion: the definitive processing guide and handbook Vol. PDL Handbook series. William Andrew, Inc, USA.

Chung CI (2000) Extrusion of polymers: theory and practice. Hanser Gardner Publications, Inc., Germany

Karian HG (ed) (2003) Handbook of polypropylene and polypropylene composites, 2nd edn. Marcel Dekker, Inc.: New York.

Lekakou C, Brandao J (1996) Extrusion of polypropylene. Part II: Process analysis of the metering zone. Polymer Eng Sci 36(1).

Rauwendaal CMdPNE (2001) Troubleshooting the extrusion process: a systematic approach to solving Plastic Extrusion Problems. Carl Hanser Verlag, Germany, p 158.

Chinellato AC et al (2010) Compatibilizing effect of acrylic acid modified polypropylene on the morphology and permeability properties of polypropylene/organoclay nanocomposites. Compos Sci Technol 70:458–465

Albdiry MT, Yousif BF (2014) Role of silanized halloysite nanotubes on structural, mechanical properties and fracture toughness of thermoset nanocomposites. Mater Des 57:279–288

Al-Badri M, Albdiry M (2021) Enhanced electrical properties of ternary CNTs/PANI wrapped by sulfonated graphene nanocomposite for supercapacitor electrodes. J Mater Sci Mater Electronics 33(2):675–682

Albdiry MT, Yousif BF (2019) Toughening of brittle polyester with functionalized halloysite nanocomposites. Compos B Eng 160:94–109

Al-Adily K, Albdiry M, Ammash H (2023) Evaluation of tensile and flexural properties of woven glass fiber/epoxy laminated composites oriented in edgewise and flatwise directions. Ain Shams Eng J, p 102255.

Barick AK, Tripathy DK (2010) Effect of organoclay on the morphology, mechanical, thermal, and rheological properties of organophilic montmorillonite nanoclay based thermoplastic polyurethane nanocomposites prepared by melt blending. Polymer Eng Sci, pp 484–498.

Bhawal P et al (2018) Superior electromagnetic interference shielding effectiveness and electro-mechanical properties of EMA-IRGO nanocomposites through the in-situ reduction of GO from melt blended EMA-GO composites. Compos B Eng 134:46–60

Spencer MW et al (2010) Morphology and properties of nanocomposites based on HDPE/HDPE-g-MA blends. Polymer 51:1056–1070

Villanueva MP et al (2010) Comparative study of nanocomposites of polyolefin compatibilizers containing kaolinite and montmorillonite organoclays. J Appl Polymer Sci 115:1325–1335

Xanthos M (ed) (2010) Functional fillers for plastics. Wiley, Weinheim, Germany.

Albdiry MT, Yousif BF, Ku H (2013) Fracture toughness and toughening mechanisms of unsaturated polyester-based clay nanocomposites. In: 13th International conference on fracture, 2013: Beijing, China.

Abd-Elnaiem AM et al (2022) Ameliorating the mechanical parameters, thermal stability, and wettability of acrylic polymer by cement filling for high-efficiency waterproofing. Polymers 14(21):4671

Abd-Elnaiem AM et al (2021) Correction to: influence of incorporation of gallium oxide nanoparticles on the structural and optical properties of polyvinyl alcohol polymer. J Inorg Organomet Polym Mater 31(10):4163–4163

Sharma SK, Nema AK, Nayak SK (2010) Polypropylene nanocomposite film: a critical evaluation on the effect of nanoclay on the mechanical, thermal, and morphological behavior. J Appl Polym Sci 115:3463–3473

Paci M, Filippi S, Magagnini P (2010) Nanostructure development in nylon 6-Cloisite 30B composites. Effects of the preparation conditions. Euro Polymer J 46:838–853.

Debnath D, Dhibar AK, Khatua BB (2010) Studies on the morphology and properties of PMMA-organoclay nanocomposites with reference to the manufacturing techniques. Polymer-Plastic Technol Eng 49:1087–1094

Herrera-Alonso JM et al (2009) Transport properties in polyurethane/clay nanocomposites as barrier materials: effect of processing conditions. J Membr Sci 337:208–214

Ali AN et al (2021) Thermal and mechanical properties of epoxy resin functionalized copper and graphene hybrids using in-situ polymerization method. Curr Nanosci 17(3):494–502

Merhari L (ed) (2009) Hybrid nanocomposites for nanotechnology: electronic, optical, magnetic and biomedical applications. Springer science LLC, USA.

