Abstract

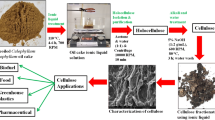

Homogeneous esterification of cellulose isolated from Stipa tenacissima plant located in the eastern region of Morocco, using anhydride and acid chloride compounds has been performed in ionic liquids (ILs) prepared in our laboratory as reaction mediums. ILs were chosen as solvents due to their green character and ability to disperse native cellulose compared to other solvents. [C4mim]OAc showed the highest solubility percentage of cellulose (15 wt%). Other principles of green chemistry were applied herein such as the uses of biomass, catalysts, and green solvents. The formed cellulosic esters were analyzed for structural, surface, and thermal properties by various analytical techniques: FTIR-ATR, NMR, XRD, TGA, and DSC. The esterificating agents were varied in this study to obtain different cellulose derivatives. Notably, high degrees of substitution (DS) were achieved for cellulose propionate (2.91) and cellulose butyrate (2.76). However, cellulose phthalate and cellulose laureate were obtained with low DS values, which affect their solubility in different solvents depending on their DS values. The effect of esterification on cellulose properties, on one hand, decreases the crystallinity index (CIr) and crystallite size, however, on the other hand, increased the surface area and pore volume. The contact angle measurements revealed an enhancement in the hydrophobicity of the cellulose esters. Particularly, cellulose propionate with high DS exhibited a significantly elevated contact angle, reaching 142.5°. This emphasizes that the hydrophobic nature of the modified cellulose can be improved by raising the DS, rather than solely relying on the length of the carbonyl chain.

Similar content being viewed by others

References

Eichhorn SJ, Dufresne A, Aranguren M, Marcovich NE, Capadona JR, Rowan SJ, Weder C, Thielemans W, Roman M, Renneckar S (2010) Current international research into cellulose nanofibres and nanocomposites. J Mater Sci 45:1–33

Abraham E, Deepa B, Pothan LA, Jacob M, Thomas S, Cvelbar U, Anandjiwala R (2011) Extraction of nanocellulose fibrils from lignocellulosic fibres: a novel approach. Carbohyd Polym 86:1468–1475

Li R, Fei J, Cai Y, Li Y, Feng J, Yao J (2009) Cellulose whiskers extracted from mulberry: a novel biomass production. Carbohyd Polym 76:94–99

Park S, Baker JO, Himmel ME, Parilla PA, Johnson DK (2010) Cellulose crystallinity index: measurement techniques and their impact on interpreting cellulase performance. Biotechnol Biofuels 3:1–10

Jin X, Chen X, Shi C, Li M, Guan Y, Yu CY, Yamada T, Sacks EJ, Peng J (2017) Determination of hemicellulose, cellulose and lignin content using visible and near infrared spectroscopy in Miscanthus sinensis. Biores Technol 241:603–609

Isogai A, Ishizu A, Nakano J (1987) Dissolution mechanism of cellulose in SO2–amine–dimethylsulfoxide. J Appl Polym Sci 33:1283–1290

Dawsey TR, McCormick CL (1990) The lithium chloride/dimethylacetamide solvent for cellulose: a literature review. J Macromol Sci Rev Macromol Chem Phys 30:405–440

Isogai A, Atalla RH (1998) Dissolution of cellulose in aqueous NaOH solutions. Cellulose 5:309–319

Klemm D, Heinze T, Philipp B, Wagenknecht W (1997) New approaches to advanced polymers by selective cellulose functionalization. Acta Polym 48:277–297

Welton T (1999) Room-temperature ionic liquids. Solvents for synthesis and catalysis. Chem Rev 99:2071–2084

Wasserscheid P, Keim W (2000) Ionic liquids—new “solutions” for transition metal catalysis. Angew Chem Int Ed 39:3772–3789

Dupont J, de Souza RF, Suarez PA (2002) Ionic liquid (molten salt) phase organometallic catalysis. Chem Rev 102:3667–3692

Zhang J, Wu J, Yu J, Zhang X, He J, Zhang J (2017) Application of ionic liquids for dissolving cellulose and fabricating cellulose-based materials: state of the art and future trends. Mater Chem Front 1:1273–1290

Swatloski RP, Spear SK, Holbrey JD, Rogers RD (2002) Dissolution of cellose with ionic liquids. J Am Chem Soc 124:4974–4975

