Abstract

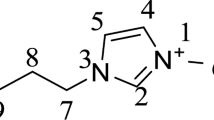

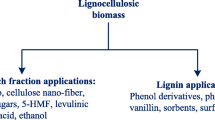

The present work reports the ionic liquid, 1-butyl-3-methylimidazolium chloride [BMIM] Cl, assisted extraction, and characterization of cellulose from the Calophyllum inophyllum de-oiled cake. The yield of the cellulose from the ionic liquid extraction was approximately 23.81 ± 1.72% w/w of the de-oiled cake, which is almost equal to any other fractionation. SEM imaging revealed the swollen nature of cellulose fibers. The results of FTIR affirmed the presence of cellulose functional groups and the absence of hemicellulose and lignin. XRD analysis revealed 81% crystallinity of the cellulose. The dominant carbon peaks from 60 to 106 ppm from CP/MAS 13C NMR also confirmed the presence and purity of cellulose. The thermal degradation pattern of extracted cellulose in between 200 and 350 °C was in good agreement with the literature. Overall, the present results confirmed that a high-quality cellulose fraction could be produced from the lignocellulosic biomass by employing a competent and green approach using the ionic liquid [BMIM] Cl.

Similar content being viewed by others

References

Ong H, Mahlia T, Masjuki H, Norhasyima R (2011) Comparison of palm oil, Jatropha curcas and Calophyllum inophyllum for biodiesel: a review. Renew Sust Energ Rev 15(8):3501–3515

Sakthivel R, Ramesh K (2017) Influence of temperature on yield, composition and properties of the sub-fractions derived from slow pyrolysis of Calophyllum inophyllum de-oiled cake. J Anal Appl Pyrolysis 127:159–169

Ayodele OO, Dawodu FA (2014) Production of biodiesel from Calophyllum inophyllum oil using a cellulose-derived catalyst. Biomass Bioenergy 70:239–248

Makkar HP (2013) Biofuel co-products as livestock feed-opportunities and challenges. AFMA Matrix 22(1):23–25

Cheng Y-S, Wu J-H, Yeh L-H (2016) Utilization of Calophyllum inophyllum shell and kernel oil cake for reducing sugar production. Bioresour Technol 212:338–341

Menon V, Rao M (2012) Trends in bioconversion of lignocellulose: biofuels, platform chemicals & biorefinery concept. Prog Energy Combust Sci 38(4):522–550

Kumar R, Tabatabaei M, Karimi K, Sárvári Horváth I (2016) Recent updates on lignocellulosic biomass derived ethanol-a review. Biofuel Res J 3(1):347–356

Elgharbawy AA, Alam MZ, Moniruzzaman M, Goto M (2016) Ionic liquid pretreatment as emerging approaches for enhanced enzymatic hydrolysis of lignocellulosic biomass. Biochem Eng J 109:252–267

Yoo CG, Pu Y, Ragauskas AJ (2017) Ionic liquids: promising green solvents for lignocellulosic biomass utilization. Curr Opin Green Sustain Chem 5:5–11

da Costa Lopes AM, Bogel-Łukasik R (2015) Acidic ionic liquids as sustainable approach of cellulose and lignocellulosic biomass conversion without additional catalysts. ChemSusChem 8(6):947–965

Zavrel M, Bross D, Funke M, Büchs J, Spiess AC (2009) High-throughput screening for ionic liquids dissolving (ligno-) cellulose. Bioresour Technol 100(9):2580–2587

Silveira MHL, Morais ARC, da Costa Lopes AM, Olekszyszen DN, Bogel-Łukasik R, Andreaus J, Pereira Ramos L (2015) Current pretreatment technologies for the development of cellulosic ethanol and biorefineries. ChemSusChem 8(20):3366–3390

da Costa Lopes AM, João KG, Morais ARC, Bogel-Łukasik E, Bogel-Łukasik R (2013) Ionic liquids as a tool for lignocellulosic biomass fractionation. Sustain Chem Processes 1(1):3

Mood SH, Golfeshan AH, Tabatabaei M, Jouzani GS, Najafi GH, Gholami M, Ardjmand M (2013) Lignocellulosic biomass to bioethanol, a comprehensive review with a focus on pretreatment. Renew Sust Energ Rev 27:77–93

Vitz J, Erdmenger T, Haensch C, Schubert US (2009) Extended dissolution studies of cellulose in imidazolium based ionic liquids. Green Chem 11(3):417–424

Araújo D, Vilarinho M, Machado A (2019) Effect of combined dilute-alkaline and green pretreatments on corncob fractionation: pretreated biomass characterization and regenerated cellulose film production. Ind Crop Prod 141:111785