Galgali G, Agarwal S, Lele A (2004) Effect of clay orientation on the tensile modulus of polypropylene-nanoclay composites. Polymer 45:6059–6069

FertigIII RS, Garnich MR (2004) Influence of constituent properties and microstructural parameters on the tensile modulus of a polymer/clay nanocomposite. Compos Sci Technol 64:2577–2588

Wilkinson AN et al (2007) Tensile properties of melt intercalated polyamide 6—Montmorillonite nanocomposites. Compos Sci Technol 67:3360–3368.

Santos KS et al (2009) Optimization of the mechanical properties of polypropylene-based nanocomposite via the addition of a combination of organoclays. Composites Part A 40:1199–1209.

Fornes TD, Paul DR (2003) Modeling properties of nylon 6/clay nanocomposites using composite theories. Polymer 44:4993–5013

Boo W-J et al (2007) Effect of nanoplatelet aspect ratio on mechanical properties of epoxy nanocomposites. Polymer 48:1075–1082

Weon J-I, Sue H-J (2005) Effects of clay orientation and aspect ratio on mechanical behavior of nylon-6 nanocomposite. Polymer 46:6325–6334

Abd-Elnaiem AM et al (2022) Mechanical characteristics and thermal stability of hybrid epoxy and acrylic polymer coating/nanoclay of various thicknesses. J Inorg Organomet Polym Mater 32(6):2094–2102

Abu-Zahra NH, Alian AM (2010) Density and cell morphology of rigid foam PVC-clay nanocomposites. Polym-Plast Technol Eng 49(3):237–243

Botlhoko OJ, Ray SS, Ramontja J (2018) Influence of functionalized exfoliated reduced graphene oxide nanoparticle localization on mechanical, thermal and electronic properties of nanobiocomposites. Eur Polymer J 102:130–140

Ali NA et al (2020) Mechanical properties and electrical conductivity of poly(methyl methacrylate)/multi-walled carbon nanotubes composites. Iran J Sci Technol Trans A Sci 44(5):1567–1576

Abd-Elnaiem AM et al (2021) Fabrication and evaluation of structural, thermal, mechanical and optical behavior of epoxy–TEOS/MWCNTs composites for solar cell covering. Polym Bull 78(7):3995–4017

Dasari A, Yu Z-Z, Mai Y-W (2007) Nanoscratching of nylon 66-based ternary nanocomposites. Acta Mater 55:635–646

Hussein S et al (2020) Enhanced thermo-mechanical properties of poly(vinyl alcohol)/poly(vinyl pyrrolidone) polymer blended with nanographene. Curr Nanosci 16(6):994–1001

Albdiry MT, Yousif BF (2013) Morphological structures and tribological performance of unsaturated polyester based untreated/silane-treated halloysite nanotubes. Mater Des 48:68–76

Hussein SI et al (2018) Effect of incorporation of conductive fillers on mechanical properties and thermal conductivity of epoxy resin composite. Appl Phys A 124(7):475

Abd-Elnaiem AM et al (2021) Influence of incorporation of gallium oxide nanoparticles on the structural and optical properties of polyvinyl alcohol polymer. J Inorg Organomet Polym Mater 31(10):4141–4149

Albdiry MT, Ku H, Yousif BF (2013) Impact fracture behaviour of silane-treated halloysite nanotubes-reinforced unsaturated polyester. Eng Fail Anal 35:718–725

Huang Y, Yang K, Dong J-Y (2006) Copolymerization of ethylene and 10-undecen-1-ol using a montmorillonite-intercalated metallocene catalyst: synthesis of polyethylene/montmorillonite nanocomposites with enhanced structural stability. Macromol Rapid Commun 27:1278–1283

Faucheu J et al (2010) Miniemulsion polymerization for synthesis of structured clay/polymer nanocomposites: short review and recent advances. Polymer 51:6–17

Slomkowski S, Alemán JV, Gilbert RG, Michael H, Horie K, Jones RG, Kubisa P, Meisel I, Mormann W, Penczek S, Stepto RFT (2011) Terminology of polymers and polymerization processes in dispersed systems. Pure Appl Chem 83(12):2229–2259

Landfester K, Schork FJ, Kusuma VA (2003) Particle size distribution in mini-emulsion polymerization. C R Chim 6:1337–1342

Kim W-J, Kim CA, Kim S (2018) Preparation and characterization of PET blended with silica–polystyrene hybrid nanocomposites. Polym Bull 75(4):1505–1517

Modesti M et al (2007) ABS/clay nanocomposites obtained by a solution technique:Influence of clay organic modifiers. Polymer Degradation Stabili 92:2206–2213.

Kiliaris P, Papaspyrides CD (2010) Polymer/layered silicate (clay) nanocomposites: an overview of flame retardancy. Prog Polym Sci 35:902–958

Haq M et al (2009) Processing techniques for bio-based unsaturated-polyester/clay nanocomposites: tensile properties, efficiency, and limits. Compos A 40:394–403.