Ren Q, Wu J, Zhang J (2003) Synthesis of 1-allyl, 3-methyle mazolium-based roomtemperature ionic liquid and preluviinary study of its dissolving cellulose

Fukaya Y, Sugimoto A, Ohno H (2006) Superior solubility of polysaccharides in low viscosity, polar, and halogen-free 1, 3-dialkylimidazolium formates. Biomacromol 7:3295–3297

Xu A, Wang J, Wang H (2010) Effects of anionic structure and lithium salts addition on the dissolution of cellulose in 1-butyl-3-methylimidazolium-based ionic liquid solvent systems. Green Chem 12:268–275

Zavrel M, Bross D, Funke M, Büchs J, Spiess AC (2009) High-throughput screening for ionic liquids dissolving (ligno-) cellulose. Biores Technol 100:2580–2587

Abe M, Fukaya Y, Ohno H (2012) Fast and facile dissolution of cellulose with tetrabutylphosphonium hydroxide containing 40 wt% water. Chem Commun 48:1808–1810

Miao J, Sun H, Yu Y, Song X, Zhang L (2014) Quaternary ammonium acetate: an efficient ionic liquid for the dissolution and regeneration of cellulose. RSC Adv 4:36721–36724

Li X, Li H, Ling Z, Xu D, You T, Wu Y-Y, Xu F (2020) Room-temperature superbase-derived ionic liquids with facile synthesis and low viscosity: powerful solvents for cellulose dissolution by destroying the cellulose aggregate structure. Macromolecules 53:3284–3295

Barthel S, Heinze T (2006) Acylation and carbanilation of cellulose in ionic liquids. Green Chem 8:301–306

Erdmenger T, Haensch C, Hoogenboom R, Schubert US (2007) Homogeneous tritylation of cellulose in 1-butyl-3-methylimidazolium chloride. Macromol Biosci 7:440–445

Köhler S, Liebert T, Heinze T (2008) Interactions of ionic liquids with polysaccharides. VI. Pure cellulose nanoparticles from trimethylsilyl cellulose synthesized in ionic liquids. J Polym Sci, Part A: Polym Chem 46:4070–4080

Gericke M, Liebert T, Heinze T (2009) Interaction of ionic liquids with polysaccharides, 8–synthesis of cellulose sulfates suitable for polyelectrolyte complex formation. Macromol Biosci 9:343–353

Granström M, Mormann W, Frank P (2014) Method of chlorinating polysaccharides or oligosaccharides

Köhler S, Liebert T, Heinze T, Vollmer A, Mischnick P, Möllmann E, Becker W (2010) Interactions of ionic liquids with polysaccharides 9. Hydroxyalkylation of cellulose without additional inorganic bases. Cellulose 17:437–448

Granström M, Kavakka J, King A, Majoinen J, Mäkelä V, Helaja J, Hietala S, Virtanen T, Maunu S-L, Argyropoulos DS (2008) Tosylation and acylation of cellulose in 1-allyl-3-methylimidazolium chloride. Cellulose 15:481–488

Xiao P, Zhang J, Feng Y, Wu J, He J, Zhang J (2014) Synthesis, characterization and properties of novel cellulose derivatives containing phosphorus: Cellulose diphenyl phosphate and its mixed esters. Cellulose 21:2369–2378

Yan C, Zhang J, Lv Y, Yu J, Wu J, Zhang J, He J (2009) Thermoplastic cellulose-graft-poly (L-lactide) copolymers homogeneously synthesized in an ionic liquid with 4-dimethylaminopyridine catalyst. Biomacromol 10:2013–2018

Guo Y, Wang X, Shen Z, Shu X, Sun R (2013) Preparation of cellulose-graft-poly (ɛ-caprolactone) nanomicelles by homogeneous ROP in ionic liquid. Carbohyd Polym 92:77–83

Wu J, Zhang J, Zhang H, He J, Ren Q, Guo M (2004) Homogeneous acetylation of cellulose in a new ionic liquid. Biomacromol 5:266–268

Heinze T, Schwikal K, Barthel S (2005) Ionic liquids as reaction medium in cellulose functionalization. Macromol Biosci 5:520–525

Luan Y, Zhang J, Zhan M, Wu J, Zhang J, He J (2013) Highly efficient propionylation and butyralation of cellulose in an ionic liquid catalyzed by 4-dimethylminopyridine. Carbohyd Polym 92:307–311