Kosan B, Michels C, Meister F (2008) Dissolution and forming of cellulose with ionic liquids. Cellulose 15(1):59–66

Arumugam A, Sandhya M, Ponnusami V (2014) Biohydrogen and polyhydroxyalkanoate co-production by Enterobacter aerogenes and Rhodobacter sphaeroides from Calophyllum inophyllum oil cake. Bioresour Technol 164:170–176

Adenuga AA, Amos OD, Oyekunle JAO, Umukoro EH (2019) Adsorption performance and mechanism of a low-cost biosorbent from spent seedcake of Calophyllum inophyllum in simultaneous cleanup of potentially toxic metals from industrial wastewater. J Environ Chem Eng 7(5):103317

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D, Crocker D (2008) Determination of structural carbohydrates and lignin in biomass. Laboratory Analytical Procedure 1617:1–16

Farhat W, Venditti R, Quick A, Taha M, Mignard N, Becquart F, Ayoub A (2017) Hemicellulose extraction and characterization for applications in paper coatings and adhesives. Ind Crop Prod 107:370–377

Zhang P, Dong S-J, Ma H-H, Zhang B-X, Wang Y-F, Hu X-M (2015) Fractionation of corn stover into cellulose, hemicellulose and lignin using a series of ionic liquids. Ind Crop Prod 76:688–696

Ling Z, Wang T, Makarem M, Cintrón MS, Cheng H, Kang X, Bacher M, Potthast A, Rosenau T, King H (2019) Effects of ball milling on the structure of cotton cellulose. Cellulose 26(1):305–328

Demirbas A (2002) Relationships between heating value and lignin, moisture, ash and extractive contents of biomass fuels. Energy Explor Exploit 20(1):105–111

Li J, Wei X, Wang Q, Chen J, Chang G, Kong L, Su J, Liu Y (2012) Homogeneous isolation of nanocellulose from sugarcane bagasse by high pressure homogenization. Carbohydr Polym 90(4):1609–1613

Trilokesh C, Uppuluri KB (2019) Isolation and characterization of cellulose nanocrystals from jackfruit peel. Sci Rep 9(1):16709. https://doi.org/10.1038/s41598-019-53412-x

Mohtar SS, Busu TNZTM, Noor AMM, Shaari N, Mat H (2017) An ionic liquid treatment and fractionation of cellulose, hemicellulose and lignin from oil palm empty fruit bunch. Carbohydr Polym 166:291–299

Rehman N, de Miranda MIG, Rosa SM, Pimentel DM, Nachtigall SM, Bica CI (2014) Cellulose and nanocellulose from maize straw: an insight on the crystal properties. J Polym Environ 22(2):252–259

Lucas M, Wagner GL, Nishiyama Y, Hanson L, Samayam IP, Schall CA, Langan P, Rector KD (2011) Reversible swelling of the cell wall of poplar biomass by ionic liquid at room temperature. Bioresour Technol 102(6):4518–4523

Moniruzzaman M, Ono T (2013) Separation and characterization of cellulose fibers from cypress wood treated with ionic liquid prior to laccase treatment. Bioresour Technol 127:132–137

Rosa SM, Rehman N, de Miranda MIG, Nachtigall SM, Bica CI (2012) Chlorine-free extraction of cellulose from rice husk and whisker isolation. Carbohydr Polym 87(2):1131–1138

Abe K, Yano H (2009) Comparison of the characteristics of cellulose microfibril aggregates of wood, rice straw and potato tuber. Cellulose 16(6):1017–1023

Morán JI, Alvarez VA, Cyras VP, Vázquez A (2008) Extraction of cellulose and preparation of nanocellulose from sisal fibers. Cellulose 15(1):149–159

Lan W, Liu C-F, Yue F-X, Sun R-C, Kennedy JF (2011) Ultrasound-assisted dissolution of cellulose in ionic liquid. Carbohydr Polym 86(2):672–677

Yang H, Yan R, Chen H, Lee DH, Zheng C (2007) Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86(12–13):1781–1788

Acknowledgments

Trilokesh C. gratefully acknowledges the CSIR, India, for the senior research fellowship. KBU and AA greatly acknowledge the financial support from the DST/SERB, India (EEQ/2019/000245 and ECR/2017/001038). We also thank the SAIF and Department of Chemistry at IIT Madras for performing solid-state NMR, SEM, XRD, and thermal analysis.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Malolan, V.V., Trilokesh, C., Uppuluri, K.B. et al. Ionic liquid assisted the extraction of cellulose from de-oiled Calophyllum inophyllum cake and its characterization. Biomass Conv. Bioref. 12, 5687–5693 (2022). https://doi.org/10.1007/s13399-020-01007-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-01007-2