Albdiry M, Almosawi A, Yousif B (2012) The synergistic effect of hybrid flame retardants on pyrolysis behaviour of hybrid composite materials. J Eng Sci Technol 7(3):351–359

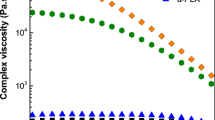

Sheng X et al (2019) Properties of two-dimensional Ti3C2 MXene/thermoplastic polyurethane nanocomposites with effective reinforcement via melt blending. Compos Sci Technol 181:107710

Sauceau M et al. (2011) New challenges in polymer foaming: a review of extrusion processes assisted by supercritical carbon dioxide. Progr Polym Sci 36(6):749–766

Ma J et al (2007) Preparation of polypropylene/sepiolite nanocomposites using supercritical CO2 assisted mixing. Eur Polymer J 43:4931–4939

Perrin-Sarazin F et al (2009) Potential of ball milling to improve clay dispersion in nanocomposites. Polymer Eng Sci, pp 651–665.

Xu Z et al (2019) Graphene oxide-supported zinc oxide nanoparticles for chloroprene rubber with improved crosslinking network and mechanical properties. Compos A Appl Sci Manuf 124:105492

Rauwendaal C (2001) Polymer extrusion 4th, edition. Carl Hanser Verlag, Munich

Gupta N, Lin TC, Shapiro M (2007) Clay-epoxy nanocomposites: processing and properties. JOM J Minerals Metals Mater Soci 59(3):61–65

Wang H, Hoa SV, Wood-Adams PM (2006) New method for the synthesis of clay/epoxy nanocomposites. J Appl Polym Sci 100:4286–4296

Lertwimolnun W, Vergnes B (2006) Effect of processing conditions on the formation of polypropylene/organoclay nanocomposites in a twin screw extruder. Polymer Eng Sci 46:314–323

Ngo T-D et al (2009) Effect of temperature, duration and speed of pre-mixing on the dispersion of clay/epoxy nanocomposites. Compos Sci Technol 69:1831–1840

Tillekeratne M et al (2006) Role of mixing parameters in the preparation of poly(ethylene vinyl acetate) nanocomposites by melt blending. J Appl Polym Sci 100:2652–2658

Matuana LM (2009) Rigid PVC/(Layered Silicate) nanocomposites produced through a novel melt-blending approach. J Vinyl Additive Technol, pp 77–86.

Feng W, Isayev AI (2004) In-situ ultrasonic compatibilization of unvulcanized and dynamically vulcanized PP/EPDM blends. Polymer Eng Sci 44(11).

Ahn Y, Kim H, Lee JW (2010) Ultrasound assisted batch-processing of EVA-organoclay nanocomposites. Korean J Chem Eng 27(2):723–728

Mainil M et al (2010) Morphology and properties of SAN-clay nanocomposites prepared principally by water-assisted extrusion. Polym Eng Sci, pp 10–21.

Awad WH et al (2009) Material properties of nanoclay PVC composites. Polymer 50:1857–1867.

Sterky K et al (2010) Influence of processing technique on morphology and mechanical properties of PVC nanocomposites. Eur Polymer J 46:1203–1209

Saber-Samandari S, Khatibi AA, Basic D (2007) An experimental study on clay/epoxy nanocomposites produced in a centrifuge. Compos B 38:102–107.

Chu D, Nguyen Q, Baird DG (2007) Effect of matrix molecular weight on the dispersion of nanoclay in unmodified high density polyethylene. Polym Compos, pp 499–511.

Wang K et al (2004) The interplay of thermodynamics and shear on the dispersion of polymer nanocomposite. Polymer 45:7953–7960

Dasari A, Yu Z-Z, Mai Y-W (2005) Effect of blending sequence on microstructure of ternary nanocomposites. Polymer 46:5986–5991

Treece MA et al (2007) Twin-screw extrusion of polypropylene-clay nanocomposites: influence of masterbatch processing, screw rotation mode, and sequence. Polym Eng Sci, pp 898–911.

Gonzalez I, Eguiazabal JI, Nazabal J (2008) Effects of the processing sequence and critical interparticle distance in PA6-clay/mSEBS nanocomposites. Eur Polymer J 44:287–299

Tu C, Nagata K, Yan S (2017) Influence of melt-mixing processing sequence on electrical conductivity of polyethylene/polypropylene blends filled with graphene. Polym Bull 74(4):1237–1252

Homminga D et al (2005) Influence of shear flow on the preparation of polymer layered silicate nanocomposites. Polymer 46:9941–9954

Martin C (2009) Twin screw extrusion developments for processing color masterbatches and compounds. In: CAD 2009, Savannah, GA. 2009: Somerville, NJ, 08876, USA.