Liu CF, Sun RC, Zhang AP, Ren JL (2007) Preparation of sugarcane bagasse cellulosic phthalate using an ionic liquid as reaction medium. Carbohyd Polym 68:17–25

Liu CF, Sun RC, Zhang AP, Ren JL, Wang XA, Qin MH, Chao ZN, Luo W (2007) Homogeneous modification of sugarcane bagasse cellulose with succinic anhydride using a ionic liquid as reaction medium. Carbohyd Res 342:919–926

Köhler S, Heinze T (2007) Efficient synthesis of cellulose furoates in 1-N-butyl-3-methylimidazolium chloride. Cellulose 14:489–495

Zhang J, Wu J, Cao Y, Sang S, Zhang J, He J (2009) Synthesis of cellulose benzoates under homogeneous conditions in an ionic liquid. Cellulose 16:299–308

Ma S, Xue X, Yu S, Wang Z (2012) High-intensity ultrasound irradiated modification of sugarcane bagasse cellulose in an ionic liquid. Ind Crops Prod 35:135–139

Li HF, Li H, Zhong X, Li XD, Gibril ME, Zhang Y, Han KQ, Yu MH (2012) Study on the chemical modification of cellulose in ionic liquid with maleic anhydride. Adv Mater Res Trans Tech Publ 581:287–291

Granström M, néePääkkö MK, Jin H, Kolehmainen E, Kilpeläinen I, Ikkala O (2011) Highly water repellent aerogels based on cellulose stearoyl esters. Polym Chem 2:1789–1796

Singh RK, Gupta P, Sharma OP, Ray SS (2015) Homogeneous synthesis of cellulose fatty esters in ionic liquid (1-butyl-3-methylimidazolium chloride) and study of their comparative antifriction property. J Ind Eng Chem 24:14–19

Heinze T, Liebert T (2001) Unconventional methods in cellulose functionalization. Prog Polym Sci 26:1689–1762

Zhang H, Wu J, Zhang J, He J (2005) 1-Allyl-3-methylimidazolium chloride room temperature ionic liquid: a new and powerful nonderivatizing solvent for cellulose. Macromolecules 38:8272–8277

Anastas P, Eghbali N (2010) Green chemistry: principles and practice. Chem Soc Rev 39:301–312

Tang J, Sisler J, Grishkewich N, Tam KC (2017) Functionalization of cellulose nanocrystals for advanced applications. J Colloid Interface Sci 494:397–409

Sèbe G, Ham-Pichavant F, Pecastaings G (2013) Dispersibility and emulsion-stabilizing effect of cellulose nanowhiskers esterified by vinyl acetate and vinyl cinnamate. Biomacromol 14:2937–2944

Cunha AG, Mougel J-B, Cathala B, Berglund LA, Capron I (2014) Preparation of double pickering emulsions stabilized by chemically tailored nanocelluloses. Langmuir 30:9327–9335

Capadona JR, Van Den Berg O, Capadona LA, Schroeter M, Rowan SJ, Tyler DJ, Weder C (2007) A versatile approach for the processing of polymer nanocomposites with self-assembled nanofibre templates. Nat Nanotechnol 2:765–769

Mariano M, El Kissi N, Dufresne A (2014) Cellulose nanocrystals and related nanocomposites: review of some properties and challenges. J Polym Sci, Part B: Polym Phys 52:791–806

Shin J, Nouranian S, Ureña-Benavides EE, Smith AE (2017) Dynamic mechanical and thermal properties of cellulose nanocrystal/epoxy nanocomposites. Green Mater 5:123–134

Molnes SN, Mamonov A, Paso KG, Strand S, Syverud K (2018) Investigation of a new application for cellulose nanocrystals: a study of the enhanced oil recovery potential by use of a green additive. Cellulose 25:2289–2301

Parajuli S, Prater LA, Heath T, Green KA, Moyer W, Hutton-Prager B, Ureña-Benavides EE (2020) Cellulose nanocrystal-stabilized dispersions of CO2, heptane, and perfluorooctane at elevated temperatures and pressures for underground CO2 sequestration. ACS Appl Nano Mater 3:12198–12208

El Idrissi A, El Barkany S, Amhamdi H, Maaroufi A-K (2013) Physicochemical characterization of celluloses extracted from Esparto “Stipa tenacissima” of Eastern Morocco. J Appl Polym Sci 128:537–548