Giraldi ALFM et al (2008) Effects of extrusion conditions on the properties of recycled poly(ethylene terephthalate)/nanoclay nanocomposites prepared by a twin-screw extruder. J Appl Polymer Sci 108:2252–2259.

Jollands M, Gupta RK (2010) Effect of mixing conditions on mechanical properties of polylactide/montmorillonite clay nanocomposites. J Appl Polym Sci 118:1489–1493

Peltola P et al (2006) Effect of rotational speed of twin screw extruder on the microstructure and rheological and mechanical properties of nanoclay-reinforced polypropylene nanocomposites. Polym Eng Sci, pp 995–1000.

Jazani OM et al (2010) Evaluation of mechanical properties of polypropylene/polycarbonate/SEBS ternary polymer blends using taguchi experimental analysis. J Appl Polym Sci 116:2312–2319

Norazlina H, Kamal Y (2021) Elucidating the plasticizing effect on mechanical and thermal properties of poly(lactic acid)/carbon nanotubes nanocomposites. Polym Bull 78(12):6911–6933

Dennis HR et al (2001) Effect of melt processing conditions on the extent of exfoliation in organoclay-based nanocomposites. Polymer 42(23):9513–9522

Zhang H-X et al (2022) Fabrication of PA6/MoS2 nanocomposites via melt blending of PA6 with PA6/PEG modified-MoS2 masterbatch. Polym Bull 79(12):10639–10652

Tadmor Z, Klein I (1969) The effect of design and operating conditions on melting in plasticating extruders. Polym Eng Sci 9(1).

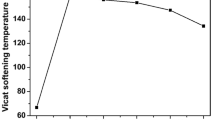

Modesti M et al (2006) Thermal behaviour of compatibilised polypropylene nanocomposite: effect of processing conditions. Polym Degrad Stab 91:672–680

Cheremisinoff NP (1989) Handbook of polymer science and technology: performance properties of plastics and elastomers, vol 2. M. Dekker, Technology & Engineering, New York.

Gong L et al (2013) The morphology and mechanical properties of PP/EPDM/nano-CaCO3 composites: effect of initial mixing state. Polym Bull 70(11):2935–2952

Villmow T, Kretzschmar B, Pötschke P (2010) Influence of screw configuration, residence time, and specific mechanical energy in twin-screw extrusion of polycaprolactone/multi-walled carbon nanotube composites. Compos Sci Technol 70:2045–2055

Tanoue S et al (2005) Melt compounding of different grades polystyrene with organoclay. Part 3: Mechanical properties. Polym Eng Sci, pp 827–837.

Pires M et al (2020) Thermal degradation of poly(lactic acid)–zeolite composites produced by melt-blending. Polym Bull 77(4):2111–2137

Pavlidou S, Papaspyrides CD (2008) A review on polymer–layered silicate nanocomposites. Prog Polym Sci 33:1119–1198

Miltner HE et al (2010) Qualitative assessment of nanofiller dispersion in poly(e-caprolactone) nanocomposites by mechanical testing, dynamic rheometry and advanced thermal analysis. Euro Polymer J 46:984–996.

Canevarolo SV, Babetto AC (2002) Effect of screw element type in degradation of polypropylene upon multiple extrusions. Adv Polym Technol 21(4):243–249

Jiang Q (2008) Modeling flow, melting, solid conveying and global behavior in intermeshing counter-rotating twin screw extruders. University of Akron.

Grünschloss E (2001) Polymer single screw extrusion: modeling. In: Buschow KHJ et al (eds) Encyclopedia of materials: science and technology. Elsevier, Oxford, pp 7491–7504

Bi C, Jiang B, Li A (2007) Digital image processing method for measuring the residence time distribution in a plasticating extruder. Polym Eng Sci 47(7):1108–1113

Housz JFI, Meijer HEH (1981) The melting performance of single screw extruders. Polym Eng Sci 21(6).

Zavadsky E, Karnis J (1985) Mathematical model of a single-screw plasticating extruder. Rheol Acta 24:556–565

Kelly, A.L., E.C. Brown, and P.D. Coates, The Effect of Screw Geometry on Melt Temperature Profile in Single Screw Extrusion. Polymer Engineering and Science 2006.

Wilczynski K (2001) SSEM: a computer model for a polymer single-screw extrusion. J Mater Process Technol 109(3):308–313.

SIMULIA (2011) Abaqus analysis user's manual. 2011: USA.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Albdiry, M. Effect of melt blending processing on mechanical properties of polymer nanocomposites: a review. Polym. Bull. 81, 5793–5821 (2024). https://doi.org/10.1007/s00289-023-05012-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-023-05012-z