Muhammad N, Man Z, Bustam Khalil MA (2012) Ionic liquid—a future solvent for the enhanced uses of wood biomass. Eur J Wood Prod 70:125–133

Liu C-F, Sun R-C, Zhang A-P, Qin M-H, Ren J-L, Wang X-A (2007) Preparation and characterization of phthalated cellulose derivatives in room-temperature ionic liquid without catalysts. J Agric Food Chem 55:2399–2406

Hinner LP, Wissner JL, Beurer A, Nebel BA, Hauer B (2016) Homogeneous vinyl ester-based synthesis of different cellulose derivatives in 1-ethyl-3-methyl-imidazolium acetate. Green Chem 18:6099–6107

Roman M, Winter WT (2004) Effect of sulfate groups from sulfuric acid hydrolysis on the thermal degradation behavior of bacterial cellulose. Biomacromol 5:1671–1677

El-Sakhawy M, Tohamy H-AS, Salama A, Kamel S (2019) Thermal properties of carboxymethyl cellulose acetate butyrate. Cellul Chem Technol 53:667–675

Fringant C, Desbrieres J, Rinaudo M (1996) Physical properties of acetylated starch-based materials: relation with their molecular characteristics. Polymer 37:2663–2673

Hatakeyama T, Nakamura K, Hatakeyama H (1982) Studies on heat capacity of cellulose and lignin by differential scanning calorimetry. Polymer 23:1801–1804

Chen Z, Zhang J, Xiao P, Tian W, Zhang J (2018) Novel thermoplastic cellulose esters containing bulky moieties and soft segments. ACS Sustain Chem Eng 6:4931–4939

Zhuang JM, Steiner PR (1993) Thermal reactions of diisocyanate (MDI) with phenols and benzylalcohols: DSC study and synthesis of MDI adducts

Edgar KJ, Arnold KM, Blount WW, Lawniczak JE, Lowman DW (1995) Synthesis and properties of cellulose acetoacetates. Macromolecules 28:4122–4128

ELIdrissi A, Barkany S, Hassan A, Maaroufi A (2012) New approach to predict the solubility of polymers, application: cellulose acetate at various DS, prepared from Alfa “Stipa tenacissima” of Eastern Morocco. J Mater Environ Sci 3:270

Huang FY, Yu Y, Wu XJ (2011) Characterization and properties of cellulose oleate. Adv Mater Res 197–198:1306–1309

El Seoud OA, Bioni TA, Dignani MT (2021) Understanding cellulose dissolution in ionic liquid-dimethyl sulfoxide binary mixtures: quantification of the relative importance of hydrogen bonding and hydrophobic interactions. J Molecul Liq 322:114848

Huang L, Wu Q, Wang Q, Wolcott M (2019) One-step activation and surface fatty acylation of cellulose fibers in a solvent-free condition. ACS Sustain Chem Eng 7:15920–15927

Hou D-F, Li M-L, Yan C, Zhou L, Liu Z-Y, Yang W, Yang M-B (2021) Mechanochemical preparation of thermoplastic cellulose oleate by ball milling. Green Chem 23:2069–2078

Zhang W, Zhou N, Zhang Y, Huang Z, Hu H, Liang J, Qin Y (2021) Construction of thermoplastic cellulose esters matrix composites with enhanced flame retardancy and mechanical properties by embedding hydrophobic magnesium hydroxide. J Appl Polym Sci 138:50677

Acknowledgements

The authors wish to express their appreciation for the financial support of this study by the National Centre Research Scientific and Technique (CNRST) (Program, No. 15/2017) and the Mohamed First University (Program: PARA1). The authors like also to deliver a special thanks to the director of the chemistry department Professor Abdelmonaem El Talhaoui for providing the analytical platform in the department of chemistry.

Funding

National Centre Research Scientific and Technique (CNRST) (Program, No. 15/2017). Mohamed First University (Program: PARA1).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declared no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Abarkan, A., Achalhi, N., El Yousfi, R. et al. “Greener” homogeneous esterification of cellulose isolated from Stipa tenacissima plant located in the Eastern region of Morocco using ionic liquids as reaction medium. Polym. Bull. 81, 5375–5402 (2024). https://doi.org/10.1007/s00289-023-04965-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-023-04965-5